AMAZON multi-meters discounts AMAZON oscilloscope discounts

LEARNING GOALS:

• understand the basic safety rules for working on electrical systems.

• access the Internet to obtain a virtual unlimited source of safety and technical related information.

• become familiar with important electrical codes, safety codes, and building codes such as NFPA 70, 70A, 70B, 70E, 73, OSHA, NIOSH, ADA, NRTL, and the ICC.

• learn about licensing, permits, plans, specifications, symbols, and notations.

• understand the role of the electrical inspector and the International Association of Electrical Inspectors.

• understand the metric system of measurement.

SAFETY IN THE WORKPLACE

Electricity is great when it is doing what it is intended to do, and that is to stay in its intended path and doing the work intended. But electricity out of its intended path can be dangerous, often resulting in fire, serious injury, or death.

Before getting into residential wiring and the National Electrical Code (NEC), we need to discuss on-the-job safety. Safety is not a joke! Electricians working on new construction, remodel work, maintenance, and repair work find that electricity is part of the work environment. Electricity is all around us, just waiting for the opportunity to get out of control.

Repeat these words: Safety First ... Safety Last ... Safety Always!

Working on switches, receptacles, luminaires, or appliances with the power turned on is dangerous. Turn off the power! In addition, check with a voltmeter to be sure the power is off.

The voltage level in a home is 120 volts between one "hot" conductor and the "neutral" conductor or grounded surface. Between the two "hot" conductors (line-to-line), the voltage is 240 volts.

An electrical shock is received when electrical current passes through the body. From basic electrical theory, you learned that line voltage appears across an open in a series circuit. Getting caught "in series" with a 120-volt circuit will give you a 120-volt shock. For example, open-circuit voltage between the two terminals of a single-pole switch on a lighting circuit is 120 volts when the switch is in the "OFF' position and the lamp(s) are in place.

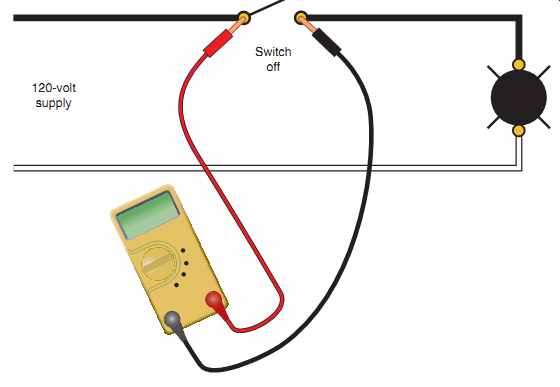

See FIG. 1. Likewise, getting caught "in series" with a 240-volt circuit will give you a 240-volt shock.

Working on equipment with the power turned on can result in death or serious injury, either as a direct result of electricity (electrocution or burns) or from an indirect secondary reaction, such as falling off a ladder or jerking away from the "hot" conductor into moving parts of equipment such as the turning blades of a fan. For example: A workman was seriously injured while working a "live" circuit that supplied a piece of equipment. He accidentally came into contact with a "hot" terminal, and reflex action caused him to pull his hand back into a turning pulley. The pulley cut deeply into his wrist, resulting in a tremendous loss of blood.

----

FIG. 1 The voltage across the two terminals of the single-pole switch

is 120 volts. 120-volt supply; Switch off

----

Dropping a metal tool onto live parts, allowing metal shavings from a drilling operation to fall onto live parts of electrical equipment, cutting into a "live" conductor and a "neutral" conductor at the same time, or touching the "live" wire and the "neutral" conductor or a grounded surface at the same time can cause injury directly or indirectly.

A short circuit or ground fault can result in a devastating arc flash that can cause serious injury or death. The heat of an electrical arc has been determined to be hotter than the sun. Tiny hot "balls" of copper can fly into your eye or onto your skin.

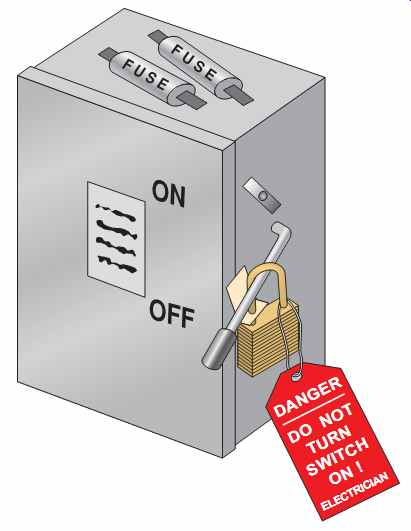

FIG. 2 shows a disconnect switch that has been locked and tagged.

Lockout/tagout (sometimes called LOTO) is the physical restraint of all hazardous energy sources that supply power to a piece of equipment. It simply means putting a padlock on the switch and applying a warning tag on the switch.

Dirt, debris, and moisture can also set the stage for equipment failure and personal injury. Neatness and cleanliness in the workplace are a must.

What about Low-Voltage Systems? Although circuits of less than 50 volts generally are considered harmless, don't get too smug when working on so-called low voltage. Low-voltage circuits are not necessarily low hazard. A slight tingle might cause a reflex. A capacitor that is discharging can give you quite a jolt, causing you to jump or pull back.

In commercial work, such as telephone systems with large battery banks, there is extreme danger even though the voltage is "low." Think of a 12-volt car battery. If you drop a wrench across the battery terminals, you will immediately see a tremendous and dangerous arc flash.

It is the current that is the harmful component of an electrical circuit. Voltage pushes the current through the circuit. If you're not careful, you might become part of the circuit.

Higher voltages can push greater currents through the body. Higher voltages like 240, 480, and 600 volts can cause severe skin burns and possibly out-of-sight injuries such as internal bleeding and/or destruction of tissues, nerves, and muscles.

Dropping a metal tool onto live parts, allowing metal shavings from a drilling operation to fall onto live parts of electrical equipment, cutting into a "live" conductor and a "neutral" conductor at the same time, or touching the "live" wire and the "neutral" conductor or a grounded surface at the same time can cause injury directly or indirectly.

A short circuit or ground fault can result in a devastating arc flash that can cause serious injury or death. The heat of an electrical arc has been determined to be hotter than the sun. Tiny hot "balls" of copper can fly into your eye or onto your skin.

FIG. 2 shows a disconnect switch that has been locked and tagged.

Lockout/tagout (sometimes called LOTO) is the physical restraint of all hazardous energy sources that supply power to a piece of equipment. It simply means putting a padlock on the switch and applying a warning tag on the switch.

Dirt, debris, and moisture can also set the stage for equipment failure and personal injury. Neatness and cleanliness in the workplace are a must.

What about Low-Voltage Systems?

Although circuits of less than 50 volts generally are considered harmless, don't get too smug when working on so-called low voltage. Low-voltage circuits are not necessarily low hazard. A slight tingle might cause a reflex. A capacitor that is discharging can give you quite a jolt, causing you to jump or pull back.

In commercial work, such as telephone systems with large battery banks, there is extreme danger even though the voltage is "low." Think of a 12-volt car battery. If you drop a wrench across the battery terminals, you will immediately see a tremendous and dangerous arc flash.

It is the current that is the harmful component of an electrical circuit. Voltage pushes the current through the circuit. If you're not careful, you might become part of the circuit.

Higher voltages can push greater currents through the body. Higher voltages like 240, 480, and 600 volts can cause severe skin burns and possibly out-of-sight injuries such as internal bleeding and/or destruction of tissues, nerves, and muscles.

It's the Law!

----

FIG. 2 A typical disconnect switch with a lock and a tag attached to it.

In the OSHA, ANSI, and NFPA standards, this is referred to as the lockout/tagout

procedure.

DANGER DO NOT TURN SWITCH ON !

ELECTRICIAN

---- Not only is it a good idea to use proper safety measures as you work on and around electrical equipment, it is required by law. Electricians and electrical contractors need to be aware of these regulations. Practicing safety is a habit-like putting on your seat belt as soon as you get into your car.

The NEC is full of requirements that are safety related. For example, 430.102(B) requires that a disconnecting means be located in sight from the motor location and the driven machinery location.

This section also has "in-sight" and "lock-off" requirements, discussed in detail in section 19.

The NEC defines a qualified person as: One who has skills and knowledge related to the construction and operation of the electrical equipment and installations and has received safety training to recognize and avoid the hazards involved. Merely telling someone or being told to "be careful" does not meet the definition of "proper training" and does not make the person qualified. An individual "qualified" in one skill might very well be "unqualified" in other skills.

According to NFPA 70E, Electrical Safety in the Workplace, circuits and conductors are not considered to be in an electrically safe condition until all sources of energy are removed, the disconnecting means is under lockout/tagout, and the absence of voltage is verified by an approved voltage tester.

The U.S. Department of Labor Occupational Safety and Health Administration (OSHA) regulations (Standards-29 CFR) is the law! This entire standard relates to safety in the workplace for general industry. Specifically, Part 1910, Subpart S, involves electrical safety requirements. The letters CFR stand for Code of Federal Regulations.

Key topics in the standard are: electric utilization systems, wiring design and protection, wiring methods, components and equipment for general use, specific purpose equipment and installations, hazardous (classified) locations, special systems, training, selection and use of work practices, use of equipment, selection and use of work practices, use of equipment, safeguards for personnel protection, and definitions (a mirror image of definitions found in the NEC).

A direct quote from 1910.333(a)(1) states that Live parts to which an employee may be exposed shall be de-energized before the employee works on or near them, unless the employer can demonstrate that de-energizing introduces additional or increased hazards or is infeasible due to equipment design or operational limitations. Live parts that operate at less than 50 volts to ground need not be de-energized if there will be no increased exposure to electrical burns or to explosion due to electric arcs.

OSHA 1910.333(c)(2) states that "Only qualified persons may work on electric circuit parts or equipment that have not been de-energized under the procedures of paragraph (b) of this section. Such persons shall be capable of working safely on energized circuits and shall be familiar with the proper use of special precautionary techniques, personal protective equipment, insulating and shielding materials, and insulated tools." OSHA 1910.399 defines a qualified person as "One familiar with the construction and operation of the equipment and the hazards involved," almost the same definition as that of the NEC.

For the most part, turning the power off then locking and tagging the disconnecting means is the safest. As the OSHA regulations state, "A lock and a tag shall be placed on each disconnecting means used to de-energize circuits and equipment." Part 1926 in the OSHA regulation (Standards-29 CFR) deals with Safety and Health Regulations for Construction. Here we find the rules for anyone involved in the construction industry, not just electrical. A few of the topics are: medical services and first aid, safety training and education, recording and reporting injuries, house keeping, personal protective equipment, means of egress, head protection, hearing protection, eye and face protection, ladders, scaffolds, rigging, hand and power tools, electrical requirements (a repeat of Part 1910, Subpart S), fall protection, and required signs and tags.

PERSONAL PROTECTIVE EQUIPMENT

Safety courses refer to personal protective equipment (PPE). These include such items as rubber gloves, insulating shoes and boots (footwear suit able for electrical work is marked with the letters "EH"), face shields, safety glasses, hard hats, ear protectors, Nomex, and similar products. OSHA 1910.132(f)(1) requires that "The employer shall provide training to each employee who is required by this section to use PPE." Working on electrical equipment while wearing rings and other jewelry is not acceptable. OSHA states that "Conductive articles of jewelry and clothing (such as watch bands, bracelets, rings, key chains, necklaces, metalized aprons, cloth with conductive thread, or metal headgear) may not be worn if they might contact exposed energized parts.

However, such articles may be worn if they are rendered nonconductive by covering, wrapping, or other insulating means."

ARC FLASH

Don't get too complacent when working on electrical equipment.

A major short circuit or ground fault at the main service panel or at the meter cabinet or base can deliver a lot of energy. On large electrical installations, an arc flash (also referred to as an arc blast)

can generate temperatures of 35,000°F (19,427°C). This is hotter than the surface on the sun. This amount of heat will instantly melt copper, aluminum, and steel. The blast will blow hot particles of metal and hot gases all over, resulting in personal injury, fatality, and/or fire. An arc flash also creates a tremendous air pressure wave that can cause serious hearing damage and/or memory loss due to the concussion. The blast might blow the victim away from the arc source.

Don't be fooled by the size of the service.

Typical residential services are 100, 150, and 200 amperes. Larger services are found on large homes.

Electricians seem to feel out of harm's way when working on residential electrical systems and seem to be more cautious when working on commercial and industrial electrical systems. A fault at a small main service panel can be just as dangerous as a fault on a large service. The available fault cur rent at the main service disconnect for all practical purposes is determined by the kVA rating and impedance of the transformer. Other major limiting factors for fault current are the size, type, and length of the service-entrance conductors. Available fault current can easily reach 22,000 amperes, as is evident by panels that have a 22,000/10,000-ampere series rating.

Short-circuit calculations are discussed in section 28.

Don't be fooled into thinking that if you cause a fault on the load side of the main disconnect that that main breaker will trip off and protect you from an arc flash. An arc flash will release the energy that the system is capable of delivering for as long as it takes the main circuit breaker to open. How much current (energy) the main breaker will "let through" is dependent on the available fault current and the breaker's opening time.

Although not required for house wiring, NEC 110.16 requires that electrical equipment, such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers, that are in other than dwelling units, and are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked to warn qualified persons of potential electric arc flash hazards. The marking shall be located so as to be clearly visible to qualified per sons before examination, adjustment, servicing, or maintenance of the equipment. More information on this subject is found in NFPA 70E and in the ANSI Standard Z535.4, Product Safety Signs and Labels.

Classifying Electrical Injuries

OSHA recognizes the four main types of electrical injuries as:

• Electrical shock (touching "live" line-to-line or line-to ground conductors) (ground-fault circuit interrupters are discussed in section 6)

• Electrocution (death due to severe electrical shock)

• Burns (from an arc flash)

• Falls (an electrical shock might cause you to lose your balance, pull back, jump, or fall off a ladder)

What to Do If You Are Involved with a Possible Electrocution

The following is taken in part from the OSHA, NIOSH, NSC regulations, and the American Heart Association recommendations. These are steps that should be taken in the event of a possible electrocution (cardiac arrest). You need to refer to the actual cardiopulmonary resuscitation (CPR) instructions for complete and detailed requirements, and to take CPR training.

• First of all, you must recognize that an emergency exists. Timing is everything. The time between the accident and arrival of paramedics is crucial. Call 911 immediately. Don't delay.

• Don't touch the person if he or she is still in contact with the live circuit.

• Shut off the power.

• Stay with the person while someone else contacts the paramedics, who have training in the basics of life support. In most localities, telephoning 911 will get you to the paramedics.

• Have the caller verify that the call was made and that help is on the way.

• Don't move the person.

• Check for bleeding; stop the bleeding if it occurs.

• If the person is unconscious, check for breathing.

• The ABCs of CPR are: airway must be clear; breathing is a must, either by the victim or the rescuer; and circulation (check pulse).

• Perform CPR if the victim is not breathing- within 4 minutes is critical. If the brain is deprived of oxygen for more than 4 minutes, brain damage will occur. If it is deprived of oxygen for more than 10 minutes, the survival rate is 1 in 100. CPR keeps oxygenated blood flowing to the brain and heart.

• Defibrillation may be necessary to reestablish a normal heartbeat. Ventricular fibrillation is common with electric shock, which causes the heartbeat to be uneven and unable to properly pump blood.

• By now, the trained paramedics should have arrived to apply advanced care.

• When it comes to an electrical shock, timing is everything!

Electrical Equipment

For safety, it is very important that electrical equipment be "listed" by a Nationally Recognized Testing Laboratory (NRTL). Concepts about listed electrical equipment are found in NEC 90.7.

NEC 110.3(B) Installation and Use: states that "Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling." OSHA rules state that "All electrical products installed in the work place shall be listed, labeled, or otherwise determined to be safe by a Nationally Recognized Testing Laboratory (NRTL)."

Who Is Responsible for Safety? You are!

The electrical inspector inspects electrical installations for compliance to the NEC. He or she is not really involved with on-the-job safety.

For on-the-job safety, OSHA puts the burden of responsibility on the employer. OSHA can impose large fines for noncompliance with its safety rules.

But since it's your own safety that we are discussing, you share the responsibility by applying safe work practices, using the proper tools and PPE equipment the contractor furnishes, and installing "Listed" electrical equipment. Be alert to what's going on around you! Do a good job of housekeeping! Tools

Using the proper tools for a job is vital to on-the job safety.

OSHA Standard 1926.302 specifically covers the requirements for hand and power tools. The American National Standards Institute (ANSI) also has standards relating to tools.

If you want to learn more about tools, visit the Web site of the Hand Tools Institute at www.hti.org.

The institute has a number of excellent safety education materials available. Of particular interest is its 90-plus-page publication Guide to Hand Tools that includes topics for selecting, proper use, maintaining, hazards involved, as well as special emphasis on eye protection using all types of hand tools.

Electrical Power Tools

You will be using portable electric power tools on the job. Electricity is usually in the form of temporary power, covered by Article 590 of the NEC.

NEC 590.6(A) requires that "All 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not a part of the permanent wiring of the building or structure and that are in use by personnel shall have ground-fault circuit interrupter protection for personnel." Because this requirement is often ignored or defeated on job sites, you should carry and use as part of your tool collection a portable GFCI of the types shown in FIG. 3--an inexpensive investment that will protect you against possible electrocution. Remember, "The future is not in the hands of fate, but in ourselves."

Digital Multimeters

Some statistics show that more injuries occur from using electrical meters than from electric shock.

For safety, electricians should use quality digital multimeters that are category rated. The International Electrotechnical Commission (IEC) Standard 1010 for Low Voltage Test, Measurement, and Control Equipment rates the ability of a meter to withstand voltage transients (surges or spikes). This standard is very similar to UL Standard 3111.

When lightning strikes a high line, or when utilities are performing switching operations, or when a capacitor is discharging, a circuit can "see" volt age transients that greatly exceed the withstand rating of the digital multimeter. The meter could explode, causing an arc flash (a fireball) that in all probability will result in personal injury. A properly selected category-rated digital multimeter is able to withstand the spike without creating an arc blast.

The leads of the meter are also able to handle high transient voltages.

FIG. 3 Two types of portable plug-in cord sets that have built-in GFCI

protection.

Digital multimeters also are category rated based on the location of the equipment to be tested, because the closer the equipment is to the power source, the greater the danger from transient voltages.

Cat IV multimeters are used where the avail able fault current is high, such as a service entrance, a service main panel, service drops, and the house meter.

Cat III multimeters are used for permanently installed loads such as in switchgear, distribution panels, motors, bus bars, feeders, short branch circuits, and appliance outlets where branch-circuit conductors are large and the distance is short.

Cat II multimeters are used on residential branch circuits for testing loads that are plugged into receptacles.

Cat I multimeters are used where the current levels are very low, such as electronic equipment.

Note that the lower the category rating, the lower is the meter's ability to withstand voltage transients. If you will be using the multimeter in all of the above situations, select the higher category rating.

Category-rated digital multimeters also contain fuses that protect against faults that happen when the meter is accidentally used to check voltage while it is inadvertently set in the current reading position.

To learn more about meters, visit the Web site of Fluke Corporation, fluke.com, for a wealth of technical information about the use of meters and other electrical and electronic measuring instruments.

Ladders

To learn more about ladders, visit the Web site of Werner Ladder Company, wernerladder.com.

You can download their pamphlet entitled Ladder Safety Tips. You will learn about the right and wrong ways to use a ladder such as: Never work on a step ladder in which the spreaders are not fully locked into position; the 4:1 ratio, which means that the base of an extension ladder should be set back (S) one-fourth the length (L) of where the upper part of the ladder is supported (S 5 1/4 L); the duty ratings, such as do not stand higher than the second step from the top for step ladders, and do not stand higher than the fourth rung from the top for extension ladders; plus many more safety tips.

Ladders are labeled with their duty rating.

Medium-duty commercial (Type II-225#), heavy duty industrial (Type I-250#), and extra-heavy-duty (Type IA-300#) ladders bear an OSHA compliance label. Light-duty household (Type III-200#) ladders do not bear an OSHA logo.

Hazardous Chemicals

You will find more and more hazardous chemicals on the job. What do you do if you get a spilled chemical on your skin or in your eyes, or if you breathe the fumes? Every manufacturer of this type of product is required to publish and make available a comprehensive data sheet called the material safety data sheet (MSDS). There are supposedly over 1.5 million of these data sheets. They contain product identification, ingredients, physical data, fire and explosion hazard data, health-hazard data, reactive data, spill or leak procedures, protection information, and special precautions.

The least you can do is to be aware that this information is available. Apprenticeship programs include some training about MSDS.

You can learn more about MSDS by checking any search engine for the letters MSDS.

TRAINING

If you want to learn more, visit manufacturers' Web sites. For example, Bussmann's Web site is www.bussmann.com. It is easy to use and has a computer program for making arc-flash and fault-current calculations. This Web site also has a technical publication Selecting Protective Devices, or bulletin SPD, a 268-plus-page publication about overcurrent protection selection, application, NEC, and safety. You can order a hard copy of the publication from them.

The OSHA Training Institute offers outreach training programs of interest to electricians, contractors, and instructors. The basic safety courses for general construction safety and health are the OSHA 10-hour and OSHA 30-hour courses. Instructors interested in becoming an outreach trainer for the 10- and 30-hour courses must complete the OSHA 500 course entitled "Trainer Course in Occupational Safety and Health Standards for the Construction Industry." To become an outreach trainer, a test must be passed. Before the end of 4 years, outreach trainers must take the OSHA 502 update course for the construction industry or the OSHA 502 update course "Update for Construction Industry Outreach Trainers." Completion cards are issued on completion of these courses.

Other courses, publications, "free loan" videos, schedules of upcoming safety training seminars, and other important information relating to safety on the job are available from OSHA for electricians, con tractors, and trainers.

Visit the OSHA Web site at OSHA.gov for everything there is to know about OSHA safety requirements in the workplace. The OSHA Web site is a virtual gold mine of information relating to safety on the job.

Another valuable source of safety information is the National Institute for Occupational Safety and Health (NIOSH), a division of the Department of Health and Human Services Centers for Disease Control and Prevention (CDC). Check out its Web site at cdc.gov/niosh. NIOSH offers an excellent downloadable 80-plus-page manual on Electrical Safety.

The National Safety Council has a vast amount of information relative to all aspects of safety.

Check out its Web site at nsc.org.

The Consumer Product Safety Commission offers many safety publications for downloading.

Visit its Web site at cpsc.gov, click on Library, click on CPSC Publications, click on By General Category, and then click on Electrical Safety. Here you will see a list of CPSC publications about GFCIs, AFCIs, metal ladder hazards, home wiring hazards, repairing aluminum wiring, and others.

The National Fire Protection Association offers many publications, videos, and a training course relating to safety. Browse its Web site at: nfpa.org.

NFPA 70E Standard for Electrical Safety in the Workplace and NFPA 70B Recommended Practices for Electrical Equipment Maintenance present much of the same text regarding electrical safety as does the OSHA regulation.

Accredited apprenticeship training programs incorporate safety training as an integral part of their curriculum.

SAFETY CANNOT BE COMPROMISED!

It is impossible to put a dollar value on a life.

Don't take chances! Use the right tools! Turn off the power. Follow a lockout/tagout procedure.

Mark the tag with a description of exactly what that particular disconnect controls.

How many times have we heard "The person would not have been injured (or electrocuted) had he turned the power OFF"? How many more times can we say it? Turn OFF the power before working on the circuit! Visit the Web sites of the various organizations mentioned earlier. The Web site list can also be found in the back of this text. These organizations have a wealth of information about on-the-job safety educational material and safety training courses.

Check out the Web site of the Electrical Safety Foundation International (ESFI) at electrical-safety.org. This organization has a tremendous amount of down-to-earth, simple to-understand electrical safety material. Some of their educational material is free; other items are priced. Certain items are downloadable. The bottom line is to reduce deaths and injuries from preventable electrical accidents.

LICENSING AND PERMITS

Most communities, counties, and/or states require electricians and electrical contractors to be licensed.

This usually means they have taken and passed a test. To maintain a valid license, many states require electricians and electrical contractors to attend and satisfactorily complete approved continuing education courses consisting of a specified number of classroom hours over a given period of time. Quite often, a community will have a "Residential Only" license for electricians and contractors that limits their activity to house wiring.

Permits are a means for a community to permanently record electrical work to be done and who is doing the work, and to schedule inspections during and after the "rough-in" stage and in the "final" stages of construction. Usually, permits must be issued prior to starting an electrical project. In most cases, homeowners are allowed to do electrical work in their own home where they live but not in other properties they might own.

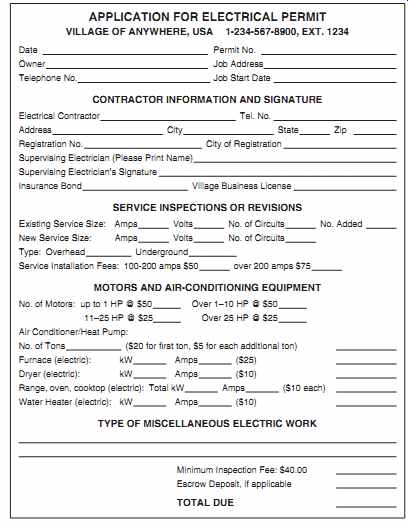

FIG. 4 is a simple application for an electrical permit form. Some permit application forms are much more detailed.

If you are not familiar with licensing and permit requirements in your area, it makes sense to check this out with your local electrical inspector or building department before starting an electrical project. Not to do so could prove to be very costly.

Many questions can be answered: you will find out what tests, if any, must be taken; which permits are needed; which electrical code is enforced in your community; minimum size electrical service; and so on. Generally, the electrical permit is taken out by an electrical contractor who is licensed and registered as an electrical contractor in the jurisdictional area.

For new construction or for a main electrical service change, you will also need to contact the electric utility.

FIG. 4 A typical Application for Electrical Permit.

Temporary Wiring

There is an ever-present electrical shock hazard on construction sites. The NEC addresses this in Article 590. This is covered in section 6.

Construction Terms

Electrical Wiring--Residential covers all aspects of typical residential wiring, with focus on the NEC. Electricians work with others on construction sites.

Knowing construction terms and symbols is therefore a key element to getting along with the other workers. A rather complete dictionary of construction terms can be found on constructionplace.com/glossary.asp. Architectural symbols are found in the Appendix of this text.

PLANS

An architect or electrical engineer prepares a set of drawings that shows the necessary instructions and details needed by the skilled workers who are to build the structure. These are referred to as plans, prints, blueprints, drawings, construction drawings, or working drawings. The sizes, quantities, and locations of the materials required and the construction features of the structural members are shown at a glance. These details of construction must be studied and interpreted by each skilled construction craftsperson-masons, carpenters, electricians, and others-before the actual work is started.

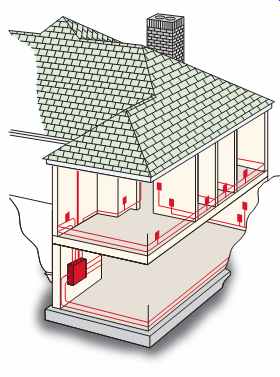

The electrician must be able to (1) convert the 2-dimensional plans into an actual electrical installation and (2) visualize the many different views of the plans and coordinate them into a 3-dimensional picture, as shown in FIG. 5.

The ability to visualize an accurate 3-dimensional picture requires a thorough knowledge of blueprint reading. Because all of the skilled trades use a common set of plans, the electrician must be able to interpret the lines and symbols that refer to the electrical installation and also those used by the other construction trades. The electrician must know the structural makeup of the building and the construction materials to be used Plans might be black line prints, which are simply photocopies; diazo prints, referred to as white line prints; or computer-aided drawings (CAD), which are most commonly used today. The need for the draftsman has for the most part become history.

We now need CAD technicians and engineers.

Today's high-tech computers and wide-frame printers allow for storage and backup of clear and concise drawings, standardization of lines in symbols, ease of making revisions, the ability to zoom in and out when viewed on a monitor, simplicity of printing (black or color), and in many cases the ability to view the structure in 2D or 3D, turn a drawing to any angle, and view the more complicated plans in layers. The larger the job, the greater the need for more detail.

Although blueprints for the most part have gone the way of the dinosaur, they are still around.

Electricians that are from an older generation are familiar with blueprints. Those of you coming into the trade will probably not see blueprints on the jobs you work on.

FIG. 5 Three-dimensional view of house wiring.

Blueprints are created by running yellowish, light-sensitive paper and transparent Mylar with black images on it through a blueprint machine, where the two sheets are exposed to a bright light for a short period of time. The light-sensitive paper turns white in all places except where the black images are.

Where the black images are, the light-sensitive paper turns blue. That is why it is called a blueprint.

A tear-out/fold-out set of full-size plans for the residence referred to throughout this text is included in the back of the guide.

A few of the more common sizes for blueprints are

• Size C (17 inches by 22 inches),

• Size B (22 inches by 34 inches), and

• Size E (34 inches by 44 inches).

SPECIFICATIONS

The specifications (specs, for short) for the electrical work indicated on the plans for the residence discussed throughout this text are found in the back of the guide, before the Appendix.

Working drawings are usually complex because of the amount of information that must be included.

To prevent confusing detail, it is standard practice to include with each set of plans a set of detailed writ ten specifications prepared by the architect.

These specifications provide general information to be used by all trades involved in the construction.

In addition, specialized information is given for the individual trades. The specifications include information on the sizes, the type, and the desired quality of the standard parts to be used in the structure.

Typical specifications include a section on "General Clauses and Conditions," which is applicable to all trades involved in the construction. This section is followed by detailed requirements for the various trades-excavating, masonry, carpentry, plumbing, heating, electrical work, painting, and others.

In the electrical specifications, the listing of standard electrical parts and supplies frequently includes the manufacturers' names and the catalog numbers of the specified items. Such information ensures that these items will be of the correct size, type, and electrical rating, and that the quality will meet a certain standard. To allow for the possibility that the contractor will not always be able to obtain the specified item, the phrase "or equivalent" is usually added after the manufacturer's name and catalog number.

The specifications are also useful to the electrical contractor in that all of the items needed for a specific job are grouped together and the type or size of each item is indicated. This information allows the contractor to prepare an accurate cost estimate without having to find all of the data on the plans.

If there is a difference between the plans and specifications, the specifications will take preference. The electrical contractor should discuss the matter with the homeowner, architect, and engineer.

The cost of the installation might vary considerably because of the difference(s), so obtain any changes to the plans and/or specifications in writing.

Next>>

Prev. | Next

Similar Articles