AMAZON multi-meters discounts AMAZON oscilloscope discounts

If you have decided that your facility needs a preventative maintenance program, you will probably need to convince someone in your organization your cause is worthy of funding. The savings a PM program will provide will always be bigger than the costs of implementing the pro gram but there will still be costs. There will be a cost for labor to do the PM work, which may include overtime until the program has an chance to start working. You may decide to invest in some CMMS computer soft ware to manage your new PM program. Some new tools and equipment may be needed to take on some new types of work. Turning your existing maintenance staff into successful preventive maintenance mechanics will probably require some additional training. All of these things cost money and need funding.

It’s important for the maintenance manager to remember no matter what business your company is in, its primary reason to be in business is to make money. Even if you work for a government organization or non profit, money is still going to be the primary driving factor in how your organization operates.

Businesses make capital investment decisions based on the potential return on investment (ROI) of an opportunity. ROI is a comparison of the money that can be made (or lost) from an investment to the cost of the in vestment. An investment with high initial costs and low expected return would be a poor investment with a low ROI. While an investment with a low initial cost and high expected return would be a wise investment with a high ROI. Most good business investments have an ROI in the range of 5% to 15%. This means that for every $100 invested, the expected gross return would typically be between $105 and $115. Businesses are always looking for the opportunities with the highest ROI.

Businesses like to make decisions based on ROI, but it can be difficult to calculate the ROI for the activities of the facilities maintenance department. It’s nearly impossible to predict how much revenue can be made by spending money on a project such as replacing the lobby carpet.

It’s assumed that a nice lobby will have a positive impact on the people visiting your company and therefore lead to more sales and increased employee productivity, but it’s not possible to really know how many more sales or how much more productivity. Therefore, much of facilities budgeting is guesswork and assumptions. Typically, we know what we spent last year so we try to spend about the same this year. No one really considers how an increase or decrease in maintenance funding would affect a businesses profits.

It can be hard to convince senior management to invest in facilities projects, because so much of the work we do contributes to the condition of the workplace but has no measurable return. Therefore, maintenance is usually seen as a cost not an investment. Most senior financial people see maintenance as a necessary evil that does not contribute to the bottom line.

However, preventive maintenance is one maintenance activity of the maintenance department that can be shown to contribute to the bottom line. To know the ROI of a PM activity, we need to know two things: The initial cost or investment and the return, in our case money saved. We know the initial investment because we can predict the man hours and materials needed to perform PM. And, since we can predict how much money we will save by extending equipment life, saving energy, and reducing repairs, we know the return on our investment. Keep in mine that a dollar saved by PM contributes as much to the bottom line as a dollar earned in other business activities. A dollar is a dollar.

PREVENTIVE MAINTENANCE TRUISM #2

A dollar saved through PM is as good as a dollar earned through any other business activity.

THE JONES-LANG-LASALLE REPORT

While PM in various forms has been a part of facilities maintenance for decades, very little research has been done on determining the real world ROI of PM. It has always been assumed that PM has a positive impact due to increased equipment life, energy savings, improved tenant satisfaction, and reduced breakdowns. Every maintenance manager can cite an example of how PM has impacted their business, but very little in the way of hard numbers has been available.

Many organizations have developed industry benchmarks of how much money "should" be spent on PM. Unfortunately, these are based on surveys of what businesses are spending, not on any measure of what spending level has the greatest return on the investment.

In 2000, Wei Lin Koo and Tracy Van Hoy, PE., both working for the real estate management firm Jones Lang LaSalle published a research pa per titled "Determining the Economic Value of Preventive Maintenance." By analyzing maintenance costs across a wide range of facilities, Koo and Van Hoy were able to determine average ROIs for several different types of capital equipment.

Their project looked at 25 years of maintenance and equipment re placement costs for roughly one million square feet of facilities across several industries. They found what many had believed to be true. They discovered that investing in good PM programs had huge financial returns. FIG. 1 shows the average ROI for PM for several different types of capital equipment.

From this chart, it’s clear to see that investing capital in the tools and man power to perform PM can have enormous returns. We said earlier that typical ROIs for successful business investments tend to be in the neighbor hood of 5-15%. ROIs of 500%, 1000%, or 2000% are simply unheard of. I don’t know of any other investment that can provide as high an ROI as a good PM program. These high ROIs are possible because the cost of replacement of capital equipment is so high and the cost of maintaining them is so low.

As an example, if we were to completely neglect a small 1Hp circulating pump, we will probably be replacing the pump at a cost of several hundred dollars in three to five years. With less than ten minutes labor and a few pennies worth of grease every six months, that same pump can reasonably be expected to last 20 years. It’s easy to see how a small investment in labor and materials to grease a pump bearing can prevent the cost of replacing the same pump 3 or 4 times over 20 years.

In future sections of this guide we will be discussing what equipment we will include in our preventive maintenance program and what equipment not to include. The possible ROIs of the different types of equipment will be a large factor in making that decision.

FIG. 2. Money spent on PM for centrifugal chillers has a return on

investment of over 1,000%.

SELLING PM TO MANAGEMENT

If PM is such a sound investment, why do so few facilities have comprehensive PM programs? There are probably three reasons for this.

First, preventive maintenance has not fully caught on in the facilities maintenance field. Industry and manufacturing depend entirely on their machinery and equipment to operate. Industry and manufacturing businesses are crippled every time a machine breaks down. Failing equipment is a daily reminder to plant management that PM is absolutely necessary.

In the field of facilities maintenance, a single broken piece of equipment is not usually crippling to the operation of the business. If one air compressor in a building is off line for a few hours or days, business can usually continue without too much inconvenience. Although the cost of a breakdown is more expensive than the cost of PM, the urgency to in vest in PM is just not there.

PM is often low on the list of management priorities for a second reason. PM addresses problems that might happen, but these problems are not guaranteed to happen. There is a reluctance to spend money on maybes, even if the long-term benefits are obvious. Businesses have limited resources and they already have guaranteed expenses that cannot be ignored. Weekly payroll will happen every week. The electric bill will need to be paid every month. Taxes will be due each quarter. But the cost of a major repair is not as certain.

Even when management understands the value of an effective PM program, there can be resistance to making the necessary small investment to prevent problems that may or may not happen. It’s human nature to assume that since nothing catastrophic happened last month we can probably get by for another month or two without PM. Unfortunately, it’s often the business-crippling equipment failure that pushes PM to the top of management's priority list. When this happens, resist the temptation to say "I told you so."

PREVENTIVE MAINTENANCE TRUISM #3

You cannot save money by skimping on PM

The third reason management is sometimes resistant to invest in PM is that PM does not provide much benefit in the very short term and a lot of the benefits of PM are hard to quantify. When a business invests in opening a new branch, management can see, touch, and feel the new building.

But when they invest in PM, they cannot see what they spent their money on. They see nothing. Of course, in this instance, seeing nothing is a good thing. Nothing is the best thing a maintenance department can have. In maintenance, the alternative to nothing is problems. However, it’s human nature to want to see what we buy. PM does not have anything to show, at least in the short term.

In the long term, the benefits will be seen in reduced maintenance costs and increased maintenance efficiency. It can be hard to convince a lot of people to think in terms of long-term benefits.

Most companies also already have a backlog of things to invest money in that could save them money. Purchasing more efficient heating and cooling equipment to reduce electrical consumption, converting to more efficient lighting, adding insulation to the building's envelope to save heating costs, installing window tinting to reduce thermal heat gain, purchasing new photocopiers that will require fewer service calls, and installing new computer or phone systems that will increase productivity may already be on a companies to do list. Preventive maintenance might be just another money-saving project awaiting funding.

If the money to start your PM program is not available right now, you may be able to start small by excluding equipment from your PM program expecting to add equipment later. Knowing the expected ROI of various types of equipment will help you to make the decision on which pieces of equipment to add. ROI should not be the only consideration if you are forced to limit the equipment to PM. You will also need to consider what equipment is causing the most disruptions to your department and which equipment is having the biggest impact on building occupants.

By choosing to PM the equipment that is taking up the biggest part of the maintenance department's time with repairs, it may be possible to reduce those repairs and find more time to PM more equipment.

PM AS A BUDGETING TOOL

In most organizations, near the year's end, the facilities department is asked to submit a budget for the following year so corporate funds can be allocated as needed. Many facilities departments just add a few percentage points to each line item of this year's budget and assume that costs will remain the same with this small adjustment for inflation.

If we have been performing preventive maintenance to all of our capital equipment and keeping accurate records of maintenance and re pairs, we will be much more prepared to develop an accurate budget of expected expenditures. If we have been inspecting our capital equipment according to our PM program, we will be aware of what equipment needs replacing, what repairs are likely, and can budget more effectively.

In an effort to control costs, facilities departments often attempt to

"limp along" old equipment until it reaches the point that no more repairs can be done. With good repair and inspection records, we will know when the cost of repairs was exceeding the cost of replacement and would be less likely to continue to waste money when replacement would be more cost effective. We can plan to replace equipment that is nearing its end of use and is starting to cost excessive money in repairs and maintenance.

If we are not inspecting our equipment regularly as a part of a PM program and are not keeping accurate records, budgeting becomes a guessing game with lots of unexpected expenses that were not accounted for. We will discuss the details of record keeping later in Section 3.

THE LONG-RANGE FACILITIES PLAN

It can have lots of different names such as "long-range planning,"

"five-year asset improvement plan," "three-year plan" or the "comprehensive maintenance plan" but most organizations try to do some broad planning at least three to five years into the future. The purpose of such planning is two-fold. First, to make sure that there is some continuity to the goals and direction a company is taking rather than changing direction every year.

And second, to anticipate future costs so there are no budget surprises.

Most medium and large companies see the building and property as an important part of its long-term planning and include facilities needs in this planning process. If it’s not already part of your corporate culture, you should try to get your department's long range planning included in the process.

If you have been keeping records of repairs, know your maintenance costs, and have been doing regular PM inspections; you should have an idea of when a particular piece of equipment is nearing the end of its useful life. Having future replacement costs of major equipment as part of the long range plan will help to soften the blow when you need money to make the replacement. The costs of any deferred maintenance projects should also be considered for inclusion in the long range financial plan.

Very large and expensive capital projects such as new roofs, repaving parking lots, and building wide upgrades of electrical or plumbing systems are sometimes only possible if financial plans were made years in advance. For particularly costly improvements, budgeting only one year in advance is often not enough time for the necessary funds to be found.

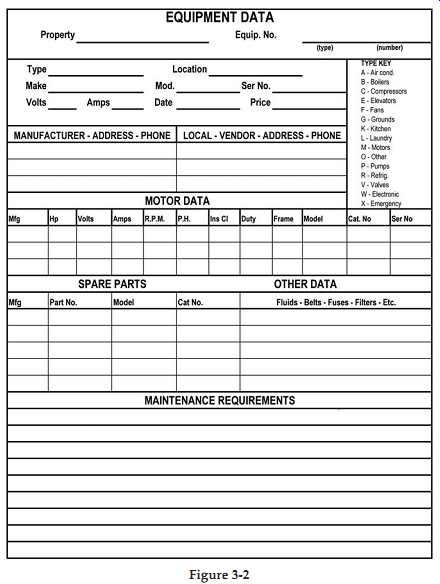

An extended outlook facilities plan should include all of the corrective maintenance (equipment repairs or replacement) and capital improvement anticipated for the next several years. In Section 3, we will discuss developing an inventory of all of a buildings capital assets or equipment.

This list of capital assets should be reviewed and each item's repair and inspection history reviewed to determine what repairs or replacements will likely be needed in the future.

A backlog of maintenance work orders (maintenance requests) and any maintenance tasks that were deferred should also be reviewed for inclusion in the long range plan. Minor maintenance work can be considered the cost of catching up and there may be maintenance requests that are large enough in scope and cost that they warrant inclusion as a capital project. A maintenance request to construct walls to divide a large meeting room into several offices could be one example of work that should be included in long range planning unless budget money and labor is available to do the work now.

THE REPAIR OR REPLACEMENT DECISION

FIG. 3. Making a repair-vs.-replace decision on large equipment, based

on intuition, is a sure way to waste money.

The decision to repair or replace a piece of equipment is one that is made every day by most maintenance managers. When faced with this decision, experienced facilities people usually rely on our experience working with similar types of equipment. We will look over a broken air handler, irrigation pump, or compressor and see there may be other failing components and that the machine is either in relatively new condition or nearly worn out and make a decision based on our gut feeling. It’s not very scientific but it’s the method most of us use. When particularly large and expensive equipment is involved or when expensive repairs are needed, it would be nice to have a way to make the repair vs. replace decision that relies on something more accurate than old fashioned intuition.

We have already discussed several reasons for maintaining good equipment history records. When determining if it will be more cost effective to repair or replace a particular piece of equipment, these records will provide the information to make the right decision and the evidence to convince others that the expenditure is justified.

There are two economic reasons to decide to replace a piece of equipment that has stopped working. The first is the cost of maintaining and operating the equipment will exceed the cost of replacement. The second is other similar pieces of equipment reached the end of their useful life at approximately the age of this one.

The first scenario, repair costs will exceed replacement costs. This is easy to understand. If a RTU (rooftop air-conditioning unit) will cost $9,000 to replace and the expected cost of repairs is $10,000, it makes sense to re place rather than repair. But we have to know the time frame for repairs before we can make the right decision. If the cost of repairs exceeds the cost of replacement this year, then the decision is easy. Both costs would come out of this year's budget and replacement will have less impact on this year's budget than repair so we replace.

However, if we know that replacement costs today would be $9,000 and repair costs will be $2,000 each year for a total cost of $10,000 over five years, it becomes less obvious whether repair or replacement today is the right choice. Repair versus replacement decisions are often subjective.

Factors such as expected useful life, available budget, and others concerns can make the repair versus replace waters murky.

The second economic reason to replace a piece of equipment is other similar pieces of equipment have reached the end of their useful life at the age of the piece in question. For example, assume you work in a hotel that has individual package terminal air conditioners (PTACs) in each hotel room. PTACs are those AC and heat units that fit in a sleeve through an exterior wall and allow each guest to adjust the temperature in their own room. You have a hundred or more of these PTACs in your hotel, all of the same model and brand. You know from your repair records that 70% of these units develop leaks in the evaporator and condenser coils by their eleventh year of service and the cost coil replacement exceeds the cost of a new unit.

If one of these PTAC units was sent down to your shop with a bad compressor, you will need to decide either to repair the unit by installing a new compressor or if it would be more responsible to replace the entire PTAC with a new one. The replacement compressor costs roughly half the cost of a new unit and this particular PTAC is 12 years old. Since we know that only a few units survive past 11 years, this unit does not have much service life left. If we install a new compressor on this unit, we are essentially wasting a compressor since we will likely end up disposing of the old unit with newly installed compressor in the very near future.

What if the PTAC needing repair was only eight years old, or only six years old? Would replacement or repair be the proper option? Fortunately, all of these questions can be answered with a simple math trick.

The trick is to figure out what the average cost of each option will be over the life of the equipment. Trying to compare $10,000 in repairs over five years with a one-time replacement cost of $9,000 is impossible. One time costs and costs over several years are not the same thing. We need to find a common unit of time that we can use for both options. As the old saying goes, "compare apples to apples, not apples to oranges." The way we do this is to figure out the equivalent annual cost or EAC of each option. After we have both options converted to the same unit of time, the comparison is easy. EAC is the total cost of an item divided by the number of years an item will be used.

===

As a simple example, if we spend $1 Million on a new roof and expect that roof to last 20 years, the equivalent annual cost (EAC) for the roof would be $1M/20 years or $50,000 per year.

In another example, if we believe that replacing a $8,000 oil burner will give us another 5 years of service life from a boiler, the EAC of this repair would be $8,000/5 years, giving an EAC of $1,600 per year.

===

Let's look at how we can use the concept of EAC to decide whether to repair or replace the RTU and PTAC in the examples just given.

===

EXAMPLE 1-REPLACE OR REPAIR RTU (rooftop unit)

Estimated cost of repair: $10,000 over the next 5 years.

Estimated cost of replacement: $9,000 one time Estimated service life (how long a new unit will last): 12 years.

To compare the cost of replacement with the cost of repair for a piece of equipment, we will need to add up all of our expenses that we can expect to occur over a specified period of time. We will also need to decide what that period of time will be. We need to decide on a period of time first.

If we replace the unit with a new one, we can expect the new RTU to have a service life of 12 years. That is a good average rule of thumb for this type of equipment. If we continue to repair the old RTU, we believe that we can get 5 more years out of the unit.

Option 1 repair RTU unit

Total cost of repairs: $10,000

Total expected years of service: 5

$10,000/5 years = $2,000 per year

Option 2 replace RTU unit

Total cost of replacement: $9,000

Total years of service: 12

$9,000/12 years = $750, per year

===

It should be easy to see, from this simplified problem, that option 2 (re placement) is less expensive in the long run then option 1 (repair). Replacing the unit is therefore the "right" answer.

It should be noted that although option 2 above is the "right" answer, if there is no money in the budget this year, an organization may opt to "waste" the repair costs for a couple of years until the replacement can budgeted. Sometimes even if we know what the right option is, the real world forces us to make another choice.

Let's look at the how we would make the repair vs. replace decision on the PTAC mentioned earlier.

===

EXAMPLE 2-REPLACE OR REPAIR PTAC (package terminal air conditioner)

Estimated cost of repair: $450 for new compressor

Estimated cost of new PTAC: $900 one time

Estimated service life if repaired: 1 year (our best guess based on other PTACs)

Estimated service life is replaced: 11 years

Option 1 repair PTAC unit

Total cost of repairs: $450

Total years of service: 1

$450/1 year = $450 per year

Option 2 replace PTAC unit

Total cost of replacement: $900

Total years of service: 11

$900/11 years = $81.82 per year

===

We can see that replacing the unit is much less expensive over the life cycle of the unit. We would therefore choose to replace the PTAC instead of making the repair.

Many books have been written about engineering economics. The examples chosen above are intentionally simplified because this is not a guide about engineering economics. This is a guide about preventive maintenance and making the right repair or replace decision is important to those of us that do PM. As part of our PM inspections, we are going to find problems with older pieces of equipment and are going to have to make these types of decisions.

These two examples only consider the costs of repairing the existing equipment or installing replacement equipment. In the real world, ALL of the costs associated with each option would need to be considered. Some of these costs would be:

• The cost of maintaining (PM and repairs) a new piece of equipment for each year of service

• Down time costs while repairs are made each time they are made

• Down time costs while a replacement is orders

• Equipment disposal costs

• Depreciation

• Salvage value

• Available utility or government rebate programs for equipment up grades

• The costs of differences in energy efficiency over time

• The cost of inflation

All of these costs can be considered in the same way as the costs in the above example. Knowing how to intelligently make the decision to re pair or replace can have a large impact on the bottom line and therefore on your department budget. Making the wrong decision on a $9,000 RTU or on a $900 PTAC most likely won’t break the bank. Many facilities projects reach into the millions of dollars. In these instances, a wrong decision based only on intuition or a gut feeling can be very expensive.

THE USEFUL LIFE OF BUILDING SYSTEMS

Budgeting, long-range planning, and making repair vs. replacement decisions all depend on knowing the useful service life of different types of equipment. There is no way to know how many years a particular piece of equipment will last, anymore than you can predict exactly when a light bulb will burn out. However, there are rules of thumb about expected equipment service life based on years of observation. These rules of thumb will provide some direction in predicting the useful life of different types of equipment.

Environmental factors, hours of operation, and maintenance history will have an impact on the service life of machinery. Salty sea air, exposure to the sun and rain, and use under heavy loads will reduce the service life of most equipment. Conversely, like the little old lady's car that only gets driven to church on Sundays, light use and protection from the elements will usually result in an increase in service life. These numbers are only a guideline. Many pieces of equipment, if maintained well, can last years beyond their expected service life while other pieces may fail earlier.

ESTIMATING PM COSTS

As mentioned earlier, a preventive maintenance program should cost nothing in the long run. In fact, a PM program should save money for an organization.

Although PM will save money in the long run, there are immediate costs associated with performing the work of PM. While these costs are more than offset by all of the associated savings discussed in Section 1, they are still real costs and need to be accounted for.

If PM is a new concept to your organization, it will be met with some caution on the part of those who hold the purse strings. The first question asked will most likely be "How much will this cost?" not "How much will this save?"

FIG. 4. Expected service life of equipment

A preventive maintenance program will eventually reduce the emergencies that your maintenance department is dealing with. In the long run, the extra work PM requires won’t increase your workload since un planned maintenance work will be reduced. Your work will simply shift to more planned activities and less emergencies. In fact, there will be time to tackle the work you have probably put on hold due to a lack of time.

However, in the very short term performing PM will require extra man hours, either in overtime or an increase in staff.

Many organizations are convinced that there is not enough money, time, or staff available to take on a PM program. Of course, these organizations will somehow find the money, the time, and hire the staff to repair what was not maintained. The familiar adage "Pay me now or pay me later" should become "Pay me a little now or pay me a lot more later."

Starting PM will require additional work until your PM program starts to show some benefits. Ideally, you will be able to either pay over time or hire temporary help. If this is not possible, don’t give up on PM. Motivate your staff; explain how much easier work will be if they can get some extra work done during the day for only 3 months. Start slowly, focusing on the PM tasks that will have the highest impact on your work load and then use the extra time saved by those tasks to start more tasks.

In the perfect world, we would all have the money and labor we need to start our PM program all at once. In the real world of budget and time restraints, sometimes it’s necessary to take baby steps.

The second area of PM costs, after labor, will be material costs. Material costs will usually be much less than the labor costs since the material involved in PM are usually very inexpensive and used in small quantities.

These include oil, grease, and other lubricants, replacement filters, parking lot sealer, paint, caulk, and the occasional replacement part if a defective part is found during an inspection.

The third area of PM costs will be the one time cost of modifying equipment or the building to make PM easier. Equipment that is difficult to PM will end up being skipped if it’s not altered in some way to make PM easier. Adding access doors to air handlers, installing ladders to reach inaccessible roofs, and installing grease-port extension-lines to move grease fit tings within reach will all increase the likelihood that someone will take the time to do PM instead of skipping a difficult piece of equipment.

The only way to answer the question, "How much will this cost?," is to add up the costs of labor, materials, and equipment modifications. In Section 3 we will create a PM schedule and calculate all of the labor

hours required for each task. The cost of materials can be estimated fairly quickly after you have done an equipment inventory and know what types of service each piece of equipment will need. The last area of costs, equipment modifications, will be harder to determine until after your PM program has started and your staff tells you the difficulty they have in performing each task. However, these modifications can be done slowly, stretched out over enough time, as your budget allows. Don’t neglect these modifications; my experience is that equipment that is difficult to PM does not get maintained properly. A facilities department mindset of continual improvement will help to make your PM program successful.

SECTION 2 SUMMARY

• Business decisions are made according to the anticipated return on investment (ROI). Preventive maintenance (PM) offers some of the highest ROIs available to business in the form of cost savings.

• The cost savings created by an effective PM program are primarily due to extended equipment service life and maintained efficiency.

PREVENTIVE MAINTENANCE TRUISM #2

A dollar saved through PM is as good as a dollar earned through any other business activity

• The repair and inspection data collected during PM activities will be valuable in helping to predict future expenses for developing bud gets and long-term planning for your organization.

• When deciding if it will be more economical to repair or replace a particular building component, the Equivalent Annual Costs (EAC) of each option needs to be calculated. Once the EAC of each option is known it’s easy to compare the cost of replacement with the cost of repair.

• Another important piece of information needed for accurate budgeting, long range planning, and making repair vs. replacement decisions is the expected service life of different types of building components.

• Although PM will offer cost savings in the long term, there will be short term start up costs when beginning a PM program. These costs will come from labor, materials, and necessary modifications which will make equipment and building components accessible for PM.