Beyond painting and roofing, you may find good reasons to work on the outside

of your house: expanding floor space, adding a window, or putting in new doors.

A simple skylight may completely change how you use a room.

This section concerns changes that affect exterior parts of the house.

The change may be a modest skylight barely noticeable from the street, or

it may be a dramatic second-floor addition that alters your entire home.

In this section you will learn how to make cosmetic changes, such as a

new window or sliding glass door. You will also learn how to expand the

living space in your home, either by converting a garage or by building

a room addition outward, upward, or downward.

Adding a New Window

New windows come in a wide range of sizes and styles. The catalog of one

manufacturer, for example, lists more than 200 different stock sizes. If

you need a nonstandard size, windows can be custom milled, so the choices

are practically unlimited. In fact, you may spend more time selecting a

new window than actually installing it.

Four basic styles of windows are available: double-hung, casement, gliding, and awning. Each style can be used alone or combined in a number of variations:

- The double-hung window is the most common and perhaps most

traditional style. It consists of two movable sashes, one above the other,

that slide up and down in wood or metal channels. Half of the window area

can be opened at a time. The old-style double-hungs employ a sash cord and balance weight concealed in the wall cavity. The newer styles, since

about 1950, operate on counterbalanced springs and a metal track.

- The casement window has single or double sashes hinged on the

side so that the entire window area swings out from the house to catch

the breeze. Older casement windows push in and out; newer models are cranked

open and shut.

- The gliding window looks like a horizontal casement but operates

like a double-hung unit. The sashes slide from side to side on plastic

or metal tracks.

- The awning window is hinged near the top and swings out from

the bottom. This style offers the advantage that it can be left open during

the rain.

Selecting a new window depends on several factors. A primary consideration

is the type of windows al ready in place. If possible, the new unit should

be an identical match or at least compatible in style, proportion, and material

to the existing windows. Mixing a large aluminum casement with multipane

double-hung wood windows can spoil the exterior appearance of the house.

Energy conservation is another important consideration. Double-glazed windows

have two panes of glass permanently sealed in the sash to create an insulating

air space. This cuts heat loss through the glass area by almost half and minimizes winter moisture problems such as fogging and condensation. If

you live in a hot or cold climate, by all means consider double glazing.

(In some areas the code demands it.) Triple glazing can be a worthwhile

investment in certain areas.

Most window styles are available in either wood or metal. As a rule wood

offers better insulation than metal. Although the heat flow through aluminum

is 1,700 times faster than through wood, more expensive metal windows are

now constructed with a thermal barrier between the inside and outside frame.

Check heat loss carefully when you compare models and prices.

Maintenance is a third factor to consider. Baked or anodized finishes on

aluminum windows require no up keep. Wood exposed to the weather requires

periodic care. One compromise is to choose a wood window encased in rigid

vinyl. These top-of-the-line windows combine the superior insulating qualities

of wood with the no-maintenance advantages of plastic.

Most prefabricated skylights are made with domes or panes of clear

or tinted glass.

Removing a Window

The steps in removing a window are basically the same for all styles. Since

double-hung windows are the most common, they’re used here to illustrate

the process.

First remove the interior stops that hold the lower sash in place. Use

a flat bar or broad wood chisel to pry the stops from the jambs. If the

edges are lapped with paint, sever the joint with a sharp utility knife.

Next remove the interior trim around the window. If the corners are mitered,

try to drive the finish nails completely through with a small nail set.

Often the interior trim can be reused once the new window is installed,

so handle these pieces with care. Use a flat bar to gently pry the side and top trim from the wall. Wrap a wood block in cloth to gain leverage and yet protect the wall surface from gouging. If the window has an interior

stool — most double-hung windows do—raise the lower sash and pry or tap

the stool from underneath to loosen and remove it.

From this point the correct procedure depends on the window. Examining

the type of installation will tell you how to proceed. Older windows are

often built in place with the jambs and exterior casings nailed to the studs.

Newer windows are installed as a unit with nails through the exterior casing

securing the window to the studs. Prying the casing loose should free the

entire unit.

If the nails in the exterior casing are visible, drive them through the

wood with a nail set. Or use a flat bar to pry the casings from the studs.

Sever any surrounding caulk with a chisel. Pry the casings loose from the

rest of the window and remove them. This should expose the nails securing

the jambs to the studs. If there’s room, slip a hacksaw blade into the opening and cut the nails. Use a chisel to pound out any shim stock hiding the nails.

An alternate technique is to disassemble the entire window, taking out

the sash first and then the jambs. If the window operates with a sash cord and weights, cut the lower cord and let the weight fall inside the wall.

Lift out the lower sash and remove the parting bead that separates the two

sashes. Then cut the remaining cord and lift out the upper sash.

If the sashes are spring-loaded, remove the cover from the metal channel.

Release the tension from the springs and lift out the lower and then the

upper sash. Pull out nails or screws holding the channels in place.

Once the sashes are removed, pry the jambs from the studs or saw them in

halt and pry out the pieces. Pull out any remaining nails inside the rough

opening.

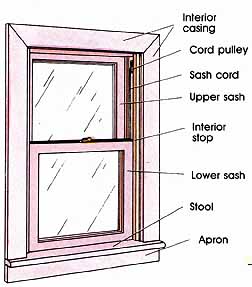

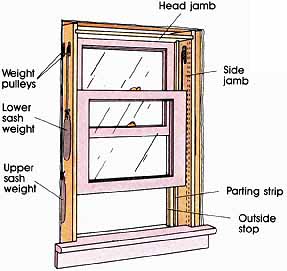

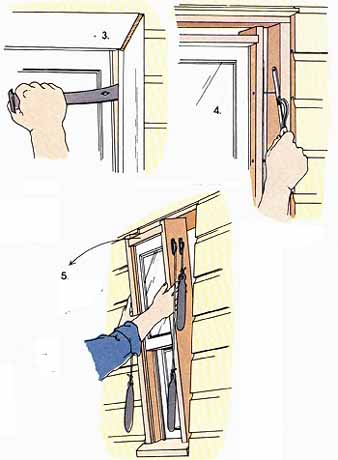

Removing an Old Window:

Removing an Old Window: 1. Remove interior casing and inside stops. (Interior casing, Cord pulley, Sash cord, Upper sash,

Interior stop, Lower sash, Stool, Apron);

2. Raise the lower sash and tap or pry the stool up.

Then move to the outside. (Side jamb, Parting strip, Outside stop)

3. Pry off the exterior casing; 4. Saw any nails that

go from the jamb into the trimmer; 5. The window should then be free—pull

it out carefully.

Installing the New Window

Measure the rough opening to be sure the new window will fit. There should

be 1/4 to 1/2-inch clearance all around. To make the opening slightly smaller,

nail spacer boards to the sides of the studs. If you’re replacing an old-style

sash-and-weight window, the rough opening is probably 2 to 2½-inches wider

on each side. The extra space accommodated the balance weights inside the

wall. Nail new studs or spacer blocks inside the opening to create the proper

size.

If there’s no building paper on the sheathing around the opening, or if

it’s in poor condition, staple new pieces in place. This minimizes air and moisture penetration once the window is installed.

Check to make sure the existing drip cap is in good condition and wide

enough to fit over the new exterior casing. If the new window or opening

doesn’t have a drip cap, cut and crimp a piece of aluminum flashing to fit.

If possible, the flashing should extend 3 to 4 inches under the siding and ½-inch beyond the exterior casing. Often you can buy pre-molded flashing

when you pick up the window.

Unless the manufacturer’s instructions say otherwise, leave any braces

in place until the window is installed. Cut off any protective horns at

either side of the frame.

From the outside, position the window in the rough opening and center it

between the trimmer studs. Most new pre-hung windows come with the exterior

casing attached. (The procedure for a custom-milled window without the exterior

trim is similar except that you secure the window by nailing through the

inside jambs. The exterior trim is added later.) The exterior casing should

fit snugly against the outside of the sheathing, under the drip cap, and between the edges of the siding.

If the siding needs to be cut, use a circular saw set to the depth of siding and trim the excess away. Make sure you don’t cut into the sheathing. Allow

1/8- to ¼-inch clearance on either side. You can fill this with caulking

later. Drive a finishing nail through the upper corner of the casing into

the header. Level the window and if necessary have a helper on the inside

shim under the side jambs. Then drive a second finishing nail through the

opposite corner of the casing.

Check the window for plumb by placing a level along the side jamb, Shim

at least two places along each jamb. Be careful not to over-shim and bow

out the jambs. Next check the sashes. If the window wobbles when opened,

more shimming is necessary If the sashes won’t open freely, the shims are

too tight. Make sure the space between the sash and the frame remains the

same when the window is opened and closed.

Once the window is level and plumb with enough shims in place, secure the

position by driving finishing nails through the sides of the exterior casing

at 10-inch intervals. Countersink the nail heads and fill with wood putty.

Caulk completely around the window between the exterior casing, drip cap, and siding. On the inside, add insulation between the window and the studs.

It’s also a good idea to cover it with a plastic vapor barrier. Reinstall

the old interior trim or add new.

Installing a New Window: 1. If the old window

had weights, odd new trimmer studs to the sides of the rough opening to

fill up the space. 2. Insert the new window into the rough opening. 3. On

the inside use shims of single pieces to make the window snug with the trimmers.

Drive finish nails through the side jamb and shims into the trimmers. 4.

Stuff insulation between the jambs and the trimmers and header; replace

the stool and the casings. 5. On the outside put some building paper in

the space between the jambs and siding and nail the casing back in place.

Cutting a Wall for a New Window

To add a new window where none exists, you must cut into the exterior wall and frame a new opening. Follow the same procedure for removing a window and re placing it with a larger size.

Locating the new window depends on preference and the present openings.

As a rule the tops of windows and doors are 6 feet 8 inches above the finish

floor, but this varies with the age and style of the house, Consistency

is the key, especially on the exterior. If the new window is the same size

as the old, align it with the top of the existing windows. If the size or

style is different, position the window carefully so the harmony of the

exterior isn’t disrupted. Positioning the window next to an existing stud

simplifies the framing, but this isn’t essential.

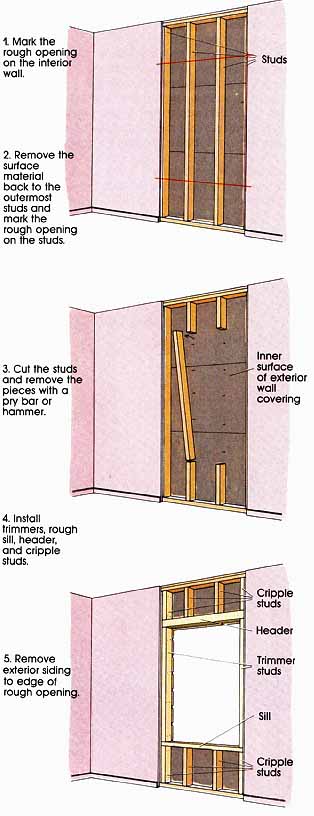

Cuffing an Opening for a New Window: 1. Mark

the rough opening on the interior wall. 2. Remove the surface material back

to the outermost studs and mark the rough opening on the studs. 3. Cut the

studs and remove the pieces with a pry-bar or hammer. 4. Install trimmers,

rough sill, header, and cripple studs. 5. Remove exterior siding to edge

of rough opening.

In planning a new window, consider safety requirements such as the need

to use safety glass for any window within 18 inches of the floor, to protect

toddlers. (Some codes require safety glass in all installations.) Also,

overall size may influence thickness of the glass, and therefore, the cost.

You should have the new unit on hand for measuring before you cut the rough

opening. If you have any questions or aren’t completely sure of the size,

be sure to check with the dealer first.

An interior wall surface is generally easier to cut and patch than exterior

siding, so start from the inside. Mark the outline of the rough opening

on the wall and locate the two studs on the outer edges. Be sure to turn

off any electrical circuits in the vicinity before you begin cutting. Remove

the insulation from the space and re route any electrical wiring. Then cut and strip the surface between the studs.

If the ceiling joists run perpendicular to the wall, erect a temporary

support to carry the bearing load (. If the ceiling joists run parallel

to the wall, supports aren’t necessary.

Next prepare a header of sufficient size to carry the weight of the wall and any other loads once the studs are cut. For openings up to 4 feet wide

supporting only the roof, the header generally should be a 4 by 4. For openings

up to 5 feet wide, the header should be a 4 by 6. But this depends on the

location of the window and the weight the header must support. Check the

local code to determine the exact size required. The header can be solid

wood or built up from 2-by lumber with plywood spacers in between. The width

of the header should be slightly less than the width of the studs. If the

studs are 3½-inches wide, use 3/8 plywood for spacers. In an older home

the studs may be wider than this, so ½-inch ply wood can be used. Nail the

header together on both sides with 16d nails staggered along its length

about every 12 inches.

Mark one of the studs inside the opening with the desired height of the

window. Add a second mark above this that includes the depth of the header

plus ¼-inch for clearance. Use a square to mark each stud and then cut with

a backsaw or reciprocating saw. To deter mine the lower cut, add the depth

of the rough opening, plus 1½ inches for a new 2-by-4 rough sill, plus ¼-inch

for clearance. Mark and cut the studs; then remove the pieces from the opening.

Use a pry bar or hit the side of the stud with a hammer to loosen from the

sheathing.

If one or two new full-length studs are necessary, toenail them to the

top and sole plates. Otherwise use the existing studs at the outer edges

of the opening. Cut two trimmer studs to fit between the sole plate and header. Use a plumb bob or level to be sure they’re plumb; then nail to

the full-length studs with 10d nails every 12 inches. Position the header

over the trimmers and check for level, Drive three or four 10d nails through

each full- length stud into the end of the header. Then toenail the header

to the trimmer studs and to the cripple studs overhead. If necessary, shim

between the cripples and the header for a snug fit. Cut and install the

rough sill by nailing it to the cripples underneath. Shim as necessary to

make the sill level. At this point the rough opening is complete, and you

can remove any temporary supports.

An alternate technique. Instead of marking and cutting the studs

inside the opening, remove them completely Cut the trimmers from the salvaged

studs; then install the trimmers and header as described previously. Cut

the necessary cripples and toenail in place. Finally add the rough sill.

A second alternative. Removing the wall surface beyond the exact

size of the rough opening, as just de scribed, simplifies the framing process.

But this also means the wall must be patched once the window is installed.

If you’re experienced with this type of framing problem, you may choose

to cut the opening closer to the exact size and thus eliminate much of the

patching. The difficulties with this approach are in cutting the wall material

precisely without damage, and in securing the trimmer studs inside a narrow

wall cavity.

Installing Sliding Glass Doors

Sliding glass doors are essentially oversize windows large enough to walk

through. Two-panel units are most common—one door slides and the other remains

stationary Triple panels are also available. Standard widths range from

5 to 8 feet, and the usual height is 80 to 82 inches. Most doors are pre-glazed;

otherwise the glass is added after the doors are in place.

Selection and installation procedures are similar to those for a pre-hung

window. Like new windows, sliding glass doors are available in wood, metal, and vinyl-clad wood. Choose a style that’s compatible with the rest of the

house. You should also consider the amount of maintenance involved.

The larger the opening, the more it jeopardizes the wall’s shear strength.

Adding plywood panels on both sides of the new door increases shear strength.

For energy savings compare different models and investigate the types of

weatherstripping and thermal barriers available. Since the glass area is

so large, double-pane insulating glass is highly recommended. If small children

may be in the house, also consider the benefits of safety glass. Accidents

happen all too easily. For safety’s sake view the additional cost as an

inexpensive insurance policy

Installing a new sliding glass door isn't that difficult since much of

the frame and hardware are pre assembled by the manufacturer. The major

task is pre paring the rough opening. For that you can refer to the previous

section on adding a new window (see above), with one precaution: when installing

a large slider in a wall supporting a second story, be careful to size

the header properly and shore the ceiling during installation. The process

of cutting and framing the opening differs in only a few ways.

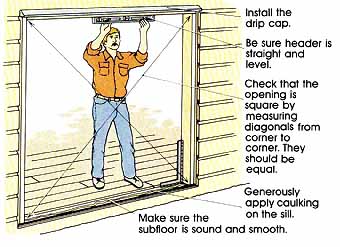

Preparing the Rough Opening for a Sliding Glass Door:

Install the drip cap. Be sure header is straight and level. Check that the

opening is square by measuring diagonals from corner to corner. They should

be equal. Generously apply caulking on the sill. Make sure the subfloor

is sound and smooth.

• It’s critical that the rough opening be square and plumb. If it isn’t,

the frame may not fit or the door may not slide or latch properly. Measure

diagonally to check.

• The subfloor should be sound and smooth. Alter you remove the sole plate,

you may need to add a tiller board to bring the subfloor to the proper depth.

Slight irregularities can be planed or sanded smooth.

• If there is a slight bow in the header material, be sure to install the

crown or high side to the top.

• Install the drip cap before the frame.

If the door frame isn’t assembled, set it up according to the directions

provided by the manufacturer. Apply a generous amount of caulking to the

bottom of the sill. Paper flashing is also advised. Working from the outside,

position the frame in the rough opening. Take care not to twist the frame

out of shape. It’s advisable to have a helper to hold the frame in place.

Otherwise secure it temporarily by driving finishing nails through the exterior

casing into the trimmer studs. If the frame has no casing, use C-clamps

to hold it against the sheathing.

Press down along the length of the sill to spread the caulking. This will

create a tight seal between the frame and the subfloor. To ensure trouble-free

operation, the sill must be level. If it isn’t, shim as necessary. Then

screw the inner edge of the sill to the subfloor every 10 to 12 inches.

If the floor is concrete, drill holes for expansion shields and anchor the

sill with screws.

Check the side jambs for plumb. At the location of each predrilled hole

in the frame, shim between the jambs and the trimmer studs. Make sure you

don’t over-shim and bow the jambs. Drill pilot holes and drive wood screws

through the jambs and shims into the trimmer studs. Follow the same procedure

for the top jamb. Tighten the screws snugly but don’t pull the jambs out

of shape. If you do, the door won’t seal or slide smoothly

For a frame with exterior casing attached, drive finishing nails through

the casing into the trimmer studs and header at 10- to 12-inch intervals.

If the manufacturer has provided a sill support, place it under the sill

overhang and secure to the exterior sheathing with screws or finishing nails.

Otherwise cut a 1-inch wood support the length of the sill and nail it in

place.

Position the stationary panel in the outer channel of the frame. To get

the right position, align the predrilled screw holes. Next secure the panel

to the frame. This depends on the type of door and the manufacturer. Most

panels are anchored with one or two brackets in the top and bottom rails,

plus security screws through the parting strip that separates the stationary and sliding panels.

Next install the sliding panel. Tip the panel at the top and slide it along

the channel to the closed position. Secure the door in the track according

to the manufacturer’s directions. Slide the door back and forth to check

its operation. If it sticks or binds or isn’t square with the frame, locate

the adjustment screws and raise or lower the door. If the frame requires

a threshold, fasten it to the floor with screws. Add insulation between

the frame and the studs; then patch the wall with wallboard or trim with

molding. Finally patch any cavities left in the finish floor with new flooring

material.

Installing Sliding Glass Doors: 1. Temporarily

secure side jambs with nails while leveling and shimming; then screw in place.

2. Level the top jamb with shims and secure with screws. 4. Install sill support

under outside sill overhang. 5. Install the stationary door in the outside

track. 6. Then install the sliding door and secure it according to the manufacturer’s

instructions. 9. Patch the wall covering where necessary and finish the floor. |