The more basic the kitting machine, the fewer add-on features the machine is capable of handling. The fancier the machine, the more options that can be added. This section helps you sort out your options so that you can make an informed purchase.

There are two variables used to create different designs: (1) fancy stitch pattern, and (2) lacework.

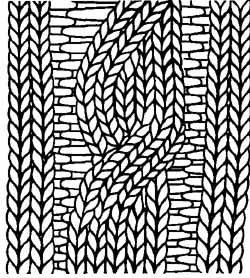

In a fancy stitch pattern, the de sign is made according to how the small variations in the yarn intertwine and cross over. These patterns will resemble stripes, squares, stars, and pleats worked right into the yarn (Fig. 12.1).In lacework, small openings are added to the patterns to give the look of lace (Fig. 12.2).

Fig. 12.1 Cable pattern

Fig. 12.2 Lacework

Changing Designs by Changing Colors

Different types of designs can be made simply by changing the color of the yarn.

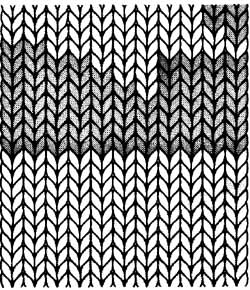

Jacquard—A fine yarn with the yarns on the back evenly flecked. The color is pulled to the front as the stitch is made. Up to four colors at a time may be used.

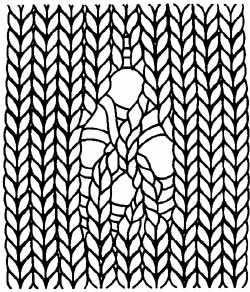

Intarsia—Large blocks of color are knitted with a single strand of each color that's twisted in and out when the colors intersect and is then picked up in the next row (Fig. 12.3). This leaves a single layer of yarn. In an intarsia design, both the front and back of the garment look the same.

Fig. 12.3 Intarsia

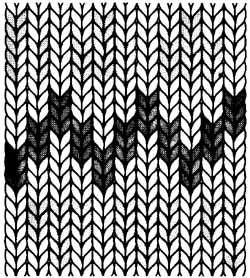

Fair Isle—The different color yarns are carried along the back and brought to the front when that color is desired (Fig. 12.4). The back has a series of long carry-over threads.

Fig. 12.4 Fair Isle pattern

Automated Features

Automated options range from punchcards and computerization of patterning, to increased color carriers for more colorful patterns, to additional beds for ribbing or patterns and motorized carriage for faster output.

The automated punch card or computerized systems determine which needle is engaged and how the pattern is formed. To achieve a uniform pat tern, each row must be knitted in exactly the right order. These automated systems make the selections even and simple. Automated options make the knitting faster and simpler, but they don't do the shaping.

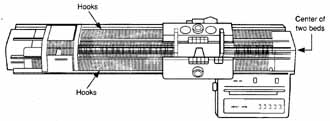

To do some stitch patterns, you need a double-bed machine. The beds are aligned with the needles meeting in the center at right angles (Fig. 12.5). A pair of interlocking carriages make both beds function as one for fancy work. The second bed is needed to make ribbing and lacework. Some machines re quire additional attachments to do ribbing.

Fig. 12-5 Double-bed knitting machine

The Tension Dial

Increasing or decreasing the tension determines the size of the stitches. A standard knitting machine has a tension dial or dials similar to a sewing machine. Adjusting the dial causes the separating plates to press against the yarn. This adjusts the drag on the yarn and makes the knitted piece tighter or looser.

Knitting frames require the change of a key plate. This plate alters how far the thread is stretched as it travels over a row. They have three to five different plates for their range of tension.

Basic Operations

Shaping

Shaping is a method of creating the outline of a completed piece. Making the knitted piece larger is called in creasing or casting on. Making the garment smaller is called decreasing or casting off.

Casting on is done to start knitting by putting the first row of loops on blank hooks or to add on large sections to the edges. This is done by hand by running thread through the hooks. Increasing is adding a few stitches into the body of the piece.

Casting off is done when the garment is completed to finish the edge and make it secure from raveling, or when an opening is needed in the center of a piece. Decreasing is knitting a few stitches together to make the row of stitches narrower.

Increasing and Decreasing

Increase and decrease must still be done by hand. The method depends on how acute a decrease or increase you need.

1. The first method uses a transfer tool with one, two, or three tines with a hole in the end of each. The tine slips into a knitted loop, lifts the stitch(es) off the hook, and eases it onto the stitch next to it. Then as the carriage moves across, the two stitches on one hook are knitted as one and the row is decreased by the number of stitches that have been moved.

2. The second method is used when you need a rapid decrease, such as the bottom of an armhole. A tool is used with a single prong with a latch hook on the end. The knit loop is put onto the tool. The next loop is put in the latch hook and pulled through the first loop. One at a time, you decrease (chain off) the number of stitches needed for the shape of the garment.

Assembly

The most common way to sew together a knitted piece is with a large hand sewing needle and a single strand of yarn. An alternative method uses the knitting machine to join two pieces. Leave the edge to be joined on the hooks and hang the additional portion of the garment you want added Onto the same hooks. A good example would be shoulder seams. The pieces are joined when you run the carriage across.

Purists will probably get huffy, but I prefer using a serger. Don’t forget to loosen your pressure regulator to pre vent ruffled edges. If you have it, use a differential feed. This is an excellent option for the knitter with limited time who still wants to make creative garments or crafts.

Weights

Some models need weights to keep the stitches in the hooks as the carriage slides over the yarn. The weights are attached to the knitted piece hanging down, to keep the loose loops taut in the channels and to prevent the piece from lifting up as you work.

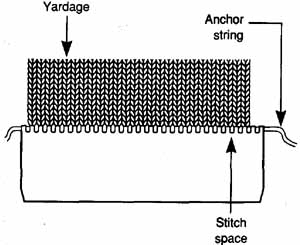

The weights are a long strip with notches for attaching a string along the entire bottom of the garment (Fig. 12.6). This type of weight is a necessity for frame knitters. Without a constant tug on the yarn, it would jump out of the hooks and drop stitches.

Fig. 12-6 Full-length weight

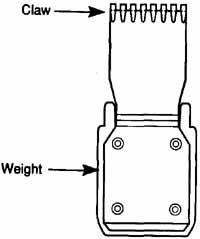

Having to manipulate the yarn around the hook any more than necessary can mean an increase in the number of skipped stitches. This would include creating cables, decreases, and other fancy patterns. Adding a small spot weight will improve the quality of the stitch. These weights have small hooks or claws that attach to the sweater body or yardage (Fig. 12.7).

Fig 12-7 Supplemental weight (front view)

The knitting frame (bulky size) requires the constant use of weights, whereas the most sophisticated standard-size machines claim not to need weights at all. Nevertheless, all machines will benefit from at least a limited use of weights to make the knitted piece smoother and to skip resistance.

Gauging Device

The gauge refers to the number of rows in one direction and the number of stitches in the other, both calculated according to the number of each in a 1” square.

These numbers are used to chart a pattern or to decide whether a pat tern will come out according to size. Knitting machines have special measuring devices to simplify this process.

Knitting Machine Tables

Knitting machines are large and cumbersome. The motion of the carriage means the machine must be clamped to whatever it sits on. Once you start a project, you can't move it without losing stitches.

All these details mean the best place for a knitting machine is on its own table. Fortunately, there are several varieties. Check with your dealer.