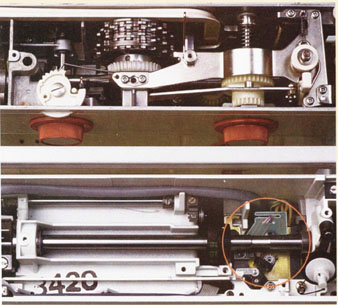

(top image) Linkages fill the head of a mechanical sewing machine,

connecting a/ movement to one motor. Eleven metal cams, one for each stitch

pattern, are mounted side by side (center of machine). (bottom image) Computerization and multiple motors eliminate many moving parts. The large center shaft controls

the needle up/down movement. The flat shaft at the bottom connects a small

stepping motor to the needle for side-to- side movement. The stepping motor

is mounted underneath the small white gear and gold plate in the circled

area. The green area is a small circuit board that controls the step motor.

Until recently, we were perfectly content with our trusty, old, but ever-reliable

1967 all-mechanical zig-zag-model sewing machine for sewing jackets, an occasional

comforter cover or to make a few shoulder pads. Then we got the itch to buy

a new machine. We thought that what we needed was a top-of-the-line mechanical

machine. The idea of computer circuitry replacing most of the gears and mechanical

parts wasn’t appealing.

And what about all that plastic that manufacturers

are using instead of metal? But still, we decided we should learn what electronics and computerization are all about. Over the next several months we spoke with

repair people and technicians who are knowledgeable about the three kinds of

machines avail able to home sewers today: mechanical, electronic, and computerized.

We asked about the features the machines offer and their reliability. We also

spoke to people who sewed on electronic and computerized machines.

Well, we eventually bought a computerized sewing machine, which is so user friendly that we’d feel comfortable letting our eight-year-old learn to sew on it. We have come to realize that computerized and electronic machines have some wonderful features. They can actually save you time, be a lot of fun to run, and make it easier to sew details, such as buttonholes, accurately. Computerized machines, however, aren’t necessarily for everyone. You may not need the features they offer, and they’re more expensive than mechanical or electronic machines (you’re paying for a lot of development and programming). To help you in your own search, here are the basics we learned about how each type of machine works.

Starting with a mechanical sewing machine

Mechanical, electronic, and computerized machines all form the basic stitch in the same way: A needle carries thread down through the fabric, where the thread is caught and looped around the bobbin mechanism, then pulled back up by a take-up lever, while the feed dog moves the fabric into position for the next stitch. This is where the similarity ends because what moves the needle, bobbin, take-up lever and feed dog varies greatly.

In mechanical machines, all movement is initiated by a single motor connected to the needle and feed dog by cams and levers. A cam is a flat wheel with a ridged edge, as you can see in the upper part of the photo on the facing page. Every stitch pattern—straight, zigzag, blind hem, overlock, scallop—has its own cam. As a cam turns (actually, all the cams turn together on a shaft), its un even surface pushes nearby levers into position, which eventually causes the needle to move in the pattern of a particular stitch.

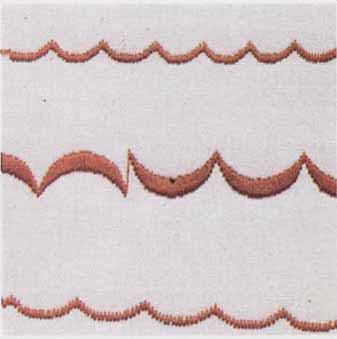

Functions such as tension, stitch length, and stitch width are manually selected by turning a dial. Once you set the stitch width and length, that’s what you get for the stitch pattern, even for a decorative stitch like a scallop, as shown in the photo below. However, because you make width and length adjustments by turning a dial, you can usually make in finitely fine adjustments.

All-mechanical sewing machines are operated by a foot pedal/motor combination that produces power in proportion to how far down you press the foot pedal. The farther down you press, the more electricity the motor gets, so the more power it produces. When you sew slowly, the motor receives less electricity and has less power, which makes sewing slowly on heavy fabric like denim more difficult; just when you need more power, you have less.

The skill of the machine operator deter mines the degree of sewing precision and control. Let’s say I’m topstitching the point of a collar and I want to pivot at the point, which means I have to stop exactly at the point with the needle down. I might sew fairly fast up to within two or three stitches of the collar point, then sew slowly or even turn the hand wheel by hand so I stop with the needle down precisely where I want it.

Another example of how the sewer’s skill affects the quality of sewing is making a buttonhole. Many mechanical machines offer a sequence on the stitch se lector dial for making a buttonhole, but the sewer must mark the ends of each buttonhole and turn the dial to control the stitching sequence so the button holes end up the same size.

Electronics adds control

The lines between machine types start blurring when we get to electronic features and computerization because they often go hand in hand. I define an electronic machine in this article as one that still has one motor, and cams and link ages, but is enhanced by electronic control. Electronics means that some of the mechanical features, like the position of the needle (up or down), are measured by an electrified sensor—an electronic eye, perhaps a switch. The sensor feeds back information to you (turning on a warning light, for example) or to the motor. Electronics adds precision and control that would require a lot more parts or be impossible to do mechanically. The sensors and control relieves the sewer of having to manually control different functions, and thus the machine requires somewhat less skill to operate.

Electronic machines generally have some or all of the following features:

• Automatic needle stop in the up or down position

• Even power at all speeds

• Slow or fast sewing speed option

• Low bobbin warning

Although all the major functions of an electronic machine are mechanical, a circuit board (a computer part containing pathways for electrical impulses) controls the special electronic features. The low bobbin thread warning signal operates, for example, with a beam of infrared or natural white light projected onto a clear plastic bobbin (see image). When the bobbin is full, the thread interrupts the beam of light; as the bobbin empties, the light beam passes through the bobbin and activates a light receiver on the other side, which gives a signal to the computer to turn on the low bobbin warning signal.

Computerized sewing machines offer programming

As the sewing machine companies added more and more innovations and stitch patterns to mechanical and electronically-enhanced mechanical machines, the advanced models became complicated, intricate, and packed with moving parts. According to one of the repair people I spoke with, some of the most complex machines were overly sensitive to being even slightly out of adjustment. Some of the internal settings were so exacting that they had to be adjusted by an expert with special equipment. To simplify the mechanics, manufacturers have been adding motors for different directions of needle and feed dog movement up/down and side to side, and feed dog forward and backward and side to side. This has eliminated many of the complex linkages (lower machine, image above) needed to operate a machine from one motor. And to coordinate the movement and synchronization of all the motors, they added a computer.

The advantage of computerization is that a sequence of steps, as simple as those for making a buttonhole, can be programmed and saved in the computer’s memory. Instead of requiring a complex cam, every type of stitch pattern is analyzed and broken down into a programmable series of distinct movements.

A computerized machine uses special electronic motors, called stepping motors. A stepping motor can rotate both clockwise and counterclockwise, unlike the motors in mechanical machines, which are generally meant to turn in only one direction. Stepping motors can turn in precise, discrete steps, or partial rotations; in fact, if you turn the gear of a stepping motor gently with your fingers, you can feel a series of distinct clicks. The amount of motor movement is proportional to the amount of stitch width and length: The width of a zigzag stitch can be as narrow as the motor step is small, for example. Wider zigzags are the result of wide motor swings.

Unlike the infinitely fine adjustments that you can make by turning the dial of a mechanical machine, the movements created by a step motor must be adjusted in increments. This isn't really a disadvantage, because the increments can be quite small— 0.1mm for stitch width and 0.05mm for length, for example. The size of increments is certainly a detail of a computerized machine that you’ll want to check, because they vary widely between models.

The stepping motor takes its orders from electrical signals coming from a main circuit board, which contains the stitch programs, electronic functions, and the memory that stores all the pro grams. Most computerized machines have buttons, rather than dials. When you press a button to select a stitch on the control panel of a computer machine, you are selecting a program and sending a signal to the circuit board. Some computerized machines can store programs for hundreds of stitch patterns, including stitches you create yourself.

Computerized machines offer the features of the electronic ones and other features available only because of the step motors and programming:

• Ability to flip patterns to create mirror images of stitch patterns.

• Ability to store the dimensions of buttonholes, so that once you’ve made one buttonhole, the rest will be identical (no marking and careful control needed.)

• Lots of buttonholes (keyhole, stretch, straight).

• Stitch patterns with varying width and length in the pattern (see image).

• Wider stitch patterns (often the result of a step motor that moves the feed dog from side to side).

• Multicolor stitches.

We would like to add a caution at this point about embroidery. Even a computerized machine is a sewing machine, not an industrial embroidery machine. Up to as many as ten industrial embroidery machines, each dedicated to a special stitch, may have been used to produce a design that you see on a ready-to-wear blouse that may not be reproducible at home. If you plan to do a lot of machine embroidery, examine each machine not just for number and combinations of stitches, but for quality of stitches and multicolor capability as well.

If you go shopping for a computerized machine, also keep in mind that all computer machines are not created equal. Some are much more user friendly than others and the only way you can see which one you like is to try them out.

All that plastic…or “they don’t make ‘em like they used to”?

Plastic parts are used in nearly all machines these days. Stay calm! Here’s some background info that relaxed me. To avoid frequent oiling and maintenance in home sewing machines, moving parts made of steel were often paired with adjacent parts of a softer metal such as bronze. Today the bronze has been replaced in many machines by Lexan, a tough, durable nylon also used to make nose cones for the space shuttle. If you’re worried that the machine you want contains cheap and non-durable plastic, ask the dealer to explain what type of plastic is in the machine -- or look at the model’s specifications or features online via its web-page description.

Repairs and warranties

You might still be wondering, as I was, whether you can trust the reliability of an electronic or computerized machine. Repair people admit that earlier computerization had its problems. Now that computerized machines have been around for a while, and redesigned and improved many times, the early problems have been solved. Computer machines to day have about the same rate of repair as mechanical machines. In fact, many of the new machines are modularly built, and snap apart for easier, faster repairs. Some repairs take one-fourth the time of the same repair on a mechanical ma chine, which represents a significant savings in labor costs. Warranties for parts and labor vary widely among companies though, so it makes sense to buy as long a warranty as you can for both.

Many people mistakenly believe that their mechanical sewing machine’s 20- or 30-year warranty covers the entire ma chine for 20 to 25 years. Actually this kind of warranty is usually limited and ensures only that the machine will be free from defects in materials and workman ship. A typical 25-year warranty covers replacement of the body of the machine if it cracks, but doesn't cover any problems due to ordinary wear and tear.

Manufacturers’ warranties on parts in all types of inexpensive machines, including the circuit board, are often for only 45 days; more commonly they range from two to five years for more expensive machines. Manufacturers’ warranties on labor, which cover the work needed for a repair, vary between zero and two years. Many dealers will extend these warranties on models that they find to be relatively trouble-free.

The price of circuit boards and other computer parts have fallen significantly in the past few years and will continue to decrease as production techniques improve, just as they have in the home computer market. For now, though, replacing a step motor or circuit board represents a major expense, and no one quite knows how long a circuit board can last. Dealers say if you have a good board, it should last for many years. It is possible to get a bad board—a circuit board which has a short life. Sometimes a problem will develop soon after you begin to sew, but it may not become apparent until the machine has been used for a thousand hours. A circuit board can cost as much as $200 and take from ten minutes to more than an hour to replace; if the parts and labor aren’t covered by a warranty, this repair could cost you $300. Thus, it makes sense to buy a computerized machine with as long a warranty on parts and labor as possible.

The longevity of computerized machines isn't yet known, because the machines are relatively new, but the manufacturers believe they will last longer than mechanical machines; they have fewer moving parts with less to go wrong. Computer machines don't require oiling except in the bobbin area, although neither do many current mechanical machines, which are now self-lubricating.

Deciding what you need

Before you buy, examine how and when you will use the machine, and for what tasks. (For some tips about testing a ma chine, see “How to test a sewing machine” on the facing page.)

I decided to buy a two-year-old computerized machine with a price tag I could afford. The friendliness and ease of use made me feel at home with my machine after only a few hours of sewing.

Many sewers say they don’t use their machine’s embroidery stitches much after the initial novelty wears off. That may happen to me after I’ve had my machine for a while. But for now, I’ve been embroidering my daughter’s name on her cloth napkin for school, and stitching dinosaurs on the new knee patch for my son’s jeans. When I press my machine’s foot pedal to the floor, the machine sews like lightning and it’s very quiet; it sounds as if it’s whispering.

Do we want computer machines? The answer is different for each of us, because our needs are different. But personally … there is no going back!

The scallop stitching of a mechanical machine (top and bottom rows)

has a constant width and length, once set. In contrast, the stitch width

of the computerized version varies from short to long (center), and the push

of a button flips the pattern.

Electronic bobbin fullness Indicator: Light from a bulb (at scissors’

point) projects on the side of a clear bobbin. When the bobbin runs low,

the light goes to the back of the bobbin case, where it hits a sensor. The

sensor triggers a warning light, a beep, or a visual message.