AMAZON multi-meters discounts AMAZON oscilloscope discounts

FIRE HYDRANTS

Fire hydrants provide a source of water for the fire department in the event of a fire. Most fire hydrants are located along public streets and are the property and maintenance responsibility of the local municipality.

When fire hydrants are located on private property, maintenance may be the responsibility of the local municipality, or of the property owner. In many places, the local fire department or water department will help building owners perform these annual tests.

FIG. 10. Fire hydrants should be flushed once each year.

PM Tasks

NFPA 25 Standard for Inspection, Testing, and Maintenance of Water Based Fire Protection Systems requires that fire hydrants are flow tested annually.

If your municipality allows this testing to be done in-house, you can do so by removing one of the fire department connection caps and opening the valve fully. Flow must be maintained for not less than 1 minute and until all debris have been cleared from the hydrant. After the flow test is complete, close the valve and make sure the hydrant barrel drains properly to prevent frost damage.

NFPA 25 Also requires that a flow test be performed every 5 years recording pressure and flow rate to verify the condition of the pipe supplying the hydrant. This test can usually be performed by your fire sprinkler service company if your local water for fire department cannot do so.

Recommended PM Frequency

Annually: Flow test

Every 5 years: Flow test with pressure and flow rate measurement.

Technical Notes

The valve seat of most fire hydrants is located either below the frost line for a ground hydrant or within the heated space of a building for a wall mounted hydrant. This prevents the hydrant from freezing in the winter. All hydrants are designed with weep holes to drain water out of the hydrant.

To remove the cap from the fire department connection or to open a fire hydrant (except for hydrants with hand wheels) you will need a hydrant wrench. A hydrant wrench is made to fit the 5-sided valve stem found on the top of the hydrant. Any other tool could damage the stem.

Whenever you are doing a flow test, be sure to notify the local fire department and water department. Flowing a fire hydrant can cause a drop in water pressure for other local water users and can dislodge dirt from municipal water lines causing dirty or cloudy water in the neighborhood for a few hours. Many municipalities perform flow tests

on privately owned hydrants so they can open other hydrants in the area at the same time to wash this dirty water out of the pipes before neighbors complain.

FIRE INSPECTIONS (MUNICIPAL)

Most jurisdictions require commercial facilities to be inspected for compliance with fire safety codes. These inspections are often performed by a municipal fire inspector, municipal or county fire marshal or a member of the local fire department.

In most cases, the local authority having jurisdiction (AHJ) will schedule these inspections and will show up unannounced. In some cases, it may be the responsibility of each facility to call and schedule an inspection. Whether it is your responsibility to schedule an inspection or not, the inspection should still be on your PM calendar as a reminder that the inspection will be coming up and your facility needs to be ready.

Fire inspectors will be looking for compliance with local fire and building codes. These local codes usually reference most of the different codes and standards published by the NFPA including:

• NFPA 72 The National Fire Alarm Code • NFPA 101 Life Safety Code • NFPA 10 Standards for Portable fire Extinguishers

• NFPA 720 Standard for the Installation of Carbon Monoxide (CO) Warning Equipment in Dwelling Units

• NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations,

• NFPA 13 Standard for the Installation of Sprinkler Systems, NFPA 17 Standard for Dry Chemical Extinguishing Systems

• NFPA 17A Standard for Wet Chemical Extinguishing Systems

• NFPA 110 Standard for Emergency and Standby Power Systems

• NFPA 25 Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems.

PM Tasks

A building should always be in compliance with fire safety codes and should always be in inspection ready condition. However, when a fire inspection is pending, it's a good time to double check your building for compliance.

Your fire inspector will often want to see the following documentation:

• Inspection report for fire sprinkler system

• Inspection report for kitchen fire suppression system

• Inspection report for fire alarm system

• Record of cleaning for kitchen exhaust hood systems

• Monthly inspection tags on portable fire extinguishers

• Monthly inspection record for in-house testing of emergency and exit lights

• Monthly record of in-house fire alarm system testing.

All of these items are explained in more detail under their respective areas in this SECTION.

Each fire inspector or department will have different inspection issues that they tend to concentrate on. The inspection focus list often changes from year to year. Some of the most commonly cited violations follow in no particular order:

• Extension cords may not be used as a substitute for permanent wiring. The NFPA considers any use over 90 days to be permanent.

Note: Most jurisdictions will allow power strips to be used if they have built in circuit breakers. Surge suppressors are not the same as circuit breakers and are not a suitable substitute.

• Exit signs and emergency lights must be lit and the backup batteries must work.

• Electric space heaters cannot be used.

• Exit hardware must open in one motion. If you have to turn a key and then push the door to get out, that is a violation.

• Flammable materials cannot be stored in the building. This includes the gasoline in the fuel tank of a lawnmower or even oil-based

paints. Flammable materials must be in a fire rated flammables storage cabinet.

• Combustible materials cannot be stored under stairways.

• No storage within 24 inches of the ceiling.

• No storage within 18 inches (vertically) of a sprinkler head.

• Pressurized cylinders (oxygen, helium, acetylene, etc.) must be secured from falling over.

• Fire lanes must be free of obstructions such as loading or unloading vehicles

• Combustible waste such as empty cardboard boxes cannot be stored in or near the building.

• Aisle ways, walkways or stairways must be kept free of obstructions.

• Electrical receptacle, junction box, or breaker panel covers must be in place.

• Smoke and fire separation doors must close and latch without assistance and seal properly.

Recommended PM Frequency

Most jurisdictions perform annual fire inspections. Some "high risk" industries such as hospitals, nursing homes, or schools may require more frequent inspections. Contact your local AHJ for information.

FIRE SPRINKLER SYSTEM

A building's water-based fire suppression must be maintained and inspected according to NFPA 25 Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems. Inspections and maintenance should be performed by qualified individuals, which usually means hiring an outside sprinkler company. In some jurisdictions, the people that inspect sprinkler systems will need to be licensed.

Make sure to maintain excellent records of all fire sprinkler inspections and repairs. Your local fire inspector or fire marshal will want to see these during your municipal fire inspections.

PM Tasks

Every part of the sprinkler system needs inspection or maintenance at different intervals. In wet pipe systems, pressure gauges are to be checked weekly to see that there is adequate water pressure and control valves are to be inspected weekly to make sure the valves are kept open. If control valves have tamper signaling devices, these only need to be inspected monthly. These visual inspections can usually be done by in-house staff if records are kept.

Fire pumps require weekly visual inspections in-house and annual testing. Dry system gauges should also be inspected weekly to verify that water has not entered the dry part of the system. Wet system gauges should be inspected monthly. These inspections can also be performed in-house.

A quarterly inspection by your inspection company should include testing alarm devices (flow switches), inspecting all fire department connections, and operating the main drain to verify that water will flow.

Finally, the entire system must be inspected annually including opening and internal inspection of any dry pipe valve, flow testing all parts of the system, inspection of the condition of all pipes, checking that spare sprinkler heads (and a head wrench) are available, testing of back flow preventers, operating all control valves through their full range of motion, and visually inspecting all sprinkler heads.

Recommended PM Frequency:

Monthly (or Weekly): Check and record gauge pressures, inspect control valves in house.

Quarterly: Quarterly sprinkler inspection by sprinkler company.

Annually: Annual inspection by sprinkler company.

Technical Notes

Building fire sprinkler systems are usually one of two types. Both types may be present in some buildings. The more common of the two types is the wet system. Wet sprinkler systems have their pipes filled with pressurized water at all times. When a fire heats any sprinkler head to the factory set activation temperature (usually 135º to 170ºF), that sprinkler head opens and water begins to flow to put out the fire.

The second common type of system is the dry system. Dry sprinkler systems use an air compressor to keep the sprinkler pipes filled with compressed air instead of water. Like a wet sprinkler system, individual sprinkler heads will open when the temperature reaches a pre-set point.

When a sprinkler head opens, the air in the pipes is expelled. This drop in air pressure causes the main "dry pipe valve" to open; flooding the pipe with water. According to NFPA 13: Standard for the Installation of Sprinkler Systems, water must reach all points of the sprinkler system within 60 seconds of a sprinkler head activation. Dry systems are used in areas that are subject to freezing such as unheated attics or garages.

There are other types of sprinkler systems that are less common in most facilities. Hazardous locations such as airplane hangers or chemical storage may require deluge sprinkler systems in which all sprinkler heads flow water at the same time.

Pre-action sprinkler systems are used where there is a concern of water damage from a damaged or malfunctioning sprinkler head. A pre-action system uses automatic valves to hold back water until a heat or smoke sensor calls for water. Condominiums or townhouses sometimes use these systems with a separate valve for each living space. If a sprinkler head or pipe is damaged in a dwelling unit, no water will flow causing property damage. However, if a head activates from heat, the valve will open allowing water to flow, putting out any fire.

See also Kitchen Fire Suppression Systems, Fire Hydrants, Fire Extinguishers.

FIRE SUPPRESSION SYSTEMS

See Kitchen Fire Suppression Systems, Fire Extinguishers, Fire Sprinklers.

FLAG POLES

Flag poles are an often overlooked item and probably minor enough not to justify being included in this list if it weren't for the problem of trying to replace a broken rope. Once the rope has broken (and probably fallen to the ground), you'll need an aerial lift truck to get a new rope over the pulley at the top of the pole.

PM Tasks

Check the rope, replace the rope when damage is noticed by taping the new rope to the butt end of the old rope and pulling the new over the pulley using the old.

Recommended PM Frequency

Daily: Make note of the condition of the rope everyday when raising and lowering the flag.

Technical Notes

Since the flag is being raised and lowered each day, the condition of the rope can easily be checked at the same time. Plastic coated wire cable doesn't stretch like rope and lasts longer. Eventually the plastic coating begins to chip off and the cable will need to be replaced before the chipping causes the cable to bind in the pulley. If a rope does fall, many fire departments will assist with replacing the rope on a flag pole.

FLOOR CARE See Carpet Care, Resilient Flooring Care.

FLOOR DRAINS

Like all sanitary drains, floor drains are constructed with plumbing traps to maintain a seal of water to keep sewer gasses out of the building. Many floor drains are installed in areas where they are never used and the water in the trap eventually evaporates letting sewer gasses in.

PM Tasks

Pour water into each drain to maintain the seal against sewer gas.

Recommended PM Frequency

Monthly

Technical Notes:

Some floor drains have "trap primers" installed that automatically feed water to the drain to maintain the water level in the trap. These primed drains will not need regular PM unless the primer fails. Most primer valves are not repairable and are simply replaced if they no longer work.

A few drops of baby oil deposited in a floor drain will form a thin film of oil on the water's surface slowing the rate of evaporation and help to extend the PM interval.

There are also barrier type drain trap seals can easily be installed inside existing floor drains. These seals have a flexible rubber chute that opens to let water into the drain but closes to prevent sewer gasses from coming into the building. It can make sense to install these on difficult to access drains or on drains that seem to cause many complaints.

FIG. 11. Barrier type drain trap

FURNACES

Forced air furnaces use electric heating coils or combustion of fuel (gas or oil) to directly warm air which is usually delivered to occupied spaces through ductwork.

PM Tasks:

All of the combustion appliance checks that apply to boiler apply to furnaces. Combustion burners (oil or gas) should be cleaned and adjusted every year by someone qualified to do this work. Oil nozzles and oil filters should be replaced, oil pump pressure should be tested, and the combustion chamber should be cleaned and inspected. Gas appliances need to be cleaned and burners adjusted for the most efficient operation. Barometric dampers should be adjusted.

In addition, furnaces will need to have their heat exchangers inspected annually by someone qualified to determine if there are any cracks or holes.

Grease or oil bearings in blowers and motors, check the condition of belts and pulleys. Clean filters.

Recommended PM Frequency:

Quarterly (during heating season): Inspect belts and pulleys, clean filters.

Annually (at start of heating season): Have furnaces professionally inspected and adjusted.

Technical Notes

A cracked heat exchanger will allow the gasses of combustion to mix with the air delivered to the building and there is a danger of carbon monoxide poisoning. Wherever combustion furnaces are used (or other combustion appliances) it is a good idea to install carbon monoxide (CO) detectors. CO detectors are often required in sleeping rooms when combustion appliances are present.

Also see "Boilers and Water Heaters" section of this SECTION.

GENERATORS

See Emergency Generators

GREASE TRAPS

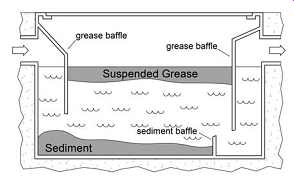

Grease traps, also called grease interceptors or FOG interceptors (fat, oil, grease), are installed as part of a facilities waste water system to collect grease which can clog pipes. Grease traps are installed at locations where grease is most likely to end up in drains. These include dishwashers, pot sinks, and other drains in commercial kitchens.

Grease traps can be small rectangular tanks installed in a kitchen floor or can be larger tanks with man hole covers installed outside the facility. Grease traps work by using baffles that block floating grease from leaving the tank and by having a discharge pipe that is below the level of floating grease.

FIG. 12. Components of a grease trap

PM Tasks

Accumulated grease needs to be removed when traps are approximately 25% filled with grease. With in-floor grease traps, this involves removing the grease trap cover and scooping the grease out of the trap into a bucket. For large grease tanks, a septic tank pumping service can be contracted to remove the grease.

Recommended PM Frequency

Quarterly: Cleaning grease traps quarterly is probably a good starting point. Kitchen usage and the type of cooking done will determine the required frequency which should be adjusted as needed to keep traps from becoming more than 25% full.

Technical Notes

Most companies that provide janitorial chemicals will offer enzymes which break down grease and extend the time between grease trap cleaning. Usually, a small chemical pump is installed at the sink which discharges into the grease trap. A timer dispenses a small amount of the enzyme into the grease trap after-hours so the enzyme has time to work on the grease in the trap.

HOT WATER HEATERS

See boilers and hot water heaters

HOT WATER TEMPERATURES

Excessive water temperatures at sinks, bath tubs, showers, or other locations can cause scalding. Children under 5 and the elderly are most susceptible to burns from hot water but hot water can burn anyone.

Most adults will suffer third-degree burns if exposed to 150 degree water for two seconds; 140 degree water for six-seconds; or 130 degree water for 30 seconds. Even at water temperatures of 120 degrees, third degree burns can occur with an exposure of 5 minutes.

Facilities such as schools, hospitals, nursing homes, assisted living facilities, and day care centers are often subject to regulations concerning potable water temperatures. In all types of facilities, excessively hot water is a safety and liability issue.

Under no circumstances should hot water exceed 120 degrees.

PM Tasks

Hot water temperatures should be taken monthly unless other regulations apply. Hospitals are often required to take water temperature readings daily and to keep a permanent record of the measurements.

Temperature readings should be taken in each area that is served by a different source of hot water and should be taken in a different location each month. The easiest way to measure the hot water is to place a drinking cup in a sink, insert a thermometer into the cup, and run the hot water into the cup allowing it to continue to overflow into the sink until a steady temperature is reached. If the water temperature exceeds 120 degrees at any time during this test, adjustments must be made.

Recommended PM Frequency

Monthly: Measure the water temperature in each area served by a different source of hot water. More frequent measurements may be required for specific industries.

Technical Notes

If water temperatures are too high, adjustments should be made to hot water heater thermostats, or to mixing valves if they are used.

Mixing valves are installed as a way to extend the supply of hot water.

Hot water at high temperature (often 140-160 degrees) and cold water are supplied to the inlet ports of the mixing valve. Inside the mixing valve, the hot and cold water is mixed provide water at the desired temperature. Mixing valves automatically and continuously adjust the mixture of hot and cold to maintain this desired outlet temperature.

When measuring water temperatures, the area served by each mixing valve must be tested individually.

Small mixing valves can be installed directly at each sink or other fixture. Some faucets and showers have mixing valves built-in. If your facility has any of these types of mixing valves or fixtures, you will need to measure water temperatures at each and every fixture because mixing

valves can fail.

Anti-scald faucets or anti-scald shower heads are excellent ways to prevent anyone from getting burned. If water temperatures exceed 120 degrees, these devices will automatically shut off the flow of water.

Anti-scald devices may be required in buildings such as schools and healthcare facilities.

HVAC

See Air Conditioners, Chillers, Cooling Towers.

ICE MACHINES

Ice machines will run more efficiently and last longer if they are maintained properly. Ice machines should also have a regular cleaning schedule to prevent the spread of diseases.

PM Tasks

Clean evaporator coil, pump, and water reservoir. Change condenser coil filter and check to make sure the condenser coil is clean.

Drain and clean the ice storage bin with a sanitizing cleanser. Check the operation of augers. Test ice level sensor to make sure it will shut down unit when bin is full.

Recommended PM Frequency

Monthly: Clean and inspect.

Annually: Change water filter.

Technical Notes

Evaporator coils are often coated with a layer of nickel or other material to help the ice cubes release easily. Using the wrong cleaning chemicals can damage this surface and ruin the evaporator coil. Use the cleaning chemicals recommended by the manufacturer.

IRRIGATION

See "Lawn Irrigation."

KITCHEN EXHAUST HOODS AND FANS

This section applies to exhaust hoods that are located directly over cooking appliances in commercial food service kitchens. NFPA 96 refers to these as "grease removal exhaust fans" and prescribes specific preventive maintenance tasks that must be performed. Kitchen exhaust fans that are only for the removal of hot air or steam should be maintained as in the section titled "Exhaust Fans." Commercial food service kitchens are required to have a grease removal exhaust fans and hood assembly located over grill tops, fryers, and other cooking equipment. Most of these hoods will include a fire suppression system with spray heads located directly over each piece of equipment.

PM Tasks

Grease filters, located directly over cooking appliances, should be cleaned as often as necessary to prevent grease build-up. Depending on the type and volume of cooking done, this could mean monthly cleaning or even running the filters through the dishwasher at the end of every night. This is a maintenance item usually handled by the kitchen manager, not maintenance staff.

NFPA 96 requires that the hood system, fan, and ductwork be inspected and cleaned prior to becoming heavily contaminated with grease. This will also vary with the type of cooking done. NFPA offers the following guidelines: hoods used for solid fuel cooking such as wood and charcoal should be cleaned monthly. Charcoal, char broiler, wok, and 24-hour cooking establishments should have the hood cleaned quarterly.

Moderate volume kitchens need cleaning semi-annually. Seasonal and occasional cooking such as camps, churches, and senior centers only require annual cleaning. Remember that these are guidelines and the amount of grease deposit is what matters in determining when it's time to have the hoods cleaned.

Exhaust hoods must be cleaned by someone that is qualified, trained, and certified to do the work. Since NFPA does not offer certification, most "qualified" service people are certified by one of several

private certifying organizations. The largest and most often cited is IKECA, the International Kitchen Exhaust Cleaning Association.

Recommended PM Frequency

Monthly, Quarterly, Semi-annually, or Annually. Depends heavily on the type and volume of cooking done. See the above section for details.

Technical Notes

The actual cleaning of your exhaust hood involves creating a water collection system below the exhaust hood using plastic sheeting and pressure washing (or steam cleaning) every internal surface of the ductwork and exhaust hood. All duct bends must have a door for access to the interior and there must be access doors at least every 12' to allow cleaning personnel to see and clean every part of the interior.

The exhaust fan will have its housing or cover removed and it too will be pressure washed. The job is complete when the entire ductwork system is cleaned to bare metal.

Also see Kitchen Fire Suppression Systems, Exhaust Fans

KITCHEN FIRE SUPPRESSION SYSTEMS

Because of the presence of natural gas and cooking oil, fires that

occur in and around cooking equipment in commercial food service kitchens often spread rapidly. Almost every commercial kitchen has a kitchen fire suppression system installed in the grease exhaust hood over

cooking appliances.

Commercial kitchen fire suppression systems from all manufacturers are often incorrectly referred to by facilities people simply as Ansul systems. Ansul is a subsidiary of Tyco Fire and Safety is one of the largest manufacturers of fire suppression equipment.

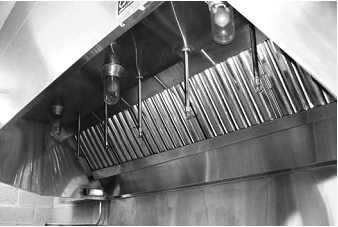

FIG. 14. Spray nozzles of a kitchen fire suppression system are located

under the exhaust hood.

PM Tasks

Each month the system should be visually inspected. This can be done by in-house staff. Check the tank pressure gauge for adequate pressure, look for missing grease caps on spray nozzles, check that nozzles are in their correct locations and not damaged or blocked. Make sure any manual activation stations have the safety pin in place and are properly labeled. Look the system over for any obvious signs of problems. An inspection tag located on the chemical tank should be initialed monthly as a record of the inspection.

There are several different regulations that apply to kitchen fire suppression systems depending on the type of suppressant used. NFPA 96 applies to grease removal exhaust hoods, NFPA 13 to water-based fire suppression systems, NFPA 17 to dry chemical systems, and NFPA 17A to wet chemical systems. All of these standards require that inspection

and servicing of the fire-extinguishing system shall be made at least every 6 months. In most jurisdictions inspections must be made by a certified or licensed inspector or installer.

Recommended PM Frequency

Monthly: Visual inspection by in-house staff.

Semi-annually: Inspection and testing by certified contractor.

Technical Notes

Kitchen fire suppression systems consist of a set of spray nozzles located over each cooking appliance, fusible links (which melt in the heat of a fire) or electronic heat detectors to activate the system, and a pressurized tank of fire suppressant which is sprayed from the nozzles to put out the fire. When the system activates, any kitchen makeup air

fans (but not exhaust fans) and the gas supply to the cooking appliances must shut down automatically.

Due to the change many restaurants and kitchens have made toward healthier but hotter burning cooking oils, older dry fire suppression systems are now considered obsolete. Many food service kitchens are being required by insurance companies or municipal inspectors to upgrade to newer wet chemical systems.

During your semi-annual inspection and test, the inspecting contractor will leave a dated inspection tag attached to the suppression chemical tank. Your local fire marshal or fire code inspector will want to see this tag during your municipal fire inspections.

See also Kitchen Exhaust Hoods and Fans, Fire Extinguishers, Fire Sprinkler Systems.

LAUNDRY (COMMERCIAL WASHERS AND DRYERS)

Hotels, hospitals, and nursing homes usually have their own in-house commercial laundry operation. Most commercial laundries include conventional washers and dryers. The largest laundry operations can include folding machinery and often employ full time laundry mechanics to maintain this equipment. Most of us will only be maintaining washers and dryers.

PM Tasks

Dryers: Inspect drive belts for condition and tightness. Grease bearings. Clean burner assembly of any lint. Clean lint from machine. Inspect inside of exhaust ducting for excessive lint or blockages.

Washers: Check hoses for signs of wear or deterioration. Check condition of door seals. Inspect drive belts and grease bearings. Check under machines for signs of leaks. Check operation of chemical pumps and verify with laundry staff that machines are not consuming chemicals at an unusual rate.

Recommended PM Frequency

Monthly Technical Notes

Inspections should be done monthly, greasing of bearings may need to be done less or more frequently, consult the manufacturer's manual.

LAWN IRRIGATION

In almost all locations, the only way for a facility to have a lush, green lawn throughout the spring, summer, and fall is through mechanical irrigation. Typically lawns require 1" to 1¼" of water each week. Two or three deep waterings each week will be much more beneficial than shallow watering every day.

One of the drawbacks of irrigation is grass that is often wet is susceptible to fungus damage, usually noticed as brown patches in the lawn. The best way to prevent fungus is to water in the early morning instead of evening. This allows the water to soak into the ground but lets the blades of grass dry quickly in the morning sun.

PM Tasks

Season Start-up: At the start of the irrigation season, control timers need to be programmed and their batteries changed. Each irrigation zone and each and every head should be checked for operation. Most service companies will verify that each head pops up and sprays water.

Few will take the time to watch each head to be sure it moves through its full range of motion. This is a time consuming but important part of making sure the system is doing its job.

Backflow prevention devices are required on irrigation systems.

Since pesticides and fertilizer can be present in the lawn, these chemicals could be siphoned back into the potable water supply if the water supply was to lose pressure. Back flow prevention devices will prevent this from happening. Backflow devices must be inspected by a certified tester or licensed plumber once or twice per year. Most jurisdictions only require one annual test for irrigation systems since they are only used for half of the year. See "Backflow Prevention Devices" for more information.

After initial startup, the best PM is to walk the lawn once a week and look for areas that are not getting watered. Pop up heads can be damaged by vandalism or mowers. Irrigation pipe underground can break causing washed out holes in the lawn. Spray heads can become clogged by dirt which may prevent them from spraying or can jam the rotation mechanism. Sprinkler valves can fail to open or fail to close.

Control timers can lose their programs or become damaged by power surges or lightening. All of these problems can be noticed by a weekly walk of the lawn. During a hot dry summer, a lot of lawn damage can be done in a few days if the irrigation is not working.

Seasonal Shutdown: At the end of the irrigation season, timers should be turned off, the water supply to the system should be turned off and the irrigation system blown out with compressed air to remove water that could freeze over the winter and cause damage. An air compressor is hooked to an air fitting near the main shut off valve and each zone is operated until only a light mist of water is seen coming from the sprinkler heads at each zone.

Recommended PM Frequency

Annually: System start-up in the spring including backflow prevention device test.

Annually: System shut down in the fall.

Weekly: Walk lawn and look for any signs of a system, zones, or individual heads that do not work.

Technical Notes

Lawn irrigation systems include various types of sprinkler, mist, or spray heads which are fed water by a network of underground pipes.

Most irrigation heads sit flush or slightly below the level of the ground and are pushed up above the surface by water pressure. Electrically operated valves called "solenoid valves" turn on the different irrigation zones. Electric wires buried with the underground pipe carries the electricity to operate these valves from the control timer. Sprinkler systems typically operate at 24V.

Brown or dead triangles, or pie wedges, of grass indicate that a sprinkler head is not rotating its full range of motion. Green growth in circles around the spray heads indicate a drop in water pressure has resulted in a smaller spray circle. This is usually caused by two zones operating at the same time, a partially closed valve, or a failed booster pump. Larger browning patches of grass usually indicate a bad zone, either due to a programming problem, a bad wire to a zone valve, or a failed zone valve.

LAWNMOWERS AND GROUNDS CARE EQUIPMENT

Lawnmowers, leaf blowers, garden tractors, chainsaws, hedge trimmers, and other grounds care equipment all need to be included on your PM calendar or schedule.

PM Tasks

Review the manufacturer operator's manuals for the specifics for each piece of equipment as they all vary widely. Typically, larger equipment will need oil changes every 50, 100, or 200 hours of operation, grease fittings will need to be greased, mower blades kept sharp and balanced, trimmer blades and chains oiled, belts inspected for wear, and tire pressure maintained. There will be other items required depending on the type of equipment you are using. In all instances, the manufacturer's operating manual will explain exactly what type of maintenance is required for each type of equipment.

Since this type of equipment is usually maintained based on hours of operation, and not based on a calendar date, it makes sense to affix a service label to each piece of equipment that says "Next service at _____ hours." For equipment without an hour meter, you can estimate based on number of hours used in a typical day or you can buy inexpensive after-market hour meters.

Recommended PM Frequency

Depends entirely on the type of equipment. See the manufacturer's literature.

LIGHTING (EXTERIOR)

Exterior lighting is clearly a safety issue as well as affecting the overall appearance of your facility.

PM Tasks

Turn on timers or cover photo-eyes to cause lighting to come on.

Walk the exterior of the facility and take notes on any fixtures that are not working and make repairs.

Also consider group re-lamping for HID fixtures as discussed in SECTION 1.

Recommended PM Frequency

Monthly: Walk facility in the evening to check all exterior lighting.

Quarterly: Adjust lighting timers for seasonal daylight changes.

Technical Notes

Many types of high intensity discharge lights (HID) will turn themselves off and on all night when bulbs start to go bad. A light that is on when lamps first light may turn itself off within 10 or 15 minutes. Lights that turn on and off are a sign of a lamp going bad. A HID light that fails to light will most likely have a bad bulb but may have a bad ballast.

Changing pole lights is easiest if done using an aerial lift truck or boom lift. It may be possible to change some pole lights using extension ladders. If you don't own an aerial lift, you can rent them from many places. It may be more cost effective to have a standing agreement with your electrical contractor to replace bulbs or ballasts that you stock each month.

HID lighting has a trait known as lumen maintenance. This is a measurement of how well a light maintains its light output over the life of the lamp. HID lamps loose intensity as they age and can loose as much as 40% of their light output near the end of their life. It often makes sense to replace HID lamps once they reach a certain percentage of their expected life or a specific loss in lumen output. See the section on group re-lamping in SECTION 1 for more details.

Next>>