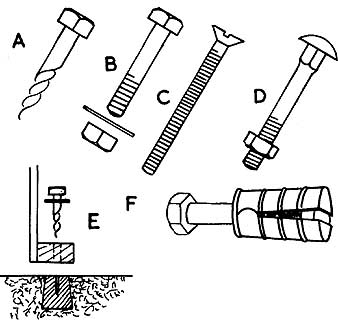

Common, flat-head, wooden screws are the alternatives to nails in some circumstances. Other types might be more appropriate to hinges or other metal attachments. In some buildings, there is a need for very large screws. You then need a lag or coach screw, which has a head to suit a wrench (figr. 2-4A). Drill for it and start it with a blow from a hammer.

Screws are made in at least as many different metals as nails and you can buy them with various protective coatings. Galvanizing tends to be rough, which might be an advantage because of its increased grip, if you are dealing with large sections of rough wood, such as posts.

figr. 2-4. You need large screws and bolts for joining parts

of buildings and anchoring them to their foundations.

Bolts are obtainable in many forms and sizes. In general, if you ask for a bolt, it's threaded to take a nut only part of its length. If you want it threaded almost to the head, you must ask for a screw. General-purpose-machine bolts have square or hexagonal heads and nuts (figr. 2-4B). Stove bolts are long and thin bolts with screwdriver heads (figr. 2-4C).

The bolts most useful in small buildings are coach or carriage bolts (figr. 2-4D). Under the shallow-domed head is a square neck which pulls into the wood and prevents the bolt from turning as you tighten the nut. It also retains the bolt in the wood, although you might knock it out. This characteristic is valuable if you want to disassemble occasionally. Always use a large washer under nuts on softwood.

For attaching wood to masonry, you have a choice of method. This choice is particularly true on the foundations. You can set special bolts in the concrete as you lay it (figr. 1-4C). An alternative is an ordinary bolt with a large washer under its head, to grip the concrete. The other way is to drill downwards, using a fastener that will grip the concrete. With the first method, you have to carefully locate the wood over bolt ends already there. In the second method, you can drill downwards through the wood and exact positioning is not so important.

Sometimes wooden blocks are let into the concrete (figr. 2-4E), but they should be rot-resistant wood or you might find that the attachment to the foundation is negligible if the wood is weakened by rot.

Methods of attaching downward into concrete involve drilling fairly large holes, for which you will need special equipment. Several types of anchor are available. They have a part which goes into the hole, and it's then expanded by driving a bolt or screw into it. A typical anchor has a body in two parts. When you drive a bolt in, you force the parts outward (figr. 2-4F).