Machine needles

Machine needles are selected according to weight and other fabric characteristics, as well as the thread type being used. In general, a needle should be fine enough to penetrate fabric without mar ring it, yet have a large enough eye that the thread does not fray or break. Needle sizes range from fine (size 9) for lightweight fabrics to heavy (size 18) for very heavy ones. Sizes 11 and 14 are used most often for general sewing. Most of the needles sold are made in a standard length that fits most modern machines. Check your machine instruction book. Needles do have different points, as explained below. Always replace dulled, bent, burred, or nicked needles; they can damage fabric.

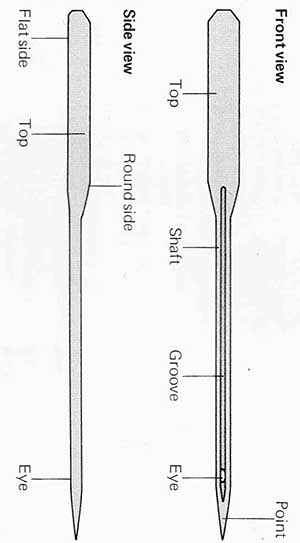

-- Front view Top Shaft Side view Round side Flat side Top Groove Eye Point

Eye

The illustrations at the left show both a front and a side close-up view of a machine needle. The thick or top portion is rounded on one side and flat on the reverse side, with the needle size usually etched into the rounded part. The thin or lower portion of the needle has a groove extending along the shaft from the rounded part to the eye. When a needle is inserted into any sewing machine, the rounded side should face the direction from which the needle is threaded. For example, if the needle is threaded from the front to the back, the rounded side should face front. This positions the groove toward the thread, permitting it to guide thread as it feeds through needle.

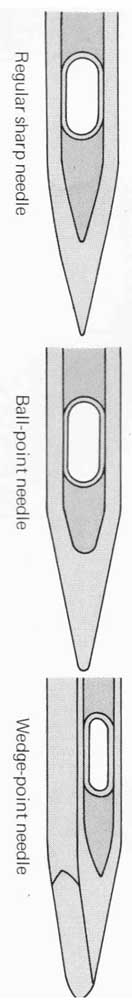

Specific sewing situations will require different needle points

Wedge-point needle:

The wedge-shaped point, designed for use on leather and vinyl, easily pierces these fabrics to make a hole that closes back upon itself. This avoids unattractive holes in the garment; also reduces the risk of stitches tearing the fabric. Wedge needles come in sizes 11 to 18. Size 11 is used for soft, pliable leathers; size 18 is suitable for heavy or multiple layers of leather.

Regular sharp needle, Regular sharp needle is ideal for all woven fabrics because it helps to produce even stitching with a minimum of fabric puckering. A regular sharp-point needle is not generally advised for sewing on knits-it can cut the yarns and cause skipped stitches. Needled range from a fine size 9 to a heavy size 18. Also available is a twin needle version (with two points) for fancy topstitching.

Ball-point needle:

The slightly rounded ball-point is recommended for all knit and elastic fabrics because it pushes between fabric yarns instead of piercing them. Some modified types can also be used for wovens (follow the manufacturer's instructions). Available in sizes from 9 to 16, with point rounded in proportion to the needle size-points of larger sizes 14 and 16 being more rounded than those of sizes 9 and 11.

-- Sewing aids

Of the many sewing aids made for home use, some, such as bobbins and pins, are necessities. Others, though not really necessary, are very handy for general sewing-a needle threader and thimble, for example. Still others, such as the loop turner, are needed only now and then for a special task, but are invaluable for that particular job. Then, too, there are the sewing aids, such as needle conditioners and scissors sharpeners, designed to help keep equipment in good working order. A sampling of such sewing aids is shown here; more are to be found on sewing counters, with new ones being invented every day. In buying sewing tools and supplies, it is wise to begin with a few basic ones, purchasing more as the need arises. In addition to aids specifically meant for sewing, other devices and some common household items can be used for sewing jobs. A magnet will pick up stray steel pins and needles. A fine crochet hook is helpful when tying short thread ends or for pulling snags to the wrong side of a knit. Tissue paper is useful in making pattern adjustments and also facilitates sewing slippery or very soft fabrics. Tweezers deftly remove tiny thread ends, tailor's tacks, and bastings. Other useful items include transparent tape to guide topstitching or hold pat tern adjustments in place, a large safety pin used to draw elastic or cord through a casing.

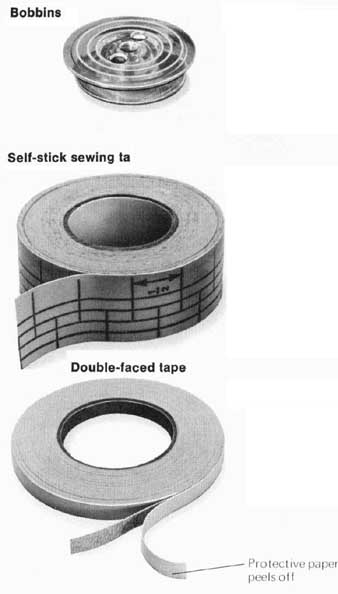

Bobbins are spool-like thread holders that supply bottom thread for machine sewing. Made of plastic or metal, they come in different types to fit specific machines.

Self-stick sewing tape has measured markings on one side to use as a stitching guide; is especially useful for top stitching. Available in two types: one that separates into various widths, with stitching done next to tape; a second that can be stitched through.

Double-faced tape (adhesive on both sides) will hold zipper in position or fabric layers together for stitching. Do not sew over tape; remove it after completing seam.

_- Protective paper peels off

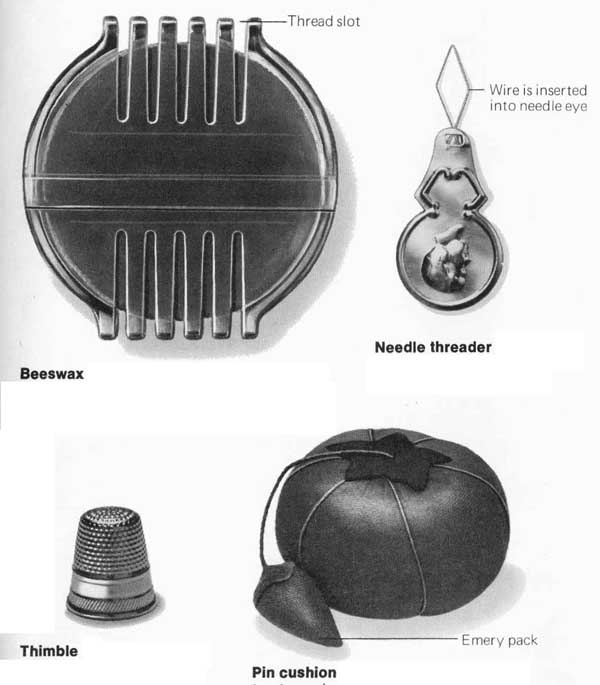

Beeswax is used to strengthen thread for hand sewing, reduce tendency to tangle and knot. Usually sold in container shown; to apply wax, thread is slipped through slots.

Needle threader eases threading of hand or machine needles. Wire is inserted into needle eye.

Thimble protects middle finger while hand sewing. Comes in sizes 6 (small) to 12 (large) for snug fit.

Pin cushion is a safe, handy place to store pins, keep them accessible. Some have an emery pack attached for cleaning both pins and needles.

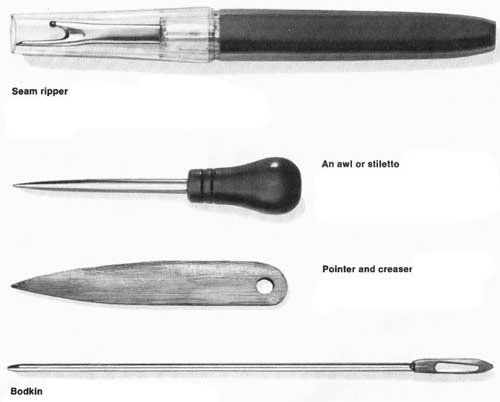

Seam ripper has sharp, curved edge for cutting seams open and a point for picking out threads. Can also be used for slashing machine-worked buttonholes. Use ripper carefully to avoid accidental cutting of fabric.

An awl or stiletto is a small, sharp instrument used to make the round holes needed for eyelets or keyhole buttonholes. For safety, tool should have snug-fitting cover.

Pointer and creaser is a flat wooden tool with a pointed end for pushing out corners, a rounded end to hold a seamline open for pressing.

Bodkin is a tool shaped like a long, blunt needle and used for threading elastic or cord through a casing. Can also be used to turn bias tubing. Bodkin types can vary; some have an eye through which elastic or cord can be threaded, others a tweezer or safety pin closure.

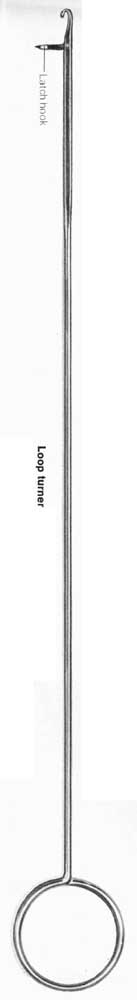

Loop turner (above) is a long, wirelike tool with a hook at the end for grasping fabric when turning bias tubing to the right side.