AMAZON multi-meters discounts AMAZON oscilloscope discounts

Air conditioning is one of the areas where proper preventive maintenance can have one of the biggest impacts on a facility's long-term costs. On average, a facilities HVAC system accounts for about 11% of total construction costs. Proper PM of HVAC equipment is important, but these systems are often complex and rely on engineering principles that not all maintenance technicians understand. If you are fortunate to have an HVAC technician on your staff, PM of your air conditioning equipment will be a simple in-house task. If you are relying on maintenance technicians from other trades your pm program will be more successful if they have a fundamental understanding of air conditioning equipment and its operation.

Federal law requires that anyone who does work on the closed refrigerant circuit of air conditioning systems be certified by the EPA in the proper procedures for working with refrigerants. Since most refrigerants contain chemicals that can contribute the depletion of the ozone layer, and global warming, there are specific procedures that must be followed to prevent the release of refrigerant to the environment. Most PM can be performed without doing any work on the closed refrigerant circuit, but any work done on the closed system will need to be done by someone with the proper EPA certification for the type of refrigeration equipment being serviced.

As part of striving for continual improvement in your PM program, consider offering HVAC training to your maintenance staff as part of investing in your people. Many community colleges and local vocational schools offer evening courses in air-conditioning installation and service.

When the necessary skills are not available in your department, it is usually money well spent to sign a PM maintenance contract with a service company who does have the required skills. A service company will cost more than doing PM in-house, however the savings realized by doing PM correctly will more than offset the cost of the PM contract.

In one facility where I worked, signing a $8,000 PM contract on food service equipment reduced the cost of repairs from $23,000 to $7000 in the first year.

This SECTION on air conditioner operation is not to be a substitute for formal training in air conditioning service. Sometimes budgets or other factors require that we start our PM program with in-house staff, even if they may not have all the skills we would like them to have for the job. Remember, some PM is better than no PM. As your PM program becomes successful, you will be able to hire qualified HVAC service staff, contract the work out, or get your existing staff the proper training to perform the work. In the mean time, this SECTION's overview of HVAC systems will help to explain some of the preventive maintenance work required.

Air conditioning and refrigeration systems are sized according to the amount of heat they can remove from a building. The two commonly used measurements of cooling or heating capacity are Btus per hour (British thermal units) or tons. One ton of cooling is equal to 12,000 Btu/hr, which is the amount of cooling required to convert one ton of water at 32ºF to ice in a 24-hour period. Window or thru-the-wall air conditioning units are usually 2 tons or less, rooftop units (RTUs) are typically between 5 and 30 tons of cooling and centralized chillers are usually sized between 100 and 500 tons. Of course these numbers can and do vary.

REFRIGERATION MACHINERY

Most of the air conditioning systems in use in facilities use the same technology that was invented by the engineer Willis Haviland Carrier in 1902. The refrigeration machine was invented to control temperature and humidity during printing operations and was used exclusively for industrial operations for the next two decades. Air conditioning wasn't used for human comfort until Carrier air-conditioners were installed in the J.L. Hudson Department Store in Detroit in 1924. Air conditioning caught on and most of us cannot imagine a world without it today.

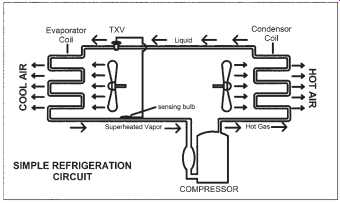

Small modifications have been made over the years but the basic design and operating principals have remained the same. Before we get into the preventive maintenance of HVAC systems, let's go over a short explanation of how a refrigeration circuit actually works. Please refer to FIG. 2.

FIG. 1. This 20-ton rooftop air conditioning unit has enough cooling capacity

to produce 20 tons of ice in 24 hours.

FIG. 2. Components of a simple refrigeration circuit.

The refrigeration system is a closed circuit. Nothing gets in and nothing gets out. The system contains refrigerant, lubricating oil for the compressor, and nothing else. Filters and dryers are usually included to make sure no other contaminants or water are present in the closed system.

The refrigerant is moved through the refrigeration circuit by the compressor. The compressor draws in refrigerant vapor on its inlet side (called suction or low pressure side) and compresses it to a high pressure which is discharged on the outlet side (discharge or high pressure side) of the compressor.

This high pressure refrigerant vapor continues through the refrigeration circuit until it reaches the condenser coil. Air is blown across the condenser coil to remove much of the heat from the refrigerant thereby cooling the refrigerant inside the coil. As the refrigerant cools, it condenses into a liquid. This is very similar to water vapor condensing on the outside of a cold glass on a humid day. In practice, the condenser coil is located outside of the building or in some way designed to expel the heat to the outside environment.

The cool liquid refrigerant, still at high pressure, is moved along from the condenser coil until it reaches the expansion device. An expansion device is nothing more than a small restriction that only allows a small amount of refrigerant to pass. There are different types of expansion devices. The simplest is called an orifice and is just a round disk with a small hole in the center. Different size holes are available for different size air conditioning equipment. The most common type of expansion device on commercial equipment is the thermostatic expansion valve or TXV. A TXV has a temperature sensing bulb and internal bellows and is able to adjust the size of its orifice to maintain a constant refrigerant temperature in the evaporator coil. Electronic expansion valves (EXVs) are an electronically adjustable version of an TXV.

Since the expansion device only has a very small opening, the refrigerant sprays out of the device in a mist of small droplets comparable to the spray from an aerosol paint can. The spray of refrigerant is now at low pressure and is moved along into the evaporator coil, sometimes referred to as a direct expansion (DX) coil. The evaporator coil is the coil where cooling takes place. Liquid refrigerant, at low pressure evaporates in the evaporator coil and becomes a low pressure vapor. As the refrigerant evaporates, it absorbs heat from the air passing over the coil. When the air gives up its heat to the expanding refrigerant, the air is cooled.

This is the fundamental principal that makes air conditioners work: as the refrigerant evaporates, it absorbs heat from the air.

If you want to see an example of an evaporating liquid absorbing heat, put a little rubbing alcohol on the palm of your hand. When the liquid rubbing alcohol evaporates it makes your hand feel cold. This is because the evaporating alcohol absorbs the heat from your palm. All liquids do this. Some do it better than others which is the reason some liquids make good refrigerants and some don't.

Leaving the evaporator coil, we have a warmer refrigerant vapor that makes its way back to the compressor inlet (suction side) to be compressed back into a liquid and start the journey all over again.

This is the basic principal of nearly all air conditioning systems.

The cold evaporator coil is used to make building air cold and the hot condenser coil is used to release the absorbed heat to the outside. Air conditioners don't really create any cold, they just absorb heat from the inside air and expel that heat to the outside air.

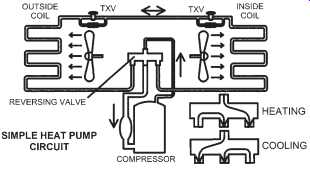

FIG. 3. Components of a simple heat pump. Notice how the reversing valve

effectively swaps the two coils.

HEAT PUMPS

Heat pumps are air-conditioners run in reverse. Many heat pumps can be used to both cool and heat building air. Heat pumps work by using a traditional refrigerant circuit with one added component, a reversing valve. A reversing valve is an electronically operated valve that effectively switches the positions of the evaporator coil and condenser coil in the refrigeration loop.

With the reversing valve in the normal, or cooling position, the refrigeration loop works exactly as described above and the system will cool the building as expected. With the reversing valve in the reversed or heating position, the evaporator coil inside the building becomes the hot condenser coil and the condenser coil outside the building becomes the cold evaporator coil. In the reversed mode, a heat pump will absorb heat from the outside air and release that heat into the building to warm the building space.

As long as the outside air is warm enough for the heat pump to be able to absorb heat, usually around 40ºF, heat pumps are a more efficient source of heat than either electric heat strips or combustion heating equipment. However, once outside temperatures drop below this temperature, another source of heat must be available. Often electric heat strips are included as supplemental heat. Because of this limitation, heat pumps may not be an economical choice in cold climates.

Heat pumps are more efficient than other types of heat because heat pumps do not need to produce heat, they only move heat from one place to another. Other types of heating equipment produce heat by burning gas or oil or by using electric current to heat a high resistance wire. This approach converts fuel or electricity to heat. Heat pumps don't do this. Heat pumps move heat from one place to another. It takes much less energy to move heat that is already there.

Coefficient of performance (COP) is used to compare the efficiency of different types of heating equipment. Electric resistance heaters have a COP of 1.0 since one unit of electricity is converted to one unit of heat. A COP of 1 means the efficiency is 100%. Heat in equals heat out.

Heat pumps can have a COP between 2.8 and 4 since they can have a heat output that is 2.8 to 4 times as large as the electricity they use. This makes heat pumps a very cost effective choice in most climates.

PREVENTIVE MAINTENANCE OF AIR CONDITIONING AND REFRIGERATION EQUIPMENT

A common air conditioner configuration is for the condenser coil, compressor, and condenser fan to be installed outside the building as one unit and for the evaporator coil, expansion valve and evaporator blower to be installed inside the building. This type of system is called a split system. The outside equipment is simply called the condenser unit and the inside unit is usually called an air handler or DX unit for direct exchange.

Another common configuration is for all of the parts of the air conditioning circuit are installed in one unit, this is known as a package system. A package system can be installed inside the building or outside. When a package unit is installed outside, building air is taken to the unit to be conditioned through ductwork. When a package unit is installed inside a building, hot air is discharged to the outside through ductwork.

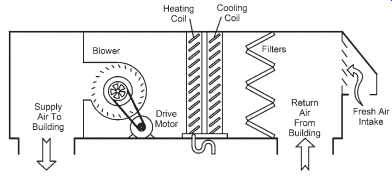

FIG. 4. Components of a typical air handler unit.

In either case, the condenser equipment is kept separate from the air handling equipment, even when they're installed in the same cabinet.

The condenser side of the system is responsible for removing heat from the system to the outside air and the air handler side of the system is responsible for cooling the air and delivering the cooled air to occupied spaces.

The air handling side of the system can also include heating equipment, filters to clean the air, outside air dampers or economizers to allow fresh air to enter the building, humidifiers, and other equipment.

Preventive Maintenance of Condensing Units-Compressors:

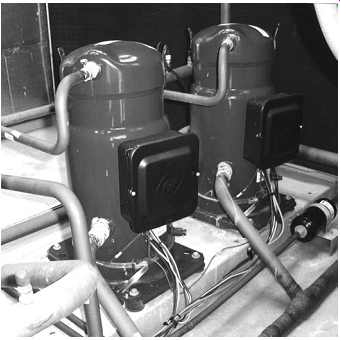

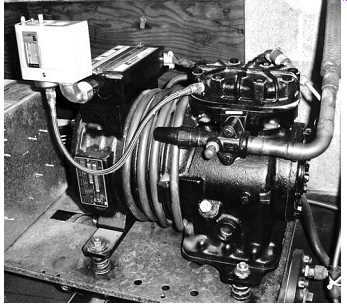

With the exception of large chillers providing hundreds of tons of cooling, most air-conditioning and refrigeration equipment uses reciprocating type compressors. These have pistons that move up and down and compress refrigerant with each piston stroke.

The compressors of small air-conditioning and refrigeration equipment are often hermetically sealed inside a welded canister and are not serviceable. If a hermetically sealed compressor fails, it is simply cut out of the refrigeration circuit (after the refrigerant is recovered from the system) and a new compressor is brazed in its place. Larger air conditioning equipment, usually over 7 or 10 tons cooling capacity, may use compressors that can be serviced. These semi-hermetic compressors can be disassembled and repaired on-site rather than discarded and replaced. The current trend is for larger cooling units to use multiple smaller hermetic compressors and as a result semi-hermetic compressors are becoming less common.

FIG. 5. Hermetic compressors are completely sealed and have no serviceable

parts.

Like most rotating machinery, the most important part of refrigeration compressor preventive maintenance is lubrication. Many serviceable refrigeration compressors have oil sight glasses where the oil level in the compressor can be checked visually. The oil line should be visible on the sight glass. If not, oil can be added to the system using a pressurized oil pump. This needs to be done by someone with the proper EPA certification to work on the closed refrigerant system. Unless the closed refrigerant loop has experienced a refrigerant leak, the oil level in the system should not change.

Refrigerant oil selection is critical. Not all refrigeration oils are compatible with all types of refrigerant and not all refrigeration oils can be mixed with the oils already in the system. There are an enormous number of mineral and synthetic refrigerant oils and the wrong oil will not blend with the refrigerant and will cause oil starvation and compressor failure. Always refer to the manufacturer's requirements on oil selection.

FIG. 6. Semi-hermetic compressors can be disassembled for repair.

Notice the oil sight glass on the bottom right for checking the oil level.

Preventive Maintenance of Condensing Units--The Condenser Coil

Condenser coils need to be kept clean. Dirt blocks air flow and reduces the rate that heat can flow out of the coil into the outside environment.

Dirty coils make refrigeration equipment inefficient and can cause a system to overheat and shut down all together. If the aluminum cooling fins are bent over or crushed, blocking air flow, a fin comb should be used to straighten the fins.

Condenser coils are usually not protected by any type of filter.

Condenser coils need to be cleaned annually, at the start of the cooling season. There are a variety of cleaners available that are sprayed on the coils and hosed off with water several minutes later. Condenser coils located outside on the ground (hopefully on a concrete or plastic pad) should have all leaves and other debris removed from inside the condenser unit and all grass, weeds, and shrubbery needs to be kept and at least 18" away from coils to allow for enough air flow around the coil.

Preventive Maintenance of Air Handlers--The Evaporator Coil

Evaporator coils (the inside coil) is protected by a filter. If a filter is blocked with dirt and dust, air will start to find a path around the coil.

When this happens, the dirt in the air bypassing the filter will clog the evaporator coil. It is important that air conditioner filters are changed frequently. Operating environment, hours of operation, and other factors will effect the necessary frequency of filter changes but most organizations change filters quarterly.

If filters are kept clean, evaporator coils need little maintenance. Air handler cabinets should be opened annually, at the start of the cooling season. Check the coil for dirt build up and use a fin comb should to remove any dirt or lint that has built up on the intake side of the coil.

Liquid coil cleaners are available but probably aren't needed and can create a housekeeping mess since many of the cleaners foam up and drip off of the coil missing the condensate pan.

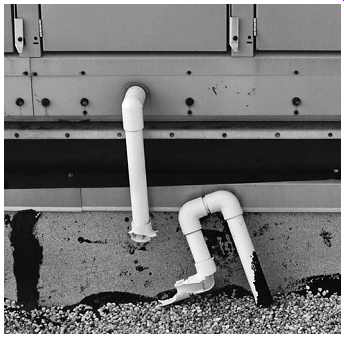

FIG. 7. A quick visual inspection of the entire unit when performing PM

will catch obvious problems like a broken condensate drain trap.

Preventive Maintenance of Air Handlers--Air Filters

The primary function of an air filter is to protect heating and cooling coils from becoming clogged with dirt and dust present in the air stream. For many years, protecting coils from clogging was the only consideration when selecting and installing air filters. Since small particles and fibers will pass through coils without clogging them, "furnace filters" were designed to only catch the largest particles. Since the air passing through the filter and into the building was building air mixed with some fresh outside air, it was at least as clean as the outside air.

At the time, this was considered sufficient filtering.

Today's workforce is concerned about indoor air quality (IAQ), sick building syndrome, allergens, and other health concerns related to air contaminants. Indoor air that is as clean as the air outside is no longer considered acceptable and air filters need to eliminate more and smaller dust particles. The facilities manager or maintenance supervisor needs to understand how filter efficiency is measured and how it relates to removing contaminants from the air.

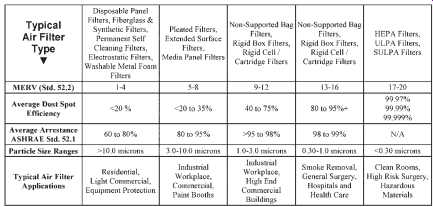

There are presently three systems that manufacturers use to determine and specify how well a filter removes dust particles from the air. These three systems were established by the American Society of Heating, Refrigeration, and Air Conditioning Engineers as ASHRAE standards 52.1 and 52.2.

The first rating system is the dust weight arrestance rating which indicates how well a filter captures dust particles and fibers larger than 10 microns. It is used to evaluate fiberglass mat type furnace filters that are intended to protect heating and cooling coils but are not very effective on fine dusts, mold spores, pollen, or other tiny allergens which may contribute to IAQ problems.

The second filter efficiency rating system is the dust spot efficiency rating which indicates how well a filter captures smaller particulates (.3-6 microns) such as fine dusts and smokes. This test is usually used to evaluate pleated and fabric bag type filters. These filters do remove much of the fine particles which contribute to IAQ difficulties.

The third and newest filter efficiency rating system is the MERV or minimum efficiency reporting value. This test measures a filters effectiveness at collecting both small and large particles (.3-10 microns) and has been the established standard since 1999. However, all three standards are still in use.

Since all three standards measure the efficiency of a filter to collect particles of different sizes, there is no way to directly compare one rating system to another. FIG. 8 shows some guidelines for comparison but since the three different systems measure different performance characteristics; there is no way to convert one system to another. Use FIG. 8 only as a rough guide for comparison.

When choosing filters, more filtration is not necessarily better.

Higher filter efficiency means reduced air flow, greater pressure drop across the filter, and more frequent filter changes since higher efficiency filters will load up with dust faster. Higher efficiency filers also cost more. Filters with MERV ratings over 8 may require modifications to ductwork to allow larger filter banks for sufficient air flow.

Most commercial office buildings, schools, and similar facilities should be using air filters with MERV ratings between five and eight.

Under most conditions, filters with these ratings will need to be changed roughly four times each year.

FIG. 8. Comparison of various filter rating systems

Preventive Maintenance of Air Handlers--Condensate Equipment

Humidity in the air will condense on the cold surface of evaporator coils. For larger air conditioning equipment, this condensate can amount to several gallons an hour in humid conditions. This is good since one of the functions of air-conditioning is humidity removal, but something needs to be done with all that water.

In most cases, there is a galvanized steel or plastic tray under the evaporator coil that catches the condensate dripping off the coil.

Condensate trays or pans need to be inspected annually, at the start of the cooling season, to be sure the tray is sloped toward the drain, to make sure the tray is not growing algae, to check steel condensate trays for rust or holes, and to check the tray for foreign matter and dirt which could clog the condensate drain line.

Dirty condensate trays can be rinsed clean with a garden hose.

Algae control tablets can be added to the tray to prevent algae growth, and epoxy sealers can be applied to repair any rust or corrosion holes.

Because condensate flow is so slow in the condensate drain lines, condensate lines tend to clog easily. The slow dripping of condensate simply isn't fast enough to flush all of the debris from the drain line.

Drain lines should be blown out with compressed air at the start of the cooling season. This can be done by blowing air from the air handler end of the drain line or from the end that is opened to the outside or to the building's sanitary drains.

When an air handler (and the incorporated evaporator coil) is located in a basement or otherwise below the level of condensate discharge, a condensate pump is used to pump condensate water up to the proper location. A failed condensate pump will cause a minor flood. Condensate pumps should be tested quarterly. Either pour water into the condensate pump or operate the float switch manually to be sure the pump operates properly. Watch the water level in the sump to be sure it goes down when the pump operates.

Preventive Maintenance of Air Handlers--Blowers

Every air handler uses a fan to move conditioned air to occupied spaces. These fans are usually centrifugal fans, also called "squirrel cage fans." Fan blades need to be kept clean, dirt on fan blades can greatly effect the efficiency of the fan and therefore how much air the fan can move. Fans should be inspected twice annually, at the start of the cooling and heating seasons, and cleaned when needed.

Bearings need to be oiled or greased quarterly or according to the manufacturer's recommendations. Belt drives should be checked quarterly and tension and alignment adjustments made and worn belts replaced. It's a good idea to stock at least one set of belts for each air handler. This will save time having to return to replace belts at a later date if a problem is discovered.

Preventive Maintenance of Air Handlers--Heating and Other Equipment

Air handlers can include many types of heating equipment. Usually the heating equipment is in series with the cooling coil and air is drawn by the blower motor through both the heating and cooling equipment during all seasons. A lockout circuit prevents both heating and cooling equipment from working at the same time unless wintertime humidity control is a problem. In that case, heating and cooling equipment may operate together.

The most common problem with electric heat is burned out heating elements or blown fuses serving the individual elements. At the start of each heating season, the heat strips should be visually inspected and your HVAC service tech or electrician should take an amperage reading of each heat strip in operation. This will reveal any heat strips that are not functioning or heat strips that are drawing more than their rated amperage and likely to fail.

Gas heating equipment should be serviced annually, at the start of the heating system. Burners should be cleaned, gas pressure checked, igniters or pilot flames tested and the operation of flame sensors verified.

The burner flame should be adjusted for highest efficiency. Finally the heat exchanger needs to be inspected for any cracks to make sure that combustion gasses, including carbon monoxide, aren't getting into the building air stream.

Oil burners should have nozzles replaced annually. Igniters and flame sensors need to be tested for operation. Oil filters should be changed annually and the oil pump pressure verified. Combustion gasses should be analyzed to determine burner efficiency. Finally the heat exchanger needs to be inspected for any cracks to make sure that combustion gasses, including carbon monoxide, aren't getting into the building.

Many air handlers will include a heating coil in addition to the evaporator cooling coil. This heating coil can be a hot water or steam coil which is provided with hot water or steam from a separate boiler plant located elsewhere in the building. The heating and cooling coils can be stacked on top of each other or even designed as one coil assembly with two sets of pipes, one for cooling and one for heating. Heating coils require the same inspection and cleaning schedule as evaporator coils discussed earlier.

COOLING TOWERS AND COOLING LOOPS

So far, we've only discussed air-conditioning equipment that exchanges heat directly with the air. Usually by absorbing heat from the air inside the building and expelling that heat into the air outside the building. Larger HVAC systems often use water as a heat exchange medium and use pipes and pumps to move the heated or chilled water from one place to another. Water can absorb and hold more heat than air and it is more efficient to exchange heat with water.

There are so many variations of using water as a heating or cooling medium that including all the different types would be impossible but we'll discuss some of the more common variations.

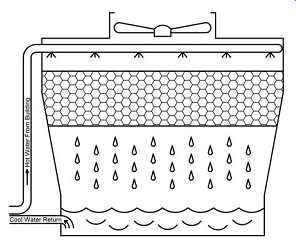

The most common method of using water to exchange heat with the outside air is a cooling loop leading to an evaporative cooling tower.

A refrigerant condenser coil is often placed in a bath of water and the water is used to absorb heat from the condenser coil to cool the refrigerant.

The hot (or at least warm) water is then pumped to a cooling tower outside of the building where it flows under gravity down a series of screens while cooling tower fans draw air through the hot water. Some of the hot water evaporates taking heat away from the remaining water leaving cool water. The cool water is pumped back into the building to cool the condenser again. The water loop that cools the condenser coil is called the condensate water loop which should not be confused with condensate water that drips from an air source evaporator coil. There are four common types of cooling towers and a cooling tower that has the condensate water open to the atmosphere as discussed above is often called a wet cooling tower.

FIG. 9. Water in a wet cooling tower cascades down through a series of

screens while air is drawn across the water to remove heat. The cooled water

is returned to the building.

FIG. 10. This hybrid cooling tower has a closed condensate loop that flows

through a closed cooling coil. A separate source of water flows over and

cools the water in the coil.

FIG. 10. This hybrid cooling tower has a closed condensate loop that flows

through a closed cooling coil. A separate source of water flows over and

cools the water in the coil.

Cooling towers can also have a closed water coil similar to a refrigerant condenser or evaporator coil. Fans draw air through the coil to remove heat from the water inside. With this type of cooling tower, no water is evaporated or open to the outside air. This type of cooling tower is often called a dry cooling tower.

A third type of cooling tower is a hybrid of the wet and dry cooling towers. This hybrid cooling tower has a closed coil as with the dry type tower but also has its own source of open water that is sprayed over the closed coil to provide more efficient cooling than air alone.

There is a fourth type of cooling tower that does not use a water loop at all called an evaporative condenser. An evaporative condenser is similar to the hybrid cooling tower example above except that refrigerant flows through the coil within the cooling tower. Instead of using a water loop to transfer heat from the building to the cooling tower, the refrigerant condenser coil is located within the cooling tower. Water is sprayed over the surface of the refrigerant condenser coil. The evaporation of water in the cooling tower absorbs heat directly from the refrigerant more efficiently than a traditional air cooled condenser coil.

In most HVAC systems using cooling towers or central chiller plants, the cooled water is circulated throughout the entire building and circulated through cooling coils or used to cool condenser coils of individual air conditioning units serving each area of the building.

Boilers can be part of the same water loop to provide warm water as a source of heat for individual heat pumps or water source heating coils for each location.

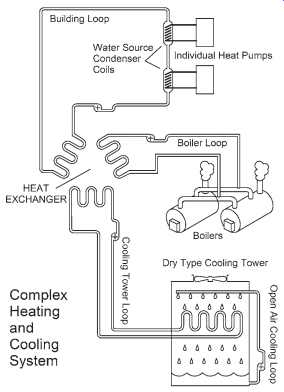

FIG. 11. A complex heating and cooling system utilizing four separate

water loops to transfer heat from one component of the system to another.

As an example of how complicated these systems can become I have worked in a building that used 4 separate water loops to transfer heat and one refrigerant loop. A drawing of this system is shown in FIG. 11.

This particular system used more than 40 individual water source heat pumps throughout the building.

Each of these heat pumps had its own refrigerant loop and exchanged heat through a condenser coil immersed in a water loop that ran through the building to each heat pump. This building loop exchanged heat with a cooling tower water loop in the summer or with a boiler heated water loop in the winter through a plate type heat exchanger. The cooling tower was of the dry type and had its own internal water loop to remove heat from the cooling tower loop between the cooling tower and heat exchanger.

Preventive Maintenance of Cooling Towers and Cooling Loops

PM of cooling towers is straightforward once you understand the separate parts that make a cooling tower work. Spray pumps should be greased quarterly when the cooling tower is in operation. Cooling tower fans and motors should be greased quarterly and belt drives checked and adjusted quarterly. Spray nozzles can clog and should be inspected monthly and cleaned or replaced as needed during cooling tower operation.

During the monthly inspection, verify operation of any automatic makeup water valves. Cooling towers should either be drained for the winter to prevent ice damage or should have water heaters that maintain the water above freezing temperature. These heating elements should be checked prior to the cold season. Leaves and other debris should be removed from the cooling tower sump monthly or more often if clogging is an issue. Once each year, the tower should be drained and the water pan checked for rust or corrosion. Epoxy coatings are available to repair minor damage and leaks to cooling tower pans and there are companies that specialize in doing this work.

The only maintenance that is required for cooling loops is chemical treatment. Chemicals to prevent corrosion and scale buildup should be added to the closed cooling loops, either by automatic treatment equipment or manually by your service company. All systems are different and there are many chemical treatment options available. A local chemical treatment company or your HVAC service company can best help you decide what chemical treatment options are best for your facility.

CHILLERS

Very large facilities often rely on chillers instead of conventional air conditioners for their cooling. Chillers are often sized to provide hundreds of tons of cooling capacity in one relatively compact machine.

One or two large chiller plants is often used to provide cooling for an entire building or even an entire campus of buildings.

Chillers are large self contained water chilling machines with all of the parts of the refrigeration machinery built into one unit. Heat from the building can be exchanged directly with the outside air or can be exchanged through a water loop and cooling tower. In either design, chillers cool a large volume of water which can be circulated throughout the building to provide space cooling via water source duct coils, or unit ventilators.

Chillers operate like conventional air conditioners with one notable exception. The refrigerant compressor is often of a unique design. Like conventional air conditioners many smaller chiller plants use reciprocating refrigerant compressors, often several compressors on one machine.

However, larger capacity machines often compress the refrigerant using a high-speed centrifugal compressor with an impeller which can rotate as fast as 50,000 RPMs compressing the refrigerant through centrifugal force.

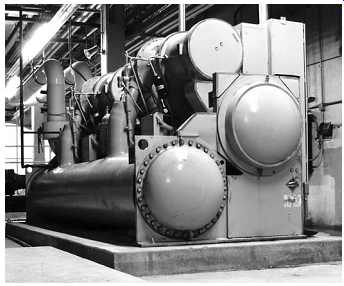

FIG. 12. Centrifugal chillers are complex and expensive machines and should

be PMd by factory-trained personnel.

Sophisticated onboard computers manage every detail of chiller operation. Compressor speed and staging, condenser and cooling water flow, water temperatures, refrigerant pressures and temperatures, expansion valve position, and many other items are managed constantly to ensure energy efficient operation.

Every manufacturer has different maintenance procedures for their chillers and there is probably no other single piece of equipment in your building, with the possible exception of the roof, where improper maintenance could be more costly. In one example from my work, A 250 ton chiller most likely had an incorrect expansion valve adjustment. This allowed a small amount of liquid refrigerant to enter the compressor while the impeller was spinning at full speed. When the rotating impeller struck the liquid refrigerant at high speed, the impeller shattered leaving shards of metal which were pumped throughout the machine along with the refrigerant and oil. The repair cost was over $40,000.

Manufacturer's maintenance standards must be followed, preferably by factory trained and certified personnel. I am a big believer in a skilled maintenance department handling nearly every project in-house.

Chillers are the exception. Skilled in-house HVAC personnel can handle basic repairs to equipment related to the chiller such as circulating pumps, flow switches, chemical treatment systems, and other items. The chiller itself should be maintained by someone who is an expert in your particular brand of chiller.

AUTOMATED CONTROLS HVAC

systems are almost certainly the most complex systems found in any commercial building. In the recent past, the temperature of each part of a building was controlled by individual stand alone air conditioning units. In many buildings, hot water or steam was piped throughout the building and there was no individual temperature regulation for each area. Either the heat was on for the building or it was off. Cooling was often controlled locally because ac units were small but there were no provisions for humidity control or any strategy to make the HVAC systems energy efficient.

By contrast, in most of today's buildings, all of the heaters, air conditioners, exhaust fans, variable frequency drives, circulating pumps, outside air dampers, cooling towers, and a network of temperature, humidity, and occupancy sensors work together, as one large system to monitor and control every aspect of a building's environment. Having such complex HVAC systems allows us to provide more comfortable interior conditions then ever before while wasting less energy.

The downside of HVAC systems that utilize these direct digital controls (DDC) or building automation controls (BAC) is that they limit the amount of repair work that can be done in-house. Most HVAC systems require outside contractors to maintain the digital control portion of the system. This small problem doesn't mean that automated HVAC controls are a bad thing. A good building automation system will save much more in energy costs than will be spent on competent service people to maintain the system's original operating parameters.

The most common problem with networked or integrated HVAC systems is that they are constantly being "tweaked" by in-house staff to the point that they no longer function as designed. Small adjustments and minor changes to the system are made by well meaning maintenance workers. Over several years, so many small changes are made that the system can no longer do its job as it was designed.

The maintenance department might be asked to adjust an air damper to satisfy an office worker who doesn't like to feel a draft. A well intentioned maintenance mechanic might disable an outside air damper to prevent rain from blowing into the building. We might rewire a networked AC unit to operate from a wall thermostat if a company executive complains about not having direct control of the temperature in her office. Add up these small modifications that are done over the years, and it's easy to see why so many building automation systems end up as expensive and complicated disasters.

Automated environmental control systems are good for buildings.

They have been around for a couple of decades and are getting smarter all the time. They do an excellent job of keeping occupants happy while conserving as much energy as possible. However, they are fragile systems and must be maintained properly by people who understand the intended operation and design of the entire system.

One of the most effective ways to maintain the original intended operation of automated controls is to write a controls narrative which briefly and simply describes the operation of the entire system. This narrative can be posted permanently in boiler rooms, mechanical rooms, and inside equipment cabinet doors. The narrative should explain the function of all the system components and explain what environmental conditions trigger what type of system response.

With a controls narrative available to everyone who works on the system, it is more likely the original intended system operation will be maintained.

HVAC PM CHECKLIST

The following checklist of items will help you when setting up your preventive maintenance schedule.

-- Clean condenser coils annually at the start of the heating season

-- Keep all vegetation at least 18" from condenser coil

-- Change air handler filters quarterly

-- Check evaporator coils annually at start of cooling season for dirt.

-- Check condensate trays, treat tray with algae control tablets, and clean condensate drain lines annually

-- Test condensate pumps monthly

-- Inspect air handler blower fans, belts, and motors twice annually.

-- Oil or grease blower motors quarterly

-- Take ohm readings of electric heat strips annually at start of heating season. Replace any defective elements or blown fuses

-- Have gas or oil fired heating equipment serviced professionally annually at the start of the heating season

-- All circulating pump motors need to be greased or oiled quarterly

-- Inspect cooling tower drive belts quarterly

-- Grease or oil cooling tower fan motors quarterly

-- Inspect, clean, or replace spray nozzles on cooling towers monthly during cooling season

-- Clean leaves or debris from the cooling tower sump monthly and check the operation of the sump makeup water valve

-- Cooling tower heating elements should be tested annually at the start of winter

-- Cooling towers should be drained annually to inspect the sump tank for corrosion or rust

SUMMARY

• The HVAC system is one of the most expensive and complex systems found in any building.

• Anyone working on the refrigerant circuit must be certified by to EPA to work with refrigerants.

• The complexity of HVAC systems often makes it necessary to rely on outside contractors to maintain and service HVAC equipment.

• The design of air conditioning equipment has not changed significantly since its invention by Willis Haviland Carrier in 1902.

• Cooling by a refrigeration circuit is accomplished by evaporating a refrigerant with an evaporator coil. The evaporating refrigerant absorbs heat from the surrounding air cooling the air.

• The absorbed heat is then transferred with the refrigerant to a condenser coil where the refrigerant is condensed back into a liquid thereby giving up its heat to the outside air.

• Heat pumps are air conditioners run in reverse. Instead of absorbing heat from the interior space and releasing it to the outside environment, heat pumps absorb heat from outside and release the heat inside.

• Selecting the proper refrigerant oil is critical. The wrong type of oil may not mix with a particular refrigerant resulting in compressor failure.

• Many HVAC systems rely on water to transfer heat from one location to another. Oftentimes, multiple water loops are used to make several transfers.

• Large facilities may use chiller plants to produce chilled water which is used to cool the building space. Chillers are very expensive and complex pieces of equipment and are best maintained by factory authorized service personnel.

• Today's buildings use automated building controls to monitor and regulate all aspects of HVAC within a facility. These systems allow a level of building control and energy efficiency that would not otherwise be possible. The down side to these systems is they must be maintained by technicians with specialized knowledge and skills.