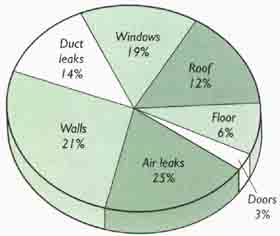

Where Your Heating Dollars Go : As this chart shows,

the windows in a typical New England house—most of which are single-pane

wooden windows with storms—only represent 19% of its annual heating bill.

Replacing them with vinyl-insulated glass windows would save less than

3% on the heating bill. Vinyl, low-e argon-gas windows would save quite

a bit more, about 11%, at very little extra cost. A set of high- performance

replacement windows may save 15% to 17%, but expect to pay a premium.

Windows are rarely a cost- effective improvement based solely on energy

savings .

Of all the materials we use in our homes, we probably expect the most of windows. They are constantly forced into compromise: We want them to let light in. then we add shades to keep light out. We require that they seal tightly against air and rain, but we want to open them to let in air, then we cover them with screens to keep insects out. We want them to keep heat in during winter and out during summer; we want them to keep water out all the time. It’s no wonder that windows end up being expensive to buy and maintain.

Some replacement windows can be installed without your

having to replace the interior or exterior trim. Although these new

windows may look and function better than the old ones, don’t be lured

by a promise of big energy savings.

The lure of replacement windows.

Replacement window manufacturers and installers often sell their products with the promise that new windows will reduce your heating and cooling bills. In certain cases, big savings may theoretically be possible, but it is rare to find a situation where that is realistic. In fact, in a typical New England house, windows account for less than 20% of annual energy costs. Even if you shuttered all of them with 4 in. of high-R insulation, you still couldn’t save any more than that.

I have seen homes in which the owners replaced their old, single-pane and storm combination windows with cheap double-pane units, and their energy bills (and street noise) actually increased. Even if you buy replacement windows at a good price and install them yourself, the payback is unlikely to be within 20 years. If you pay someone to install inexpensive replacement windows, it’s more likely to be 40 years or more, far longer than the expected service life of the windows themselves. In short, the benefits of replacement windows are often overstated. If you’re buying replacement windows. You need to do your homework: Windows are expensive, and buying the wrong ones can be a costly mistake.

TIP: If you are buying new windows, get the best ones that you can afford. But don’t buy replacement windows just for energy savings.

IN DETAIL: Replacement windows usually don’t pay for themselves in energy savings. But once a house has had air-sealing, insulation, and duct-sealing, the energy costs associated with windows make up a proportionately larger percentage of the total energy dollars. At that point, window improvements may make more economic sense, and when you do replace windows for any other reason, the added cost of high-performance windows is usually easy to justify based on the energy savings they offer.

WHAT CAN GO WRONG: Don’t waste time weather stripping windows and doors unless you’ve first air-sealed your attic and basement. Otherwise, you’ll just build a chimney, with nice, tight sides of weatherproofed doors and windows and insulated walls. Air will leak in from the basement, flow up through the house, and out from the attic.

Types of windows

Up until the 1960s, standard windows in the United States were built with a single layer of glass. In cold climates, they were often accompanied by storm windows. Since then, standard fire has been a sealed double layer of clear glass, commonly called insulated glass. Now, homes with single-pane glass are relatively rare in the cold- and mixed—climate zones of the United States.

Typically, the insulated glass used in most residential windows is composed of two layers of glass separated by a metal spacer and sealed to keep out moisture. But not all insulated glass windows are the same—most of the improvements in window technology over the past two decades are practically invisible, but the energy performance from window to window can vary a lot.

Most significant energy features fall into three categories: improvements in the glass, or glazing; improvements in the spacers at the edge of the glazing: and improvements in the sash and frame materials. Glazing improvements can be further divided into two categories-: reduction conductive heat loss and control of solar heat gain.

Energy-efficient features, such as Low-e coatings, warm-edge spacers, and thermal-improved frames, can improve window performance significantly but they the can also be confusing. The frame material does matter—aluminum frames, which are inexpensive and durable, perform poorly in cold climates but don’t have as much effect in warm climates. Wood, vinyl, and wood-clad frames and sashes conduct less heat, so they help you keep it in (or out).

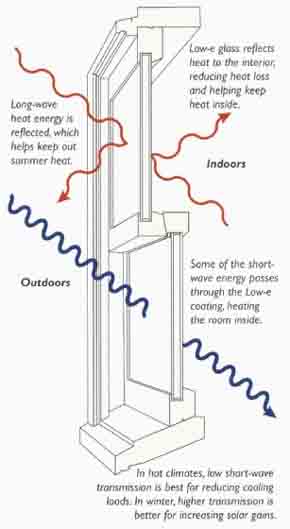

Low-e Glass Reflects Heat, Saving Heating and Cooling

Energy:

A Low-e coating on glass reflects heat reducing conductive heat transfer.

The amount of short-wave energy the glass should transmit depends on

your climate. Low-e coatings also reduce ultraviolet (UV) rays, which

fade furnishings.

Some of the short wave energy passes through the Low-e coating, heating the room inside.

In hot climates, law short-wave transmission is best for reducing cooling loads. In winter, higher transmission is better for increasing solar gains.

In cold or mixed climates, most homes with older single-pane

windows probably have some variation of this triple-track aluminum-frame

storm window.

Most new windows are made with sealed, double-glass units.

The edge spacer separates the two layers of glass and provides an insulating

airspace that keeps out moisture. However, aluminum spacers conduct heat

and are a thermal weak link in the design of a window.

Low-e coatings and gas fills

Two window technologies that are fully commercialized and readily available are Low-e coatings and gas fills. Low-e coatings help improve the thermal performance of windows by controlling the amount of solar energy that passes through them and decreasing the amount of radiated heat transfer. The coating is virtually invisible and is applied to one of the inner surf of the sealed double-glazed unit. Low-e windows also have warmer indoor surface temperatures in winter (and cooler in summer), making indoors more comfortable year-round.

Gas fills -- typically argon or krypton -- replace the air that would normally be between the layers of glass. Usually added to Low-e windows, these non-toxic, inert gases further decrease the amount of conducted heat, primarily a heating-season benefit. Low-e coatings and as fills cost a little more, but at $20 to $50 per window (assuming the same frame and sash), the upgrade from ordinary insulating glass to Low-e with argon is well worth it, because their extra cost can he quickly recovered in energy savings.

This fiberglass frame conducts much less heat than vinyl and

wooden frames do, and it is more dimensionally stable, too. This Canadian-made

sample has a third layer of glass, instead of plastic film.

92-2.jpg Anatomy of a High-Efficiency Window: Heat mirror glazing systems usually contain one or two layers of plastic film suspended between two layers of glass. The plastic film has an additional low-e coating embedded in it, but the film is much lighter and thinner than additional glass layers would be. These windows usually have warm- edge spacers, an alternative to the standard heat- conducting metal spacers. Layers of heat mirror film have Low-e coatings embedded in them to further enhance the unit’s performance. Low-e coating on inner surface of glass. The spaces between glass and film are filled with argon or krypton gas to. Improve heating performance.

Advanced windows

A number of other window features that are relatively new to the market are gaining a foothold in the industry. Some of them, such as warm-edge spacers, are finding applications in a wide variety of products. Others, including multiple layers of heat mirror film and insulated fiberglass frames, are found in premium products that cost considerably more. In general, depending upon the climate in which you live and the climate-specific features of the windows. Our advice is to buy the best windows that you can afford.

TIP: Low-e windows can significantly reduce heat loss in winter and heat gain in summer, making your home more comfortable year-round.

WHAT CAN GO WRONG: One thing to consider when buying new windows is the quality of the edge seals. Pay attention to the manufacturer’s warranty, which should give you some idea as to how long the seals will last. Well-designed and constructed edge seals should last 20 years or more. When the seals fail, moisture can condense between the panes of glass, giving them a cloudy appearance.

The death knell of any sealed glazing unit is the failure of the edge seal, which allows moisture to migrate into the space between the glass, resulting in condensation.

Next: Replacing Windows