A building under construction creates many temporary disruptions, dislocations, and hazards in its vicinity. The soil and vegetation are torn up. Roads and sidewalks are often obstructed and natural surface drainage patterns interrupted. Heavy construction vehicles often break the pavement accidentally. Construction work generates noise, dust, and fumes. Power tools and construction machinery present hazards to fingers and limbs. Tools and materials may fall or be blown by wind from higher levels of the building. Edges of floors and holes in floors for pipes, wires, ducts, stairs, and elevators create the risk of accidental falls. The chances of accidental fire are higher during construction than in the finished building, with debris accumulating and various fuel-burning torches and heaters in use. The partly finished building is attractive to thieves, vandals, and adventure seekers, making it doubly vulnerable to fire and accident. Therefore the construction process itself needs careful design attention in order to minimize its danger and unpleasantness and to maximize its efficiency and economy.

Temporary utilities are needed during the construction process: water, electricity for power tools and temporary illumination, telephone lines, temporary toilets, and waste removal services. Construction workers need parking or other transportation arrangements. The contractor must provide a system of temporary drainage to keep excavations free of water and to control surface drainage. Precautions must be taken to prevent soil erosion by wind or water. Nearby wetlands, forests, and buildings must be protected from dust and runoff. Trucks bringing materials to the site need delivery routes that will disrupt traffic as little as possible and avoid disturbing residential areas. An area of the site for unloading materials is required, adjacent to dry, safe areas where materials can be stored until needed. There must be lifting and carrying devices to unload trucks, stack and unstack materials, lift materials and workers to the various levels of the building, and transport materials across each level.

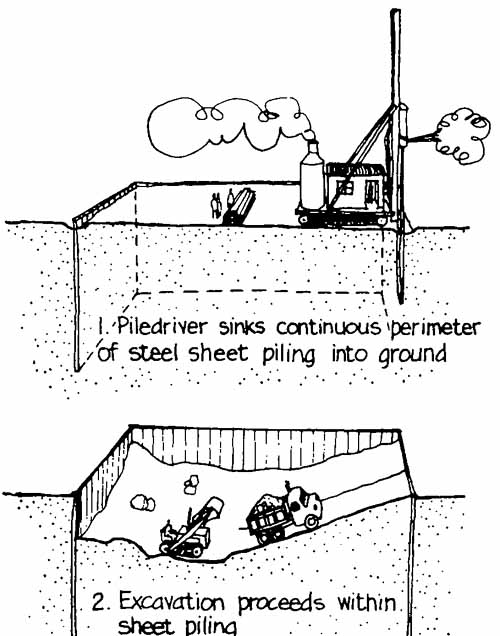

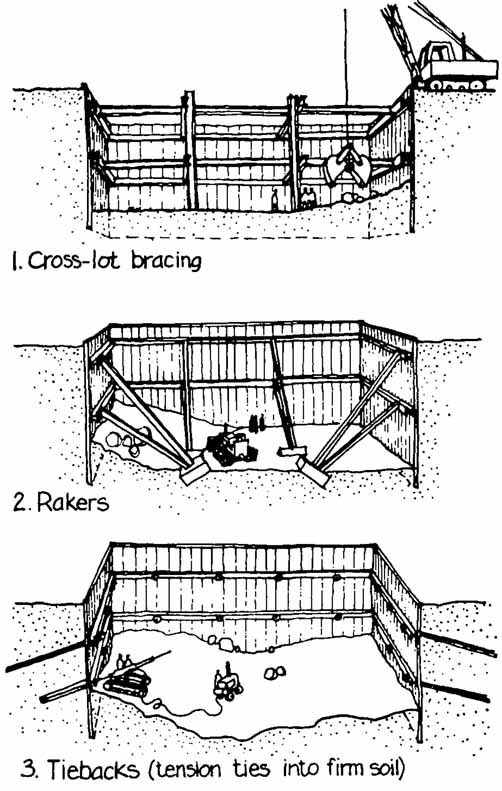

On many projects, the contractor must erect temporary fences and barriers of various kinds to protect the public from the hazards of the work and to protect the work from intruders. Trees must be fenced and padded against accidental damage by construction machinery. If excavations are in unstable soil or too close to roads or adjacent buildings, they must be shored to prevent collapse of the surrounding soil (Figs. 6-20, 7-20). If the excavation is to go below the level of the foundations of adjacent buildings, those buildings may have to be supported temporarily against subsidence or sliding. If the level of water in the ground is above the bottom of the excavation, the site must be dewatered to make construction possible.

ill. 6-20: Shoring an Excavation with Sheet Piling: 1. Piledriver Continuous

perimeter of steel sheet piling into ground. 2. Excavation proceeds within

sheet piling. As excavation deepens, sheet piling must be braced.

ill. 7-20: Alternative Methods of bracing sheet piling. 1. Cross-lot. Bracing;

2. Rakers; 3. Tiebacks (tension ties into firm soil).

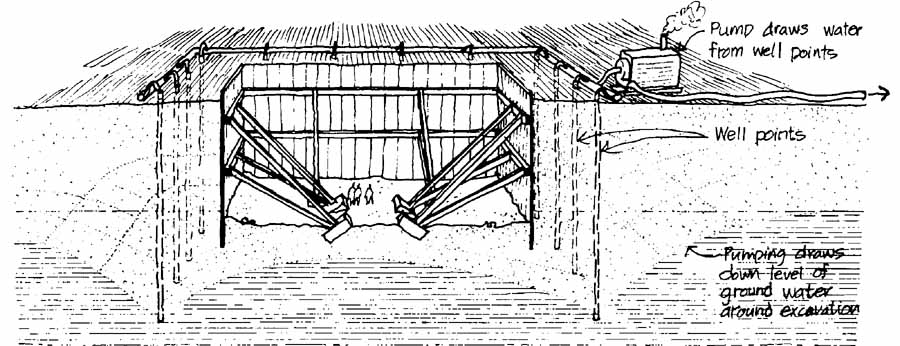

ill. 8-20: (Click here or image for full size) Pump draws water from well

points; Well points; Pumping draws down level of ground water; around excavation.

Dewatering may be as simple as digging a shallow pit in the deepest part of the excavation and pumping out any water that accumulates in it, but often it involves installing well points and a system of piping and pumps to draw down the level of ground water around the site (ill. 8-20).

As the building rises, workers need scaffolding, ladders, and hydraulic lifts for access to the various surfaces of the building. In taller buildings, one or more temporary elevators may be required. Many structural elements need temporary support: knee braces for walls, formwork for concrete, centering for masonry arches, and temporary diagonal braces of plank or cable throughout wood or steel frames. All these will later be removed as the structure becomes self-supporting. For safety and convenience, contractors may install temporary floors of wood planking in steel building frames until the permanent floors are in place and temporary railings have been installed at edges and openings of floors.

Temporary protection against the weather is required in several areas of the building site: The contractor and subcontractors need one or more portable field offices. Sheds or trailers often store tools and valuable materials on the site or shelter specific areas of work such as those around large power saws for cutting wood or masonry. Waterproof tarpaulins shelter piles of materials. In severe weather, tarpaulins act as roofs or walls throughout a building site to shelter work and workers from wind, rain, snow, or cold air. In winter, temporary heating stoves protect concrete or masonry work against freezing and help paint and plaster to dry. In very hot weather, sunshading may have to be provided (ill. 9-20).

ill. 9-20. Click here or image for full-sized view.

Workers on a construction job are exposed to many dangers; building contracting has one of the highest rates of on-the-job injury of any industry in the United States. As a result, many protective devices are required for the various trades. The hard safety helmet is universal to protect the head against dropped objects or from bumping against overhead hazards. Hard-toed safety shoes protect feet from dropped tools or materials. Non-slip soles serve an obvious safety function. Goggles of various types protect eyes from the sparks and glare of welding and keep flying chips and dust from power tools out of the eyes. Leather gloves, aprons, dust-filtering respirator masks, and safety belts or safety lines are required for certain trades. Even the ironworkers who erect structural steel frames wear safety harnesses that are clipped securely to safety cables strung tightly between columns, and roofers are secured to roofs with similar devices. Scaffolding must have guard rails to prevent workers from falling off. Most power tools have built-in safety features such as self-returning blade guards, anti-kickback devices, and self-opening switches to shut off the tool if it's accidentally dropped. First-aid kits and fire extinguishers are kept close at hand, and instructions about medical and fire assistance are prominently posted. Medical and hospitalization insurance for injured workers is required by law. A safety officer is appointed by the contractor on each construction site to ensure that all aspects of the work are clean and safe. In the United States, federal government inspectors check construction sites to see that contractors comply with the complex provisions of the Occupational Safety and Health Act (OSHA).

The workers normally own their small construction tools — hammers, handsaws, and so forth. Larger tools belong to the general contractor or subcontractors. But if a contractor does not like to keep a large inventory of construction equipment, he or she may rent or lease very large or highly specialized tools from an equipment-rental firm.

Every shipment of material that goes into a building must be checked upon delivery to ensure that it meets the written specifications. Each piece of lumber or plywood comes from the mill with a printed identification of its species and grade that makes on-site inspection easy. Structural steel is delivered with a certificate from the steel mill of its composition and quality. Most other building materials are similarly marked or certified with indications of their origins and quality.

Materials such as concrete and mortar, which are put in place wet, can't be thoroughly checked for quality at the time of their placement, because there is no sure way of knowing what their strength will be after they have hardened. The standard procedure is to cast several small samples of material from each batch in special molds. These samples are carefully marked, recorded in a logbook along with the locations in the building where the corresponding batch of material was used, and kept on the site for a standard period of hardening. Then they are transported to a laboratory where their strength is determined by crushing them in a calibrated hydraulic press. If the crushing strength is above the specified minimum value, all is well. If it's not, work done with the batches of material from which the samples were taken may have to be taken out and done over.

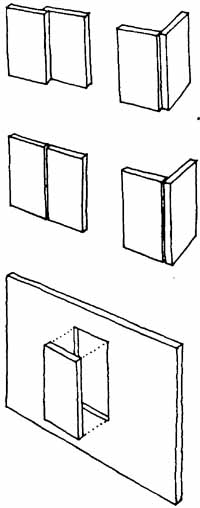

With the aid of modern measuring and leveling instruments, buildings are built with a surprising degree of precision, but they are not like watches or cameras. One must assume that even the best- produced building components—because of their large size, ship ping damage they may have suffered, water they may have absorbed in transit or on the job site, and variations in temperature—may not be square, flat, true, plumb, perfect, or accurate at the time they are installed in a building. One must also assume that a worker may not always measure or install a piece exactly as it should be, especially in the rougher sorts of work such as concrete work and wood framing. For a few building components, such as structural steel, there is an industry-wide standard specifying the maximum amounts of various sorts of distortions and inaccuracies that can be expected in the product when it arrives at the construction site. For most components, however, we must assume that dimensional accuracy of plus or minus one-quarter inch (6 mm) is reasonable to expect in buildings. Discrepancies of an inch or several inches (25 mm or more) sometimes must be accepted. Under these conditions, joints in which one piece of material simply laps over another are the easiest and safest to make (ill. 10-20 below). Where materials must be butted at two or more sides, it’ s essential that intentional gaps be provided to allow for inaccurate positioning and fitting. The openings for window and door units in wood-frame walls are always larger than the units themselves. When the units are installed, they are leveled and located accurately by means of small wedges around the perimeter. The siding covers the resulting gap on the outside, and the interior wall finish conceals it on the inside. Concrete or metal exterior wall panels are installed with intentional gaps between them, typically one-quarter-inch to 1-inch wide (6 to 25 mm). These are intended as much for thermal movement and structural deflection as for ease of installation. The metal mounting clips on such panels provide generous adjustments for accurate leveling and locating before a permanent attachment is made.

ill. 10-20: (Top) Overlapping joints: Lots of margin for error; (Middle) Butt

joints: Less margin for error; (Bottom) Butt joints on four sides: Least

margin for error.

In planning a construction job, it's important that those materials that must present a good, finished appearance be installed as late in the process as possible and that they be protected from damage until the last worker is out of the building. In many buildings, for example, it would be easiest to install the finish flooring early in construction, during the framing operation. If this were done, however, the surface would be exposed to the abrasion, chipping, scratching, indentations, dripping, and spotting caused by the feet, tools, materials, spillage, and miscellaneous accidents associated with all the subsequent work in the building. Instead, even at the cost of some inconvenience, installing finish floors is one of the very last jobs to be done in a building.

Designers must consider carefully what is to be left exposed in a building. It might be attractive to expose the wood framing in the wall of a house—but what will the wall really look like, with the irregular member spacings around openings, the natural defects in the lumber, the grade-marking stamps, the dents left by the carpenter’s hammer, the leftover pencil marks, and the electrical wiring and plumbing pipes drilled coarsely through? If a wall’s framing is to be seen, it demands close attention to appropriate lumber grades and careful routing of pipes and wires. It also demands a higher and more time-consuming quality of workmanship than a framing carpenter is normally asked to do. Usually it's cheaper to follow the standard procedure of bringing in gypsum wallboard workers and painters to cover the wall in several successively better-finished layers of work, letting the carpenter, electrician, and plumber work in their customarily rough and efficient ways.

It is readily apparent when examining any of the traditional ways of putting buildings together in our society that a principle is generally followed of sequencing construction so that each of the trades covers up and smooths over the work of the previous trades. The fourth-from-last trades to do their work in a typical building install large areas of flat material—siding, wall panels, lath, gypsum wallboard—that crudely cover the exposed innards of the building. The third-from-last crews are the smoothers-on of gooey substances—sealants, plaster, wallboard joint compound—that obscure the worst gaps in the flat materials. The next-to-last crews install flooring, cover plates, heating and lighting fixtures, cover strips, and moldings of various sorts. The last crew, the painters, brighten and conceal all these layers with a thin cosmetic and preservative coating, ready for the final cleanup of construction debris, the final inspections of all parties concerned, and the handing of the keys to the owner. The building, after a long and often-troubled period of gestation, is born at last.

Previous: Organizing the Larger Project Next: The Cost of Building