The old saying that first impressions are lasting ones is especially true about a home. An attractive, well-maintained exterior says a lot about the occupants of a house. Whether you are interested in selling your house or fixing it up to en joy it yourself, an attractive exterior adds value and comfort. A good paint job on the siding and decorative trim and a nicely landscaped yard make the house look better and also make it a more pleasant place to be. Well-maintained gutters prevent water damage. A well-maintained surface on the driveway and walkways makes the house safer and also makes it look cared for. Plaster and mortar that are in good condition make the house more watertight, reducing the chance of water damage and improving the appearance of the house as well. These are just a few of many small and medium upgrades you can do to keep the exterior of your house safe and in good condition.

Most realtors agree that curb appeal is more important in selling a house than any of its other features. Although this guide isn’t just about fixing up a house to sell it, people do move frequently—sometimes when they least expect to—and a well-maintained home commands the best price because it shows well.

A new columned arbor is the handsome link that relates the garage to the house and transforms the entryway to this home.

Small Exterior Upgrades

Maintenance is the most cost-effective way to deal with the exterior of the house, because most exterior features, such as siding, roofing, and masonry, are expensive to replace. Many exterior maintenance projects are inexpensive and easy. Like all the small projects listed in this guide, these upgrades cost less than $900 and can be completed in a day or two.

Improving Exterior Lighting

For the money, exterior lighting enhances a home and landscaping more than most other exterior improvements.

The least expensive and easiest system to install is a low- voltage system. It is also more energy efficient and less expensive to operate than a standard system, because power is stepped down from the standard 120 volts, in most cases to 12 volts. The system consists of individual light fixtures and a transformer that plugs into a standard outlet, usually with a timer. Because the connecting wires carry only low voltage and are waterproof, they can be strung above ground or buried below ground.

Solar-powered systems are also available. They are more cost-efficient than standard electric fixtures to install and operate (they don’t use electricity), which more than offsets their higher purchase price.

Light switches that detect motion and body heat have come down in price since they originally appeared on the market. Any movement in the area at which the detector is aimed will turn on the light. As long as the movement continues, the light will stay on. The switch also includes an adjustable timer that will shut off the lights automatically after no motion has been detected for a specified length of time. Carrying out the trash or walking between the garage and the house at night are both safer with lights that come on automatically.

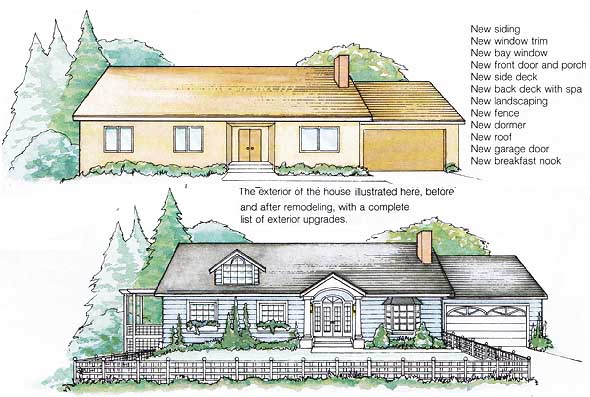

Exterior Upgrades: The exterior of the house shown earlier is illustrated

here, before and after remodeling, with a complete list of exterior upgrades.

- New siding

- New window trim

- New bay window

- New front door and porch

- New side deck

- New back deck with spa

- New landscaping

- New fence

- New dormer

- New roof

- New garage door

- New breakfast nook

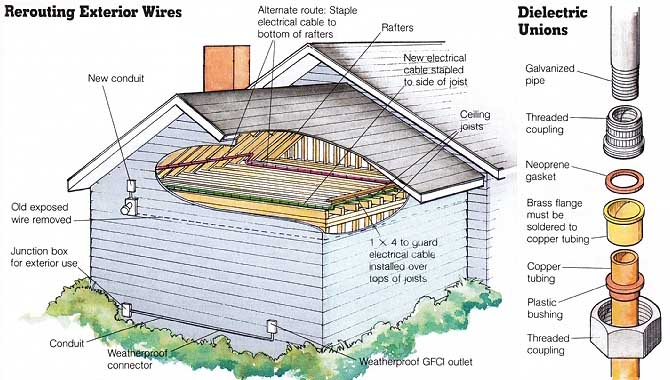

Rerouting Exterior Wires: ; Dielectric Unions:

Repairing Electrical Wiring

Improper wiring can cause fires. All exposed exterior wiring should be encased in a proper electrical conduit (a metal pipe).

Ideally, exposed wiring should be moved into the attic or basement area. It is safer there, and moving it indoors avoids unsightly wires and pipes on the exterior. In most cases, running wiring in the attic or basement area is less expensive than using conduit on the exterior, since the metal pipe, the connectors, and the tools required to work with conduit are expensive.

If hiding the wire is not possible, then running a conduit is the only smart choice left. A 25-foot length of exposed wire can be made safe in an afternoon. Use waterproof boxes and wire made for use inside conduit. Never use electrical tape to join and protect wire connections. Electricity can arc through the tape across two wires (or a wire and the junction box) and could cause a fire. Special wire connectors are made to prevent this from happening.

Place a weatherproof junction box at the point where the wire exits the house. Run electrical conduit from the box to the place where the wire ends. At that point, connect another unction, plug, or light box to the conduit. String new wire from the first junction box to the last one.

Although the National Electrical Code regulates electrical installations, the code can be superseded by municipal laws. It is wise to consult local building officials for advice prior to starting an electrical project.

Repairing Faucets

Leaky faucets can waste a lot of water. Faucet gaskets are usually the culprit. They have a tendency to hum; the dried gasket vibrates as water passes over it. You can replace these gaskets in about half an hour at very little expense. A faulty faucet valve can cause reduced water flow. For just a few dollars more, you can replace the entire hose bibb or faucet in about the same time it takes to replace a gasket.

Replacing a faucet is simple. First, turn off the main water inlet valve. Then unscrew the old faucet (counterclockwise) with two pipe wrenches or a large pair of channel-type pliers. Having the proper wrench or pliers makes this an easy task. Finally, wrap the threads of the replacement faucet with pipe joint tape, or paint them with pipe joint compound, and screw the faucet into place.

Unclogging Sewer Drains

Root growth and grease build up are the two most difficult intruders to remove from a sewer drain. If a 25-foot snake won’t clear the drain, chances are that one or both of these problems exists.

Unclogging such obstructions is a task for professionals. Cleaning sewer drains improperly can damage the pipes be yond repair, and replacement can cost thousands of dollars.

If you are thinking of having a sewer-cleaning company do the work, require them to guarantee that they will replace any pipe that they damage during the cleaning process. Ask them to give a price for unclogging the drain before they start the work.

Replacing Clogged Water Pipes

Clogged water pipes, evidenced by reduced water flow through out the house, not just in one fixture, can't be cleaned. They must be replaced.

Galvanized pipe should be replaced with copper pipe; it lasts longer. Use dielectric unions where the new copper pipe connects to old galvanized pipe, to prevent an electrolytic reaction (the deterioration of metal that results when dissimilar metals come into contact with each other in the presence of water).

Repairing Cracked Stucco

The most important part of re pairing cracked stucco is blending the repaired cracks into the existing surface. The type of caulk to use depends on the thickness of the crack. For cracks less than ¼-inch thick, use a paintable silicone caulk. It shrinks less than others and remains pliable enough to withstand movement as the joint expands and contracts with changes in temperature.

Apply the caulk to the open joint, force it into the crack with a putty knife, and then use a dampened sponge to match the surface of the caulk to the stucco surface being re paired. Avoid using too much caulk; a wide caulked joint can be as unsightly as the original crack.

For cracks larger than ¼-inch thick, use a stucco-patching com pound. For maximum adhesion, thoroughly clean the crack of all debris and loose stucco. Then mix and apply the patching compound according to the manufacturer’s directions.

Keep in mind that patching compound only fills the crack—it does not bond the broken edges of the stucco—so that any movement of the stucco, due to settling or earth quakes, will probably cause a crack to open up again.

Repairing Wood Siding

Wood siding that's split or cracked can be mended with exterior-grade patching com pound. For major damage, use epoxy-based wood fillers. With the proper technique, the re pair will be invisible. Before mending wood siding with patching compound or epoxy, it's important to ensure that the damaged siding is securely fastened. If not, it should be renailed and the new nail holes patched.

To mend smoothly finished siding, use a paint scraper to expose bare wood. Then, with a 2-inch-wide putty knife, push patching compound into the crack. At first, while the freshly spread putty is still wet, it will bulge at the crack. As it dries it will shrink and recede into the crack. Each coat of patching compound should be applied and then sanded when dry. Two or three applications will be necessary. Applying the compound too thick in an effort to hide the crack with one coat can result in a lot of unnecessary sanding. To prevent the first coat of patching com pound from pulling out of the crack as you are wiping it onto the wood with the putty knife, dip the cleaned blade of the putty knife into a container of water and re-wipe the puttied surface.

To mend rough- or re-sawn surfaced siding, follow the technique for mending smooth wood, but use a wire brush instead of sandpaper on the patch. The wire bristles will cut irregular grooves into the dried patching compound, making the patch less visible.

Replacing Damaged Wood Siding

Siding that's too damaged to be repaired with patching com pound can be patch-replaced. This involves removing the damaged siding and replacing it with new material. When a sheet of plywood is damaged, the entire piece must be re placed, but the removal is easy. Simply use a cat’s paw (nail remover) to pull out all the nails that hold the plywood in place, use the removed ply wood as a pattern to cut a new piece, patch the siding paper with an approved patching compound, and then nail on the new piece of plywood.

Plank siding is not as expensive as plywood to repair be cause the amount of wood required for a patch can be restricted to the damaged area. However, the process is more labor intensive and can damage the siding paper.

To make the repair, cut out the damaged plank with a circular saw. Adjust the blade depth to /i6 inch less than the thickness of the siding, which is usually ¾ inch thick. After cutting the material, remove the nails with a cat’s paw, and then remove the siding and use it as a pattern to make the replacement piece. The process for replacing plank siding is the same as for plywood siding. Seal all joints—new and old— with exterior caulk.

If a plumbing pipe penetrates the siding to be replaced, turn off the water, cap the sup ply pipe, drill the hole in the siding at the pipe location, in stall the siding, replace the cap with the pipe, and turn on the water. Trying to cut around a hose bibb will leave a large, unsightly hole in the siding that will make the repair look unprofessional. Follow a similar procedure for electrical devices.

If the siding on an entire side of the house must be re placed, this project could be a medium to large upgrade.

Repairing Roof Leaks

Roof leaks are not expensive to repair, but finding the location of the leak can be a challenge. For example, water dripping from the living room ceiling could be coming from a leak over the kitchen. Water has a tendency to travel along the underside of the roof sheathing and rafters before finally dripping down into the house. Water stains on the rafters indicate that a leak exists, but they do not necessarily indicate where the leak is on the roof.

Finding a leak is not difficult, but it can be time-consuming; hence, hiring a contractor to find the leak can be expensive. To find a leak yourself, use a hose to spray small areas of the roof (one 5- or 6-foot-square area at a time) heavily with water. The smaller the area you spray, the better your chance of pinpointing the location of the leak. Spray for about ten minutes in each area; less time may not be sufficient for the water to pass through to where it can be seen. If no attic exists, and there is a layer of interior finish material such as wallboard, remove it and expose the roof rafters. Water can puddle atop the wallboard for 15 to 30 minutes before beginning to drip through.

For a sloped roof, start at the overhang (the lowest point) and work toward the ridge (the highest point), being careful not to spray water up under the shingles. Sloped roofs are not completely watertight and can leak if water is forced underneath the shingles.

Caution: Be extremely careful when walking on a sloped roof, especially when it's wet.

Once you have found the leak, replace the shingle or shingles causing the problem, or use roofing mastic to patch the underlying roofing felt. If metal flashing is found to be the culprit, liquid solder is the appropriate patch material.

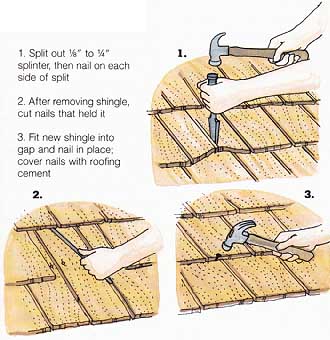

Repairing a Bowed Shake: 1. Split out 1/8” to ¼” splinter,

then nail on each side of split; 2. After removing shingle, cut nails that

held it; 3. Fit new shingle into gap and nail in place; cover nails with

roofing cement.

Caring for Wood Roofs

Keeping wood shingle and shake roofs clean and water- resistant helps deter leaks. Wood shingles and shakes are easily and quickly damaged by the sun’s ultraviolet rays. Sun and wind evaporate the natural oils found in the wood, allowing it to absorb water. The wood then expands, causing the shingles to split and cup (curl).

Keeping the roof clean also inhibits the growth of mildew and other fungi. Although moss, leaves, and other debris don’t damage wood roofing material, they trap moisture that can cause damage. The moisture provides an ideal habitat for fungal growth, such as soft rot, which quickly deteriorates wood.

The easiest way to clean a roof is to power-wash it. The best time is in the fall, before heavy winter weather begins. Be careful not to force water underneath the shingles. Every third year, follow the washing with a light spray of shingle and floor oil. Be sure that it's specified for roof applications and meets local fire requirements. The oil keeps water from traveling deep into the wood and helps prevent cup ping and splitting by keeping the shingles soft, pliable, and water-resistant. Mixing a small amount of paint pigment, available in a range of colors and sold in tubes, into the oil will ward off damage caused by ultraviolet rays.

Caution: Be extremely careful when walking on an oiled sloped roof. When oiling a roof, it's wise to be tied to the other side of the roof with a sturdy safety rope.

Cleaning is an important part of roof maintenance. To prolong the life of your roof, it's also important to replace shingles that are beyond repair and to treat the roof with a preserving chemical. This should be done every five years. Once the roof is clean, replace split and damaged shingles. Finally, apply a chemical to the entire roof to preserve and protect the shingles. Either an oil-based or a water-based solvent can be used to carry the chemical. In dry climates the oil-based solvents are better. The chemical used to help pre serve wood shingles is an approved pesticide (such as copper naphthenate), so take care to apply it properly. Paint pigment is purchased separately and added to the chemical to hide the green cast left by the pesticide and to blend the new shingles into the rest of the roof.

Using a reputable roof maintenance company is an alternative to doing it yourself. It is important to hire a firm that offers a five-year unconditional guarantee. Roof maintenance done correctly every five years can save 40 percent over the cost of replacing a roof. Painting roof shingles may void any warranties and is not recommended.

Cleaning Gutters and Downspouts

Gutters and downspouts are designed to prevent rainwater from falling onto the ground near the foundation of the house. This preventive mea sure is important because wet soil adjacent to a foundation undermines the support needed for the foundation to remain stable. Downspout drain leaders should extend at least 3 feet from the foundation before draining onto the ground. Many communities re quire downspouts to drain into an underground piping system that carries all rainwater into a local storm drain system.

As a point of information, the storm drain system and sanitary sewer system are usually separate entities. Sewer systems are supposed to route waste to treatment plants; storm drain systems usually drain into nearby rivers, streams, or settling ponds, moving flooding to a safe place outside the community.

If gutters and downspouts aren’t kept clean, water will overflow onto the ground adjacent to the foundation, and the foundation may shift as a result. When the house shifts, walls crack, floors buckle, and windows and doors don’t operate smoothly. Preventing this problem is as easy as sweeping and hosing out gutters and downspouts at the end of fall, and adding leaders to the end of the downspouts to carry water a minimum of 3 feet away from the foundation.

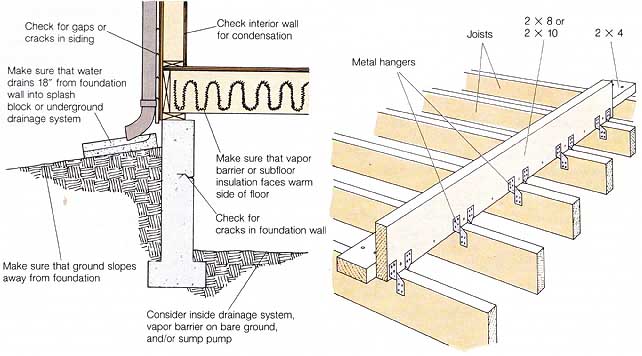

Solving Grading and Drainage Problems

If floors are squeaking or buckling, windows and doors are not operating properly, or plaster is cracking, the problem may originate with an unstable foundation.

A house is only as stable as its foundation, and a foundation is only as stable as the soil on which it rests. When the moisture content of the soil is excessive due to poor drainage, the entire house is affected.

Proper grading is essential for good drainage. All surfaces (dirt, concrete, brick, and so on) within 30 inches of the perimeter of the house must slope away from the foundation at 1/4 inch of fall for each linear foot of travel. Otherwise, water will settle around the foundation and can cause it to shift.

On flat building lots (as op posed to hillside property), proper grading is usually all that's needed. However, in some situations an under ground French drain can be used to carry water away from the foundation (see illustration). Even on flat in-town lots, the ground must be graded to slope slightly so that water will run off toward municipal storm drains.

Checking for Moisture Problems: Check for gaps or cracks in siding,

Consider inside drainage system, vapor barrier on bare ground, and /or sump

pump, Make sure that water drains 18” from foundation wall into splash

block or underground drainage system; Constructing a Strongback: An Alternative

to Straightening Ceiling Joists

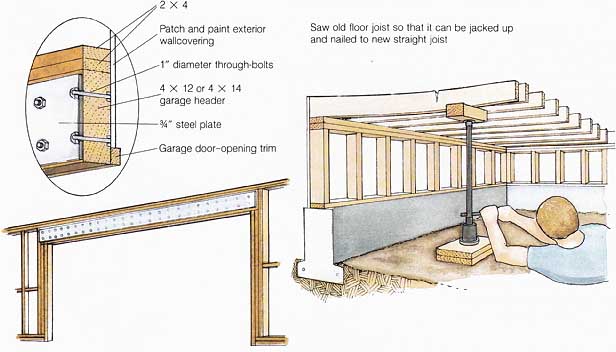

Fixing a Sagging Garage Door Opening: 2X4, Patch and paint exterior

wallcovering, 1” diameter through-bolts; Fixing a Sagging Floor: Saw

old floor joist so that it can be jacked up and nailed to new straight

joist

Controlling Structural Pest Damage

Eliminating earth-to-wood con tact is an almost cost-free project that can reduce the possibility of rot and termite infestation.

The Uniform Building Code requires earth to be at least 6 inches away from any wood in the home; the Federal Housing Administration requires 8 inches. There are two reasons for eliminating earth-to-wood contact: Earth in contact with wood (or any cellulose material) attracts termites and related pests and gives them direct access to a food source; and wet earth in contact with wood promotes fungus growth, which causes wood to rot. It begins when the wetness of wood reaches 20 to 30 percent.

To eliminate earth-to-wood contact, remove all earth (including planting bed areas and cellulose debris) within at least 6 inches of all wood structures. Most stucco exteriors have wood behind them near their base and should be dealt with like wood siding.

If a fence butts up against the exterior wall of the house, add flashing in the form of a thin layer of galvanized sheet metal between the fence and the house, to keep termites from traveling from the fence into the exterior siding and then into the structure.

If no earth-to-wood contact exists, finding termite trails is easy. Termites avoid light and prefer to travel from the earth into a home through tunnels that they create from mud. It is wise to inspect the exposed subarea frequently for mud tunnels. They are about the size of a pencil and can be found against the inside of the foundation wall between the ground and any nearby wood. If you find termite tunnels, call specialist in structural pest control to exterminate the termites.

Fixing Deteriorating Posts

Wood posts that sit directly on concrete, such as posts that support patio or porch covers, can deteriorate after several years. The post absorbs rain and irrigation water, fungus damage begins, and the post starts to rot at the bottom.

Repair is easy. First, brace whatever the post is supporting with temporary posts; then cut off the lowermost inch of ye post with a handsaw, and paint the cut with wood preservative. Reconnect the post to the concrete with a sheet-metal post base (with spacer). Move the cut post out of the way, attach the post base with concrete nails, and then place the spacer in the base, followed by the post. Remove the temporary brace, and finally nail the top of the post base securely to the post. The spacer inside the post base supports the post far enough above the concrete to deter future capillary action, keeping the post dry and ex tending its life.

Fixing Sagging Garage Door Openings

In an older home a sag may occur in the garage door header, the horizontal wood timber above the door that makes up the top of the opening. A sagging header is caused by either the weight of the roof or the weight of the floor above the garage door. Once the header has sagged, it must be either replaced or raised and braced with a, steel plate.

As a do-it-yourself project, replacement is by far the more cost-effective option because this project is labor intensive. If done by a professional, this would be a medium upgrade.

Use temporary supports to hold the structure in place while the header is being re placed. Cut all nailed connections, using a reciprocating saw with a metal-cutting blade. Remove the header and use it as a pattern for its replacement. The replacement timber should be the strongest grade of lumber available—select structural.

If the work will be done by professionals, adding metal bracing can be more cost- effective than replacing the header, because less labor is involved. If you choose bracing, contact a structural engineer to determine the thickness of the steel plate and the number and size of the bolts to be used to make the repair with a steel-plate brace.

Fixing Other Sagging Framing Members

Floor, ceiling, and roof framing members can also sag after being in place for many years. The fibers tear at the lower side of the horizontal framing member as a result of the weight from above. With roof rafters and ceiling joists, the weight of the roof can cause this to hap pen. With floors, furniture or load-bearing walls can be the culprit.

Once a horizontal framing member has sagged and completely dried out, its shape is almost permanent. To repair it, cut the sagging member at its lowest point, raise it to a point slightly higher than its original position, and then sister (glue and nail or bolt) a new framing member alongside it.

When sistering a new horizontal framing member to an old one, it's wise to use a larger size for the sistered piece when possible; it will be stronger and resist sagging more effectively. For example, you would sister a 2 by 8 floor joist with a 2 by 8, 2 by 10, or 2 by 12 if space allowed.

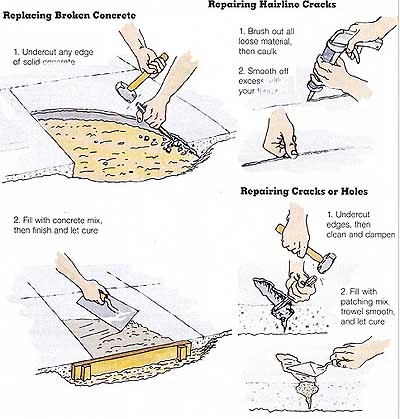

Upgrading Concrete Flatwork and Blacktop

Walkways and driveways with cracked concrete or potholed blacktop can be unsightly and dangerous. Damage usually occurs when the earth below heaves or shifts, a condition usually brought on by extreme drying, as from a drought, by excessive moisture, or by alternate freezing and thawing.

If no drought exists, chances are that excessive landscape irrigation water or wet weather are causing the damage. Once it occurs, the additional openings in the surface allow even more moisture to permeate the ground below. Patching com pounds, which are formulated to expand and contract with changes in temperature at the same rate as the concrete or blacktop, can help to prevent continued water seepage. Be aware, however, that patching compounds are not permanent and will require continued maintenance. In addition, it may be difficult to match the original color.

Concrete is cracked beyond repair when patches don’t hold, existing cracks widen, new cracks develop, and major shifting occurs. If you want to replace the concrete, have a soils (or geotechnical) engineer recommend a method of replacement. For example, before pouring the new concrete, digging out 6 to 8 inches of earth and replacing it with compacted rock could reduce the chance of future cracking. Installing a grid of ½-inch steel rebar and using a mix of concrete that contains more cement than usual might also help.

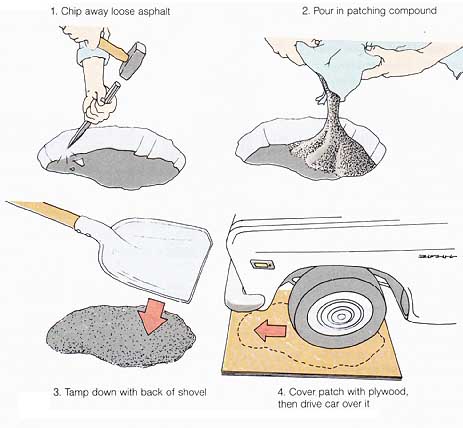

Blacktop sealer protects blacktop against weather dam age. To repair small cracks in blacktop, brush out any loose matter and fill the cracks with butyl cement. Smooth the top with a putty knife. Fill large cracks and holes with blacktop patching compound, packing it down with a shovel or tamp. Lay a board over the area, and drive on it with your car to compact it completely. See illustration at right.

Repairing Damaged Concrete: Replacing Broken Concrete: 1

Undercut any edge of solid concrete; 2. Fill with concrete mix, then finish and let cure. Repairing Hairline Cracks: 1. Brush out

all loose material, then caulk; 2. Smooth off excess. Repairing

Cracks or Holes

Patching Concrete Foundations

Foundation cracks can be unsightly but may not indicate serious damage. When you notice cracks (hairline or other wise), it's best to consult a structural engineer to ensure that a serious problem does not exist.

For do-it-yourself cosmetic repairs of cracks that are not serious, use latex concrete patching compound. The easiest type is already mixed, although patching compound is also available in powdered form that you mix with water.

Maintaining Exterior Caulk

Maintaining caulk on the exterior of the house is an easy, an expensive face-lift that can save thousands of dollars. Caulk is used to create a water seal at joints, especially around windows and doors. Eventually, the caulk dries out, causing it to shrink and crack. Water can then reach framing members, which can result in serious fungus damage.

The best kind of caulk for the exterior of the house is paintable silicone. Silicone caulk was not available when older homes were built; latex caulk, which dries out, was used then instead.

The most obvious caulked joints in a house are wood-framed windows where the glass fits into the frame and is sealed with glazer’s putty. Unlike other caulk, glazer’s putty becomes extremely brittle after it has been in place for several years. Since removing the brittle putty could result in cracked window panes, simply rough up the old putty with a wire brush, and then apply new putty with a putty knife. If the old putty has been painted, re move all paint before applying the new putty.

Glazer’s putty has a linseed- oil base, and therefore is water- resistant. However, it will last longer if it's painted.

Repairing Holes in Blacktop: 1. Chip away loose asphalt; 2. Pour in

patching compound; 3. Tamp down with back of shovel; 4. Cover patch with

plywood, then drive car over it.

Insulating Walls, Ceilings, and Floors

You can make your home more comfortable and reduce heating and cooling costs by adding insulation to walls, ceilings, and floors. This upgrade is not done to the exterior of the house (although adding wall insulation can be done from the outside), but it affects the building envelope and is there fore considered an exterior upgrade.

Insulating floors and ceilings that are accessible by a crawl space or an attic is an easy do-it-yourself project. Insulation is relatively inexpensive to buy and simple to install.

Batt insulation is the best type. It comes in rolls in widths designed to fit between framing members that are either 16 inches or 24 inches on center. You can cut the insulation to length or to odd widths with a utility knife or a pair of scissors.

Foil-backed insulation is not recommended, because condensation occurs at the foil layer, which can cause water damage. Paper-backed or back less insulation is better. If you use paper-backed insulation, place the paper toward the in side of the house.

In the attic, simply lay insulation in place; pierce the paper backing if you are installing it over existing insulation. In the basement area, position insulation between the floor framing members, and hold it in place with flexible rods, baling wire, or fiberglass netting nailed to the bottom of the floor framing members.

Use caution when working with fiberglass insulation to prevent the minute glass particles from entering the body or becoming embedded in the skin. Wear a breathing mask to keep from inhaling the particles, use goggles for eye protection, and cover the entire body (including the head) with clothing. Use duct tape to seal clothing at the neck, wrists, and ankles.

Note: For walls and for ceilings where no attic exists it's best to have a professional in stall insulation. This project qualifies as a medium upgrade; special equipment is required to blow cellulose insulation into the wall and ceiling cavities. Keep in mind that fiber glass insulation is more resistant to moisture than cellulose insulation and if installed properly will last longer.

Controlling Air Infiltration

Insulating without controlling air infiltration is like trying to bake without closing the oven door. Infiltration control includes weather-stripping doors and windows, sealing penetrations between the basement area and the living area above, sealing penetrations between the attic and the living area below, and installing gaskets or sealing all penetrations in exterior wallcoverings.

Infiltration control is even less expensive than insulating and is easier to do. Canned spray foam, scraps of sheet metal, and rubber switch-plate and outlet gaskets are the materials used. For example, in the attic or basement area, you can seal large holes at pipe or duct penetrations with a scrap of sheet metal; seal smaller openings with expanding spray foam. To seal heat-register covers in walls, floors, or ceilings, remove the cover, fill the gap between the supply duct and the wallboard with foam, and replace the cover.

To find penetrations in a previously insulated attic, use a lighted candle. Air escaping from the living area below exerts pressure as it passes through small holes into the attic—sometimes with enough force to extinguish the candle but always with enough to cause the flame to flutter. Be careful when performing this test, and carry along a small fire extinguisher.

A surprising amount of air can enter a house through switch plates and electrical out lets. Installing gaskets under these covers is an easy, inexpensive, cost-effective upgrade that will help to eliminate air infiltration. The gaskets are available at hardware stores. Simply remove the switch plate or outlet cover, install the gasket, and replace the cover. You can reuse the original screws that hold the cover in place— the rubber gaskets are thin.

Although any kind of weather stripping is better than none at all, weather stripping that's attached with nails or screws is far superior to the pre-glued stick-on type. For doors, the most effective (and most expensive) weather stripping is the interlocking type. Some companies specialize in the installation of inter locking weather stripping.

Doors and windows should be weather-stripped where the fixed frame meets a moving part (on the top, bottom, and both sides). Double doors should also be weather stripped where the two doors meet in the middle.

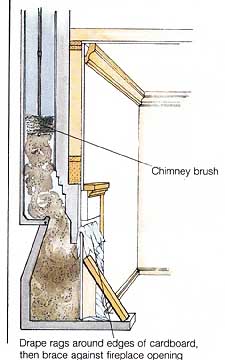

Cleaning Chimneys

Fireplaces that are used frequently, especially those that are fueled with resinous wood such as pine or fir, cause a greater creosote buildup in the chimney than less frequently used fireplaces or those in which hardwoods, such as oak, ash, or walnut, are burned. Creosote is a by-product of combustion that adheres to chimney walls. It is flammable and under certain conditions can be explosive. It should not be allowed to build up in the chimney for long periods of time.

A chimney sweep can thoroughly inspect and clean a chimney in a few hours. See the illustration above to do it yourself. If cracks are found in the masonry, have a licensed or certified professional do the re pairs. Do not use the fireplace until the repairs are completed, since cracked masonry can cause a house fire.

Cleaning a Chimney: Drape rags around edges of cardboard,

then brace against fireplace opening.