Wallboard is known by many names. Whether it’s called gypsum-board, plasterboard,

drywall, or Sheetrock (a trade name), the product is the same: a solid gypsum

core covered on both sides with heavy paper. It’s an inexpensive, all-purpose

surface that can be used in any room of the house.

Installing wallboard panels is relatively simple. It’s the taping and finishing

that require patience and practice. Before you decide to do it yourself,

consider hiring professionals to handle the job. This is especially true

if you dislike projects requiring careful attention to detail. As a rule

of thumb, if more than three panels or 100 square feet are involved, get

estimates first. The total cost of a professional job may compare favorably

with your material costs alone.

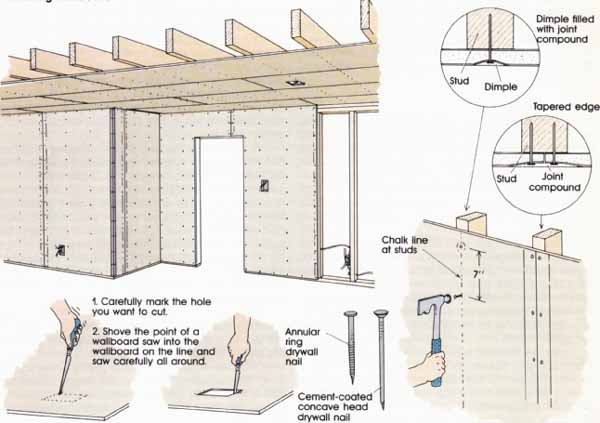

Installing Wallboard: 1, Carefully mark the hole you

want to cut. 2. Shove the point of a wallboard saw into the wallboard

on the line and saw carefully all around.

Planning

Begin by planning the installation on paper. Work out a pattern that results

in the fewest number of joints. Al though minimizing waste is always a concern,

in this case minimizing your labor is even more important. Wallboard is

so inexpensive that you should use full sheets whenever you can. It’s not

worth bothering with small pieces just to save a few dollars.

The long edges of wallboard panels are tapered slightly to accommodate

several coats of joint com pound; the 4-foot edges aren't . So plan to join

panels along the long, beveled edge whenever possible. When end joints can’t

be avoided, stagger them so they’ll be less noticeable.

Longer panels, such as 4 by 12s or even 4 by los, make it possible to span

the entire length of most walls. Planning joints to fall above and below

windows and above doors also means less taping. For ceilings, use panels

that span the longest distance, providing they run perpendicular to the

joists. The longer lengths are heavier and harder to install, but you’ll

save time because less finishing is required.

Preparing Studs and Joists

Before any panels are applied, prepare the studs and joists. Pull any nails and scrape away small pieces of old wallboard or paneling. If you are replacing

lath and plaster, the new wallboard probably isn’t the same thickness as

the old surface. In order to make the trim around doors and windows lie

properly, use any of the following techniques that apply.

• Add matching wood strips behind the trim to fill the gaps. This takes

time but is practical if there isn’t much trim. If the gaps are small, you

may be able to fill them with caulking after the wallboard is installed.

• Use two layers of wallboard. This solution is generally too expensive

to be feasible, although it does provide extra soundproofing.

• Shim the studs with old lath or any suitable stock that creates the proper

depth. For example, to replace 3 plaster with 1/2-inch wallboard, shim the

studs with 1/4- by 1 ½-inch lath. Tack the lath in place along the length

of each stud. When the panels are applied, use a longer nail that drives

through both wallboard and lath into the stud.

• Check the studs with a plumb bob to see if they are reasonably plumb.

As long as the wall is a smooth plane, slight irregularities won’t be noticed.

Use shim stock to correct obvious problems.

• Check the wall and ceiling surfaces to see if they are square. Measure

the diagonals of the surface. If the dimensions disagree by more than 1/2

inch, you may need to trim one or more panels along the edge to fit. Or

you can try compensating slightly as each panel goes up. Otherwise you’ll

come to a panel that falls off the edge of a stud or joist.

• Check the wall and ceiling for sufficient nailing surfaces. Wallboard

panels should not be applied with unsupported edges. If a corner or ceiling

line needs a nailing surface, nail in lengths of 1 by 2s or 2 by 4s as needed.

If only part of the surface is to be replaced, and the old wallboard is

cut next to a stud, nail a 1 by 2 along the stud to serve as a nailer for

the new panel.

• Check where any wires or pipes go through the studs or joists. They should

be at least 1 1/4 inches back from the edge, or protected by metal stud

guards.

• Finally evaluate whether any of the walls needs additional shear strength.

Adding shear strength usually involves glue nailing 1 or 3 plywood to the

studs before wallboard is applied. Your building department or a qualified

engineer can advise you and recommend a nailing pattern for the plywood

panels. If you have to strip some walls anyway; adding shear panels in the

right places is a very cheap way to substantially strengthen your home.

Cutting Panels

When cutting panels, use a guide such as a 4-foot-long wallboard T-square

or a straightedge. Any long, straight piece of wood will do. The panel can

be leaning against the wall or lying flat on the floor. With a sharp utility

knife, cut through the face paper and score the gypsum core. Use several

light strokes rather than bearing down on the knife. Then apply firm, even

pressure to snap along the cut. Fold the cut portion back and slit the paper

on the other side.

To cut an opening, first measure carefully. Then double check it. Remember

which surface is the front and always measure from the top down. A technique that's sometimes helpful is to cover the edges of electrical boxes with

chalk. Then transfer the chalk to the wall board by pressing the panel against

the wall. However, be sure to keep cuts on the front of the panel smooth,

with no ripped paper.

Once the opening is marked, cut the sides with the utility knife and punch

out with a hammer. Or, using a pointed wallboard saw, start the cut by plunging

it through the panels well within the outline. For right angles mark the

opening with a pencil and cut the shorter leg with a wallboard saw. Then

cut and snap the remaining leg with the utility knife. For U-shaped openings

first cut the two opposite legs with a saw and then cut and snap the remaining

side with the knife.

Cut edges will often be slightly uneven. Don’t waste time planing or chipping

them smooth. Cut the panels 1/4 inch short in the first place. The jagged

edges will fit together more easily, and the gap can be filled later with

joint compound. Without enough clearance, at tempts to force the panel in

place will usually break the core and spoil the edge.

Applying Panels

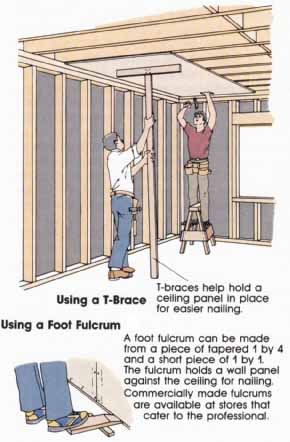

Apply the ceiling panels first. For this you need at least one helper,

maybe two. (A 4-by-8 panel 1/2 inch thick weighs about 60 pounds.) Even

with a helper, renting a wallboard jack or using two T-braces, called deadmen,

is a good idea. Make the braces from 1 by 4s or 2 by 4s. The top of the

T should be 2 to 3 feet wide, and the total length should be the floor-to-ceiling

height plus 3/4 inch. Be careful not to gouge the paper surface of the panel.

Another technique is to temporarily nail a 1 by 4 to the ceiling joist and use this as a lip for the edge of the wallboard. This carries some of the

weight while the panel is nailed in place.

Position the length of the panel perpendicular to the ceiling joists. The

edges should cover just half the width of the surrounding joists. Drive

nails through the center of the panel first and then work around the perimeter.

If you have difficulty sighting the joists, mark the panels with a pencil

or snap a chalk line as a guide. The correct nailing pattern depends on

the local building code. Check this beforehand. In many instances this is

every 7 inches on ceiling panels and every 8 inches for walls. Along the

perimeter the nails should be 3/8 to 1/2 inch from the edge. Once the nail

is flush, give it one last blow to slightly dimple the surface but not hard

enough to break the paper. This allows the nail heads to be covered with

tape and joint compound. Don’t countersink the nails or break the paper.

To cover the walls begin, with an upper corner and position the panel flush

with the ceiling. For vertical panels lift from the bottom edge with a foot

lever, which is simply two pieces of 1 by 4 or shim stock used to create

a fulcrum. If you’re applying the panels horizontally, have a helper support

some of the weight. Several nails or a wood block nailed beneath the lower

edge of the panel can also serve as temporary supports.

Be sure the leading edge of the panel is vertical and covers just half

the width of the last stud. If the corner isn’t square, you can leave a

gap of up to 1/2 inch, which can be covered with tape and joint compound.

If the studs are new wood, use two nails 2 inches apart spaced every 12

inches, instead of a single nail every 7 or 8 inches. This will minimize

the chance of popped nails in the future.

Once the wall panels are in place, cover any out side corners with metal

corner beads. Drive nails through the bead into the framing about every

5 or 6 inches. The nail heads and bead will be covered with joint compound.

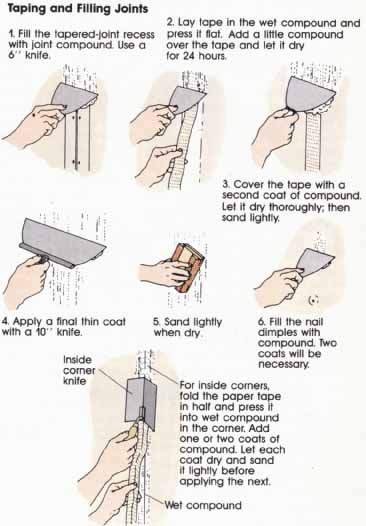

Taping and Finishing

To cover the joints and nail heads, use the ready-mix joint compound that

comes in gallon or 5-gallon containers. Use a separate container or mortarboard

while applying the compound. Otherwise dried pieces will work their way

into the fresh compound and make the job more difficult. In total you will

put down three separate layers (each about 1/16-inch thick), gradually build

lug the surface each time. Keep in mind that smooth, neat work at each stage

is rewarded with less work in the long run and a better-looking finish job.

Using a 6-inch knife, cover all the nail holes in the center of the panels

with joint compound. Next fill the gap between panels and spread a thin

layer about 4 or 5 inches wide over the joint. Use your fingers or your

knife to press a section of paper tape into the wet com pound. Although

the most efficient technique is to unroll the tape with one hand and use

the other to smooth the tape with the knife, this takes practice. Feather

out the edges and add a small amount of compound over the top of the paper.

Be sure to eliminate any wrinkles or air bubbles. For inside corners apply

compound to both sides. Then fold the paper in hall, press into the corner. and smooth with the knife.

Let this first coat dry overnight. Repeat with a second coat 24 hours later,

feathering out several inches on either side of the first coat. The total

width of the joints is now 7 to 10 inches.

Use a 10-inch knife for the third and final coat. The width of the joints

should be about 10 to 13 inches. For inside corners it’s often easier to

do one side at a time and let the compound dry Then come back and do the

other side.

After the compound is thoroughly dry smooth the joints and nail heads with

80- or 100-grade sandpaper wrapped around a wood block. If you’ve done a

careful job with the knives, there’s little sanding to be done. Because

the paper on the panels fuzzes easily, be sure to sand only the compound.

An alternate technique that eliminates the gypsum dust is to use a wet sponge.

This smooths the compound nicely as long as the surface isn’t allowed to

get too wet.

The next step is either painting or texturing. Texturing involves trowel

techniques best left to a professional. Painting involves priming with a

special latex sealer called PVA and finishing with a final coat or two of

the chosen color.

Using a T-Brace: T-braces help hold a ceiling

panel in place for easier nailing. Using a Foot Fulcrum: A foot

fulcrum can be made from a piece of tapered 1 by 4 and a short piece of

1 by 1. The fulcrum holds a wall panel against the ceiling for nailing.

Commercially made fulcrums are available at stores that cater to the professional.

Taping and Filling Joints: 1. Fill the tapered-joint

recess with joint compound. Use a 6” knife. 2. Lay tape in the wet compound and press it flat. Add a little compound over the tape and let it dry for

24 hours. 3. Cover the tape with a second coat of compound. Let it dry thoroughly;

then sand lightly. 4. Apply a final thin coat with a 10” knife. 5. Sand

lightly when dry. 6. Fill the nail dimples with compound. Two coats will

be necessary. Inside corner knife; For inside corners, fold the paper tape

in half and press it into wet compound in the corner. Add one or two coats

of compound. Let each coat dry and sand it lightly before applying the next.

|