Since the purpose of a mini-farm is to meet a substantial portion of your food needs, you should store your food so that it is available over the course of the year . The four methods of food preservation that we use and will be explaining in this section are canning, freezing, dehydrating, and root cellaring. These methods have all been practiced for decades in the United States and can be undertaken with confidence. Each method has its strengths and weaknesses, which is why they are all covered. Advanced techniques that we won't be explaining in this section include cheese making, wine making, and meat curing.

Canning

Perhaps the most intimidating form of food preservation for the uninitiated is canning. Stories are everywhere about people dying from botulism because of improperly canned foods, so some people conclude that canning is an art like making fugu (the poisonous Japanese blowfish) in that the slightest mishap will render canned foods unfit. Fortunately, these impressions are not accurate. Modern canning methods are the result of decades of research and can be followed by anybody with a sixth-grade education. (Yes, I knew somebody personally with a sixth-grade education who canned safely.) Those few cases of poorly canned goods resulting in botulism poisoning in the modern era stem from people who do not follow the most basic directions on how to can.

Current standards for home canning come from research by the USDA that is continually updated. Most of the standards haven't changed for decades, because the research methods are quite thorough. The USDA researchers deliberately introduce viable heat resistant bacteria spores into foods in home canning jars and then use temperature sensors inside the jars as they are canned. After canning, the cans are kept at the precise temperature necessary for best bacterial growth for several months and then opened in a sterile environment and tested for presence of the bacteria or any other spoilage.

The USDA standards published around World War I allowed for up to 2% spoilage, but the standards published since that time require 0% spoilage. This means that foods canned at home using current USDA guidelines are completely safe. Actually, the times and temperatures provided by the USDA also contain a safety factor.

This means that if experimenters achieved 0% spoilage at 237 degrees for 11 minutes, the standards specify 240 degrees for 15 minutes. Times and temperatures are always rounded up, never down.

There are two methods of canning: boiling water bath and steam pressure. The choice of method depends on the level of acidity of the food being canned. This is because the length of time that spoilage organisms will survive at a given temperature is longer in foods that are less acidic. So less acidic foods get canned using the steam pressure method that produces a temperature of 240 degrees; more acidic foods get canned in a boiling water bath that produces temperatures of 212 degrees. The length of time specified for canning is based on how long it takes the heat to fully penetrate a particular food in a particular-sized jar . The standards are written for half-pint, pint, and quart jars. If a mixture (such as stew) is being canned, then the canning time and temperature for the entire mixture is based on that of the ingredient that requires the most time. By using the correct method, container , and processing time, you can be assured of the safety of your canned food.

Home Canning Jars

Jars for home canning are available at Walmart and many hardware and grocery stores, although their availability is seasonal.

These jars are heavy walled and specifically designed to withstand the rigors of temperature, pressure, and vacuum created by home canning. Forget the old-style (though attractive) jars with rubber gaskets and wire closures since they are no longer recommended by the USDA. Today's standards specify two-piece caps that include a reusable metal ring called a "band" and a flat non-reusable lid that has a sealing compound around its outer edge. The bands can be used until they have warped or rusted, but the lids must be thrown away once they have been used and bought new.

Home canning jars are expensive--about $7/dozen at the time of writing. So figure a bit over $0.50 apiece. However , their durability easily justifies their cost-home canning jars will last decades. By the time a jar has seen use for 20 seasons, its cost has dropped to $0.02. Once the jars and bands are purchased (new jars usually come with bands), you just need to buy new lids for each use- which are usually less than $0.10 each. There are a handful of brands of home canning jars available, and on the basis of my own experience, we recommend Ball and Kerr, which are both manufactured in the United States by Jarden Corporation. I especially recommend Ball lids, because their underside is coated with a compound that keeps the food from coming into contact with the metal of the lid. This helps food stay fresher longer , and they cost the same as non-coated lids.

My stepmother often used glass jars from spaghetti sauce, mayonnaise, and similar products as long as the bands and lids fit and the rims were free from nicks or imperfections that would prevent a good seal. The good news is that she saved money. The bad news is that sometimes these jars would break and create a mess and lose the food. Most authorities counsel against using these one-trip glass jars because they aren't properly tempered, and their higher risk of breakage could cause injury and loss of valuable food.

For these reasons, we recommend using jars specifically designed for home canning. If economy is a big consideration, then it is worthwhile to visit yard sales and flea markets where you can buy inexpensive, properly designed jars for home canning.

Foods and Canning Methods

As we mentioned earlier , the type of canning method required depends on how acidic the food is. Acidic foods (with a pH of less than 4.6) need only a water bath canning method while less acidic foods (with a pH greater than 4.6) require steam pressure canning.

Unfortunately, the combination of time and temperature in a pressure canner can render some foods less nutritious and other foods unappetizing. Broccoli is a good example in that it requires such an extensive period of pressure canning to be safe that the results aren't worth eating. Broccoli is much better preserved through either freezing or pickling. The goal, then, is to use the method that preserves the maximum nutrition and palatability while maintaining a good margin of safety. So if we don't list a canning method for a vegetable, it is because we have determined that it is better preserved using some other method.

An age-old method for canning foods that cannot be safely canned otherwise is to raise the acidity of the food by either fermenting it or adding vinegar . Sauerkraut is a great example because cabbage is not suitable for either canning or freezing in its fresh state, but if acidified through lactic acid fermentation (and thereby becoming sauerkraut), it can be canned in a boiling water bath while retaining its most important health benefits. (Technically, with great care, you can freeze grated cabbage, but your results may vary.) Pickles are made either by fermenting vegetables in a brine (which raises their acidity through the production of lactic acid) and/or by adding vinegar . These methods create a sufficiently acidic product so that only a brief period in a water bath canner is required.

Boiling water bath canning is suitable for all fruits, jams, jellies, preserves, and pickles. Tomatoes are right at the margin of pH 4.6, so they can be safely canned in a boiling water bath if a known amount of citric acid (or commercial bottled lemon juice) is added.

The correct amount is one tablespoon of lemon juice or 1/4 teaspoon of citric acid per pint. Vinegar can be used instead, at the rate of two tablespoons per pint, but it can cause off-flavors. The only time I would recommend vinegar is in salsa. The acidity (or , rather , the taste of the acidity) can be offset by adding two tablespoons of sugar for every tablespoon of lemon juice, which won't interfere with the canning process. While few people choose to can figs (usually they are dehydrated instead), it is worth noting that they are right on the border line of acidity as well and should have lemon juice added in the same proportion as tomatoes if they are being canned. Everything else-vegetables, meats, seafood, and poultry-must be canned in a steam pressure canner.

Boiling water canners are pretty much maintenance free. Just wash them like any other pot, and you are done. Pressure canners, on the other hand, require some minimal maintenance. The accuracy of the dial gage on top of the canner should be checked annually by your Cooperative Extension Service. If it is inaccurate, send it to the manufacturer for recalibration. When the canner is not in use, store it with the lid turned upside down on top of the body.

Never immerse the lid or dial gage in water! Instead, clean them with a damp cloth and mild detergent if needed. Clean any vent holes with a pipe cleaner . The rubber seal should be removed and cleaned with a damp cloth after each use. Some manufacturers recommend that the gasket be given a light coat of vegetable oil, and some don't-so be certain to follow the manufacturer's directions. If you follow manufacturer's directions in using your pressure canner , it won't explode, as was sometimes the case years ago. Modern canners have a number of built-in safety features that our grandmothers' models lacked, and aside from deliberately defeating those safety mechanisms, an explosion is practically impossible.

Foods to be canned are packed into hot glass jars using either the fresh-pack or the hot-pack method. The methods are pretty much self-explanatory from their names: Fresh-packed foods are put into the jars fresh and then hot liquid, brine, or syrup is added, and hot packed foods are put into jars after having been heated to boiling.

In some cases, either method can be used. Once packed, the jar is filled with liquid (brine, broth, syrup, pickling juice, etc. depending on the recipe) up to within 1/4 to 1 inch from the top of the jar . This space is called headspace and is needed to accommodate the expansion of the food in the jar as it is heated and allow for a good vacuum seal.

Using a Boiling Water Canner

Boiling water canners come with a wire rack that holds the jars so that they won't be sitting on the bottom of the canner or bumping into each other and breaking. Using a rack ensures that water of the same temperature surrounds the jars on all sides so that heating is even and therefore the best results are obtained.

Jars need to be sterilized for canning. My method is a little different from that in most books, but it works quite well, and I've never had a jar spoil.

1. Fill the canner halfway with the hottest water from the tap.

2. Put the jars you plan to use in the rack, without any lids.

3. Submerge the rack and jars in the canner , adding enough tap water to completely fill all the jars and stand 1-1/2 inches above the tops of the jars.

4. Put on the lid and bring water to a vigorous boil, then adjust the heat to obtain a steady rolling boil.

5. Meanwhile, put a smaller pot on the stove without water , uncovered, but apply no heat. Put the lids (but not the bands) in this pot, making sure that the sealing compound is facing up.

6. Remove the jars from the canner one at a time using a jar lifter , and empty the boiling water in them into the smaller pot until it is nearly full and set them aside on a dish towel. (Once the smaller pot is full, empty the water in the remaining jars into the sink.) Keep the lids in the standing boiling water at this point-additional heating of the lids is not required.

7. Lift up the rack in the canner so that it is supported by the sides of the canner.

8. Put the product into the jars (a special canning funnel is helpful for this), allowing for proper headspace, get the lids out of the hot water in the smaller pot one at a time using tongs, and place them on the jars, then secure with a screw band tightened only finger-tight. (If you tighten it any more than that, the jar will break when you heat it in the canner.)

9. Put the filled jars in the wire rack, and submerge them in the water in the canner.

10. Turn up the heat on the burner a bit if needed to maintain a steady rolling boil. Start the timer once that boil has been achieved and put the lid on the canner.

11. Once the appropriate time has elapsed, remove the jars and place them on a dish towel at least 2 inches from each other on all sides and allow to sit undisturbed for at least 12 hours.

12. If additional product (more than one canner load) is being processed, pour the water back into the canner from the smaller pot, put clean jars in, and add any needed water to completely fill and submerge with 1-1/2 inches of water on top of the jars, then repeat the process starting at Step 4.

Using a Pressure Canner

Each pressure canner is a little different, so read the manufacturer's directions and employ those in preference to mine if there is a contradiction. Pressure canners don't rely on completely submerging the jars. Instead, they rely on surrounding the jars with superheated steam at 240 degrees. They also come with a rack, but instead of being made of wire to hold jars securely in place like with a boiling water canner, it is a simple aluminum plate with holes in it.

Put it in the canner so that the holes are facing up. When using a pressure canner , I don't sterilize the jars before use. Instead, I just make sure they are extremely clean, and I keep them in a large pot of near-boiling water at a simmer . You can also wash them in a dishwasher and keep them hot with the dishwasher's heating element.

1. Put the rack in the canner and put three inches of very hot tap water into the bottom.

2. Put already-filled and lidded jars on the rack using a jar lifter , leaving some space between the jars.

3. Put the lid on the canner , but leave off the weighted gage, turn up the heat until steam starts coming out of the port where you would put the weighted gage, and let the steam exhaust for 10 minutes.

4. Put the weighted gage on the port and keep the heat adjusted for a steady rocking motion of the gage. Start timing from when the steady rocking motion starts.

5. Once the time is up, turn off the heat and let the canner sit until the dial gage reads zero or when no steam escapes when the weighted gage is nudged. Wait an additional 2 minutes just to be sure.

6. Remove the cover and then remove the jars with a jar lifter and put them on a towel, leaving 2 inches between them on all sides.

7. Leave the jars undisturbed for 24 hours.

Fruits

Practically any fruit can be canned, and all except figs are sufficiently acidic that they can be canned without additives. (Figs require the addition of one teaspoon of lemon juice per pint.) Fruit should be in peak condition, free from obvious blemishes or rot, and well washed. To be sufficiently heated during the canning process, fruits that are larger than one inch should be cut up so that no single piece is larger than a one inch cube. Pits and stones of large-seeded fruit should be removed, and the fruit should be treated in an antioxidant solution, particularly once it has been cut to prevent discoloration. Antioxidant solutions can be bought commercially, or you can make your own by mixing 3/4 cup of bottled lemon juice with a gallon of water.

Fruits are usually canned in sugar syrups because the sugar helps the fruit keep its color , shape, and flavor , although the sugar isn't strictly necessary to prevent bacterial spoilage. If you prefer , can the fruits by using plain water rather than a syrup. I don't recommend the use of artificial sweeteners in syrup because saccharine turns bitter from canning and aspartame loses its sweetness. (If you have ever bought a diet soda and thought that it tasted a bit like dirt, that means that the product was stored in an area of high temperature and the artificial sweetener was damaged.) A "very light" syrup uses two tablespoons of sugar per cup of water , a "light" syrup uses four tablespoons per cup of water and a "medium" syrup uses seven tablespoons per cup of water.

To fresh-pack fruits, add them to the jars and then pour simmering syrup (or water) into the jar until it is filled up to within 1/4 inch of the rim. Put the lids and screw bands on the jars finger tight, and completely submerge in a boiling water canner for the specified time for that particular fruit. Then remove the jars from the canner and leave them to cool for at least 12 hours. Hot-packed fruits are handled pretty much the same except that the fruit is mixed with the syrup and brought to a light boil, and then fruit and syrup are added to the jar together.

Applesauce

Home-canned applesauce was a favorite of mine as a kid-I'd open up a couple of homemade biscuits on my plate, heap a generous quantity of applesauce on top, and dig in. Applesauce canned at home is simple, delicious, rich, and flavorful-nothing like the homogenized products available at the grocery store. Naturally, the same process used for applesauce can also be used for pears, quinces, and other fruits. Feel free to experiment! Here is my recipe and procedure for semi-chunky applesauce. Yield: 22-26 pints Semichunky Applesauce 1 bushel of at least two types of apples, one type being rather sweet a bag of white and/or brown sugar (the actual amount added depends on your taste and the apples selected)

cinnamon to taste

allspice to taste

nutmeg to taste

lemon if desired

Procedure

Wash 3/4 of the apples and remove stems, cut up into 1-inch chunks, including the core and peels, and put into a very large pot with about 1-inch of water in the bottom. (You can buy a simple contraption for a few bucks that cores and cuts apples into segments in just one motion--we recommend it highly!) Dip in an antioxidant solution once cut.

Cook until all of the chunks are soft throughout. Start off on high heat and then lower to medium-high.

Run the cooked apples through a strainer to remove the skins and seeds and put them back in the pot. (You can do this hot if you are careful.) We use a Villaware V200 food strainer because I could get it for less than $50 and it came with the right screen for my two favorite foods-applesauce and spaghetti sauce. There are a number of strainers on the market-including the classic Squeezo strainer-that will also work fine.

Peel and core the remaining apples, cut up into small chunks, and add them to the pot as well. (we have a "Back to Basics" Peel-Away apple peeler that peels, cores, and slices quickly in a single operation. It costs less than $20 at a cooking store.) Continue cooking on medium-high until the newly added chunks are soft.

Add sugar , lemon, and spices to taste. You will probably need less than 1/4 cup of sugar per pint if you used some sweet apples.

Reduce heat to a simmer to keep the sauce hot while canning.

Pour the sauce into freshly washed pint or quart canning jars, leaving 1/2 inch of headspace.

Put on the lids and bands finger-tight.

Completely submerge jars in boiling water in a boiling water canner for 15 minutes for pints or 20 minutes for quarts.

Allow the jars to cool in a draft-free place for at least 12 hours before removing the bands, labeling, and storing in a cool dry place for up to two years.

Enjoy! Jellies

Jellies are made from fruit juice and sugar , and use heat and sugar for their preservation. The distinctive consistency of jelly comes from an interaction between the acids in the fruit, the pectin it contains, the sugar, and heat. Many fruits contain enough natural acid and pectin to make jelly without having to add anything but sugar. These include sour apples, crab apples, sour cane fruits, cranberries, gooseberries, grapes, and currants. Some fruits are slightly deficient in acid, pectin, or both and will require a small amount of added lemon juice, pectin, or both. These include ripe apples, ripe blackberries, wine grapes, cherries, and elderberries.

Finally, some fruits simply won't make jelly without adding a significant quantity of lemon juice and/or pectin. These include strawberries, apricots, plums, pears, blueberries, and raspberries.

Because sugar plays an important role in the preservation of jellies, the amount called for in a recipe shouldn't be reduced. It also plays an important role in making the product gel, so using too little sugar can result in a syrup instead of a jelly.

The juice used to make jelly can be extracted in a number of ways. If you use a juice machine, use it only for fruits that would require added pectin anyway, such as berries, plums, and pears.

This is because a juice machine won't properly extract the pectin from high-pectin fruits. The traditional way of extracting the juice is to clean and cut up the whole fruit (it is important to leave the peels on because pectin is concentrated near the peel) and put it in a flat bottom pot on the stove with added water . For soft fruits, use just enough water to prevent scorching, but with hard fruits like pears you might need as much as a cup of water per pound of fruit. The fruit is cooked over medium heat until soft and then poured through a jelly bag. If you want a crystal-clear product (which I don't personally care about but many folks find aesthetically important), it is important not to squeeze the jelly bag but instead let the juice come through naturally and slowly. You should get about one cup of juice per pound of fruit. Jelly bags in various sizes can be purchased from cooking stores and over the Internet. If you use a juice machine, you should still strain the resulting juice through a jelly bag. If you can't find jelly bags, you can use a double-layer of cheesecloth lining a colander instead.

Once the juice has been extracted, it is combined with sugar and other ingredients (e.g., lemon juice and/or pectin depending on the recipe) and boiled on the stove until it reaches a temperature of 220 degrees as measured with a candy thermometer . The boiling point of pure water is 212 degrees, but that boiling point is raised when other substances such as sugar are added to the water . As water evaporates and the proportion of sugar in the water increases, the boiling point will slowly increase. If you live in the mountains, subtract 2 degrees for every 1,000 feet you live above sea level. So if you live at 3,000 feet, subtract 6 degrees-so boil the mixture only until it reaches 214 degrees. This is because the higher you are above sea level, the more easily water will evaporate because of lower air pressure.

Once the required temperature has been reached, fill sterilized jars with the hot mixture up to 1/4 inch from the top, put the two piece caps on the jars finger-tight, and process in a boiling water canner for five minutes for half-pint or pint size. There are all sorts of jelly recipes on the Internet, but here are two of my favorites.

Strawberry Rhubarb Jelly

3 pints of strawberries

1-1/2 lbs of rhubarb stalks

6 cups of sugar

3/4 cup of liquid pectin

Pulverize and then liquefy the strawberries and rhubarb in a blender . Using either a jelly bag or two layers of cheesecloth, gently squeeze out 3-1/2 cups of juice and put it in a saucepan, mixing with the sugar , and then bring to a rolling boil. Add the pectin and allow to boil vigorously for one minute only, remove from heat, and immediately pour into hot sterile jars, leaving 1/4 inch of headspace. Process five minutes in a boiling water canner . Yield: 5 half-pints.

Apple Jelly

5 lbs apples

5 whole cloves

1/2 tsp cinnamon

8 cups water

8 cups sugar

Wash the apples and cut them in quarters, and put them in a covered casserole pan with the eight cups of water and spices. Put in the oven at 225 degrees overnight. In the morning, strain through cheesecloth or a jelly bag and collect the liquid. Add it to the cooking pot one cup at a time, simultaneously adding one cup of sugar for every cup of liquid. Heat to a rolling boil, stirring constantly, and check with a candy thermometer until it is boiling at 220 degrees. Immediately pour into hot sterilized pint or half-pint jars, tighten the lids finger-tight, and process for five minutes in a boiling water canner. Yield: 8 half-pints.

The same techniques covered in the recipes above can be used successfully with other fruits. For fruits high in natural pectin and acid, use the second recipe as a guide, and use the first recipe as a guide for fruits lacking pectin. For fruits that lack both pectin and acidity, use the first recipe as a guide but add 1-1/2 tsp of lemon juice per cup of liquid. Jams are made the same way except the entire fruit is pulverized and used, rather than just the juice.

Brined Pickles and Kraut

Pickling preserves food by raising its level of acidity. It is used for foods that are not naturally acidic enough to be safely canned using a boiling water method. The two methods most widely used are lactic acid fermentation in brine, and infusing with vinegar.

Brine fermentation is most often used with cucumbers to make kosher-style dill pickles, but it is also used to make sauerkraut. Many other vegetables-like collard greens-can also be processed this way, but since I've never tried it myself, I can't guarantee the results will be tasty! There are three very important aspects of doing brine fermentation. First, keep everything clean. Second, use only plain salt with no additives whatsoever, or all sorts of cloudiness and discolorations will result. (Regular salt contains anticaking agents that will make the brine cloudy as well as iodine that will inhibit proper fermentation. Use canning salt!) Finally, pay close attention to the correct procedure, or your pickles will be soft and possibly even slimy.

Brine fermentation can take several weeks. It is also temperature sensitive and works best at temperatures ranging from 55 to 75 degrees. Before starting brined pickles, make sure you have both the time and the space to leave the containers undisturbed for a while. You should only use glass, nonchipped enamel, or food grade plastic containers for fermentation. Under no circumstances should you consider using a metallic container because the product will become contaminated and possibly even poisonous. Don't use old-fashioned wooden barrels because sterilizing them is practically impossible. Start off with well-cleaned containers and well-washed produce.

Brined Dill Pickles

5 lbs of 3- to 4-inch pickling cucumbers 3 heaping Tbsp whole pickling spice 8 heads of fresh dill (1/3 of a bunch) 3/4 cup white (distilled) vinegar 1/2 cup pickling salt 5 pints (10 cups) of clean pure water The proportions of salt, vinegar , and water in this recipe are not approximations-measure them exactly! You can double or quadruple the recipe if you keep the proportions the same for a larger batch of pickles. Put half of the pickling spices and a light layer of dill in the bottom of a clean food-grade plastic pail or pickling crock. Put in the cucumbers. Mix the remaining dill and spices with the salt, vinegar , and water and pour over the cucumbers. If the amount of liquid isn't enough to come about two inches above the cucumbers, make more liquid from water , salt, and vinegar according to the same proportions. Take a clean plate and place it on top of the cucumbers so they are held completely under the brine. The plate may need to be weighted down with a second plate. Cover the container loosely with plastic wrap covered with a clean towel held on with a couple of bungee cords tied together around the container like a big rubber band. Try to keep at room temperature-certainly no warmer than 72 degrees and no cooler than 60 degrees.

Uncover and check the pickles for scum once a day. Use a clean spoon to scoop off any scum, then put the towel back on. This should be the only time the pickles are uncovered. After three weeks, check the pickles by removing one from the container , cutting it lengthwise, and tasting it. If it is translucent and tastes like a good dill pickle, you are ready to can the pickles. If not, wait another week and try again.

Once the pickles are ready, remove them from the brine and pack into cleaned and cooled glass jars with a couple of heads of dill added to each jar . Take the brine, pour it into a large saucepan, and bring it to a boil, then pour it over the pickles in the jars, leaving 1/4-inch headspace. If you run out of brine, make additional brine from 4 pints of water , 1/4 cup of salt and 2 cups of vinegar raised to boiling. (Again, proportions are exact rather than approximate- use measuring cups!) Put the lids on finger-tight, and process 10 minutes for pints or 15 minutes for quarts in a boiling water canner. Yield: 10 pints.

Sauerkraut Cabbage Canning/pickling salt

Any sort of cabbage can be used for this recipe, but larger heads tend to be sweeter . Remove any damaged outer leaves, quarter the heads, and remove the hard cores, then weigh the cabbage on a kitchen scale. Weighing the cabbage is important because the weight determines the amount of salt to use-3 Tbsp of salt per 5 pounds of cabbage. Shred the cabbage into slices of about 1/8 inch thickness, and using clean hands thoroughly mix the cabbage with the salt. Put the mixture into a five-gallon food-grade plastic container a little at a time and use a clean potato masher to mash the mixture until enough juice has been squeezed out of the cabbage that at least one or two inches of juice are above the cabbage by the time all the cabbage has been added.

Fill and seal a non-colored food-grade plastic bag with a mixture of 6 Tbsp salt and one gallon of water , and put this on the cabbage to weigh it down and keep it completely submerged, then cover the top of the container with plastic wrap. Keep the container at room temperature, and in four weeks, your sauerkraut will be ready. Just like with the brined pickles above, check daily for scum and remove any that you find. Once the kraut is ready, pour it in a large pot (or a portion of it at a time depending on the relative size of your pot) and heat while stirring to 190 degrees as indicated by a candy thermometer . Do NOT let it boil. Pack into clean canning jars and add brine to leave 1/4 inch of headspace, and process in a boiling water canner for 15 minutes for pints or 20 minutes for quarts.

Yield: depends on how much cabbage you use.

Quick Process Pickles

Quick process pickles rely on vinegar for their acidity rather than fermentation, so they are faster and easier to make. (And you needn't worry about scum!) The vinegar used to make pickles lends its own character to the pickles, so be cautious about using flavored vinegars such as red wine, cider , or balsamic vinegar unless specifically required in a recipe. When the type of vinegar isn't mentioned in a recipe, use white distilled vinegar . The preservation process relies on a certain specific amount of acid, so always use vinegar that is 5% acidity.

Bread and Butter

Pickles 4 lbs cucumbers, washed but not peeled 3 thinly sliced medium onions 1/3 cup of canning salt 4 cups distilled vinegar 3 cups sugar 2 Tbsp mustard seed 1 Tbsp + 1 tsp celery seed 1-1/2 tsp turmeric 2 tsp whole black pepper Slice the cucumbers 1/4-inch thick and the onions as thinly as practical. Combine all of the ingredients except the cucumbers and onions in a large sauce pot and bring to a simmer (not a boil!). Add the cucumber and onion slices, and bring to a very light boil before turning down the heat to low. Pack the slices into jars and then fill with pickling liquid to 1/4 inch headspace, and put the lids on the jars finger-tight.

For the most crisp pickles, pasteurize by placing the jars in water deep enough to be at least 1 inch over the top of the jar lids that is kept at 180-185 degrees (check with a candy thermometer) for 30 minutes. Alternately, you can process in boiling water for 10 minutes for either pints or quarts. Allow to sit six weeks before using for the development of full flavor. Yield: 4 pints.

Vegetables

Vegetables (other than tomatoes) are not acidic enough to be canned using the boiling water method. Instead, they must be processed in a pressure canner for a fairly long period of time. The process is essentially the same for all vegetables, the only difference being in the processing time. For larger vegetables, cut into pieces so that there is at least one dimension less than 1/2-inch thick, bring pieces to a boil in water (to which 1/2 tsp of salt per quart can optionally be added), pour hot into clean jars allowing the right amount of head space, put on the caps finger-tight, and process for the time specified in Table 19 . You might consider using a little sliver (1/2-inch × 1-inch) of kombu kelp instead of salt. Kelp enhances the flavor of canned vegetables because of the natural glutamaic acid that it contains.

Generally, the pressure canning methods employed with vegetables destroy a good portion of the vitamin C, so I recommend freezing instead. Regardless, the macronutrient and mineral values of vegetables remain intact after canning, so it is worthwhile if you don't have a freezer or reliable electric service.

Meat

Meat is usually better vacuum sealed and frozen, but where the electrical supply is unreliable or too expensive, canning meat is a viable alternative. Because canning times and temperatures for meats are significant, most vitamins that can be destroyed by heat, especially vitamin C, are destroyed in the process. On the other hand, both the protein and mineral value is unaffected, so as long as you have plenty of vegetables in your diet, canned meat isn't a problem.

While the USDA says that putting raw meat into jars and then processing it is safe, it is my opinion that the flavor suffers. So I recommend that all meats first be soaked for an hour in a brine made with 1 Tbsp salt to a gallon of water and then at least lightly browned in a little vegetable oil until rare and then packing into the jars. Once the meat is packed into the jars, the jars should be filled with boiling water , meat broth, or tomato juice to leave the amount of headspace described in Table 19 . Most people prefer 1/2 tsp of salt added per pint, but this is optional. Put on the lids finger-tight, and process for the appropriate length of time. You can season meats before canning them, but avoid sage because the prolonged high temperatures can cause bitterness. Also, any meat broth you u se shouldn't contain flour , corn starch, or any other thickening agent because under pressure canning conditions, thickening agents congeal and make it impossible to get all of the air properly evacuated from the cans, and the risk of spoilage is increased.

Soups, Stews, and Other Mixtures

When canning anything that is a mixture of more than one ingredient, the time and headspace requirements from Table 19 that are the longest and largest for any of the ingredients apply. So if, for example, a mixture of carrots and peas were being canned, the processing time and headspace requirements for peas would be used since those are the greatest. The same warning about thickening agents regarding meats applies to stews as well.

Buffalo

Stew 4 lbs buffalo stew meat cut into 1-inch cubes 12 medium red potatoes cut into 1/2 inch cubes 5 medium yellow onions, diced 2 lbs of carrots sliced 1/4-inch thick 2 stalks celery 1 Tbsp cooking oil 1 tsp salt 1/2 tsp ground black pepper 1 tsp thyme 1 clove garlic 3 quarts water Get the three quarts of water boiling in a large saucepan and brown the stew meat in oil in the bottom of another large saucepan.

Add all of the spices and vegetables to the meat, stir thoroughly, cover , and allow to cook down for five minutes. Then pour in the three quarts of boiling water slowly and carefully, and bring everything to a boil. Put into jars leaving 1 inch of headspace, and process in a pressure canner for 75 minutes for pints or 90 minutes for quarts. Yield: 9 pints.

Freezing Like canning, freezing has its pros and cons. In its favor is that it is easier and quicker to freeze vegetables and meats than it is to pressure can them, and the resulting product is usually closer to fresh in terms of quality. Some things, like broccoli, are just plain inedible when canned but perfectly fine when frozen. The downside is that when freezing an appreciable amount of food, a large freezer is required-which isn't cheap. Figure at least $300 for a new one at current market price. Also a consideration is the ongoing ever increasing cost of electricity. And, if you are in an area prone to long electrical outages, you could lose the entire contents of your freezer if you don't maintain a backup power supply of some sort.

So you'll have to weigh the advantages and disadvantages. We have a reliable electric supply and not a lot of spare time at my house, so we do a lot of freezing.

We used to freeze in regular freezer bags from the grocery store or wrap things in freezer paper . No more! Now, the only method I use, and the only method we recommend, is vacuum sealing. Vacuum sealing consistently yields a superior product that keeps up to five times longer, so it is what we'll describe.

Getting a Sealer

We got my first vacuum sealer at a Boy Scouts yard sale, complete with instructions and a bunch of bags, for $3. Evidently, people often purchase sealers thinking they will be handy and use them once or twice, and then they end up in the yard sale bin. It may not be practical to wait around for a sealer to show up at a yard sale while harvest season comes and goes--but it never hurts to look.

There is another big reason why these sealers end up in the yard sale bin: the price of bags. The name-brand bags at the store that carry the same name as the sealer you buy will cost over $0.50 each. You don't have to do a lot of math to see that spending that much on just the bag to store a product (like broccoli) that you could buy frozen at the store for $0.99 isn't a winning proposition.

We'll give you some solutions to that problem in the next section.

There are two suitable sealers on the market in various configurations available at department stores-the Seal-a-Meal and the FoodSaver . I've found both to be adequate, though you will find the FoodSaver a bit more expensive. We prefer the Seal-a-Meal since its design allows it to work better with a wide variety of bags. These are light-duty home-use units. They work fine for the amount of freezing that we do for the carbohydrates and vegetables for a family of three because we tend to freeze in relatively small batches of 10 or fewer packages at a time. Heavy-duty commercial units are available-but you should hold off on these until you see if the less expensive home-use units will meet your needs. Certainly they will work fine as you ramp up for the first couple of years.

Bags

As mentioned earlier, the name-brand bags for sealers are expensive-sometimes even more than $0.50 apiece. Luckily, you can get around this problem a number of ways. First, keep an eye out for the sealers and bags at yard sales. Second, use plastic rolls instead of premade bags because by cutting them to size for what you are freezing, you will use a lot less and save money. Finally, you can buy bags and rolls from brands other than those made by the manufacturer of your sealer . Two sources come to mind. First, a number of manufacturers make less expensive bags and/or rolls including Black and Decker, FoodFresh Vacstrip, and Magic Vac.

These usually cost less than half of what the other bags do. Second, check the Internet. There are eBay stores dedicated strictly to vacuum sealers that offer good deals and also Web sites dedicated entirely to getting good prices on bags, such as vacuum-sealer bags.com. With these resources in hand, you will see the superior properties of vacuum sealing become financially viable.

The Freezing Process

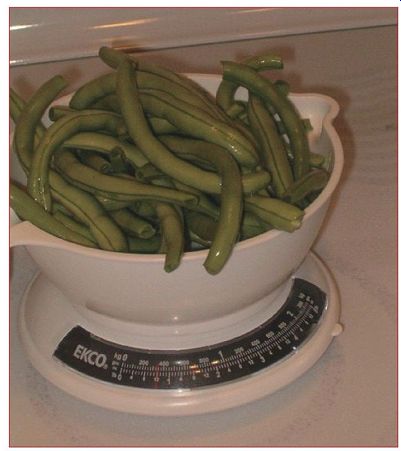

Freezing is a six-part process that requires harvesting, blanching, cooling, drying, sealing, and freezing. First, since no form of food preservation can actually improve the quality of food, harvest as close to freezing time as possible, and thoroughly clean the produce. Hose it off with the garden hose outside first, then put it in a big bucket to soak that contains two tablespoons of salt per gallon of water to draw out any insects. Then cut it up as needed, rinse out the salt, and weigh it into portions using a kitchen scale. For vegetables, figure 4 ounces per person. So for a family of four , you'll want your bagged portions to be about 16 ounces, or 12 ounces for a family of three.

----- Weighing produce for consistent portions helps with menu planning.

Next comes blanching. Blanching serves to inhibit the enzymes that destroy the quality of food in storage. There are two common methods-placing the produce in boiling water for a period of time, or steaming it for a slightly longer period of time. Both methods work, but I recommend steaming because it preserves more of the vitamin content of the food. The blanching time varies depending on what is being frozen (see Table 18).

When the allotted blanching time has passed, the produce should be dumped into a bucket of ice water so that it is cooled down immediately. (we slip a metal colander into the bucket first so that it holds the produce and makes it easy to retrieve.) Leave the produce in the ice water for the same amount of time as it was being blanched, then take it out and put it between a couple of super-clean, dry, and fluffy towels to pat dry. You have to do this when vacuum sealing otherwise the large water content gets in the way of making a good seal.

------- This steam blancher is just one of many steamers available.

------ Cooling down the produce in ice water after blanching.

------------------- Table 18: Blanching Times

Produce | Water Blanch | Steam Blanch

Artichoke, globe 7-10 min Not recommended Artichoke, Jerusalem (chunks) 5 min 7 min Asparagus 3 min spears 4 min Beans, lima, butter, 3 min edamame 5 min Beans, string 4 min 6 min Beet roots, sliced 1/4" 12 min Not recommended

Broccoli 4 min 4 min Brussels 4 min sprouts 6 min Cabbage, shredded 2 min 3 min Carrots 3 min 5 min Corn (on the cob) 10 min Not recommended Corn (whole kernel) 5 min 7 min Greens of all sorts 3 min 5 min Parsnips, sliced 2 min 3 min Peas, shelled of all 2 min sorts 3 min Peppers 3 min 4 min Potatoes, sliced/cubed 5 min 7 min Turnips, diced 3 min 4 min

--------------------

Once the produce has been dried, it is placed into bags and sealed. After the bags have been sealed, put them into the freezer in various locations so that they will freeze more quickly. Come back and rearrange them in 24 hours.

For some vegetables, particularly potatoes, and Jerusalem artichokes, discoloration can be a problem. This is easily solved by adding one tablespoon of citric acid or two tablespoons of lemon juice per gallon of water to the ice water being used to cool the vegetables after blanching.

Meats and fruits aren't handled the same way as vegetables.

Usually, meats are frozen raw, though we find that they freeze better if first soaked in a light brine (one tablespoon salt/gallon) to draw out any blood and then patted dry. The reason for drawing out the blood is so it doesn't interfere with vacuum sealing. Another way to accomplish the same thing (which we do with ground meats) is put the meat in a regular zipper bag and put it in the freezer overnight, then remove it from the zipper bag and immediately seal it in a vacuum bag-the frozen juices then won't interfere with sealing.

With wild game such as squirrel or deer , we recommend soaking for an hour in a light brine, as that removes some of the "gaminess" from the meat.

----------- Drying the produce with freshly cleaned towels before bagging.

------------ Sealing with a vacuum sealer preserves freshness longer.

Fruit is best frozen in a sugar syrup like used when canning. Once the sugar is dissolved in the water , you can add 1/4 teaspoon of vitamin C or 2 teaspoons of lemon juice per pint of syrup to prevent darkening. Slice or dice the fruit and put it in a can or freeze jar or suitable plastic container and then cover the fruit with syrup, leaving one inch of headspace to allow for expansion in the freezer.

Dehydrating

Drying food is one of the oldest methods of food preservation. By removing most of the moisture from foods, enzymatic action and microbial growth are retarded, and the food will keep for a long time. Food loses more nutritional value from drying than from freezing, and dehydrated foods will seldom reconstitute with water to look like appetizing fresh produce. But even at that, dehydrated products make a conveniently stored, tasty, and healthy addition to soups, stews, and sauces. When my daughter was little, I used to powder mixed dehydrated vegetables in a blender and stir that powder into her spaghetti sauce so she'd get a mix of vegetables without knowing it. She also loves dehydrated apple rings as a snack, and other dehydrated fruits make a great addition to oatmeal in the morning.

Just like vacuum sealers, dehydrators run the gamut from inexpensive units available at department stores costing less than $50 all the way to commercial-sized behemoths. We recommend starting with a small model that includes a fan and thermostat since that will be easy and trouble free. You can always switch to a more expensive commercial or even homemade unit later . (Dehydrators lend themselves easily to homemade solutions, and literally dozens of free designs-including solar designs-are available on the Internet just by doing a Web search that includes the terms "homemade" and "dehydrator . ") You can use a dehydrator for fruits, vegetables, and meats, though the process for the three is somewhat different.

Vegetables destined for the dehydrator need to be cut in slices no more than 1/4 inch thick and blanched just as though they were going to be frozen. This helps them dehydrate better and keep longer. Fruits should also be sliced no more than 1/4-inch thick and then dipped in a solution containing one tablespoon lemon juice per quart of water before being put in the dehydrator. Fruit shouldn't be blanched. Every dehydrator is different in terms of its drying characteristics, so use the drying times and temperatures recommended in the literature that comes with your particular model.

Meats, especially ground meat and poultry, are problematic because dehydrating is not the same thing as cooking, and the temperature seldom gets high enough to ensure pathogen destruction. This becomes an issue because bacterial contamination of these meats is common, so failure to thoroughly cook them can result in serious illness or even death. There are some jerky mixes available at department stores that are specifically formulated to deal with potential contamination of ground meats through the use of nitrites. If you choose to use one of these mixes, follow the directions precisely! Outside of this exception, we don't recommend making jerky or dried meat from either ground meats or poultry.

Other meats-like beef steak/roast, venison, buffalo, and so forth- are perfectly fine.

Most jerky recipes are for raw meat. In recent years, a number of universities have done studies and concluded that the practice can no longer be considered safe and that meat for jerky should be precooked in a boiling marinade. With the foregoing in mind, then, here is my general-purpose jerky recipe.

Brett's General-Purpose Jerky

Start with pre-frozen and partially thawed beef, buffalo, moose, venison, and so on. Trim away any visible fat and slice meat into uniform 1/4-inch-thick slices across the grain.

Create marinade in a saucepan by combining 2-1/4 cups of water , 3/4 cup teriyaki soy sauce, 1/2 tsp of liquid smoke, and a dash of Tabasco sauce. Raise to a gentle rolling boil.

Putting only a few strips of meat in at a time, boil a few strips

in the marinade until uniformly gray then remove from the marinade with tongs and place on the drying rack of the dehydrator . Repeat this process until all of the meat strips have been used.

Dry according to manufacturer's directions, or at a temperature of 140 to 150 degrees for six or more hours.

Test to see if the jerky is done by taking a piece off the dehydrator , letting it cool to room temperature, then bending it. If it cracks but doesn't break, it is done.

Root Cellaring

Root cellaring is one of the best methods of preserving certain foods, including onions, cabbage, potatoes, carrots, parsnips, and apples, among others. The key to success at cold storage is establishing conditions conducive to long storage life, and these conditions include darkness, certain temperatures, and particular ranges of humidity.

Many things can be preserved via root cellaring for some small period of time ranging from days to a couple of weeks, while others can be preserved for times ranging from several weeks to several months. Invariably, food that can be stored only for a short time is better preserved via some other method. This includes all brassicas except late cabbage, asparagus, beans, sweet corn, cucumbers, summer squash, lettuce, tomatoes, eggplant, spinach, melons, and peas.

Other foods, though, can be preserved in a root cellar for extended periods assuming proper temperatures and humidity are maintained. Unfortunately, these aren't the same for all crops, but thankfully we don't have to be too fine-grained in our specification because, in general, crops that do well in a root cellar fall into broad categories.

Everything but onions and garlic will do well with humidity ranging from 85% to 95%. Onions and garlic require humidity ranging from 50% to 75%. All fruits store best at temperatures as close to 32 degrees F as possible, and almost all vegetables as well, except for late potatoes, which do best at 35 degrees F to 40 degrees F.

So, in general, cold storage requires an environment that is humid, dark, and close to 32 degrees F without going under . The real question becomes how to create and maintain such an environment in homes that were not designed with root cellars.

If you have a cellar of any sort, a portion of it can be turned into a root cellar simply be walling off a corner , insulating the walls thoroughly, providing some sturdy shelves up off the floor , and installing some ventilation that will allow cool air to enter near the floor (PVC pipe is good for this) and warm air to exit near the ceiling. You'll want a thermometer so you can keep an eye on the temperature and shut off or limit ventilation if it starts to sink too low. (This may or may not be a problem depending on where you live.) If humidity is insufficient, you can add a humidifier.

Most produce should be placed in open-weave baskets and kept up off the floor and shouldn't be piled deeply as the pressure from the weight of produce on the lower layers could cause premature rotting. Fruits should be stored only one layer deep and, if possible, individually wrapped in tissue and not touching other fruit. Carrots and parsnips should have the tops snapped off and then be buried in dampened clean sand in a box sitting on the floor.

If you don't have a basement, you could bury a drum in the ground or build an external root cellar . For more details on how to build root cellars, check out the book Root Cellaring by Mike and Nancy Bubel.

-----------

Table 19: Canning Times and Methods

--------------

------------

----