Basic Structure

Our homes rarely let us down because, even as they evolved architecturally, wood frame houses maintained basic design principles that make them sturdy.

Below is an example. The weight from the roof compresses the rafters and tenses the ceiling joists. These forces transfer the weight to the load-bearing walls. Weight compresses the wood along the top of the floor joists. It also tenses the wood along the bottom, which allows the floor joists to transfer weight to the bearing walls. The foundation transfers weight to the ground.

Platform framing is the standard residential construction method used today. It allows builders and do-it-yourselfers to use shorter and lighter framing members than houses of the past. Studs, joists and rafters are typically spaced at 16- or 24-in, intervals to create strength and make optimum use of standard materials such as 2x4 studs, 4x8 sheets of ply wood and 4x12 sheets of drywall.

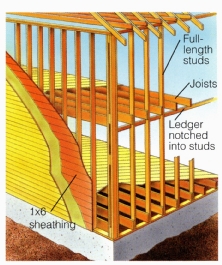

Balloon framing, employed primarily from 1850 through the early 1900s, made use of studs that extend from foundation to roof. Intermediate floors are supported by ledger boards notched into the studs. Walls were usually sheathed with 1-in-thick boards to stiffen the structure, then finished with wood lap siding, stucco or brick.

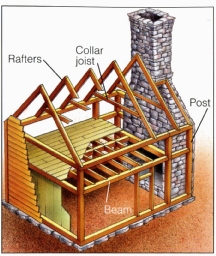

Timber frame houses rely on strong, large- dimension posts and beams to support the roof, walls and floors. Originally the spaces between beams and posts were filled with mudded and plastered sticks or whatever materials were available. Eventually wood sheathing and siding were used to make the structures more weather-tight.

Beams

Beams are used to support weight in areas that aren't supported by walls. You'll see them running down the centers of basements and across large openings. Consult a structural engineer before adding, moving or modifying any beam.

- Steel I-beams are the most compact, making them ideal for long spans.

- Glue-laminated beams are made from layers of dimensional lumber stacked and glued.

- Built-up beams are made from built- up layers

of dimensional lumber, plywood or oriented strand boardlike materials.

Joists

Joist size is determined by the distance they span, how closely spaced they are and the weight they carry. Wood truss joists and I-beam joists can be manufactured in a variety of depths, thicknesses and lengths to accommodate these variables.

- Solid wood joists , commonly in 2x8, 2x10 and 2x12 dimensions, are widely available and easily cut and nailed on site.

- Truss joists can be manufactured to span long distances. Pipes, wires and duct work can easily be run through the web openings.

- Wood I-beams can also be manufactured to

span long distances. Many contain knock-out holes for running wires and small pipes.