Your choice of wind turbines is somewhat limited. Even so, you need to know your options and choose wisely. This section will help you understand your options. We'll begin with the basics by examining the types of wind generators and then explore the components of the most common turbines: the horizontal axis machines. We'll also briefly examine vertical axis wind turbines and dispel the common myths about them. We'll also discuss features that will ensure many years of low-maintenance. We follow this discussion with a brief exploration of homemade wind machines.

The Anatomy of a Wind Turbine

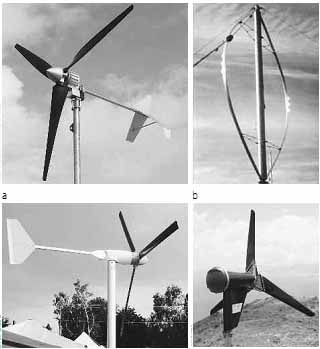

Most wind turbines on the market today are known as horizontal axis wind turbines or HAWTs ( Ill. 5.1a). The second type is the vertical axis wind turbine or VAWT ( Ill. 5.1b).

Horizontal Axis Wind Turbines

Horizontal axis wind turbines come in two basic varieties: upwind or downwind ( Ill. 5.2a and b). In most HAWTs, the rotor is located on the upwind side of the tower when the turbine is operating, hence the name, upwind turbine. Those in which the rotor is located on the downwind side of the turbine when the wind is blowing are referred to as downwind turbines.

Ill.5.1: (a) Horizontal axis wind turbine (b) Vertical

axis wind turbine. Although there's a lot of interest these days in vertical

axis wind turbines, they are mounted at ground level, which exposes them

to unproductive low-speed winds.

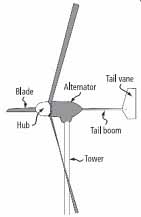

Upwind HAWTs consist of three main parts: (1) a rotor, (2) an alternator, and (3) a tail (Ill. 5.3). As noted in Section 3, the rotor consists of blades attached to a central hub covered by a nose cone to improve aerodynamics. Most upwind turbines have three blades. This entire assembly rotates when wind blows past the blades, hence the name "rotor."

Ill.5.3: Anatomy of a Wind Generator. A wind turbine

consists of blades attached to a hub, forming the rotor. The rotor in

this turbine is attached via a shaft (not shown) to the rotor of the

alternator. When the rotor of the turbine spins, it produces electricity.

In many small wind turbines the rotor is attached to a shaft that's attached to an alternator, a device that produces AC electricity. As the name implies, in HAWTs the axis of the rotor is oriented horizontally, that is, parallel to the ground.

Alternators produce electricity. They consist of two main parts: a set of stationary windings, known as the stator; and a set of rotating magnets, known as the rotor. Most small wind turbines use metal magnets, rather than electromagnets. The movement of the magnets around the windings (as the blades spin) induces an electrical current in the windings. Wind turbines, therefore, first convert the kinetic energy of the wind into mechanical energy (rotation). The mechanical energy is then converted into electrical energy in the alternator.

HAWTs can also be classified according to their end use.

Turbines designed to charge batteries are called "battery-charging turbines." Turbines designed to connect to the grid are referred to as "battery-less grid-tie turbines."

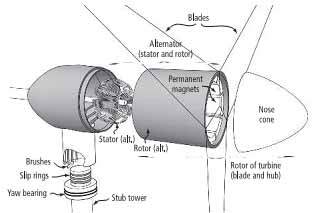

Ill.5.4: Anatomy of a Modern Wind Turbine. Many small

wind turbines now directly link the rotor of the turbine to the rotor

of the alternator, as shown here. The magnets are attached to the inside

of the can, shown in the drawing. They rotate around the stationary

windings of the alternator stator.

Ill. 5.4 shows another common wind turbine configuration. In this design, there's no shaft. The blades of the turbine attach to a faceplate that is attached directly to a cylindrical metal "can." Together the blades and the face plate form the rotor of the turbine. The can to which the faceplate is attached contains magnets.

They spin around a set of stationary coils of copper wire, the windings. The can is therefore also the rotor of the alternator. The windings constitute the stator of the alternator. As the rotor of the turbine spins, the magnets rotate around the windings, producing AC electricity in the windings via electromagnetic induction.

Alternators in many modern small wind turbines contain high strength rare earth magnets. Rare earth magnets contain neodymium, iron and boron. They produce a much stronger magnetic field than conventional iron or ceramic magnets used in some small wind turbines. The stronger the magnetic field, the greater the output of a wind turbine, all things being equal. Alternators that contain mag nets such as these are referred to as permanent magnetic generators.

Electricity leaves the alternator via wires that attach to the stator. In most turbines, like the one shown in Ill. 5.4, these wires terminate on metal brushes. The brushes, in turn, contact slip rings, which are brass rings located near the yaw bearing. The yaw bearing allows the turbine to turn in response to changes in the wind direction. The brushes transfer electricity from the alternator to the slip rings. The slip rings, in turn, connect to a cable (electric wire) that runs down the length of the tower. Electricity flows from the alternator to the brushes to the slip rings and then down the tower.

====

Alternator vs. Generator

A generator is a machine that converts mechanical energy into electrical energy, either AC or DC. A generator that produces AC is called an AC generator or, more commonly, an alternator. Alternators that produce DC electricity are known as DC generators or simply generators. Most, if not all, modern wind turbines contain alternators, which pro duce AC electricity. Some of these turbines are equipped with rectifiers, devices that convert the AC to DC, which is then sent down the tower.

====

Wind generators such as the ones shown in Ill. 5.4 are known as direct drive turbines because the rotor of the turbine is attached directly to the rotor of the alternator. As a result, the rotor and the alternator turn at the same speed. Although virtually all modern residential wind machines are direct drive, a few of the small wind turbines contain gearboxes. They're located between the rotor of the turbine and the rotor of the alternator. Gearboxes increase the speed at which the alternator spins, increasing the output of the alternator.

This allows the alternator to be much smaller and also maintains a rotor speed (blade speed) that is safe and quiet. These turbines are known as gear-driven turbines.

Another important component of most horizontal axis wind machines is the tail. The tail typically consists of a boom and a vane. The tail boom connects the tail vane to the body of the turbine.

Tails keep the rotor of the wind turbine pointing into the wind. If the wind direction shifts, the tale vane turns the turbine into the wind, ensuring maximum electrical energy production. The rotation of a wind machine on a tower as it tracks the wind direction is referred to as yawing.

Although upwind turbines dominate the market, several manufacturers produce downwind turbines: Proven, Southwest Wind Power (Skystream), Entegrity, Ventera and PGE. These wind turbines contain no tails.

Downwind turbines work well. However, if the wind dies down and then reverses direction, downwind turbines can get caught in the upwind position (with blades upwind from the tower). When stuck upwind, downwind turbines are unable to spin and generate electricity. As the wind speed increases or shifts direction, however, the turbine aligns properly.

Vertical Axis Wind Turbines

There's another type of wind machine that is getting a lot of attention these days. It is known as a vertical axis wind turbine. As shown in Ill. 5.1b, the blades of a vertical axis wind turbine (VAWT) are attached to a central vertical shaft. When the blades spin, the shaft spins. The shaft is attached to an alternator generally located at the bottom of the shaft, often at ground level.

Vertical axis wind energy devices have been around for a long time, about 3,000 years. Proponents of VAWTs tout a number of supposed advantages over HAWTs, most of which are either wrong or grossly exaggerated. One of them is that they can capture wind from any direction. The machines don't need to be oriented into the wind as the HAWTs do. In addition, proponents like to claim that VAWTs are immune to turbulence that wrecks havoc with HAWTs.

Another supposed advantage is that VAWTs can be mounted close to the ground - even on top of buildings - where they capture ground-level winds. This eliminates the need for tall and costly towers and the need to obtain the zoning variances sometimes required to install horizontal axis wind turbines on tall towers.

Yet another supposed advantage of VAWTs stems from the fact that the generator can be mounted at ground level. This, say proponents, makes it easier to access and repair the generator should the need arise. There's no need to climb the tower - or lower a wind generator to the ground - to perform routine maintenance or to replace damaged parts.

Unfortunately, years of experience with VAWTS have been rather discouraging. "Hundreds of commercial VAWTs were installed in California in the late 1980s and early 1990s," Robert Aram reminds us. "They all failed and were removed from service. These were not experimental units, but production units." In addition, VAWTs are less efficient than horizontal axis wind machines. "For a given swept area," Jim Green notes, "they just don't extract as much wind energy as a well-designed HAWT." Moreover, the blades of VAWTs are prone to fatigue created as the blades spin around the central axis. The vertically oriented blades used in some early models, for instance, twisted and bent as they rotated in the wind. This caused the blades to flex and crack. Over time, the blades broke apart, sometimes leading to catastrophic failure. Because of these problems, VAWTs have proven less reliable than HAWTs.

"The VAWT does have an advantage in dealing with wind direction shifts," agrees R. Prius, wind energy expert and manufacturer of Abundant Renewable Energy turbines (horizontal axis wind turbines). However, rapidly changing wind direction that occurs in turbulent low-level winds increases fatigue on a VAWT, just like a HAWT. "Fatigue leads to equipment failure, which has been a major problem with VAWTs." Many VAWTs also require large bearings at the top of the tower to permit rotation of the shaft. When the top bearings or the blades need replacement, you've got a job on your hands.

Although VAWTs can capture ground-level winds, just like any turbine installed on a too-short tower, they are just as sensitive to turbulence and ground drag as horizontal axis wind turbines. As you learned in Section 2, ground-level winds are subject to friction (which creates ground drag). Both ground drag and turbulence in lower-level winds diminish the power available to any turbine mounted close to the ground - so much so that there is very little extractable energy in wind in such locations. The lower the wind speed, the less electricity a turbine will produce. In addition, dead air spaces form behind buildings and other ground clutter. Placing a VAWT in such a location renders it useless. So just because a VAWT can be mounted at ground level doesn't mean it will pro duce enough electricity to be worthwhile.

VAWTs are less reliable and less efficient than HAWTs. They just don't stack up against horizontal axis wind turbines. The few advantages they offer can't counter the many, some say fatal, disadvantages.

The Main Components of Wind Turbines

To help you select a wind turbine that's built to last, let's take a closer look at the main components of modern wind turbines, starting with blades and generators.

Blades

Blades are a vital component of a wind turbine. Manufacturers make blades from several different types of materials. Although wood was once commonly used to make blades for small wind turbines, we're not aware of any companies that manufacture blades exclusively from wood. It's just too expensive and time consuming.

The blades of modern wind turbines are typically made of extremely durable and relatively inexpensive synthetic materials, various types of plastic or composites - plastic reinforced with fiberglass or carbon fibers, for example. These synthetic blades typically last between 10 and 20 years. and , unlike the metal blades once used in small wind turbines, plastic blades don't interfere with television, satellite TV or wireless Internet signals. Table 5.1 lists some examples of blade materials commonly used today.

Table 5.1 Composition of Small Wind Turbine Blades

Company |

Blade Material |

Abundant Renewable Energy Bergey Windpower Wind Turbine Industries Proven Southwest Windpower

|

Fiberglass Fiberglass Fiberglass Polypropylene (WT600) Fiberglass (WT2500, WT6000 and WT15000) Polypropylene reinforced with fiberglass fiberglass |

Most modern residential wind machines - both upwind and downwind models - have three blades. Although certain manufacturers produce two- and six-blade turbines (for sailboats), three-blade wind turbines are the industry standard. They provide the best overall performance. They are quieter and suffer less wear and tear than one- and two-blade models.

Generators

Most residential wind machines on the market contain permanent magnet alternators, described earlier, although larger turbines in the small turbine range, like the remanufactured Jacobs 31-20, incorporate electromagnets (magnets created by running electricity through wire coils in the alternator). As noted in Section 3, most wind turbines produce wild three-phase AC, initially. The wild AC output is converted (rectified) to DC electricity by a rectifier. The rectifier may be located in the wind turbine itself or in the controller. Controllers are typically mounted next to the inverter or may be incorporated in the inverter. DC electricity is then sent to the battery bank.

At least one manufacturer (Endurance) is now producing a small turbine that contains an induction generator. This wind turbine produces grid-compatible AC power without the use of an inverter. An induction generator looks a lot like electric induction motors used in modern society. When spun faster than its normal operating speed, an induction generator produces AC electricity.

Because an induction generator synchronizes with the grid - that is, produces electricity at the same frequency and voltage - no inverter is required. But what features should you look for?

What to Look for When Buying a Wind Machine

While there are many turbines on the market, careful load and site analysis will narrow the field considerably. Once you have deter mined your average monthly electrical load and the average wind speed on your site, you can select a wind turbine that will produce enough electricity to meet your demands.

Manufacturers provide a plethora of technical data on their wind machines that can be used to make comparisons. Unfortunately, most of it is useless. Further complicating matters, "There can be a big difference in reliability, ruggedness, and life expectancy from one brand to the next," according Bergey Windpower.

So how do you go about selecting a wind machine? Although wind turbines can be compared using many criteria, there are only a handful that really matter: (1) swept area, (2) durability, (3) annual energy output, (4) governing mechanism, (5) shut-down mechanism, and (6) sound.

Swept Area

Swept area is the area of the circle described by the spinning blades of a turbine. Because the blades of a wind turbine convert wind energy into electrical energy, the swept area is the collector area of the turbine. The greater the swept area, the greater the collector area. The bigger the swept area, the more energy you'll be able to capture from the wind. To get the most out of a wind turbine - to produce the most electricity at the lowest cost - select a wind turbine with the greatest swept area. Swept area allows for easy comparison of different models.

Swept area is determined by rotor diameter. The rotor diameter is the distance from one side of the circle created by the spinning blades to a point on the opposite side or about twice the length of the blades. When comparing wind turbines, then, the rotor diameter is a pretty good measure of how much electricity a turbine will generate. Although other features such as the efficiency of the generator and the design of the blades influence energy production, for most turbines they pale in comparison to the influence of rotor diameter and , hence, swept area.

Manufacturers list the rotor diameter in feet or meters - often both. The greater the blade length, the greater the rotor diameter and the greater the swept area.

Most manufacturers also list the swept area of the rotor. Swept area is presented in square feet or square meters - sometimes both.

Annual Energy Output

Another, even more useful, measure is the annual energy output (AEO) or annual energy production (AEP) at various wind speeds.

The AEO of a given wind turbine is presented as kilowatt-hours of electricity produced at various average wind speeds. Like the US EPA's estimated gas mileage for vehicles, AEO gives buyers a convenient way to compare models. As in the estimated gas mileage rating, however, AEOs won't tell you exactly how much electricity a wind machine will produce at a site. Performance varies depending on a number of factors such as turbulence and the density of the air.

Durability: Tower Top Weight Another extremely important criterion is durability. The most important measure of durability is tower top weight - how much a wind turbine weighs. Four turbines that produce about the same amount of electricity are for example, the Proven WT2500 (419 pounds), the ARE110 (315 pounds), the Skystream 3.7 (170 pounds) and the Whisper 500 (155 pounds). The weight differences are in some cases substantial.

In our experience, heavyweight wind turbines tend to survive the longest - sometimes many years longer than medium or lightweight turbines. Weight is usually reflected in the price. Remember, however, that you get what you pay for. Producing electricity on a precarious perch 80 to 165 feet above the ground isn't a job you want to relegate to the lowest bidder, which is invariably the lightest turbine.

Balance of System Cost

Before you buy a machine, consider the total system cost. You'll need to purchase a tower and pay for installation, unless, of course, you install the tower yourself. Even then, you'll need to pay for concrete, rebar and equipment to excavate the foundation and anchors.

You'll also need to run electrical wire from the turbine to the house and purchase an inverter (although they're included in most battery-less grid-tie wind turbines). If you're going off-grid or want battery backup for your grid-connected system, you'll also need to buy batteries. All of this will add to the cost. The cost of the turbine itself may range from 10 to 40 percent of the total system cost.

Governing Systems

Found in all wind generators worth buying, governing, or overspeed control, systems are designed to prevent a wind generator from burning out or breaking apart in high winds. They do this by slowing down the rotor when the wind reaches a certain speed, known as the governing wind speed. Why is this necessary? As wind speed increases, the rotor of a wind turbine spins more rapidly. The increase in the revolutions per minute (rpm) increases electrical output. Although electrical output is a desirable goal, if it exceeds the machine's rated output, the generator could overheat and burn out. In addition, centrifugal forces in high wind speeds exert incredible forces on wind turbines that can tear them apart if the rotor speed is not governed.

Ill.5.5: Microturbines. Many microturbines like

the Marlec (shown here) have no governing mechanism to slow the rotor

in high winds. They rely on the relatively low rotor speed and rugged

construction to endure high winds.

A governing system is essential because it allows the turbine to shed extra energy when the winds are really strong. Not all wind turbines come with governing mechanisms, however. Many of the smallest wind turbines, the micro-turbines, with rated outputs of around 400 watts, for example, have no governing mechanisms (Ill. 5.5).

(These turbines are too small to produce a significant amount of electricity for most applications.) Larger wind turbines, those with swept areas over 38 square feet, however, come with overspeed controls. Two types are commonly found: furling and blade pitch.

Furling

Most manufacturers protect their wind turbines by furling. Furling is accomplished in one of two ways, both of which shift the position of the rotor (hub and blades) relative to the wind. This turns the blades out of the wind, decreasing the amount of rotor swept area that intercepts the wind. Reducing the swept area reduces the speed at which the rotor turns and the energy collected. Slowing the rotor will protect the wind turbine from damage.

Manufacturers employ two main types of furling: horizontal and vertical. In horizontal furling, the rotor turns out of the wind by turning sideways. For this reason, horizontal furling is also known as side furling. In vertical furling, the rotor rotates upward with the same effect. "Angle furling" is a combination of the two.

Ill. 5.6: Side Furling: This wind turbine is not broken, it is side

furling in high winds, which slows the rotor and protects the machine

from damage.

Ill. 5.7: Vertical Furling: Horizontal or side furling is achieved,

in part, by hinging the tail. In side-furling turbines, a hinge is located

between the tail boom and the body of the turbine. As you can see from

Ill. 5.6, the turbine is also slightly offset from the yaw axis - that

is, the yaw bearing is attached to the side of the turbine body, not

its center so the turbine is not directly over the tower. Because the

turbine is offset from the yaw axis, the force of the wind on the blades

tends to rotate the machine around the yaw axis. However, the tail resists

this rotation and keeps the rotor facing into the wind.

In light winds, the forces on the rotor and tail are small and the wind holds the tail in its normal position - straight behind the turbine. However, in strong winds, the increasing forces on the rotor overcome the force of the wind on the tail. Since the tail creates more force than the offset rotor, the tail stays mostly aligned with the wind and the turbine turns away from the wind. As a result, the turbine folds on itself. This slows the rotor.

Vertical furling is achieved by moving the hinge in front of the yaw axis and rotating it slightly. In high winds, the force of the wind tilts the rotor up, while the tail stays oriented downwind. As in side furling, this reduces its speed (Ill. 5.7).

When fully furled, the rotor of a vertical furling turbine resembles a helicopter rotor. When wind speed declines, however, the rotor returns to its normal operating position. Shock absorbers are often used to ease the rotor back into position.

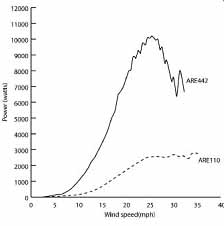

Furling reduces the amount of energy collected by the rotor.

Although electrical output typically continues, it usually occurs at a lower rate, as shown in the power curve of the ARE442 in Ill. 5.8.

Ill. 5.8: Power Curves. The electrical production of the ARE442, like

that of many other turbines, declines significantly in high wind speeds

as a result of overspeed controls that protect the wind turbine from

damage. The power production of the ARE110 plateaus, so the machine continues

to produce a significant amount of energy in high winds.

Ill. 5.9: Pitch Control - Blade-Actuated Governor. Numerous ingenious

methods of blade pitch control have been devised. In this turbine, a

Jacobs 31-20, the springs are part of a complex and effective blade pitch

control mechanism.

Changing Blade Pitch

The second type of overspeed control involves a change in the angle of the blades, known as blade pitch, to reduce rotor speed. Blade pitch changes automatically in these turbines as wind speed increases over a certain level. The greater the wind speed above the operating range of the machine, the more the blades rotate (pitch). Changing the angle of the blade reduces rotor speed.

Pitch control typically requires springs, gears and weights ingeniously arranged to produce the desired effect (Ill. 5.9). Some machines, like the Jacobs, use the weight of the blade itself to change the pitch.

Blade pitch functions admirably, but is not as widely used as horizontal and vertical furling mechanisms. Of the two, blade pitch control is more expensive, but provides better control of blade speed and is more reliable. Bottom line: although furling mechanisms are cheaper, cheap is not necessarily better when it comes to a wind machine. The goal in buying a wind machine is to purchase the most reliable and most durable turbine. That said, you may only have a few choices among the turbines that produce the amount of electricity you need and most of home-scale wind turbines use furling.

Shut-Down Mechanisms

Small wind turbines should include a reliable shut-down mechanism. They allow a turbine to be turned off so operators can maintain and repair a wind turbine without fear of injury. They also provide a means of shutting a wind machine down when extremely violent storms, especially thunderstorms, are approaching. Maintenance personnel engage the shut-down mechanisms when they need to work on a turbine, but they also typically secure the blades with rope - just in case the wind comes up while they're servicing a turbine.

Wind turbines contain two types of shut-down mechanisms: mechanical and electrical. Mechanical systems include disc brakes and folding tails. Both are manually activated. They're attached to a cable that runs down the tower. Tightening the cable activates the brake or folds the tail (side furling the machine), stopping the rotor (Ill. 5.10).

Ill. 5.10: Cable Winch on Tower. One may shut down a Jacobs

wind turbine by tightening the cable attached to the tail of the turbine.

Although disc brakes may seem like a good idea, they are not fail-safe. If the cable breaks in violent storm, for example, an operator would be helpless to stop the turbine. There's no way to apply the brakes! Although folding the tail protects the rotor from over-speeding, it doesn't stop it from rotating. This presents a potential risk to service personnel working on the tower, unless another means of stopping the rotor, such as a disc brake, is available. Furthermore, if the cable breaks in high winds, when the machine is shut down, the tail will swing back into the wind and the wind turbine will start back up. If the winds are strong enough, this could seriously damage the turbine. Some wind turbines come with electrical brakes, a.k.a. dynamic brakes. Dynamic braking is the least expensive option and is found in many small-scale wind turbines.

Dynamic braking is a fairly simple approach that is found in turbines equipped with permanent magnet alternators. It consists of a switch inside the house or at the base of the tower. When the brake switch is closed, it short-circuits the wind machine, rapidly slowing the rotor.

In dynamic braking, the braking force is proportional to the rotor speed. As the rotor slows down, the braking force diminishes. As the rotor speed approaches zero, so does the braking force. In low to moderate winds, dynamic braking should either stop the rotor or slow it down considerably. However, dynamic braking may not completely stop the rotor in high winds. In winds blowing over 20 miles per hour, for instance, dynamic brakes can't be counted on. If a wind machine is shut down prior to a storm's arrival, strong winds may overpower the brakes, causing the rotors to start turning. In high wind speeds that force the blades to start spinning slowly, energy is dissipated in the windings of the alternator, which could cause it to burn up. Not all dynamic brakes are created equal.

Those found in Southwest Windpower 's Skystream 3.7 and turbines made by Proven and Abundant Renewable Energy are 100% reliable, as far as we can tell.

Shut-down mechanisms of a wind turbine should be high on the list of considerations, right up there with swept area and tower top weight. If the turbine is to be serviced on the tower, the shut-down mechanism should be capable of completely stopping the rotor. Don't buy a turbine without a shut-down mechanism. Inexpensive wind turbine designs without a reliable shut-down mechanism are a short-sighted gamble, at best.

Sound Levels

The sound a turbine produces is another important factor to consider, both for your own peace of mind and your neighbors'. All residential wind machines produce sound. Sounds emanate from the blades as they spin. They produce a swooshing sound. Sound is also produced when a turbine furls in high winds. Rotation of the rotor in the alternator also produces sound, as do gears in gear driven wind turbines. (Sound test reports can be found at the National Renewable Energy Laboratory's website.) Sound levels increase as wind speed increases. However, sound from a wind turbine is often difficult to detect and is rarely a nuisance, as noted in Section 1. Remember, too, that mounting a turbine high off the ground - typically 80 to 120 feet - to reach the smoothest, most powerful winds significantly reduces sound levels at ground level.

Even so, it is important to consider sound levels. One way is to observe turbines you are considering in operation under a variety of wind speeds. If you can't, you may want to ask homeowners or business owners who have installed the turbines you are considering for their experiences.

Another method is to check out the rpm of the turbines at their rated outputs. Rated output is the output in watts at a certain wind speed, known as rated speed. Knowing this gives an idea of how much sound they'll produce - the higher the rpm, the more sound. The rpm of a wind turbine also give an indication of quality. Generally, less expensive and less durable turbines spin at a higher rpm. They rely on less expensive generators that operate at high speeds to produce energy. In addition, higher rpm machines are subject to more wear and tear and tend not to last as long.

Other Considerations

Although swept area, weight, annual energy output, governing mechanisms, shut-down mechanisms and sound levels are the most important factors to consider when buying a wind machine, there are other details that manufacturers provide. We think readers should be familiar with them, but not let them overly influence their judgment.

Cut-In Speed

One factor that is of little relevance is the cut-in speed - the wind speed at which a wind generator starts producing electricity. Most turbines don't produce appreciable amounts of electricity until wind speeds reach 10 miles per hour. They produce full power at speeds from about 23 to 30 miles per hour.

Some manufacturers recommend installing a turbine with the lowest cut-in speed possible in areas of low wind to make better use of the wind resource. However, because low wind speeds hold very little energy, low speed cut-in isn't important.

Power Curves

Another useless bit of information provided by wind turbine manufacturers is the power curve like the ones shown in Ill. 5.8.

Power curves are graphical representation of the power production of a wind turbine (in watts) at different wind speeds.

While power curves make for good visuals, they aren't always accurate. They're not always obtained under the most ideal test conditions. Moreover, they are a bit misleading to the uninitiated.

That's because most wind turbines operate at relatively low wind speeds - around 10 to 20 miles per hour - and very rarely operate at the peak of the power curve. As you can see, wind turbines produce much less electricity at lower wind speeds. When considering a wind turbine, what's important is how much energy it will produce at your site on your tower at your average wind speed - that is, the AEO. Rated Power

Last but not least is a measurement known as rated power, one we've avoided using as much as possible in this book. Rated power is the output in watts at rated wind speed. Much like the output of solar electric modules, rated power of wind turbines was devised to give buyers a way to compare products. Buyers, for instance, typically compare one kilowatt or ten kilowatt turbines as they would compare solar modules.

Rated power is of limited usefulness in large part because there are currently no standards in the wind industry (as there are in the solar industry) for determining rated power. Manufacturers determine rated power in different ways and at different wind speeds - the rated wind speed. This situation will change because the small wind industry is developing a standard technique of measuring performance.

To see why rated power is less than ideal, consider three wind turbines with identical rated power of 1,000 watts or 1 kilowatt:

(1) Bergey's XL.1, (2) Southwest Windpower's Whisper 200, and (3) Eveready's Kestrel 1000. At first blush, you might assume that all three wind turbines are identical. After all, they're one kilowatt turbines. However, Southwest Windpower 's Whisper 200 achieves its 1,000-watt rated output at 26 miles per hour. Bergey's XL.1 produces its 1,000-watt rated power at 24.6 miles per hour, and Eveready's Kestrel cranks out 1,000 watts at 23.5 miles per hour.

Although it might seem that the wind turbine that produces 1,000 watts at the lowest wind speed would be the best buy, that's not necessarily true. There's much more to consider, including swept area, tower top weight and AEO. As noted learned earlier, in most cases the wind turbine with the largest swept area produces the most electricity, but don't make that assumption without looking at the annual energy output. At an average wind speed of 8 miles per hour, the Kestrel 1000 will produce about 900 kilowatt-hours of electricity annually. The Whisper 200 will produce about 720 kilowatt-hours annually and the Bergey will produce approximately 660. (These numbers are based on the manufacturers' estimates.) It is also important to note that rated power is one point on the power curve and is the output at a wind speed that is much higher than those typically encountered at most sites. Thus, the rated wind speed only represents a small fraction of the wind resource at a site. We're interested in output in the typical range of wind speeds at our site, which is well below the rated power. Our advice on rated power: forget it.

Final Factors

When shopping for a wind turbine, be sure to check into the company's customer service record - how well it supports its dealers and customers. Some companies like Bergey Windpower and Abundant Renewable Energy have stellar service records. Be sure that the company you buy from offers technical advice should you have trouble and that their technical support staff speaks your native tongue.

Another factor to consider is how long the company has been in business. Doing business with a company that been in business for a while, say ten or more years, is a good idea. A related criterion to take into consideration is how long a wind turbine has been on the market. The longer a wind turbine has been on the market, the better. It has been tried and tested and improved upon.

It's also important to check on the availability of parts. Parts shipped from foreign countries, such as China , Europe , South Africa or Mexico may take months to arrive, if they're available at all.

Meanwhile, your $30,000 wind energy system sits idle. When shop ping, check to see if the importer of the wind turbine you are interested in stocks spare parts.

It's a good idea to consider the number of moving parts and wear points in a turbine. Some designs, like the Jacobs turbines manufactured by Wind Turbine Industries in Minnesota , contain a lot of moving parts, which results in numerous wear points - up to 300. These machines may require a lot of tinkering at 100 feet.

Be sure to check out the warranty. Warranties typically run five years. The longer the better. In June 2009, Bergey Windpower boosted its warranty to 10 years; others have pledged to follow suit. Also be sure to determine what warranties cover. Is it materials and workmanship or parts only? Does it include shipping? Unfortunately, most warranties do not cover the cost of labor.

We recommend buying from a local dealer/installer, too. That way, you'll have local support, even if you opt to do the installation yourself. Be sure to ask for references and interview them.

If you buy from an online wholesaler, be aware that most of these companies do not offer technical support, installation advice or assistance. Nor do they offer replacement parts or repair services. If you buy cheap, you are on your own when you need help.

We believe that it is a good idea to stick with name brand wind turbines and avoid newcomers and foreign imports, especially Chinese-made machines, at least at this time. Buying a used or reconditioned wind turbine may be an economical option, but it's not a very good idea. The problem with used wind turbines is that you don't often know what you're getting.

If you buy a remanufactured wind turbine, you want to be sure that the machine has been fully reconditioned, not just painted and with new blades installed. Make sure that the equipment supplied with the turbine, like the controller or inverter are code compliant.

You may also want to obtain an extended warranty. Also be sure you can find a tower for the turbine before you purchase it. Suitable tall towers for the larger small-scale wind machines are hard to find.

Building Your Own Wind Machine

If don't have the cash to buy a wind turbine or want the challenge of making your own turbine, you may want to consider building your own wind turbine (Ill. 5.11). Building your own wind generator provides invaluable experience. Directions for how to build a wind machine are available online.

At sites like H. Piggott's (scoraigwind.com) or D. Burtman's (otherpower.com), you'll find a listing of other valuable websites and resources.

Homebrew wind turbine master Hugh Piggott's website sells step-by-step plans for building axial-flux alternator turbines.

There are even a couple of books on the subject: Windpower Workshop by H. Piggott and a more recent title, Homebrew Wind Power: A Hands-On Guide to Harnessing the Wind by Other Power's D. Burtman and Don Fenk, which is an extremely well-written and thorough treatise on the subject. Rather than provide a full description of this subject, which would take a section or two, maybe even an entire book, we recommend you consult these resources. We also recommend that you sign up for a workshop, for example, through The Evergreen Institute or otherpower.com.

Building a wind generator is not that difficult, if you are mechanically inclined and persistent. You will need a shop and some common hand and power tools. "The hardest part of designing a small windmill for electricity production is to find a suitable generator," writes Piggott in Windpower Workshop. "For best performance you'll need a reliable, low-speed generator that's pretty efficient in light winds," he adds. Piggott strongly recommends permanent magnet alternators. "Unfortunately, permanent magnetic alternators are difficult to find." Piggott lists some sources, among them motorcycle alternators and welders. Unfortunately, each one has a significant down side. See his website and book for more on this and other options.

Ill.5.11: This amazingly quiet wind turbine designed and built by the folks from otherpower.com is remarkably reliable and efficient. Other Power sells kits that require some assembly

for independent and budget-constrained buyers.

Car alternators are popular among do-it-yourselfers; however, they require high rpm and are not always very efficient. They also require a lot of electricity to power the electromagnets that create the magnetic field. You'll also need to rewind the stator coils so they produce electricity at the lower speeds common in wind turbines.

This is a big job for those without experience. Most people who've tried this route give up in failure. When building a wind turbine, you'll also have to design and build blades and install controls. Blades and rotors are particularly tricky. They need to be carefully matched to the generator. Most homemade wind turbines use wooden blades, which must be hand carved.

You will also need to incorporate overspeed controls and a shut down mechanism. and don't forget you will need an inverter matched to the turbine. Be wary of cheaply made wind turbines like those with blades fashioned from PVC pipe. Remember, too, that you need to install the turbine on a tower. Tower designs can also be found online. Be careful, however; homemade towers often leave much to be desired. Towers are far more complicated to design than wind turbines. Your best and safest bet is to buy a new or used tower.

Conclusion

Buying a wind turbine isn't easy. There are a lot of factors to take into account. Price is only one of them. Be sure to choose a machine that meets your needs. If you're installing a grid-connected system, choose a grid-tie turbine. If you're installing a battery-based sys tem, look for a battery-charging turbine.

Be sure to take into consideration key factors such as the swept area, annual energy output and durability. If you want a turbine that will last for many years, you'll need to look for one of the meatier models. It will cost more initially, but will outlast its cheaper cousins, costing much less in the long run.

Next: (coming soon)

Prev: (coming soon)