AMAZON multi-meters discounts AMAZON oscilloscope discounts

Indoor air quality (IAQ) is a relatively new topic that has recently exploded as a major issue for facilities maintenance departments across the country. IAQ problems in the workplace have been a familiar news story in recent years and concerns among building users is on the rise.

Even with widespread IAQ concerns, there seems to be a lot of mystery among facilities managers about IAQ and how to solve IAQ problems.

In this section, we'll try to answer many of the mysteries surrounding IAQ and identify some of the preventive maintenance that can prevent IAQ problems from ever starting. Preventive maintenance can have a significant impact on the quality of indoor air. Every maintenance manager and PM technician should be familiar with how their work impacts the indoor environment.

The energy crisis of the 1970s helped to spawn many of the indoor air quality problems in facilities. The energy crisis led commercial buildings to be built to a new standard of energy efficiency. For the first time, architects and contractors were vigilant to prevent the loss of conditioned air to the outside and infiltration of outside air into a facility. Buildings built prior to the energy crisis were not built to such air tight standards. In a time when fuel was cheap and abundant, leaky, energy wasting buildings were perfectly acceptable. Leaky buildings don't buildup concentrations of indoor air pollutants and don't have problems with IAQ. Over the past 3 decades, thousands of new, nearly air tight, facilities have been built and as a result, IAQ problems have become a significant issue for many maintenance departments.

THE 3 PARTS OF IAQ PROBLEMS (THE 3 P'S)

As our first step in understanding IAQ, let's first identify what constitutes an indoor air quality problem. All indoor air quality problems have three components; we'll call them the three Ps. The three P's are:

1. Pollutant source

2. Pathway for the pollutant to reach people

3. People who are affected by the pollutant

The simple relationship between the 3 P's is pollutants move through pathways to reach people.

Pollutants--The First P

The sources of these pollutants are nearly unlimited. Tobacco smoke, pollen, paint fumes, cleaning chemicals, and dust from maintenance activities are just a few of the common pollutant sources. Some pollutants such as sewer gas are perceptible by nearly everyone and nearly everyone would consider the pollutant to be a problem in the workplace. Other pollutants such as pollen or mold spores only present problems to a few individuals and may not even be noticeable by most.

Nearly anything can be a pollutant if there is someone present who is sensitive to that particular contaminant.

The Most Common IAQ Pollutants

Biological Contaminants--These include mold, dust mites, pet dander, viruses, bacteria, or droppings from rodents or insects. Most of the biological contaminants are found in damp or wet areas such as air conditioners, bathrooms, kitchens, or in areas that have roof or other leaks. Dust mites, mold, pet dander, and insect or rodent droppings can trigger asthma or allergic reactions in building occupants. Bacterial diseases such as Legionella can be associated with moisture in ventilation systems.

Dust--often a result of maintenance activities, poor housekeeping, or dirty and clogged air filters bypassing air around the filter.

Tobacco Smoke--contains more than 40 chemicals know to cause cancer and many others that are irritants. Exposure can trigger asthma in some individuals.

Radon--a colorless, odorless radioactive gas produced by the decay of uranium in rock below the soil. Can enter buildings from the soil and is undetectable without laboratory testing. Prolonged exposure is linked to lung cancer.

Asbestos--a material used in many building materials prior to 1975. Asbestos can be found in floor tiles, insulation, wall board, ceiling tiles, construction adhesives, and other places. Tiny asbestos fibers are associated with asbestosis (hardening of lung tissue) and some cancers. As long as asbestos remains undisturbed and intact it presents no hazard. Once disturbed, airborne asbestos fibers present a serious health risk.

Volatile Organic Compounds (VOCs)--solvents found in paint, stains, caulk, and some industrial cleaners. VOCs in the air typically have a strong odor and can cause many health symptoms in sensitive individuals such as headaches and nausea. Long term exposure is linked to a wide range of mental and physical ailments.

Mold Spores--sources can be mold growth inside a building or spores can be brought into a building from outside through the building's HVAC system. Mold spores exist everywhere and only a few species trigger asthma or other allergic reactions in sensitive individuals. An environmental consultant can have surface dust tested to see what types of mold are present.

Cleaning Products--perfumes or other chemicals found in housekeeping chemicals may cause headaches, nausea, or other allergic reactions in some individuals.

Pesticides--today's pesticides are used in extremely low concentrations and are more target specific than in the past. The inert ingredients in some pesticides may cause eye, ear, or throat irritation and although very rare in commercial buildings, prolonged exposure to high levels of some pesticides can cause nervous system damage, liver damage, and cancer.

Pathways--The Second P Pollutants are only a problem when they make their way to people. The route they take to get there is the pollutant's pathway. Pathways can be any route from the pollutant source and can be difficult to determine.

Pollutants can travel through ductwork, above ceilings, down corridors, through open doorways, or even through cracks and gaps in building construction.

Pollen can be drawn into a building through an air conditioning unit's outside air damper and delivered via ductwork through an entire building; Sewer gas can travel through a dry floor drain trap into a kitchen; or the unpleasant odors associated with a locker room can travel through the open locker room door into a gym.

People--The Third P Contaminants in the air do not cause a problem unless they bother people. Everyone reacts differently to different contaminants. Those of us who work in facilities are constantly in contact with all sorts of air pollutants. Everyday we're exposed to sawdust, adhesives, solvents, welding gases, paint, sewer gas, and all types of dust and dirt. Most of us aren't very sensitive to these things. If we were sensitive, we would have chosen a different line of work. Because most air contaminants don't bother us, we may tend to underestimate the effects of these things on other people.

Indoor air problems can be subtle. In many cases, one or only a few individuals are affected while no one else shows any symptoms at all. In these cases, it can be easy to dismiss the complaint as unfounded since no one else has complained. Not all suspected IAQ complaints turn out to be valid IAQ problems. However, different individuals react differently to air quality issues and all IAQ concerns deserve to be properly investigated.

Different sensitivities among individuals are one of the things that can make solving IAQ problems so difficult. It can be very difficult to track down the source of something in the air if you aren't able to detect it yourself or when you don't know what type of air-born contaminant is causing a problem Most of the IAQ issues we deal with on a regular basis are easy.

Someone smells garbage, paint, or sewer gas and we can figure out where the odor is coming from and can eliminate it. Most of these IAQ problems are so common and so easy to solve that we never even consider them to be IAQ problems.

Unfortunately, the most often discussed IAQ issues are the ones that are difficult to figure out. Many times, an IAQ concern is just a short list of symptoms that an occupant experiences only while they are in the building. Some of the most common symptoms reported as suspected IAQ problems are:

• Headache

• Coughing and sneezing

• Fatigue

• Dry eyes, nose, throat

• Shortness of breath

• Dry skin or rash

• Congestion

• Shortness of breath

• Malaise

• Nausea

While all of these symptoms can legitimately be caused by IAQ, they can also be caused by dozens of other ailments. Knowing when a physical symptom is actually IAQ related can be difficult or impossible.

COMFORT ISSUES

To confuse matters further, many of the IAQ complaints a maintenance department receives are actually comfort complaints that have nothing to do with contaminants in the air. Comfort issues typically involve temperature or humidity levels and not pollutants.

Temperature and humidity problems, particularly low humidity, can cause many of the same symptoms as IAQ problems. Dry eyes, nose, throat or skin, skin rashes; coughing, fatigue, and headache can be associated with low humidity levels.

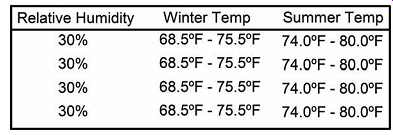

The American Society of Heating, Refrigeration, and Air-Conditioning, Engineers (ASHRAE) publishes a standard (ASHRAE standard 55-1992) that describes the temperature and humidity levels that are comfortable for the majority (80%) of people in a building. FIG. 1 summarizes the standard.

FIG. 1. ASHRAE recommended temperature and humidity ranges for human comfort.

FIG. 1. ASHRAE recommended temperature and humidity ranges for human comfort.

Extremely low humidity can cause respiratory problems unrelated to IAQ. However, both high and low humidity extremes can cause IAQ problems. High relative humidity can cause mold growth while extremely low relative humidity can cause mold spores to be released into the air. Mold is a common allergen and asthma trigger.

Another common issue with occupant comfort is the amount of fresh air introduced into a building. ASHRE standard 62-1989, Ventilation Standard for Acceptable Indoor Air Quality, recommends 15 to 20 cubic feet per minute (CFM) of fresh air be brought into every space for each occupant. That means that if an office has 10 people working in cubicles, requiring 20 CFM each, the total fresh air introduced to that space should be 200 cubic feet every minute. This can be accomplished by bringing 200cfm of fresh air into the room or by bringing in fresh air at another location and exhausting 200 CFM from the room so that fresh air is drawn into the room from other parts of the building.

The 15CFM and 20 CFM figure has changed many times over the years and has been settled on as the amount of fresh air that the majority of people (80%) consider to be comfortable. Below this air exchange rate, some building users will describe the environment as "stuffy" and may complain of human odors while many people will find the space to be "drafty" at air exchange rates above these recommendations.

An exchange rate of 20 CFM per person should keep the carbon dioxide (CO2) levels at around 1000 parts per million (ppm). As occupants breathe, they use oxygen and exhale carbon dioxide. The carbon dioxide levels will continue to rise if no fresh air is brought into the space. CO2 levels above 1000 ppm is generally considered to be an indication of poor air exchange. Although, in older buildings built to older standards, properly operating HVAC systems may allow a CO2 concentration to be slightly above 1000ppm.

Dangerous levels of CO2 are not likely to be found in facilities.

OSHA has established 5000 ppm of CO2 as the permissible exposure limit for 8 hours of exposure per day and 30,000ppm as a permissible exposure limit for exposures of 15 minutes or less. ASHRAE recommends that indoor CO2 not be higher than 700 ppm above the level found in the outside air to minimize human odors and maintain comfort.

CO2 in the outdoor environment varies but is typically somewhere around 300 ppm.

SOLVING IAQ PROBLEMS

Just as IAQ problems include the 3 P's, pollutants, pathways, and people, the solution to IAQ problems will be in the areas of the 3 P's.

We'll look at each one separately.

Pollutants-Solving Problems:

Since all IAQ problems include a pollutant, the simplest solution may be to eliminate the pollutant source. For many pollutants such as cleaning chemicals, paints, and other maintenance chemicals, alternative products can be chosen. Pollutants such as solvents, gasoline, or stored pesticides can be moved to another storage location, preferably outside of the building. Garbage odors or vehicle exhaust can be drawn into buildings through fresh air intakes. These items can often be moved to another location. Environmental tobacco smoke is often a source of complaints that can be solved by implementing a no smoking policy or designating smoking areas away from work areas.

When a pollutant can't be substituted or moved, a pollutant in the air can often be exhausted from a building by proper use of ventilation.

Using exhaust fans or even opening a door or window at the pollutant source can prevent the pollutant from entering other parts of the building. Exhaust fans in rest rooms, kitchens, and parking garages are common examples of ventilation at a pollutant source.

Pollutants from outdoors such as pollen or dust can often be filtered from the air entering a building. Filters with MERV (Minimum Efficiency Reporting Value) ratings between 5 and 8 usually provide adequate dust removal for most situations. Removing mold spores usually requires more dense filters with MERV ratings between 9 and 12. Recirculated building air can also be filtered to remove contaminants and prevent relocating contaminants from one location to another. Changing from low density filters to higher density filters may require equipment modifications since denser filters tend to restrict air flow.

Pathways--Solving Problems

When a pollutant source can't be eliminated, it may be possible to eliminate the pathway the pollutant uses to reach people. This can be done in two ways. The first is to provide a physical barrier to air movement and the second is to change pressure relationships to make air flow in a different direction.

Creating a physical barrier to air movement can be as easy as closing a door. Maintenance activities such as painting, gluing, welding, soldering, or sawing can put contaminants into the air. Simply keeping the maintenance department or boiler room doors closed to the rest of the building can eliminate pollutants from getting into the rest of the building.

Temporary physical barriers can be created by hanging plastic sheeting around maintenance work to keep dust contained. This is commonly done to contain asbestos fibers, lead dust, and airborne mold during abatement and remediation work.

The second way to block pollutant pathways is to alter pressure relationships. In a building, air is constantly moving from areas of high air pressure to areas of low pressure. These pressure differentials exist from several sources. Heated air tends to rise through a building creating a low pressure area near the bottom of buildings, a phenomenon known as "stack effect." Mechanical ventilation creates zones of low pressure while make up air fans cause localized areas of high pressure.

Wind blowing against open windows and doors can create high or low pressures within buildings depending on the direction of the wind.

Since air always moves from high pressure to low pressure, we want to have our lowest pressures at pollutant sources. By doing this, we are bringing air to the pollutant instead of delivering polluted air to the rest of the building. As already discussed, mechanical ventilation with exhaust fans at the pollutant source is a common solution to problems of contaminated air. While ventilation fans at the pollutant source are exhausting the pollutant to the outside, they are also causing a low pressure zone at the pollutant. This low pressure causes air flow toward the pollutant preventing polluted air from flowing toward building occupants.

People--Solving Problems:

When a pollutant can't be eliminated at the source and its pathway can't be blocked, the only solution left is to make changes to the people being affected. These changes usually mean moving those that are sensitive to the pollutant to another location or limiting the time spent in the affected area.

Letting an employee swap offices with someone less sensitive to a particular allergen is a workable solution in many cases. Work spaces can sometimes be rearranged to adapt areas with poor IAQ into storage or other rarely occupied space.

If an individual is having problems such as allergic reactions, headaches or other medical issues, he should see his family physician. More information about solving sick building syndrome problems is discussed below.

The 8 Common IAQ Solutions:

1. Physically removing the pollutant source from the building

2. Finding a substitute product for the pollutant

3. Removal of the pollutant by increasing exhaust ventilation at the pollutant source

4. Bringing in fresh air to dilute the pollutant

5. Eliminating a particulate pollutant with proper selection of air filters

6. Creating a physical barrier between the pollutant and affected people

7. Rebalancing pressure relationships with mechanical ventilation

8. Relocating affected people away from the pollutant

THE "M" WORD

The IAQ contaminant with the biggest fear factor is probably mold.

Mold is such a public panic issue that it's often referred to as "the M word" among facilities managers.

Molds will be found everywhere in a building. Mold can grow on practically any organic material as long as air and moisture are present.

Mold can even thrive on the surface of non-organic materials by surviving on organic surface dust. It would be impossible to eliminate all of the mold and mold spores within a building. If you were to take a dust sample from any location and look at the sample under the microscope, you would find several species of mold.

There are many different types of mold. Some molds can trigger allergic reactions or asthma attacks in individuals sensitive to molds.

Some species of molds produce toxins called mycotoxins which can cause a wide range of health symptoms in people, some very serious.

Often when an individual suspects they are suffering from sick building syndrome, they will assume the problem is related to mold.

Mold can be a trigger for many health problems. An allergist can determine if a person is sensitive and to which species of mold. An environmental consulting contractor should be able to take dust samples to determine if the types of mold present are the same mold species causing allergic symptoms.

The best way to prevent mold problems is to keep moisture out of your building with proper preventive maintenance of the building envelope. When carpets, drywall, or other building materials get wet, they must be thoroughly dried within 48 hours. Carpet extractors, wet vacuums, drying fans, and portable dehumidifiers can speed the drying process.

Once mold does become established, it must be removed. Mold on the surface of non-porous materials such as stone, laminate, or plastic, can be wiped clean using a 10% solution of chlorine bleach. If mold has grown on porous materials including wall board, ceiling tiles, or carpet, the material must be removed. When removing mold covered material be sure to wear personal protective equipment including goggles, gloves, disposable overalls, and a respirator with HEPA filters.

Mold remediation involving large areas, typically more than 100 square feet, are best handled by experienced mold re-mediators since the EPA recommends full containment. Full containment includes constructing a containment barrier of double layers of plastic, building a decontamination chamber, and creating two air locks to prevent contaminating any other parts of the building.

DIFFICULT IAQ PROBLEMS--SICK BUILDING SYNDROME

Most of the IAQ problems facility managers see are fairly straight forward. There is a known pollutant, causing an obvious problem.

Most of these are nothing more serious than an objectionable odor.

These complaints are easy to solve by any of the methods mentioned earlier.

Unfortunately, some IAQ problems are not as simple. When a building user complains of headaches, fatigue, or respiratory problems they believe to be caused by poor indoor air quality, it can be difficult to determine if air quality is the culprit.

The term "sick building syndrome" is used to describe cases where building occupants experience physical symptoms while in a building that disappear when the person is no longer in the building.

While many physical symptoms, such as headache, cough, or itchy skin can legitimately be caused by poor IAQ, they can also be caused by dozens of other ailments or stressors such as building lighting, noise, temperature, humidity, poor ergonomics, or even job stress.

Facility managers and maintenance supervisors are not physicians and aren't qualified to diagnose health issues. Solving a complex IAQ problem or investigating a suspected case of sick building syndrome will often require the assistance of experts in other fields. If we follow a systematic approach and know when to rely on specialists, even difficult IAQ problems can be solved to everyone's satisfaction.

Collecting Data

The first step in solving a difficult IAQ problem is to collect as much data about the problem as possible. These data should include both the environmental conditions and the occupant's experiences.

The building occupant having symptoms should be recruited to help with the investigation. The occupant should be asked to keep a daily log of their symptoms on an hourly basis; writing down each hour any observations about their own symptoms and their working environment. Including the occupant in the investigation not only provides the data necessary to hopefully solve the problem but also helps to eliminate the mistrust and suspicion which often accompanies IAQ concerns.

Every hour, the person having symptoms should be asked to record the time; any environmental observations such as "too hot," "too cold," "drafty" etc; and how they are feeling at the time. They should be asked to keep this log for at least one full work week.

While these data are being collected, the facilities or maintenance department should be recording temperature and humidity data at least hourly. The easiest way to do this is to place a small temperature and humidity data recorder in the room and record the temperature and humidity throughout the day for several days or even weeks.

FIG. 2. Several manufacturers make small temperature and humidity data

recorders that can be used for IAQ investigations.

Inexpensive temperature and humidity data recorders are available with prices which start around $100. These tiny recorders can be placed in a location to continually record data and then be taken back to the facility's office to upload the data into a computer. Software provided by the data recorder's manufacturer can chart the data over time.

While temperature and humidity measurements are critical, measuring CO2 levels can also be helpful in solving IAQ problems. Small inexpensive CO2 data recorders are available that are nearly identical to the T&H recorders previously mentioned. Typically CO2 levels under 700 ppm indicate excessive ventilation while CO2 above 1,200 ppm indicate that ventilation rates are less than desirable.

Data should be recorded for at least a week and the occupant's log of symptoms should be compared to the temperature, humidity, and CO2 logs that have been collected. A correlation may become obvious.

If symptoms of dry eyes, nose, and throat are reported each time the relative humidity dropped below 30%, it should become obvious that the problem is one of low humidity which could be solved by installing or repairing a humidifier. If a staff member feels nauseous whenever the CO2 level in a room rises above 2000 ppm, there is a strong indication that the space in inadequately ventilated and the stuffy feeling is causing the feeling of nausea.

Seeking Professional Assistance

When IAQ complaints involve human medical symptoms, the maintenance department may not be able to find a cause or solution to anyone's satisfaction. For most of us, our expertise is not in environmental science or medicine. Like all other facilities and maintenance problems, if we don't have the necessary expertise in-house to solve a problem, we hire outside contractors who do. When we are dealing with health issues which may be related to indoor air, the experts we need to rely on are doctors, your local or state department of health, and independent environmental consultants.

Any building occupant complaining of health symptoms should be encouraged to see his or her doctor. If the symptoms seem to be related to an allergen, they will most likely be referred to an allergy specialist. An allergist will likely perform a test to determine which specific allergens cause the patient to have symptoms. Ask the employee if they would be willing to share a copy of these results with you for the purposes of finding a solution to the problem. Also be sure to ask if the employee's physician had any suggestions as to the cause of the symptoms.

Keep in mind that any medical test or treatment is confidential and an employee is under no obligation to provide an employer with this information. If an employee does volunteer to share this information, you cannot share the information with others, such as your environmental consultant, without the employee's permission.

The next step in your investigation will probably be to hire an environmental consultant to help with your investigation. A qualified consultant that specializes in IAQ will have the necessary skills to solve any legitimate IAQ problem. Most of these individuals either have degrees in environmental science or are certified industrial hygienists who specialize in understanding how the workplace environment affects workers.

Your environmental consultant will probably take air or dust spot samples and have these tested at a laboratory to see if they contain any of the allergens that were determined by the effected employee's allergist.

If allergens are present, a variety of methods will be used to track down the source of the problem. Air sampling gives us a snapshot of what is in the air right now. Dust samples tell us what pollutants have been in the air over a much longer period of time.

Occasionally, the news media reports on a disease cluster in a particular industry or a particular workplace. A disease cluster is an unusual grouping of a health problem such as a group of individuals from one department getting a particular form of cancer or several women in one building having miscarriages within a short period of time. Some diseases such as Legionella or tuberculosis tend to occur in clusters of people who work or live together.

Most suspected cases of disease clusters turn out to be statistically insignificant, meaning that the apparent cluster is simply a coincidence.

However, throughout history, many industries had clusters of disease caused by problems with the air quality in the workplace. The most well known of these is probably asbestosis or specific cancers that result from exposure to asbestos fibers. Whenever there is concern there may be a disease cluster in a facility, you should not hesitate to request assistance from your local or state department of health.

EFFECTIVE COMMUNICATION

There may not be any other facilities issue that can escalate from concern to panic as quickly as concerns about IAQ. Maybe it's fear of what can't be seen or fear of possible outcomes such as cancer, asbestosis, or other health risks. Even when the risks are small or when suspected problems are unfounded, panic and mistrust are always lurking around the corner wherever IAQ is concerned.

The rule concerning IAQ investigation should be to act quickly.

Some IAQ worries can be dangerous and should be treated as urgently as any life-safety issue would be treated. Acting quickly can protect people from actual harm if it exists and helps assure staff that the organization takes their concerns seriously, and is being diligent in solving the problem. Not responding quickly validates fears that the company knows about a health risk and is hiding something. It's not enough to just investigate quickly. Concerned staff need to be kept informed.

IAQ investigation can be a lengthy process. Time spent collecting data or waiting for an environmental consultant's report can be seen as stalling. It is vital to make an effort to keep staff informed at every step in the process and to regularly remind them that action is being taken to find a solution. To avoid problems of rumors starting from a misunderstood or forgotten conversation, put it in writing. Regular and frequent emails or memos to staff can have a huge impact on how your investigation is received. A brief note explaining what has been done so far to solve the problem and a timeline for work to come will ensure that everyone has accurate information and not harmful rumors.

Consider sending these informational emails or memos not only to the staff immediately affected but to the entire department, floor, wing, or the entire facility.

PM TASKS THAT EFFECT IAQ

Many of our normal PM tasks will have an impact on our buildings indoor air quality. SECTION 11 lists many PM tasks that should be performed. A few that effect PM are:

Pouring water into floor drains monthly prevents floor drains from drying out and losing their seal against sewer gasses. Sewer gas entering a building is a very common cause of bad odor IAQ complaints.

Changing air conditioner filters quarterly keeps air flowing through the filter to remove larger pollutants and dirt particles from the air. If we don't change filters, the filters will eventually become so clogged with dirt and dust that air will find a path around the filter and will not be filtered at all.

Having boilers, furnaces and other gas burning appliances serviced annually will help to assure that burners are operating efficiently and not creating poisonous carbon monoxide gas. Changing CO detector batteries twice a year and changing CO detectors every two years also helps to keep dangerous CO away from the third P, people.

Inspecting exhaust fans quarterly and changing belts and greasing bearings will maintain air exchanges within your building at appropriate levels. Maintaining proper air exchange rates prevents the build up of human odors and carbon dioxide. Keeping exhaust fans operating in areas where odors are generated such as rest rooms, kitchens, and maintenance shops will help to stop IAQ odor complaints.

Roof inspections are intended to prevent water from entering a building. Wet building materials can often result in mold growth. Many individuals are sensitive to specific species of molds and can cause allergic reactions or trigger asthma. Roof inspections can therefore have an impact on the indoor environment.

Keeping air conditioner condensate drain lines clear of obstructions will prevent standing water and mold growth in condensate trays. These are only a few of the many PT tasks that can have a positive impact on the quality of indoor air.

SUMMARY

• Indoor air quality problems involve the three P's: pollutants, pathways, and people.

• Issues such as temperature, humidity, and air exchange rate are comfort issues and are not necessarily IAQ issues.

• IAQ problems can be solved in three ways, the three P's.

• Pollutant solutions include physically removing the pollutant source from the building, finding a substitute product for the pollutant, removal of the pollutant by increasing exhaust ventilation at the pollutant source, bringing in fresh air to dilute the pollutant, or eliminating a particulate pollutant with proper selection of air filters.

Pathway solutions include both creating a physical barrier between the pollutant and affected people and rebalancing pressure relationships with mechanical ventilation.

• People solutions involve relocating affected people away from the pollutant or limiting exposure time.

• The term "sick building syndrome" is used to describe cases where building occupants experience physical symptoms while in a building that disappear when the person is no longer in the building.

• Suspected cases of sick building syndrome require the collection of data, including physical symptoms, temperature, humidity, and carbon dioxide levels.

• If a building occupant suspects that they are suffering symptoms from something at work they should be encouraged to see their physician to help determine the actual cause of the symptoms.

• Environmental consultants can offer valuable assistance in investigating and solving IAQ problems.

• Keeping building occupants informed during IAQ investigations will help to prevent the fears, mistrust, and panic which often accompany IAQ concerns.

• Many of the PM tasks that we perform can have a positive effect on IAQ and can prevent many IQA problems.