If wind is a viable option for you, you’ll next need to determine which machine and tower to buy. You’ve got lots of choices. This decision typically hinges

on two basic considerations: how much electricity you want to generate from

the wind and how much money you have to spend.

As you shall soon see, there

are hidden traps for those who don’t shop carefully. I’ll explain how you can

avoid these traps in this section.

Choosing a Wind Generator

As just noted, choosing a wind generator can be tricky. Soon you’ll discover that there are numerous manufacturers and numerous models to choose from, ranging from 400-watt to 20,000-watt units. Moreover, there are many different factors to consider when making a decision, among them rotor size, cut-in wind speed, rated output, peak output, swept area, weight, and price. There’s also the issue of noise and reliability. Finding information on the latter may be difficult.

As you shall soon discover, not all of the information provided on wind machines by manufacturers and retailers is useful, To help avoid confusion, let’s see what factors are the most important to consider, Bear in mind, though, if you are dealing with local wind energy suppliers/installers, they can often ease the pain a bit, A reliable supplier/installer, for example, typically recommends a few models with which he or she has had success, Be sure to hire someone whose opinions are based on experience and not what they’ve read in the product literature or been told by company sales staff.

Wind machines can also be purchased through national suppliers like Gaiam Real Goods or online suppliers. Although such sources typically carry models that work well for them, you should know as much as you can about wind machines before putting your money down.

In this section, I’ll provide a great deal of information in an effort to help you under stand the most important factors you’ll need to consider when shopping for a reliable wind machine. If you want to do a detailed analysis of your options before talking to a local dealer! installer or before perusing catalogs of various online suppliers, I strongly recommend that you read and digest Mick Cabrillo’s article on choosing a home-sized wind generator. It is published in the August / September 2002 issue of Home Power magazine. This piece, titled “Apples and Oranges, Choosing a Home-Sized Wind Generator,” is Mick’s fourth article on the subject in Home Power over a period of ten years. (Neal updates the piece every few years.) Reading and studying this excellent piece will provide a very solid understanding of wind machines and what to look for, That said, let’s take a look at the most important criteria you’ll need to assess when shopping for a wind generator.

Wind Machine: Which Size is Right for Your Home Wind generators for use in homes, on farms and ranches, and in small businesses, come in many sizes, ranging from 400 watts to 20,000 watts. This measurement is their output at a certain wind speed, and serves as a rough guide for selecting a machine. Generally, the 400- to 1,000-watt machines only supply 40 to 200 kwh of electricity per month, and only in areas with good solid 12-mile-per-hour average wind speeds. Most homes in America consume around 750 to 1,000 kilowatt hours per month. All-electric homes could easily consume 1,500 to 2,500 kwh per month, as would a small business or a farm or ranch operation. Unless your home or business is super-efficient, you will need a larger wind machine, around 2,500 to 6,000 watts. Even then, you’ll need to use electricity efficiently unless you install one of the largest and costliest models with rated power values of 10,000 kwh. Or you could install a hybrid system: a smaller wind generator with a PV array. |

Swept Area

As you may recall, the spinning blade assembly is known as the rotor, It is the collector of wind. As noted earlier, the rotor converts the movement of air passing by the blades into mechanical energy. It, in turn, is converted into electrical energy by the generator. As a general rule, the larger the rotor, the more electricity it will produce. As Neal Cabrillo points out in his piece in Home Power, a wind generator’s rotor size “is a pretty good measure of how much electricity a wind generator can produce:’ Although other features such as the efficiency of the generator and the design of the blades can influence efficiency, Cabrillo argues that “they pale when compared to the overall influence of the size of the rotor.” With wind machines, size does matter.

Rotor size is indicated by the length of the blade, which is the diameter of the circle described by the spinning blades. The area of that circle is known as the swept area.

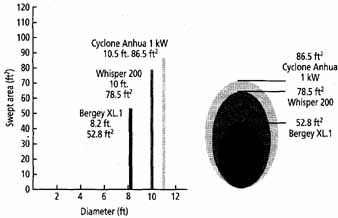

The swept area is measured in square feet or square meters. ___ 8-6 illustrates the differences in swept area of three household- sized wind machines. You can quickly pick out the high-energy models just by looking at the swept area,

Hugh Piggott of Scoraig Wind Electric in Scotland points out that “Swept area is easier to measure and harder to lie about than performance.” This is the one factor that allows for easy comparison of different models.

Cut-In Speed

Household-sized wind machines start producing useful amounts of electricity at wind speeds in the range of six to eight miles per hour. This is known as the cut-in speed. Because the cut-in speeds of most models fall within a narrow range, this generally won’t be a feature that will influence your decision.

The swept area varies dramatically from one wind machine

to the next. By and large, you should choose the model with the greatest

swept area. It will produce the most electricity at your site.

Rated Output

As you may recall, PVs are compared by their output — the amount of electricity they produce under standard conditions, Wind machine manufacturers, perhaps wanting to assist customers in making a decision, also rate the output of their products. They provide rated output data on various models in watts. Bergey Windpower’s BWC XL.1, for instance, has a rated power output of 1,000 watts. So does Southwest Windpower’s Whisper 200 and the Cyclone Anhua 1 kW wind turbine,

The trouble is, there are no set standards in the wind industry, as there are in the solar electric industry, for determining rated out put. All three manufacturers rate their wind machines at different wind speeds (called rated wind speeds). Bergey rated their machine at 24.6 mph, while Southwest Windpower rated theirs at 26 mph, and Cyclone rated theirs at 20 mph. So which one would be better

Because they are all rated at different wind speeds, you can’t really say. You would think that the wind machine that produces 1,000 watts at the lowest wind speed would be the best buy. But not so. Not in this case.

To make a decision, you’d be better off looking at the swept area. In this case, the swept area of the Bergey is 52.8 square feet, the Whisper is 78.5 square feet, and the Cyclone Anhua is 86.5 square feet. Which one will produce the most electricity for you

The model with the largest swept area, Let’s let Neal Cabrillo have the last word on this subject: “While comparing PVs based on rated wattage makes for great cost comparisons, comparing rated outputs is a poor way to compare wind generators. You are far better off comparing swept areas or the kWh per month of electricity the different systems will produce at different average wind speeds:’ In the example just given, the Bergey produces 115 kWh per month in an area with 10 mph wind, while the Whisper produces 125 kWh per month. Unfortunately, there’s no published data on the number of kwh of electricity produced by the 1 kW Cyclone Anhua, but we suspect it would be higher yet.

Governing System

All wind machines come with a mechanism to prevent the generator from burning out in high winds. Whys

High winds increase the RPMs of a wind machine, producing more power. However, really high RPMs can lead to overheating and burnout, They can also literally tear a wind machine apart, causing parts to break, just like a car engine that revs too high.

Manufacturers install two basic types of governor. One type simply turns the blades out of the wind so they stop spinning or, for one model, slow down, The blades, for instance, may tilt up and out of the wind. Although this type of governing mechanism protects wind machines from damage, it does greatly reduce, even halt, power production.

The other governing system changes the blade pitch, that is, the angle of the blades, so they no longer intercept the wind as efficiently. This causes the rotor to spin at a slower rate. Although blade pitch governing systems allow wind machines to continue to produce power, they require more moving parts. The more moving parts you have, the more maintenance. Talk to local installers for their recommendations.

Shut-Down Mechanism

Some wind machine manufacturers include a shut-down mechanism — a mechanical or electrical device that allows an operator to shut a wind generator off, This is important because it allows the owner to repair or maintain the wind machine without fear of injury. It also provides a means to shut the wind machine down when a violent storm is approaching.

Shut-down mechanisms come in many varieties from disc and dynamic brakes to folding tails — that’s right, tails that fold in such a way that the wind machine is forced out of the wind and the blades stop rotating.

Neal Cabrillo believes that the shut-down mechanism of a wind turbine is another key factor to consider when shopping for a wind machine. Unfortunately, he notes, “very few turbines have reliable shut-down mechanisms:’ The most effective seem to be those systems that allow the operator to crank the tail out of the wind or engage a disc brake. They are usually attached to a cable attached to a winch located at the base of the tower.

Noise Wind machines are not, by their very nature, quiet, although some models are significantly quieter than others, and some of these are so quiet you have to look to see if they are actually spinning. Noise is primarily generated by the blades cutting through the air. As a general rule, the blades of light-weight wind generators spin faster than heavy-weight units. As a result, the high rpm light-weight models tend to be noisier than their powerful heavy-weight cousins. One light-weight model in particular, the Air turns into a monster at high speeds, growling fiercely in the wind. Fortunately for all concerned, the greatest noise levels occur at high wind speeds, when background noise increases as well — for example, when the leaves and branches of trees are being blown by the wind. Also, fortunately for us, sound drops off fairly quickly with distance. Thus, the taller the tower, the less noise you will hear. |

Some Less Meaningful Measures

Manufacturers provide a host of other, relatively useless (at least to most buyers) measurements such as peak output and maximum design wind speed. Peak output is how much electricity the wind machine can produce at maximum power output; this is usually above the rated wind speed. While this figure may be of interest, it is of little relevance to buyers. The question you should be asking, according to wind energy engineer Eric Eggleston is “What will this wind generator do at my site in my average wind speed”.

Maximum design wind speed is another number sales people throw around, It’s meant to signal to the buyer the sturdiness of the machine, However, according to Cabrillo, “it has little bearing on the expected life of a wind generator”.

Cabrillo points out that wind generators are designed to survive wind speeds of 120 mph or more, but they are not necessarily tested at these speeds or repeatedly tested at these speeds — to see if the claims really hold up over time. The fact is, more machines are damaged by turbulence than high winds.

Even in high wind situations, says Cabrillo, it is not the wind that usually damages wind generators, it is flying debris, Cabrillo argues that the best criterion for durability is tower top weight: how much the unit weighs. “My experience,” says Cabrillo, “is that heavy duty wind generators survive, and light duty turbines do not:’ Therefore, even though most wind machines are rated for 120 mph or greater maximum wind speeds, “experience indicates that many of the lighter turbines can't handle sites with heavier winds or turbulence.” Of the three models we are examining, the Bergey XL.1 weighs 75 pounds, the Whisper H80 weighs a mere 65 pounds, and the Anhua tops the scales at 149 pounds. Cabrillo goes on to say, ”Be forewarned! Weight ... will be reflected in the price.” As a rule, the heavier the unit, the more you will pay, although low-cost Chinese wind machines could break that rule.

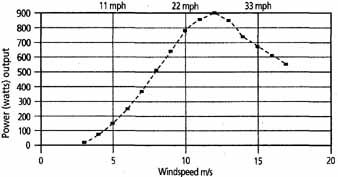

Another common but fairly useless tool for evaluating wind machines is their power curve, like the one shown in the ___ below. This graph plots the power production in watts at different wind speeds. While it is nice to look at, it doesn’t really help you very much in making a decision, Again, the more valuable measures are swept area, kwh per month in different wind speeds, and weight.

This power curve shows the output of an ARE1 10 wind

machine at various wind speeds.

Cost Factors

You’ll learn a lot more about other measurements in Cabrillo’s article, but by now you’ve gotten the main points: weight and swept area should be the primary criteria for selecting a wind machine, Cost comes into play, too. That is to say, comparing costs on the basis of weight and swept area can help you decide, Cabrillo recommends calculating the cost per unit of weight and cost per unit of swept area. Table 8-1 shows the cost of the three models we examined earlier based on weight and swept area.

Purchasing a Tower

Wind machines constitute a major expense in any wind system, but these costs are often rivaled by tower costs. Before we talk about costs, let’s take a look at your options.

Towers come in two basic varieties: free standing and guyed. Each type has a couple of subtypes.

Free-Standing Towers

Free-standing towers are those that require no additional support: they are self-supporting. Because they have a relatively small footprint, they are ideal for applications where space is limited.

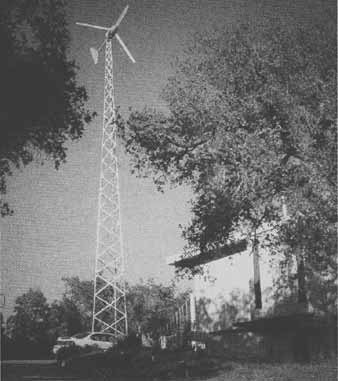

The most common free-standing tower is the lattice or truss tower, shown in the figure below. Lattice towers resemble the latticework of arbors. The Eiffel Tower in Paris is an example of a lattice structure.

The lattice or truss tower is strong and durable and an excellent choice for mounting larger wind machines. It can be supported

by guy wires, if necessary.

Lattice towers are secured to a massive foundation and are engineered to withstand powerful winds. Because of the large amount of metal that goes into them and because of the need for a sturdy anchoring foundation, they are the most expensive tower option.

Comparison of Three Wind Generators:

Model |

Swept Area (sq. ft.) |

kwh per month at 10 mph |

Weight (lbs) |

$ |

Cost/square foot swept area |

Cost / lbs |

Bergey XL.1 |

52.8 |

115 |

75 |

$2,450 |

$46.40 |

$32.66 |

Southwest Windpower Whisper 200 |

78.5 |

125 |

65 |

$2,602 |

$33.15 |

$40.03 |

1 kW Cyclone Anhua |

86.5 |

N/A |

149 |

$1,829 |

$21.4 |

$12.27 |

Free-standing lattice towers are typically installed in 20-foot sections. Paul Grippe, an internationally recognized wind expert and author of several popular books on wind power for residential use, describes the process like this: “For small wind machines, the sections are typically preassembled and welded together prior to delivery For larger machines, the tower is shipped ‘knocked down’ or in parts and must be assembled on the site.” Large towers are typically assembled on the ground, then erected with a crane and bolted to the foundation, Some installers assemble towers in the upright position piece by piece, which Grippe considers a risky and time-consuming venture. Yet another method is to install a tower that’s hinged at the base. The tower is then assembled on the ground, the wind generator is attached, and the assembly is tilted up using a variety of different techniques.

Rigid metal poles can also be used to create free-standing towers for wind machines, Most poles or masts are made from steel, although other materials are sometimes used.

Pole towers are usually installed with a crane, though they can be hinged at the base and tipped into place as well. (I’ll describe how this is accomplished momentarily.) Pole towers are anchored in a concrete foundation that is even more hefty than that required for a truss tower.

Poles are more expensive than lattice style free-standing towers, according to Neal Cabrillo. Whatever choice you make, you need to be sure that the tower is strong enough to withstand the winds in your area and strong enough to support the weight of the wind machine, both of which can be quite substantial, Several of the largest home-sized wind machines weigh around 1,000 pounds. The Jacobs 3 1-20, admittedly the heavyweight of the residential- or business-sized units, weighs an amazing 2,500 pounds!

The Mathematics of Wind Power The electrical output of a wind energy system depends on many factors: the most important are air density swept area, and wind velocity. This relationship is expressed in the mathematical equation P = ½ c x A x V What this equation tells us is that the greater the density of the air, the greater the swept area, and the greater the velocity, the higher the power output (measured in watts). Air density varies with elevation above sea level and humidity. Although we have no control over air density, there are a few things one should know. First of all, if you live in the mountains where air is less dense, you’ll need to lower your wind machine’s rating accordingly. Don’t expect it to produce as much electricity as it would at a lower elevation at any given wind speed. Second, you can expect greater output from a wind machine in the winter — about 13 percent greater — because the air is a bit denser in the winter than the summer. This is great for those who are installing a hybrid wind/PV system. While you can’t control air density, you can control swept area and wind velocity. Swept area, as explained earlier, is determined by rotor size. The bigger the rotor, the greater the swept area. Select a wind generator with the largest possible swept area. You can also affect wind speed by choosing the best site and installing your wind generator on the tallest tower possible. This allows you to raise the wind machine into the fastest winds and will have an enormous effect on power production. For example, by doubling the wind speed from 8 miles per hour to 16 miles per hour, power production increases by 800 percent! |

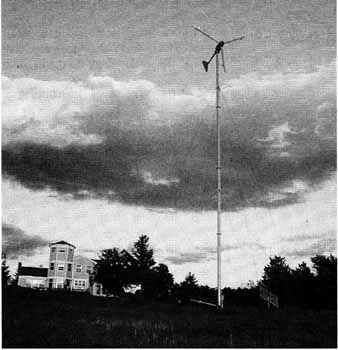

Guyed Towers

Guyed towers typically consist of steel pipe or lattice uprights supported by cables called guy wires that run from the tower to anchors in the ground. ( ___ below). Guyed towers are cheaper than free-standing towers and are therefore the most commonly used towers for household-sized wind machines.

Guy wires help hold many towers in place. Wires are installed

in groups of three to four. Typically, each segment of the tower is guyed.

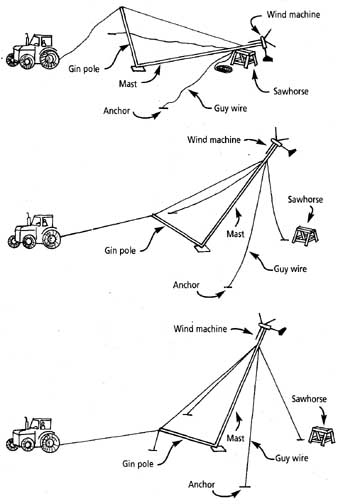

Steel pipe can be used for the masts of all household-sized wind machines, The steel pipes are assembled section by section, secured by bolts or slipped together, then erected using a crane or a gin pole. A gin pole is a pole anchored to the bottom of the mast that allows the assembly to be tilted up using a tractor, truck, or heavy-duty winch ( ___ below).

The gin pole shown here allows an installer to tip a

large tower into place without an expensive crane.

For the largest wind machines, the lattice tower is the tower of choice, They’re strong, mass-produced for the telecommunications industry and therefore widely available, and cheaper than other options. They’re also avail able in different strengths. Like free-standing lattice towers, they can be assembled in the horizontal position on the ground then tilted into place, or can be assembled upright, one section at a time or in their entirety, using a crane.

in all guyed towers, strong steel cable is attached to the tower and anchored in the ground using an assortment of anchoring mechanisms, depending on the soil type. Smaller towers require an extra-high-strength stranded- steel cable, Large towers may use aircraft cable, which is even stronger. Installers use three guy wires for each section of the tower, while tilt-up guyed towers have four, Manufacturers typically specify guy radius — that is, how far out the anchors for the guy wires need to be for optimal strength.

Tower Kits

If all of this seems a bit daunting, don’t be dismayed. A professional installer will design a system for you, order the components, assemble the tower, mount your wind machine, and raise the tower ... for a price, of course. If you’d like to try your hand at this, you’ll be happy to know that several manufacturers sell tower kits designed and engineered for their wind machines. Southwest Windpower, Lake Michigan Wind and Sun, Abundant Renewable Energy, and Bergey, for instance, all provide affordable tower kits. Because it doesn’t make sense to ship fairly inexpensive, but very heavy and bulky steel tubing long distances, Southwest Windpower kits pro vide all of the materials you need except the poles. Their kits don’t include the anchors, either, because the type of anchor varies from one location to another, depending on the soil type. You can purchase steel pipe locally at a building supply outlet or steel fence supplier. You can purchase the anchors from Southwest Windpower separately, or from a local wind energy supplier/installer, or directly from the manufacturer (the last option is usually the least expensive). To learn more about towers, you may want to read a piece, “Wind Generator Tower Basics” in Home Power magazine.

Tips on Finding a Supplier or Installer

If wind is a viable option to you — that is, you have enough wind in your area and can afford to buy and install a machine — you have two obvious options for proceeding. You can purchase and install the equipment your self or you can hire a professional. If you select the first route, you’ll need to do a lot more in-depth research. You’ll also need to read up on installation. You’d also be wise to take a course on wind energy that includes hands-on installation work, Be careful, Installation can be dangerous to people and equipment. You don’t want a $5,000 to $25,000 wind machine to come crashing down because you made a mistake during installation.

When purchasing a wind machine, be sure to check out warranties and read the fine print. Warranties run from one to five years. Also check out how long companies you are considering have been in business.

The second option is to go with a local supplier/installer. Their expertise can be highly valuable. A local expert can also help you troubleshoot problems once the system is up and running and can repair and maintain your system, if need be, Yes, I did say maintain.

Wind energy systems need periodic maintenance like any mechanical and electrical system. Batteries require maintenance, which is described in Section 7. Wind machines and towers also require periodic inspection and maintenance, Larger units may, for instance, need grease or oil changes. As Neal Cabrillo points out, “All towers and wind turbines require annual inspections at the very least. If you are not into maintenance, don’t buy a wind turbine:’

Although manufacturers have made tremendous strides in improving the quality of their wind generators since the early 1980s, mostly by simplify their machines and using stronger, more durable materials such as car bon-reinforced blades and new metal alloys, don forget: wind machines are exposed to extreme weather (heat and cold, snow, ice, and fierce wind) and amazing stresses, Fortunately, many problems that arise are simple ones, like loose bolts, that can be fixed in seconds. If left unattended, though, small problems can lead to catastrophic failures!

Blades may require maintenance, too. For example, some blades may need a new coat of paint from time to time. Wooden blades may have protective tape on their leading edges to protect them against grit in the air. The tape may need to be replaced from time to time, and , of course, bearings may wear out and need replacement.

To maintain a wind generator, you’ll either need to periodically ascend the lattice tower using a climbing harness —very care fully so as not to fall — or lower the machine to ground level if you have a tilt-up tower, After 20 years of successful operation, the guts of the wind machine may even have to be ripped out and replaced.

As Neal Cabrillo points out, “The life of a wind generator is directly related to the owner’s involvement with the system and its maintenance:’ If you expect a wind machine to work doggedly in its harsh environment with out maintenance, wind power might not be for you. That’s a pretty unrealistic expectation.

Some Tips on Installing a Wind Machine

To be effective, wind machines need to be installed in a good windy site, usually upwind of buildings and other obstructions, If installed downwind, they need to be significantly past the wind shadow — the relatively windless eddy created by obstructions. The best wind, as you’ve already learned, is the smoothest and strongest wind located 80 feet or more above the ground. The higher the better. To access the best wind, wind turbines for household, farm, business, and ranch use are erected on poles or towers ranging from about 80 to 120 feet above ground level, Most serious installations are 80 to 120 feet above ground.

Also, wind machines need to be placed on towers so that the entire rotor is at least 30 feet above the closest obstruction or treeline within 500 feet, Whatever you do, do not mount a wind machine on a roof or against a building — even if a supplier provides special mounts for such applications. The vibrations will be conducted into the building and can be very annoying. I know, I tried this ... just to test it, of course. (Yeah, right!) Moreover, buildings create air turbulence that lowers performance and increases wear and tear on the machine.

While we’re on this topic, be sure to mount your DC wind generator as close to the inverter as possible. This is important for two reasons: to reduce line loss and to reduce the need for larger (and more costly) electrical wire, (The larger the wire, the lower the electrical resistance. The lower the electrical resistance, the lower the line loss.) Installation manuals will help you determine the gauge wire you will need.

Before you decide to install your own wind generator, be sure to read more on the subject. Paul Gripe’s more advanced books on wind power are a good start, You may also want to check out the superb video An Introduction to Residential Wind Power with Neal Cabrillo.

If you feel comfortable with the installation process, be sure to study instruction manuals from the manufacturer, It wouldn’t be a bad idea to sign up for a course on wind energy through the Midwest Renewable Energy Association, Solar Energy International, the Solar Living Institute, or some other organization.

Next: Money Matters: What Does it Cost?