While the rise of the skyscraper is often attributed to the invention of the structural- steel frame, its success is in no small part due to the invention of the passenger elevator. For what would be the value of a steel-framed building too tall for people to access by stair? Indeed, the increasing height of these towers over time mirrored the development of elevator technology: commercial buildings got taller and more plentiful as elevators got better and faster.

The earliest elevators predated the first skyscrapers by decades, and were fairly primitive. They carried freight, not people, and were powered by steam—generally relying on what is sometimes referred to as “plunger technology.” These freight elevators sat on top of a large piston fitted into a cylinder sunk into the ground; increasing the steam pressure in the cylinder would force the elevator up the hatchway.

Plunger technology was reliable, but it had its limitations: the steel column, or plunger, that raised the car needed to sit in a pit as far below the ground as the building itself was tall. And the technology was slow—suitable for freight, perhaps, but not for office workers in a hurry.

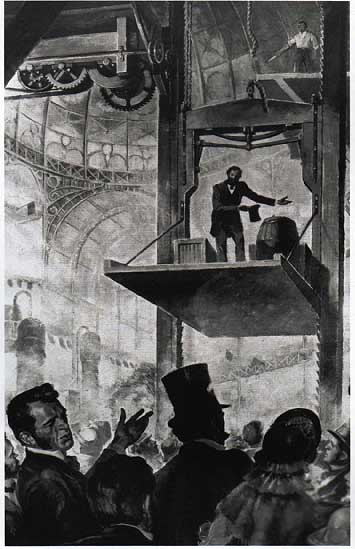

Undoubtedly the biggest breakthrough in the history of elevators came in the early 1850s, when Elisha Otis introduced the ‘ elevator,” which relied on cables and pulleys for lifting (rather than on plunger technology). His famous demonstration at the Crystal Palace Exhibition in 1854, in which he stood in an open elevator cab and then cut its cables, marked the beginning of the passenger elevator era.

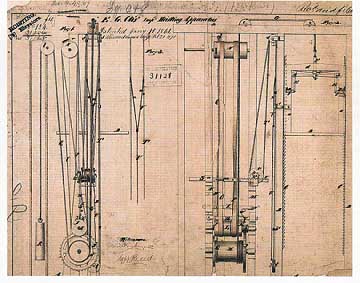

Otis received a patent for his steam- powered elevator in 1861, by which point several of his new inventions had been installed in buildings in New York. But they were cumbersome affairs and moved in ponderous fashion through the few shafts that had been designed to accommodate the new experiment in vertical travel.

The first hydraulically powered elevator was developed by William Hale in Chicago in 1870. The elevator cab moved up and down on top of a long piston inside a cylinder set deep into the ground. Smoother and somewhat faster than steam power, hydraulic power quickly set the design standard for new elevators. However, the hydraulic lift was still slow, and it was not until electric motors could be married to Otis’s safe, cable-based technology that cabs would move fast enough to serve buildings taller than six or seven stories.

Initial experiments with electricity in the 1880s and 1890s were not totally successful, as the stepping up and down of electricity led to very sudden elevator starts and stops. But with the introduction of Otis’s variable-speed electric motor in 1903, the ride became much smoother. Within a decade, “traction elevators,” as the new cable and pulley-based system became known, made their appearance in new office buildings in New York and Chicago.

Over the course of the next several decades, a series of other improvements in elevator performance—including smoother safety brakes and automatic leveling—were commercialized, many by the Otis Company. Safety was also important, leading to innovations such as automatic door opening and closing, load sensors, and motion sensors.

The ingenuity of Otis’s invention went well beyond just speed and safety. Because his elevator relied on a counterweight to assist in lifting the cab, it required relatively small amounts of electricity to operate; without the counterweight, elevators would consume on average seven times more electricity than with it. Even today, elevators remain the most energy- efficient aspect of a tall building; they’re responsible for no more than about 5 percent of the energy consumed by a fully climate- controlled skyscraper.

Today’s elevators come in shapes that would surprise even Otis. Double-deck elevators allow loading and unloading at adjacent floors simultaneously, while twin-shaft systems feature multiple cabs moving within the same shaft. These and others now travel at speeds he could hardly have imagined—limited only by the ability of the human ear to adjust to changes in air pressure.

But perhaps more notable than any of the refinements to the original technology has been the durability of the basic concept itself over the course of the twentieth century. Nearly every one of the thousands of elevators serving urban skyscrapers today still relies on the basic principles of Otis’s safety elevator: cables, counterweights, and a catch system to stop the cab’s fall in the unlikely event of a cable breakage.

Elisha Otis’s elevator patent drawing, January 1861

Elisha Otis at the Crystal Palace Exhibition in London, 1854

Elisha Otis at the Crystal Palace Exhibition in London, 1854

How Elevators Work:

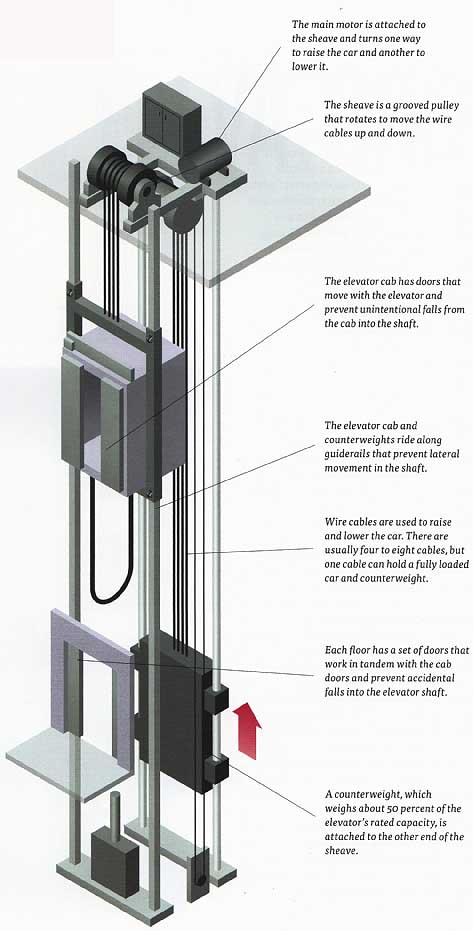

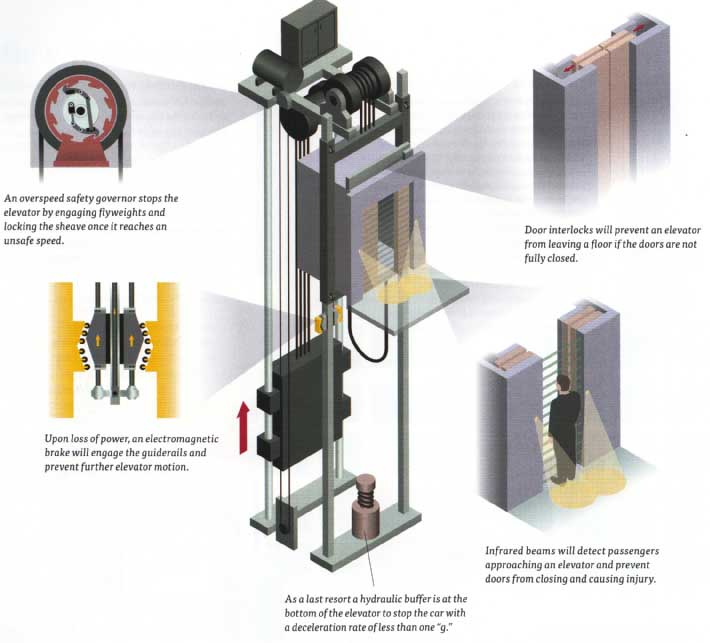

The basics of traction elevators are the same throughout the world. Woven steel cables are attached to the top of an elevator cab and wrapped in special grooves around a pulley (known as a “drive sheave” or “sheave”). The other end of the cables is attached to a counterweight, weighing roughly the same as a half-loaded cab. The balance between the car and the counterweight means that the motor’s only job is to overcome friction.

Both car and counterweight move up and down the shaft on guiderails. These keep the car and the counterweight from swaying, and help stop the car. A variety of safety features exist to prevent the cab from falling through the hoistway, including a “governor” mechanism that senses undue speed and deploys a set of brakes that lock the cab in place along the guiderail. Generally, the sheave, motor, and governor are housed in a machine room located directly above the shaft.

Traction elevators come in two varieties: “geared” and “gearless.” In geared elevators, the motor turns a gear that rotates the sheave. The presence of gears makes turning easier and therefore requires a less powerful motor, though it also reduces the speed with which these elevators can travel (350 to 500 feet, or 107 to 152 meters, per minute). In elevators with gearless traction systems, the motor rotates the sheave directly and therefore permits movement at higher speeds (over 500 feet, or 152 meters, per minute).

All elevators share a variety of safety features, including two sets of doors: one on the car itself and one on the floors opening into the shaft. Both are operated by an electric motor hooked up to the elevator’s computer. Most elevators also feature load sensors, which tell the elevator computer how full the car is, and motion sensors, which keep the car doors from closing if they detect an obstruction. They also incorporate a computer that registers and processes calls from users.

The elevator cab has doors that move with the elevator and prevent unintentional

foils from the cab into the shaft.

The elevator cab and counterweights ride along guiderails that prevent lateral movement in the shaft.

Wire cobles ore used to raise and lower the car. There ore usually four to eight cobles, but one coble can hold a fully boded car and counterweight.

Bach floor has a set of doors that work in tandem with the cob doors and prevent accidental foils into the elevator shaft.

A counterweight, which weighs about 50 percent of the elevator’s rated capacity, is attached to the other end of the sheave.

The main motor is attached to the sheave and turns one way to raise the car and another to lower it.

The sheave is a grooved pulley that rotates to move the wire cables up and down.

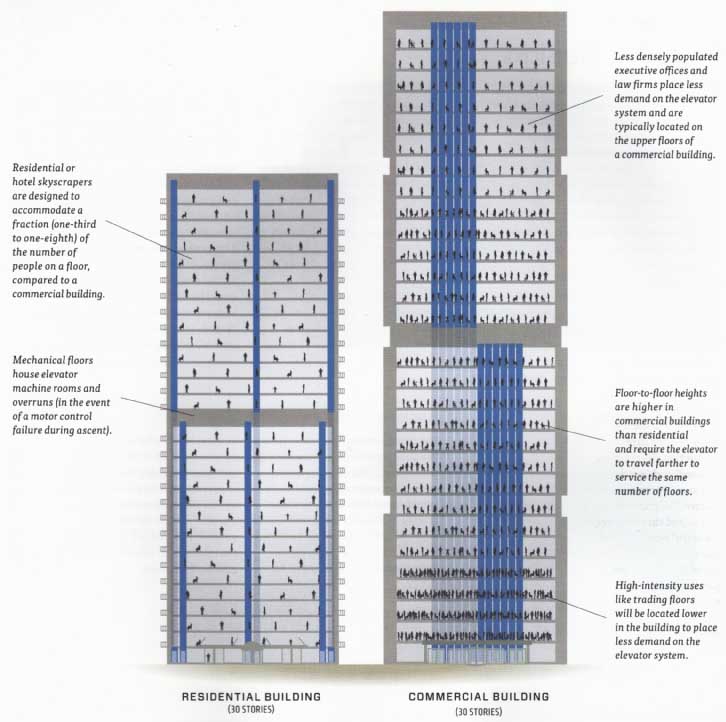

Residential or hotel skyscrapers are designed to accommodate a fraction (one-third to one-eighth) of the number of people on a floor, cam pared to a commercial building.

Mechanical floors house elevator machine rooms and overruns (in the event of a motor control failure during ascent).

Less densely populated executive offices and law firms place less demand on the elevator system and are typically located on the upper floors of a commercial building.

Floor-to-floor heights ore higher in commercial buildings than residential and require the elevator to travel farther to service the some number of floors.

High-intensity uses like trading floors will be located lower in the building to place less demand on the elevator system.

RESIDENTIAL BUILDING (30 STORIES); COMMERCIAL BUILDING (30 STORIES)

Servicing a Tower:

Both residential and commercial skyscrapers rely heavily on elevators to move people. But the number, size, and layout of elevators required to serve residential and commercial towers will vary dramatically from one another in almost all cases.

Because natural light need not penetrate the interior of the floors, commercial buildings typically have larger floor plates than residential towers. They are also more densely populated, at least during the day, and exhibit morning, lunchtime, and evening peak travel times. Residential elevator usage is more stable, with smaller numbers moving up and down throughout the day and night.

Elevators in a commercial building will typically be located in a central core area that also serves as home to the wiring and piping that runs vertically through the building. In contrast, elevator shafts in a residential building will be located in different parts of the building so they may directly serve individual apartments.

Elevators in commercial buildings must also travel farther, and therefore faster, as the height of each commercial floor is generally at least so percent greater than its residential counterpart. And office workers are impatient, so waiting times must be calculated to fall squarely within the acceptable range.

Elevator Design:

Designing a vertical transportation system for a skyscraper is among the most complex tasks developers and their architects face, and involves a series of related decisions. How many elevators are needed? How large should they be? How fast must they travel? How should they be con figured—back-to- back or in a straight line? Should a one-stop ride, known as “direct descent,” be provided or is an express/local system a better way to move large numbers of people?

Getting these decisions wrong can be very costly to a developer. “Over-elevatoring,” or providing more vertical lift capacity than needed, means the unnecessary loss of rentable space. On the other hand, “under-elevatoring” usually results in unacceptable waits and travel times, unhappy tenants, and a bad reputation for the building.

Addressing these design questions requires, as a first step, a series of mathematical calculations. The number of people who will be traveling in and out of the building on a daily basis must be forecast. Generally this is a function of how much square footage is allocated to each employee or resident—a figure that can vary greatly based on the type of work or the sizes of the residences.

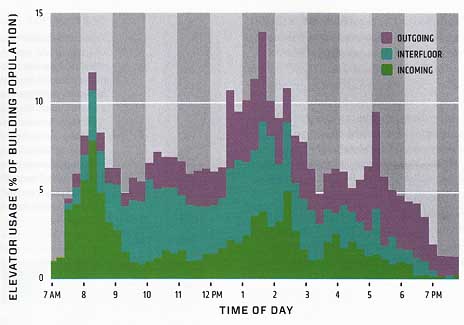

A second step is estimating what percentage of those people might move in or out of the building within a peak period known as the “five-minute handling capacity.” This can range from a low of 7 percent for residential buildings to a high of between 20 and 25 percent in office towers, where a large number of employees from one company might share the same working hours.

A number of other criteria factor into the design process, including passenger waiting time, load factors, and total trip time. In each case the developer must decide what level of service it wants to provide to building occupants. In an office building in New York, For example, morning wait times ranging from 20 to 25 seconds are considered good, while those between 30 and 35 seconds are generally considered unacceptable.

--

Freight elevators:

FREIGHT ELEVATOR; PASSENGER ELEVATOR

The largest passenger elevators in skyscrapers are shuttles that ferry people to sky lobbies or observation decks; these can hold weights up to 10,000 to 12,000 pounds (4,500 to 5,400 kilograms) and carry more than 40 passengers. But even smaller skyscrapers will have at least one large freight elevator to move goods and equipment throughout the building. These will typically be several feet deeper and taller than passenger elevators, and will almost always descend directly to an area adjacent to the building’s loading dock.

--

Banking on height:

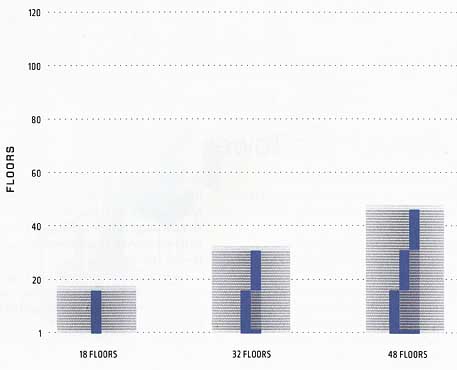

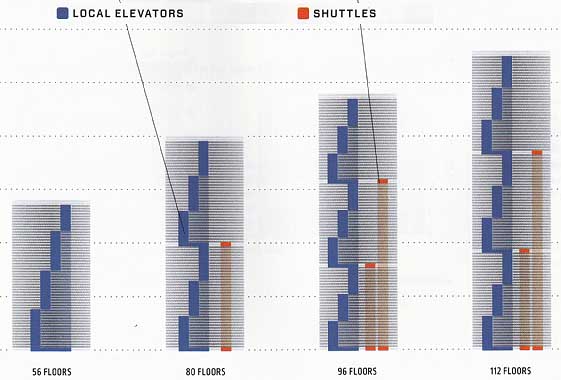

The configuration of elevator banks in a building is largely a function of its height. One bank, generally made up of eight elevators, is usually enough to serve 15 to 20 stories; two banks (a low-rise and a high-rise) are required for buildings of up to 35 stories. Three banks are necessary to reach 40 or 45 stories; four banks will provide service up to 55 or 60 floors. In buildings above 60 floors, a system of express shuttles to one or more sky lobbies, where passengers transfer to local elevators, will generally be needed to minimize the incursion of elevator shafts into the floor plate.

• LOCAL ELEVATORS: Passenger elevators come in a variety of sizes and are generally distinguished by the weight they carry. Typically office elevators will be larger than residential ones and will range anywhere from 2,500 to 4,000 pounds (1100 to 1800 kilograms) in carrying capacity—and carry anywhere from 10 to 25 people.

• SHUTTLES: Supertall buildings often feature express shuttles to sky lobbies, where passengers can switch to local elevators to access higher floors. This configuration allows the “locals” above the sky lobby to occupy the same shaft as the local elevators serving the lower floors and leaves more rentable space on each floor.

Shuttle elevators made their debut at the World Trade Center in the early 1970s, traveling to sky lobbies on the forty-fourth and the seventy-eighth floors. Each shuttle elevator featured front and rear doors that opened for speedier, unidirectional loading and unloading.

Elevator Rush Hour:

In elevator lingo, “capacity” generally refers to the maximum number of people a building’s elevators can handle during a given five-minute period. In office buildings, a vertical transportation system will typically be designed to handle roughly 12 percent of the building’s population in this time. The most complicated peak is at lunchtime, when people are moving both up and down. In residential buildings with less concentrated traffic patterns, elevator systems are generally designed to handle no more than 7 or 8 % of residents during the morning peak.

56 FLOORS; 80 FLOORS; 96 FLOORS; 112 FLOORS

New Technologies:

While Elisha Otis’s cable-based, counterweight-supported safety elevator has remained the backbone of skyscraper elevators around the world, it’s continually being improved upon around the margins— mostly in ways that enable developers to move larger numbers of people to their destinations faster, without increasing the footprint of the elevator shafts.

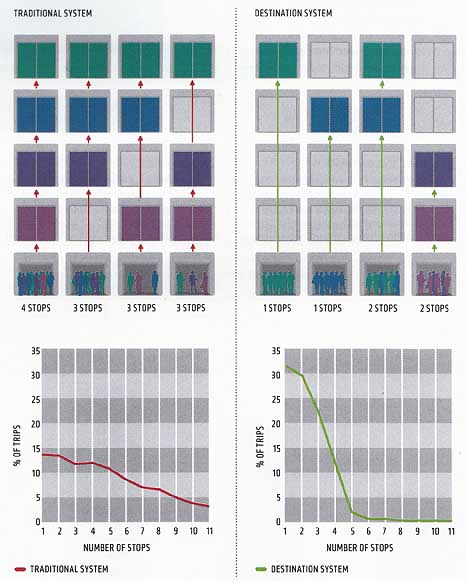

Some of the most interesting innovations are the most disconcerting to the casual elevator user, including advances in elevator-dispatching technology. Historically, elevator brains have assigned cabs to floors based on “estimated time of arrival” dispatching—i.e., the elevator that will get to a floor first in the direction the passenger is going is assigned to collect him or her, regardless of the number of stops it will make before or after.

In new “destination dispatch” systems, the elevator computer relies on a different set of algorithms for grouping elevator users going to the same or adjacent floors. Instead of pushing a button to call an elevator at random, users rely on a keypad or security card to identify their destination at a panel in or near the elevator bank. The computer then indicates a cab assignment. Once aboard the designated elevator, the user will automatically be taken to his or her destination.

Other advances in computerization and elevator “logic” have also served to speed up passenger throughput. By monitoring daily traffic flows, elevator control systems are now able to “learn” where the most efficient place to position cabs might be at a specific time on a given day. For example, passenger flows from one floor of an office to another for a regular i a.m. Tuesday meeting will be noted by the system, and one or more cabs will be deployed to “wait” nearby at that time each Tuesday for the expected call from users.

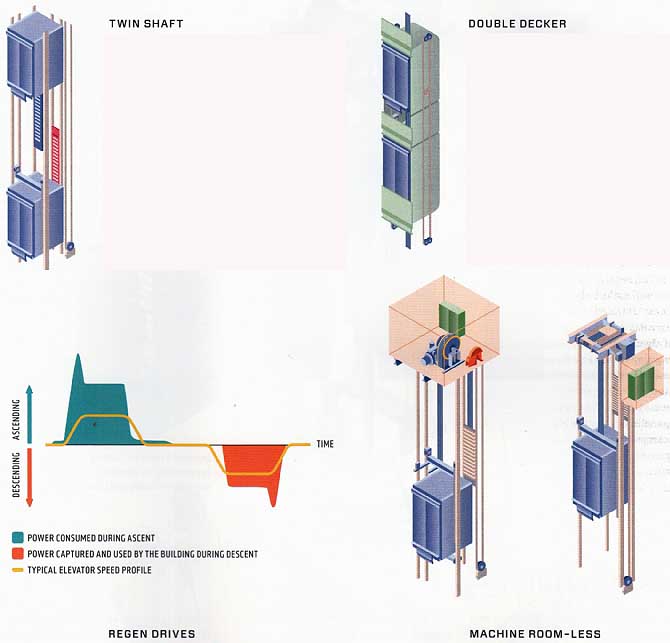

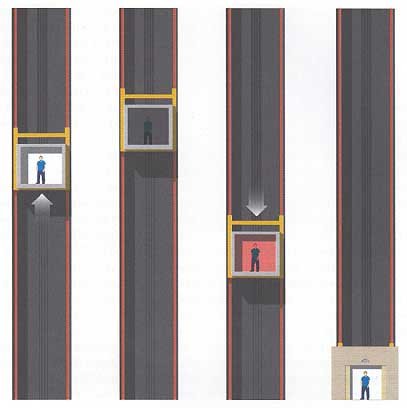

Some advances in passenger-carrying capacity relate to the body rather than the brain of the elevator. Double-deck elevators, which feature an upper and lower cab stacked vertically within one elevator frame, are now in common use. Less common but equally notable are twin-shaft systems; these feature two cabs moving independently within one hoistway.

DESTINATION CONTROL: Traditional dispatch systems are based on minimizing waiting time for passengers without factoring in total trip time. Typically o rider calls an elevator and takes the next available car; the system does not differentiate between a car that subsequently stops at every floor and one that makes a single stop.

Rather than load every waiting person in the car without regard to final destination, the destination dispatch system aims to minimize total trip time by directing passengers to a specific elevator headed far their floor. The result of grouping passengers in this manner is less crowded cars that make fewer stops and therefore get them to their destination sooner.

TRADITIONAL SYSTEM; DESTINATION SYSTEM; NUMBER OF STOPS

TWIN SHAFT: The idea of multiple, unattached cabs moving within one shaft debuted in 1931, in a 20-Story Pittsburgh office tower. The lower cab served the lower 10 floors and the upper cab the remaining 10. Elevator attendants “driving” these cars relied on blocking signals, similar to those present in subway systems, and the cabs themselves moved only in the same direction. The experiment proved unsuccessful, and twin-shaft technology did not reappear until 2003, when it was featured in a university building in Stuttgart, Germany. In today’s iteration the two elevators have their own traction drives, with all moves determined by a destination-dispatch system. Safety features include automatic speed reduction as cars approach one another and emergency brake deployment if minimum safety distances are breached.

REGEN DRIVES: The “regenerative” technology associated with traction systems can deliver significant energy savings by converting normally wasted energy into electricity. As the cab descends, the elevator’s motor acts as a generator and pumps current back into the building’s power supply—rat her than just dissipating it as waste heat.

DOUBLE DECKER: Double-deck elevators offer the same advantages as double-deck buses and trains—i.e., a doubling of capacity for only a modest amount more fuel. Unlike their transit counterparts, however, the loading and unloading of each deck occurs on different floors rather than through the same doors. Although the technology dates bock to an early experiment in New York in the 1930s (which aimed to simultaneously serve the ground- and subway— level entrances of a building), it was not until the late twentieth century that double-deck technology proved itself commercially. It’s now employed around the world, including at the Citicorp Center in New York, at First Canadian Place in Toronto, and at the Petronas Towers in Malaysia.

MACHINE ROOM-LESS: Traditionally the engine, governor, and controller mechanism are located in a machine room located above the elevator shaft. In “machine room—less” elevators they are located in a structure housed within the hoistway itself— avoiding the construction costs and space requirements of a typical machine room. This is possible due to a new form of flat, polyurethane coated steel belt, which is significantly thinner than steel cables and permits a smaller, flatter sheave mechanism. Rarely used on buildings above 30 stories, it can prove cost-effective in the design of smaller skyscrapers.

• POWER CONSUMED DURING ASCENT

• POWER CAPTURED AND USED BY THE BUILDING DURING DESCENT

• TYPICAL ELEVATOR SPEED PROFILE

An overspeed safety governor stops the elevator by engaging flyweights and locking the sheave once it reaches an unsafe speed.

Upon loss of power, an electromagnetic brake will engage the guiderails and prevent further elevator motion.

As a last resort a hydraulic buffer is at the bottom of the elevator to stop the car with a deceleration rate of less than one “g”.

Door interlocks will prevent an elevator from leaving a floor if the doors are not fully closed.

Infrared beams will detect passengers approaching an elevator and prevent doors from closing and causing injury.

Elevator Safety:

As far as urban transportation goes, travel by elevator is far safer than traveling by train, car, or bus. The roughly two dozen deaths a year associated with elevators generally involve maintenance workers falling into an open shaft or getting entangled in elevator machinery. (A rare documented case of an elevator free fall occurred in 1945, when an Army B-25 bomber hit the Empire State Building in fog and its landing gear fell down an elevator shaft, snapping the elevator cables. The cab fell over 75 stories, but the elevator operator survived the fall: compressed air under the cab slowed its fall, and the severed cables, hanging from beneath the car, piled up in the pit and acted as a coiled spring.)

Most skyscraper dwellers are wholly unaware of the numerous safety mechanisms designed into modern traction elevators. Foremost among these mechanisms is the governor, which senses the speed of travel and can automatically bring the machine to a stop by engaging a locking mechanism along the guiderail. It’s by no means the only braking mechanism: electromagnetic brakes, kept in an open position for travel, automatically engage when the car loses power for any reason. Likewise, an automatic braking system near the top and bottom of the shaft will be triggered if the car moves too far in either direction.

Other safety features include sensors, which detect people or objects in the doorway and stop or reverse door closures; interlocks and door restraints, which prevent the elevator from leaving a landing if both sets of doors are not closed or from opening when it’s between floors; emergency lighting and telecom systems; and a buffer system at the base of the hoistway pit, which works like a cushion to soften any unlikely landing.

When Power Fails:

When power fails in a skyscraper, the safety brake on individual elevators is automatically triggered. Mounted between the motor and drive sheave, the brake operates like a spring and is at all times kept in a retracted, or open, position by electricity. A power failure will thus cause it to extend and engage immediately.

Inmost cases the loss of electric power also kick-starts an emergency generator— usually within 60 seconds of the power failure. Once the generator is triggered, emergency lighting comes on. Generator power then brings the building’s cars, one by one, back to the lobby, where their doors are opened, lights are dimmed, and power supply is shut down.

If for some reason, the elevator doesn’t move immediately to the lobby, an “alarm,” or “help,” button within the cab is available to call for assistance. A telecom connection to the building’s operations center is also provided. In some cases this connection is two-way; in others it serves only as a channel for incoming calls and instructions.

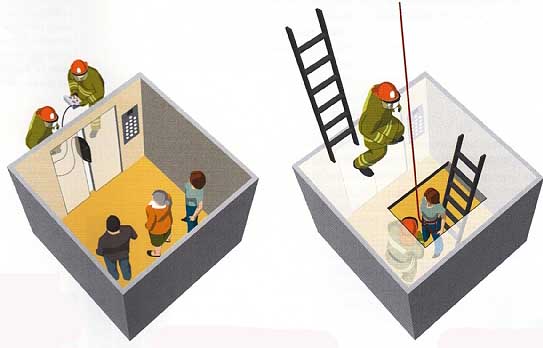

Elevator rescue: Most elevator rescues are made by technicians who fix a computer glitch and get a stuck car moving again. However, when a car is stuck due to a prolonged power failure or some other electromechanical problem, firefighters or other rescue personnel may be called in to free stuck passengers.

Almost all elevators have a door at the top that rescue personnel can use to gain access via the elevator shaft. Untrained personnel should never use this door to try to escape.

Similar to the “jaws of life” used to free passengers from automobiles in car accidents, a pneumatic device maybe used by rescue personnel to free a stuck door.

Elevator Speed:

Although the basics of traction-elevator technology have remained largely the same for the last century, elevator speeds have increased greatly since Otis’s day. Today’s high-speed elevators can and do travel as fast or faster than airplanes climbing or descending—and suffer many of the same human limitations.

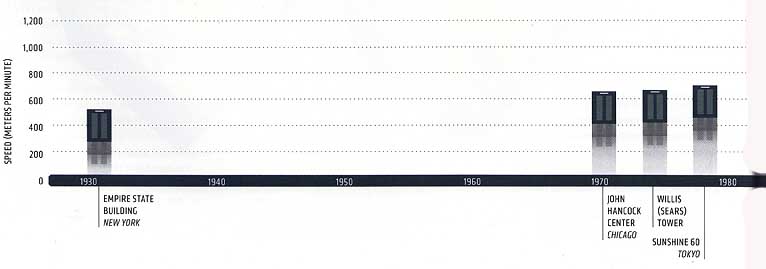

The world’s tallest buildings, many of them in Asia, are home to the world’s fastest elevators. This tie between vertical speed and skyscrapers dates back to the Woolworth Building, which boasted the world’s fastest elevators (traveling 650 feet or 200 meters per minute) when it opened as the world’s tallest building in New York in 1913. Less than 20 years later, the Empire State Building showcased even faster elevators— at 900 feet (275 meters) per minute. The John Hancock Tower in Chicago set the record for the supertall buildings of the 197os, traveling at over 2,000 feet (609 meters) per minute.

Today’s high-speed elevators travel significantly faster than ever before. The Yokohama Landmark Tower debuted in Tokyo in 1993 with elevators reaching 2,300 feet (700 meters) per minute, or over 26 miles (42 km) per hour. A decade later its elevators were surpassed by those of Taipei 101—two of which reach the incredible speed of over 3,000 feet (914 meters) per minute, or 34 miles (s4 km) per hour.

The limits on elevator speed are not technical—they are human. Riders can be affected by many aspects of speed, including the jerkiness of stopping and starting, the noise and occasional horizontal sway associated with hoistway travel, and—perhaps most important in the case of skyscrapers—the impact of air pressure changes.

Air pressure changes are particularly limiting. Similar to air travel, changes in air pressure between the inner ear and the external environment are less troubling on ascent than they are on descent—when the eustachian tubes that equalize pressure between the two can fail to open and painful “ear block” can result. In deference to this reality (and after a legal suit against the Sears Tower for eardrum damage), all high-speed elevators travel up significantly faster than they do down.

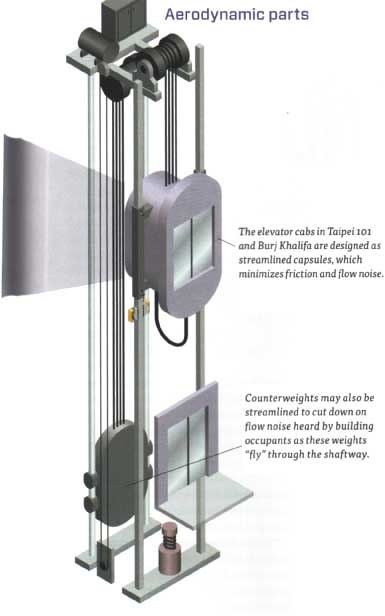

New technologies can reduce the impact of high-speed elevator travel on passengers. Suppressers and insulation minimize vibration inside the cab. Aerodynamically shaped cars reduce the noise associated with high-speed movement through the hoistway. Double-paneled construction can make cars airtight and prevent whistling. And in the most extreme cases, including the elevators at Taipei 101, the cabin can be gradually pressurized as it descends.

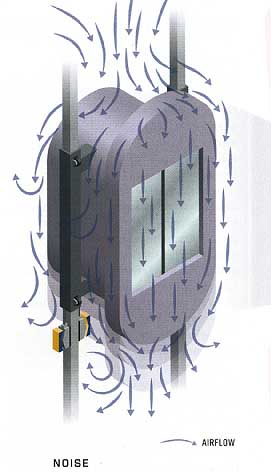

NOISE: Traveling at maximum speeds nearing 40 miles per hour (64 km/br), elevator cobs and components are designed using computer simulations and aerodynamic principles similar to automobiles and aircraft to minimize noise for passengers as well as building occupants near the shafts.

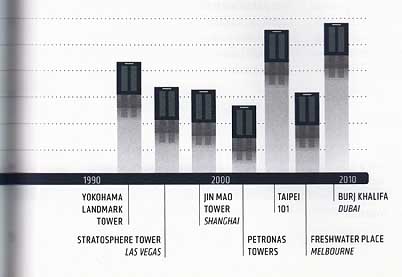

The world’s fastest elevators--Overtime, maximum elevator speeds have tracked

closely with skyscraper height records as building designers found efficient

ways to move larger numbers of people higher in the sky.

EMPIRE STATE BUILDING, NEW YORK; JOHN HANCOCK CENTER, CHICAGO; WILLIS (SEARS) TOWER; SUNSHINE 60 TOKYO YOKOHAMA LANDMARK TOWER; STRATOSPHERE TOWER, LAS VEGAS; JIN MAO TOWER SHANGHAI; PETRONAS TOWERS; TAIPEI 101; FRESH WATER PLACE, MELBOURNE; BURJ KHALIFA, DUBAI

Aerodynamic parts:

The elevator cabs in Taipei 101 and Burj Khalifa are designed as streamlined capsules, which minimizes friction and flow noise.

Counterweights may also be streamlined to cut down on flow noise heard by building occupants as these weights “fly” through the shaftway.

Asia’s fastest elevator -- Until recently Asia was home to the world’s fastest elevators. Traveling express from the ground to the observation deck at Taipei 101, two high-speed elevators reach over 3,000 feet (915 meters) per minute, or 34mph (54 km/hr), on the trip up—a full 30 percent faster than any other elevator in the world at its opening—and roughly 1,900 feet (580 meters) per minute, or 22 mph (35 km/hr), on the trip down. Only the observation deck elevators at the Burj Khalifa, which opened in Dubai in January 2010, are designed to ascend faster— at 3,500 feet (1,076 meters) per minute, or 40 mph (64 km/hr).

Both the cars and the counterweights at Taipei 101 are shaped like bullets, to reduce drag. To reduce noise the elevators feature acoustic tiles and sound insulation shrouds. Because conventional bronze safety shoes would melt under the high braking temperatures, ceramic braking shoes were used instead. In addition, a sophisticated system of vibration suppression was designed specifically for the building.

But the most notable feature of Taipei 101’s express elevators is its air- pressurization system, which is designed to protect the ears of observation deck visitors en route back down to the ground. It relies on suction and discharge blowers to adjust the atmospheric pressure in the elevator car, beginning as soon as the doors close at the top and continuing at a uniform pace as the car descends.

In addition to its express elevators, the skyscraper has another 59 elevators, including 34 double-deckers and 25 individual large-capacity elevators.

Previous: Construction

Next: Power, Air, and Water