Boilers, an old standby in the Northeast, are becoming more popular around the country with the advent of radiant, hydro-air, and hybrid systems. Instead of heating air, a boiler heats water.

The classic boiler system uses hydronic distribution. Water is heated by the boiler and pumped through pipes to hot water radiators or baseboard fin-tube convectors to heat the house. Some older systems use a boiler to make steam, which expands to fill steam radiators without the need for a circulator pump.

Radiant Floor Heating In the past decade, built-in radiant floor hydronic systems have become quite popular. Quiet and out of sight, they employ specialized flexible tubing embedded in concrete slabs or framed flooring systems, turning the entire floor surface into a cozy, low-temperature radiator. When properly designed and installed, radiant floor systems provide reliable, even heat with unsurpassed comfort. Radiant heating is commonly touted as an energy saver, because people are comfortable at a lower thermostat set point. However, recent research has shown no significant difference in thermostat settings between radiant floor houses and others, suggesting that energy savings are largely theoretical.

|

Basic maintenance

Boiler maintenance is similar to that of a gas or oil furnace, but there is no blower fan to clean. Oil boilers should be serviced once a year, while gas boilers should be serviced every two to three years.

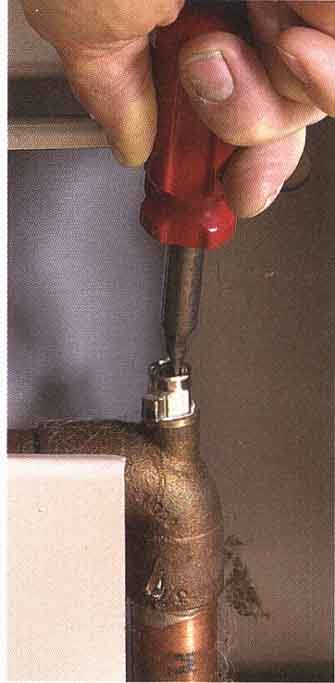

Any swishing or gurgling sounds that you hear in the radiators indicate air trapped in the system, which reduces heat-exchange efficiency. A service technician can bleed out the air and show you how to do it if it is needed frequently.

Occasionally, bleed valves may need to be installed or replaced. The technician should check the hydronic system pressure and expansion tank; the smallest leak anywhere in the system should be repaired immediately to prevent corrosion-causing oxygen from being brought in via makeup water connections.

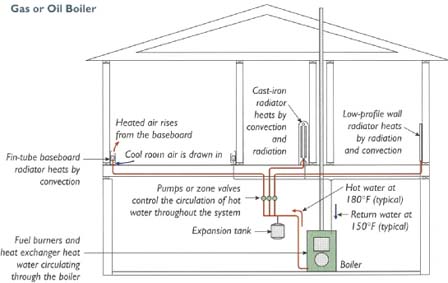

Gas or Oil Boiler Boilers heat water, which is circulated throughout the house to deliver heat. Valves or individual pumps may control the flaw to separate zones in the building. Occasionally, Euro peon- style hardware is used for continuous circulation and individual thermostats mounted on each baseboard. In the popular fin-tube baseboard, a copper pipe runs through the middle of an array of aluminum fins; the large surface area of the fins provides heat transfer to the air. The air moves through the baseboard by natural convection: Cool air is drawn in from the bottom and the heated air rises and escapes from the top. Older houses may have cast-iron hot water radiators; recently, European-style wall radiators have become popular. All three are shown here, though they ore not usually mixed in the same house.

|

Boiler controls and upgrades

A typical hot water boiler operates throughout the winter with a water temperature determined by the Aquastat, or low limit, setting (an Aquastat is like a thermostat that senses the water temperature inside the boiler and shuts off the burner when the water is hot enough). Boiler controls may maintain full boiler temperature throughout the year, which is very inefficient but necessary if a tankless coil water heater heats the domestic hoi water. In the absence of tankless coil, typical boiler controls may be set either to maintain constant boiler temperature all winter or to shut down and let the boiler cool off when not in use. Clearly, the latter is more efficient and is the preferred configuration.

Electronic pilot ignition may be installed on gas boilers and furnaces. Another improvement that can save boiler energy is installing a mechanical vent damper. This device closes off the flue pipe after the burner shuts off, stopping the flow of heat through the heat exchanger and up the chimney It costs $125 to $350 installed. I don’t recommend gravity-actuated vent dampers that depend on the heat from the burner to stay open; they are much more likely to contribute to backdrafting. (Vent dampers are not much benefit to a furnace; a low fan-off temperature setting allows the fan to carry most of the residual heat into the house after the burner stops.)

A new oil boiler may have an efficiency rating of 84% or higher.

Every hydronic radiator should have a bleed valve, which can

be opened slightly with a screwdriver or a special key to let trapped air

escape.

This vent damper automatically opens when the boiler fires,

then closes when the burner shuts down, reducing the amount of heat lost

through the chimney.

PRO TIP: When air-venting doesn’t work properly on a steam-heating system, it can lead to uneven heating, large temperature fluctuations, and discomfort CAUTION: common problem with team systems is too much pressure. The boiler pressure controls should be set just high enough so that the boiler shuts down just as each radiator fills with steam. Too much steam pressure increases the boiler’s cycling losses and leads to over heating. That can particularly be a problem if the building envelope’s efficiency is improved dramatically and /or some radiators are removed during remodeling. Timed-cycle controllers vary the boiler cycle length to match the outdoor temperature, further improving the system’s efficiency. TRADE SECRET: If you have an oil-fired boiler or a furnace with a standard, inefficient oil burner, have a technician replace the burner with a flame-retention burner. Those units, which cost about $400 to $500, do a better job of mixing the oil with the combustion air, which better controls the fire. They also reduce the amount of heat lost up the chimney, bringing the overall efficiency |

Steam boilers

Steam boilers are very different from hot water boilers. Steam systems were popular in the early 20th century and many of them are still in service in older homes. Instead of relying on pumps to circulate hot water, steam boilers boil water to create steam. The steam naturally expands to fill all the pipes and radiators in the system, distributing heat throughout the house. Although steam-heat distribution is simple and reliable, steam boilers have a number of unique maintenance and efficiency issues.

Most residential steam systems are one-pipe systems. When the thermostat calls for heat, the boiler fires and steam begins expanding to fill the system. As the steam expands, it displaces air contained in the pipes and radiators, and that air must be allowed to escape through air vents typically located at the top of each steam radiator. Once the steam reaches the radiator, the air vent senses the heat and closes, keeping the steam inside. As the steam emits heat through the radiator, it condenses to water and flows back via gravity through the same pipes to the boiler.

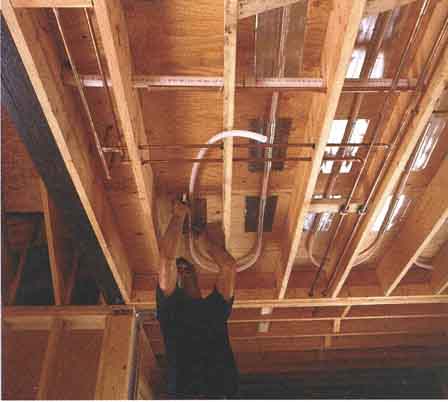

Pipe Insulation Both hydronic and steam-boiler systems can benefit from insulating distribution pipes, particularly in unconditioned basements and crawl spaces. Be sure to install insulation neatly, and miter the corners to minimize pipe exposure. Use a good-quality tape, where necessary, to hold the insulation in place and keep the seams closed. Wrap the tape several turns around the insulation; don’t just run it lengthwise along the seam. and for safety’s sake, don’t disturb any boiler piping that appears to have asbestos insulation on it already.

|

Air-venting systems that aren’t working properly can lead to uneven heating, large temperature fluctuations, and discomfort. A tune-up can increase energy efficiency and comfort dramatically. If the air vents are too small, if there are not enough of them, or if they are clogged with mineral deposits, air gets trapped in the system, and the steam can't reach its destination. Having a professional replace malfunctioning air vents, add extra vents to radiators, and add special high-volume air vents to large central supply pipes can improve steam-system efficiency by quickly get ting the heat where it is needed. Thermostatically controlled vents can reduce the rate of steam delivery to some rooms, reducing overheating and improving overall comfort.

Two-pipe steam systems (less common in residences) have a separate condensate-return pipe.

Instead of air vents, two-pipe systems have a steam trap at each radiator. Steam-trap maintenance is critical for proper operation, and all the steam traps in a system should be replaced or rebuilt at the same time, not one by one.

In addition to the standard cleaning and tuning that every boiler or furnace requires regularly, many steam systems need periodic adjustments to the water level, which is typically done by the homeowner. Steam boilers also need regular water maintenance; periodically, boiler water should be drained to remove sediment and rust. Chemically treating steam-boiler water reduces corrosion and improves steam distribution efficiency. Steam-boiler water maintenance should always be performed by technicians with experience in local water conditions and steam maintenance.

TIP: If you are planning to replace an old heating system with a new, energy-efficient one, stick with the same fuel- and heat-distribution system CAUTION: Atmospheric vented combustion equipment depends on waste heat to carry combustion byproducts up the chimney. That waste heat is one of the major sources of inefficiency in old furnaces and boilers. New, high-efficiency equipment wastes much less heat. Cool chimneys can condense water, potentially damaging the structure and the equipment. Old masonry chimneys can be retrofitted with aluminum or stainless-steel liners, which eliminate condensation and improve draft velocity (they should be installed by a professional). Many new furnaces and boilers can be vented directly through a sidewall or band joist, eliminating the need to upgrade an old chimney. Be careful if you upgrade your furnace or boiler; an atmospheric hot water heater left alone to vent through an old chimney may also cause problems. |

Zoning Distribution Systems Dividing a house into multiple heating zones, each with separate thermostatic temperature control, is often considered an energy-saving, as well as a comfort, feature. The theory is that people may lower the thermostat independently in parts of the house they are not using, reducing heat loss from those areas. Whether this saves energy depends entirely on people’s habits, The simplest form of zoning is the installation of more than one heating system, each serving a section of the house with its own thermostat. In homes with electric baseboards, each room is usually a separate zone. Newer two-story homes often have a separate furnace and air conditioner to serve each floor. Individual heating systems can be divided into separate zones with varying success, Hot water boilers can easily be zoned with separate circulator pumps and piping; residential steam systems are pretty much impossible to zone. Furnaces and heat pumps can be zoned with special dampers that block airflow to various sections of the house, but those installations typically suffer efficiency problems. All ducted heating systems, especially heat pumps, depend on adequate airflow, When only one zone calls for heat, the airflow is choked off and efficiency suffers dramatically. One way around this problem is to install multi-speed equipment. Some high-end furnaces have modulating burners, the best heat pumps have dual-speed compressors, and both have variable-speed blowers, Those features allow the equipment to run more efficiently when there is only partial demand. They even improve the efficiency of single-zone systems by matching the equipment output to the load in mild conditions. |

Next: Upgrading or Replacing Heating Equipment

Prev: Electric-Resistance Heat