AMAZON multi-meters discounts AMAZON oscilloscope discounts

As a by-product of the woodworking process, sawdust occurs at practically every phase of a project: when dressing lumber (with hand-planes or thickness planers and jointers), when cutting out and shaping parts (with power saws and handsaws, routers, shapers, and drills), and when smoothing parts (with stationary sanders, power finis sanders, and hand-sanding blocks). Different types of operations create different-size chips, from large shavings to fine dust. This assortment of wood debris presents a variety of problems for the woodworker, from a mere nuisance and a disposal hassle to a safety hazard that can pose a serious threat to respiratory health. In this section, I'll examine these problems thoroughly and then explore a variety of solutions in subsequent sections.

Different Forms of Dust

It's important to differentiate the various kinds of dust created in the woods hop because each type of dust is best contained and controlled b a different set of strategies. Further, you'll need to consider the amount of different-size debris you create when selecting and sizing your dust collection system's filtration. Let's start by looking at each kind of woo debris (see the photo on the facing page), how it's created, and what k of problems it presents. Sizes obviously aren't absolute --a single tool or operation can produce a wide range of sizes of dust particles and wood debris; I've separated them out here for the sake of discussion.

Fig 1-1 Different kinds of woodworking tools create different kinds of wood debris, including large shavings from a handplane, chips and sawdust generated by bladed and bitted tools, and fine wood powder created by sanding operations.

Fig. 1-2: Large Shavings: Large chips and shavings are created when bundles or sheets of fibers are sheared from surface or edge of wood. Cutting action of plane blade

LARGE SHAVINGS

The largest shavings typically found in the woods hop are produced by powered cutterhead tools-including thickness planers, jointers, and shapers (fitted with long or large-diameter cutters)-and hand tools, such as chisels, carving and turning tools, and handplanes. These tools typically shear wood from the surface or edge of a board, removing fibers in long bundles, as shown in the drawing above.

Hand operations such as planing a surface with a well-tuned handplane can remove wide, continuous sheets of wood-not unlike unrolling a roll of paper towels. A power machine's rapidly spinning cutter-head produces shorter shavings since the blades travel through an arc, with each stroke removing a short shaving as it passes through its cut. Thickness planing or jointing long-grained softwoods (such as pine and hemlock) at slower feed rates produces longer, larger shavings, while planing short grained hardwoods (such as mahogany and ebony) at higher feed rates produces shorter, smaller shavings and chips. Shaping operations with large cutters also produce large shavings and chips-and occasionally small chunks of wood torn from a shaped edge or surface as well.

Because of their size and volume, large shavings accumulate quickly and occupy a lot of space. If your shop is small and you don't get rid of large shavings regularly, you'll end up tripping over pulpy mountains that accumulate underfoot and make getting around the shop hazardous.

Stationary machines with dust chutes or catch bins fill up so quickly that shavings clog the tool's cutter-head. The catch bin on my old Davis and Wells 6-in. jointer works fine during the occasional edge dressing but quickly gets stuffed after any significant amount of edge trimming say, when preparing a gang of boards for gluing up into panels for cabinet doors.

It's astonishing how quickly you can generate an extra-large plastic trash bag's worth of shavings when thicknessing a stack of boards on a thickness planer (see the photo at left). The shavings seem to pile up faster than snow during a winter storm in Buffalo. A common problem when running a thickness planer without dust collection is shavings ending up on top of the board just ahead of the out-feed roller. The roller presses these shavings into the top surface of the board as it passes through the planer. You end up scraping shavings off the freshly planed surface or, worse, have a board with shallow depressions where shavings were embedded in the surface. This problem is particularly vexing when taking deep cuts on very hard woods; the thick chips can leave indentations nearly 1/16-in. deep! Large shavings also present significant problems when shaping with large cutters working with the grain of the wood, during tasks such as raising panels or shaping railings and large moldings. If the shavings aren't collected, they accumulate around the cutter and tend to obscure the operator's view of the cutter-head and workpiece, which is clearly dangerous since there's a natural tendency to sweep shavings out of the way with your hand.

Roughing out a bowl blank on a lathe also produces sizable shavings that can become a nuisance. With a properly sharpened tool taking a shear cut, continuous shavings stream off the edge of the tool like ribbon unwinding from a spool. When turning green wood, these long, fibrous shavings can obscure the edge of the tool and entangle the tool and /or the turner, posing a hazard as well as a nuisance.

Because of their relatively large size and weight, shavings are the most difficult of all wood waste to collect, even with a small central dust collection system. It takes more energy to capture and transport large shavings through a vacuum hose or collection-system ductwork than to collect smaller chips and sawdust. The airflow from the vacuum/collector not only must have enough velocity (the speed of the collector's air suction) to capture shavings but also a high volume of airflow to handle the copious amounts of chips output by a thickness planer or shaper.

Fig 1-p6 Without dust collection, the large shavings generated by even a small thickness planer grow into mountains of debris that get underfoot and can create a fire hazard.

Central Collection is Best: A powerful, well-designed central collection system provides the best means for successfully collecting shavings from woodworking machines. Shop vacuums with small capacity canisters can quickly become overloaded, and long, stringy shavings easily clog the small-diameter (1 -in. to 1 1/2-in.-dia.) hoses found on many models these days.

CHIPS and SAWDUST

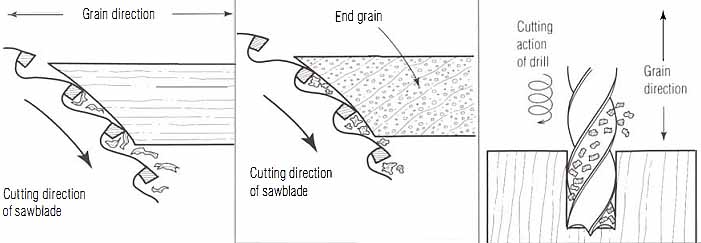

A wide range of cutting tools produces chips and sawdust, including power saws and handsaws, boring tools (such as drills and countersinks), and small- to medium-size shaper and router bits. Depending on the type of blade, bit, or cutter and a number of other variables, debris ranges in size from shredded cheese-size chips to fine-grained sawdust. Generally, cuts taken with the grain, as when ripping stock or dadoing on the table saw (see the drawing above left), create large chips and coarse sawdust. Smaller chips and finer sawdust are produced by cuts taken across the grain, as when crosscutting, as shown in the drawing above center, or by cuts into end grain, as when cutting tenon cheeks on the table saw, plunge-cutting a mortise with a router, or boring dowel holes in a face-frame rail (see the drawing above right) . Other factors that influence the coarseness or fineness of chips produced include:

• The design of the tool-the number of knives/teeth and their design, relief angles and gullet sizes, as well as the diameter of a cutter and its rim speed. Larger-diameter, faster-spinning blades and bits generally take more cuts per inch and hence produce finer chips. Rip blades with chisel-like low-angle teeth and large gullets produce longer shavings than cutoff blades with lots of high-angle, alternate-top bevel (ATB) teeth. Router bits or small shaper cutters with more flutes/knives produce finer shavings.

• The type of material and its strength and density. Cutting dense hardwood produces smaller chips than cutting softwood. Cutting plywood produces smaller chips since cutting in any direction penetrates layers both across and with the grain. Sawing or machining particle board, hardboard (such as Masonite®), and fiberboard (such as MDF, or medium-density fiberboard) produces fine dust, part of which is dust from the adhesives used to manufacture these products.

• The condition of the blade or cutter, including sharpness, balance, and degree of runout. A dull sawblade makes finer dust than a sharp one, and a poorly balanced cutter or blade with lots of run-out takes a slightly wider cut, thus producing slightly more sawdust.

Fig. p7: Long-Grain Wood Chips: Large, long-grain

chips are formed when wood fibers are sliced off with the grain, as when ripping

a board. Cross-Grain Wood Chips: Smaller Chips are created

when small bits of wood fibers are severed across the grain, as when crosscutting

a board. Fine Sawdust: Fine sawdust is made when bits of short

grain are sheared from the ends of long fiber bundles, as when cutting or boring

into end grain.

Although less bulky than large shavings, chips and sawdust can also pile up with surprising rapidity. Often-used machines, such as table saws, not connected to a dust-collection system quickly accumulate enough sawdust to clog the working parts to the point where you can't tilt or lower the blade easily (tilt stops for square and 45-degree cuts are thrown off as well). If you own a table saw with an enclosed base (such as a Delta® Unisaw® or a Powermatic® model 66 saw) that isn't connected to a collection system, you've undoubtedly had the occasion to open the trap door in the base and scoop out copious quantities of sawdust (see the photo below). Shaper and router tables also generate mountains of chips and sawdust, even when using relatively small bits and cutters.

Besides clogging a machine or power tool's internal works, accumulating sawdust can also ruin workpieces. Parts sometimes get cut too short or narrow when small chips keep the end of a board from bearing flush against an end stop or rip fence. When working freehand with a portable power tool such as a sabersaw, free-flying sawdust obscures the line of cut, often resulting in a miscut.

A simple but annoying aspect of woods hop sawdust is its tendency to stick to the bottom of your work shoes (it seems to have a special affinity for the tread pattern on sneakers). You end up tracking the sawdust around the shop and , if you work at or near home, into your house as well.

===

Dust Collection Keeps Cullers Sharp: An important reason for sucking away sawdust during the cutting process is that it actually reduces the dulling of cutting edges and teeth.

Chips that aren't evacuated bounce around and are re-cut many times before they're ejected. This repeated cutting causes more heat buildup, and it dulls teeth quicker since the teeth are doing more work than they need to.

===

Fig. p8: It's astonishing how quickly sawdust and chips can accumulate under closed-base machines, such as this table saw. If not cleaned out regularly, chips can quickly foul a tool's works.

FINE WOOD POWDER

Although most wood-machining operations create small amounts of fine wood dust, powder is a primary product of sanding wood. Whether you deposit a thin layer of powder on the bench or create an ominous cloud of woody effluent is greatly influenced by your means of sanding. Random orbit sanders (electric or pneumatic) are hard to beat for their ability to smooth a surface quickly and efficiently, but they're also champs at throwing out great billowing clouds of dust in every direction. Even if you simply sand by hand with a piece of sandpaper wrapped around a wood block, you still end up churning out a noticeable amount of very fine dust.

Fine wood dust is composed of particles that are really broken pieces of wood fiber abraded from the side, face, or end grain of a board (see the drawing on the facing page). Think of each particle as a tiny chip that's been scraped off by the abrasive particles on the surface of the sandpaper as it scours the wood. Finer-grit sandpaper is covered with finer abrasive particles and , hence, creates finer-size dust particles.

Sanding dust also creates problems for the sandpaper used to create it.

Fine wood dust churned out by power-sanding machines-such as stationary belt, disk, or oscillating spindle sanders-tends to embed in the surface of the sandpaper where it clogs abrasive particles and decreases their efficiency. This problem is especially bad when sanding resinous woods, such as pine, and oily woods, like teak. As the clogging gets worse, more heat is generated during sanding, which causes glazing that shortens the life of abrasive disks, drums, or belts or ruins them rapidly. Since a replacement belt for a wide-belt sander (such as a Timesaver®) can cost over $100, clogging from fine sanding dust is a big problem indeed.

Fig. p9-0: Power sanders-including belt, random-orbit, and orbital sanders-make Quick work of smoothing rough surfaces but can create clouds of extra-fine wood powder, which wafts about the shop and becomes both a nuisance and a health hazard.

Fig. p9-1: Wood Powder: Fine wood powder is produced when tiny particles of wood are scraped off a wood surface by sharp edges of abrasive particles. Cutting action of sandpaper vs. Grain direction Fig. p10: Sweeping the shop floor with a broom or blowing off benches and machinery with a compressed-air hose may be expedient, but it also sends tons of fine dust flying. For more breathable air, always clean up with a shop vacuum or hose connected to a central collection system.

Most other problems caused by sanding dust are the result of the particles' smallness. Very fine dust is measured in microns (abbreviated μm): One micron equals one thousandth of a millimeter. Larger particles, 100 µμm and bigger, tend to fall to the floor quickly. In contrast, wood powder is so fine that it's easily suspended in the air where it wafts around for a long time (a 5μm particle stays aloft for 30 min. or longer, depending on the amount of air movement in the shop). The lightness of the particles explains why you can run a power sander over a large panel, blow or brush the top clean, and then come back half an hour later and find that a thin layer of fine powder has recoated everything.

If you don't keep your shop's floors and benches tidy, just picking up a board or walking around can raise a dusty cloud. Even sweeping with a broom stirs the dust up like crazy. Fine dust also makes it difficult to do any kind of finishing in the same space that you make sawdust; particles continue to settle as the finish dries, and you end up with a nubbly surface.

Fine dust easily floats under doorways and through ventilation ducts to infiltrate spaces adjacent to workshops, such as offices, finishing booths, or (if your shop is attached to your house) your living room. The dust also clings tenaciously to your clothing and travels indoors whenever you run in for a refreshing beverage in the middle of a work session.

The good news is that capturing and collecting fine wood dust is easier than corralling larger chips and shavings. A typical shop vacuum's air volume and velocity is sufficient to collect fine dust from portable power tools. Dust created by hand-sanding can be mitigated by shop ventilation or with an air-filtration device (see section 4). Capturing dust from large power sanders, such as drum or stroke sanders, is a walk in the park for a central collection system, provided that the machine's dust hood is well designed. The bad news is that uncaptured fine dust presents the most serious hazard to the woodworker: an assault on respiratory health. Ironically, it's the smaller dust particles-10μm and less-that create the biggest respiratory problems, ranging from mildly annoying to life threatening, as we'll see in the next section.

Sawdust and Respiratory Health

Most woodworkers who have installed dust collection in their shops, be it a small shop vacuum or a large central collection system, rest easy thinking that they've got sawdust beat. But usually there's still an invisible culprit lurking in the shop: the wood powder with particles so small that it can pass right through the filters on some vacuums and the bag fabric used for inexpensive chip collectors. Like demon seeds ready to unleash contagion, these diminutive dust particles are so light that they can travel around on the air itself, held aloft by static electricity and circulating air currents.

You can barely see the largest particles under ordinary lighting, but they're there, remaining airborne for hours after the last board has been sanded.

What's more insidious is that the smallest particles are the most harmful to your lungs.

How small are the fine dust particles that can harm us? We can't see most of them: Individual particles smaller than 100μm (0.1mm) are invisible to the unaided eye. Particles between 10μm and 20μm tend to become trapped in the outer passages of your respiratory system (resulting in the grotty goo that you see on a clean hanky when you blow your nose after a sanding session). Minute wood-powder particles-particularly those between 0.3μm and 10μm-easily penetrate deep into the farthest reaches of your lungs, even into the tiny air sacs called alveoli. Really tiny particles (under 0.3μm) are small enough to be expelled by exhalation.

===

Fig. p11: Check for Dust in the Dark: To check for fine dust in your shop, shut the lights off some evening after a sanding session, and then shine a flashlight across the shop; the concentrated beam will reveal a swirling swarm of talcum powder-like dust. The phenomenon is known as he Tyndall effect; you've seen it in the movie theater when dust or smoke passes in front of the projection beam.

===

HOW FINE DUST HURTS YOUR LUNGS

Because we breathe in a certain amount of dust in our everyday lives, our bodies have built-in protection mechanisms, as depicted in the drawing above. These respiratory defenses include: nasal hairs, which snag large particles as you inhale; mucus, a sticky blanket that lines your respiratory tract and acts like flypaper to capture errant dust particles; and cilia, which are tiny hairs that line your respiratory tract. Like the tentacles of a sea anemone, the cilia work to transport dust particles trapped in the mucus (using a beating motion that takes place about 10 times each second) and move them toward the back of your throat where they can be swallowed or coughed up. The cough reflex is a protective reaction that works to expel the mucus and dust that builds up in the respiratory system. Finally, deep in your lungs, alveolar macro phages clean out dust that gets into your alveolar sacs.

Fig. p12: The Human Body's Respiratory

Defenses against Dust Nasal Hairs: Coarse hairs that trap larger dust particles that are inhaled

Cilia: Tiny, hair-like arms that work to sweep dust-laden mucus out of the lungs and air passages Mucus Blanket: A sticky coating that lines entire respiratory system; catches microscopic dust particles like flypaper, so they can be discarded by the cilia

Cough Reflex: A protective natural reflex that helps to expel dust and mucus from the respiratory tract

Alveolar Macrophages: Special cells that travel around the alveoli, serving to clean out dust that interferes with the alveoli's function of oxygenating the blood and expelling carbon dioxide

Minute dust particles harm us by interfering with the lungs' functions in a variety of ways. As large quantities of dust particles become lodged in the lungs, they tend to foul the dust-ejection systems described in the previous paragraph. Copious amounts of dust clog the natural cleaning action of the lungs' cilia, which leads to irritation. As the cilia become more clogged, their effectiveness is reduced, so the lungs lose capacity to eject dust. Eventually, chronic exposure leads to permanent damage of the lungs' tissues, resulting in the buildup of scar tissue.

By restricting the absorption of oxygen into the blood, chronic exposure to fine dust can lead to shortness of breath and dizziness. The effects of dust can also weaken the body's natural defense mechanisms, making you more susceptible to bacterial or viral infection and illness. Long periods of exposure to fine wood powder can lead to conditions similar to cold and flu symptoms, including coughing, sneezing, bronchial inflammation, shortness of breath, and a runny nose as a result of increases in discharge of saliva and phlegm from the respiratory passages. The kind of lung problems that sometimes develop in woodworkers from chronic inhalation of wood dust are similar to those developed by longtime smokers: chronic bronchitis and emphysema.

Worse, chronic exposure to wood dust may even cause cancer: The National Institute for Occupational Safety and Health (NIOSH) considers both hardwood and softwood dust to be potentially carcinogenic to humans. Three types of cancers associated with wood-dust exposure are nasal and sinus cancer, Hodgkin's disease, and lung and other cancers.

Woodworkers are about 1,000 times more likely to develop nose cancer than non-woodworkers (although only one out of every 1,500 active woodworkers will ever have to deal with this horror). As with the respiratory problems described in the previous paragraph, nasal cancer tends to develop over many years, sometimes with decades between initial exposure and the outbreak of symptoms.

OTHER DANGERS CARRIED IN WOOD DUST

In addition to the harmful effects of the dust particles themselves, wood workers may also be negatively affected by soluble chemical components carried in or along with wood dust. These chemicals include a whole gamut of resins and extractives, commonly found in (but not limited to) exotic species of hardwoods. Extractives serve a living tree by repelling insect attacks and retarding the decay of the tree's nonliving heartwood.

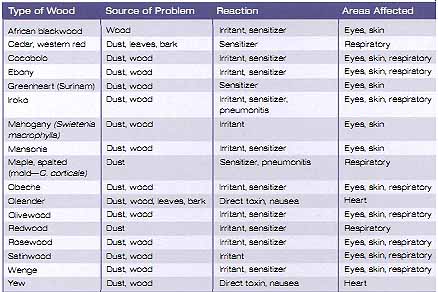

Wood dust carrying extractives can exacerbate the effects of the fine dust particles themselves or cause allergic reactions in woodworkers who are sensitive to the extractives' chemical makeup (sometimes after only limited contact). These chemicals include natural classes of compounds with strange-sounding names, such as alkaloids, glycosides, saponins, and quinones. Wood species with extractives that are more prone to cause allergic reactions include redwood, mahogany, boxwood, western red cedar, yew, satinwood, teak, ebony, and wenge (see the chart above). Western red cedar is one of the most infamous of these species because it contains an allergen called plicatic acid that causes a condition commonly know as red-cedar asthma.

Another possible source of allergic reactions from wood dust are the spores of fungi that can be contained in the dust. Certain fungi cause decorative staining in woods, known as spalting (see the photo on the facing page). Dust from spalted wood has been suspected of causing idiopathic pulmonary fibrosis, a horrific disease that's treatable only by lung transplant and can result in death. Even a fungus occurring in the bark of a tree can cause allergic reactions or worse. A condition known as maple bark disease is ostensibly caused by the fungal spores found in maple bark, which are released when the wood is cut or when maple burls are turned on the lathe.

Table of TOXIC WOODS: African blackwood Cedar, western red Coco bolo

Ebony Greenheart ( Surinam)

Iroko Mahogany (Swietenia macrophylla)

Mansonia Maple, spalted (mold-C. corticate)

Obeche Oleander Olivewood Redwood Rosewood Satinwood Wenge Yew

Fig. p15: Decorative and exotic woods, such as the spalted olive turning (left) and the rosewood and spalted maple boards (center), can cause allergic reactions ranging from mild to serious.

The sawdust created when cutting man-made sheet goods-such as particleboard, plywood, and melamine-coated particleboard (right)-includes not only wood particles but also glue and other potentially harmful substances.

In addition to the potentially harmful effects from the natural compounds found in wood, there's also the danger of dust from the adhesives used in woodworking. These include glues used to manufacture wood-based materials, such as particleboard and plywood, and glues used to assemble projects. One of these adhesives-polyurethane glue-contains isocyanates, which cause severe reactions in some people. Working with recycled wood (from old houses and barns) can also present health problems. This wood may be coated with lead-based paints or treated with wood preservatives containing toxic substances, such as pentachlorophenol and copper naphthenate (known commercially as copper green). Pressure treated lumber is also impregnated with these kinds of preservatives, including chromate copper arsenate (CCA). When you cut, plane, shape, or sand such wood, you create dust that can carry these substances into your lungs, where they are subsequently absorbed into your bloodstream.

Severe symptoms from exposure to both natural and manufactured chemicals in wood dust may include skin rashes, headaches, facial swelling, wheezing and coughing, and conjunctivitis (irritation of the eyes ). Ingestion can also be a factor because particles trapped in the mouth and nose usually end up getting swallowed, where toxins are absorbed by the digestive tract. Fine dust from tropical woods-such as Indonesian teak, cocobolo, and rengas ( Borneo rosewood}-can cause irritation to the skin.

Even touching these woods can cause acute skin rashes in some people.

Just as with the respiratory problems from fine dust particles themselves, what makes the breathing of other chemicals carried by wood dust such an insidious problem is that symptoms don't always manifest themselves quickly. Unless you exhibit an allergic reaction that suddenly alerts you to a wood dust-related health problem, symptoms might take years or even decades-to appear. I read one story about a longtime woodworker who was commissioned to build a couple of dozen redwood cabinets. One afternoon, he was having difficulty breathing (his bronchial tubes became inflamed by the volatile oils in redwood dust, causing constriction in his air passageways ). By the time he got home, his breathing was so labored that he had to go to the local emergency room, where a doctor diagnosed a condition known as occupational asthma. Treatment required him to take a bronchial-dilation medication, and because his air passageways were sensitized and prone to overreact to any kind of dust, he had to stay away from dusty environments (including his own woodshop) and continue taking medication for several years.

As with most serious health problems, it's always more difficult to overcome a problem once the body has experienced chronic damage. This is yet another good reason to evaluate your dust-control needs carefully so that you're not trading your future good health for the enjoyment (and income, if woodworking is your vocation) you get from your pastime-or your profession-of woodworking.

HOW MUCH DUST IS TOO MUCH?

How much wood dust can you breathe and still be safe? To protect people who work in the wood-products industry (as well as in dozens of other industries ), the Occupational Safety and Health Administration (OSHA) has developed a set of guidelines for wood-dust and worker-respiratory safety. While the regulations imposed by OSHA are designed for woodworking businesses with one or more employees, the guidelines also provide hobbyists and weekend woodworkers with a good understanding of how little fine dust it takes (over time) to cause respiratory problems.

To meet current OSHA regulations (OSHA 29 CFR 19 10. 1000), the total amount of respirable dust particles (1Oflm or smaller) in a shop should average no more than 5mg (one gram equals 1,000 milligrams ) per cubic meter of air over an 8-hr. period. This is referred to as a time-weighted average or TWA. While this standard applies to most common hardwoods and softwoods, dust from "allergy-prone)) woods, such as western red cedar, must be kept down below half that amount: a TWA of 2.5mg/cubic meter over an 8-hr. period. While these amounts are averages over time, OSHA also specifies a ceiling for dust concentration for exposures longer than 15 min.

This ceiling, known as the short-term exposure limit (or STEL), is 10mg/ cubic meter. For up-to-date information about the latest OSHA standards, check OSHA's website (www.osha.gov) or contact your state office.

While OSHA dust standards are highly regarded, they are not the strictest. The exposure limit recommended by NIOSH for all softwood and hardwood dusts (except western red cedar) is only 1mg/cubic meter for a 10-hr. workday and a 40-hr. workweek. In a garage-size shop, this translates to less than 150mg ( 1/8 tsp.) of dust for every 10 hr. of shop time.

While these amounts may sound minuscule, daily exposure over many years clearly has no small impact on respiratory health.

===

Meeting OSHA's Dust Standards: For an average small shop (say, a 24-ft. -sq. garage with 9-ft. ceilings, equal to approximately 147 cubic meters), the OSHA standard allows a maximum of 735mg (about 1/4 tsp. ) of wood dust over an 8-hr. period. This means that in a single work day, the average amount of fine dust in a cubic foot of space should equal only a little more than one tenth of a milligram about the weight of a flea!

===

EVALUATING DUST LEVELS IN YOUR SHOP

How can you tell if your shop has too much fine dust floating around in it? Unfortunately, you probably can't. To quantify accurately how much airborne fine dust there is in your shop requires a direct-sampling measurement. This is done by taking a sample of dusty shop air and then processing a predetermined volume through a special device that measures the amount of dust in it. You can hire an industrial-ventilation specialist to come to your shop, evaluate your dust problems, and recommend remedies for them. However, hiring a specialist is an expensive proposition, usually necessary only for professional businesses and one that most hobbyist and part-time woodworkers don't really need to undertake.

On a practical level, if you're power sanding without some form of collection and are spewing out great clouds of visible dust, you can bet that you're churning out unhealthy levels of invisible, respirable dust as well.

Regardless of what tools you use, if you find yourself picking gobs of dust out of your nose at the end of an average day of woodworking, you've almost certainly been exposed to too much dust.

For most of us, the best way to ensure that the air quality in our shops is not deleterious to our health is to act preemptively: Control fine dust before its adverse effects become a problem. The means to put the kibosh on dust involves implementing control measures such as collecting at the source, using air-filtration devices, and wearing personal-protection devices such as respirators, all of which are discussed extensively in later sections of this guide. Controlling fine dust is especially important if you power-sand often and with gusto because no other kind of fine-dust production equals the output of a power sander.

Fire and Explosion Hazards Beyond the risks of long-term exposure to wood dust, the greatest immediate hazard of having wood chips and dust around the shop is the risk of fire: Just think of what you typically use to touch off a blaze in your fireplace or barbecue-it's probably wood kindling. Any wood debris, from shavings to chips and powder, can be ignited with remarkably little effort.

A tiny spark generated by a machine's on/off switch or from the process of grinding a sharp edge on a chisel might be all it takes to turn your cozy shop into a deadly inferno.

Smoking in the shop is clearly a grave hazard; I heard one story (which fortunately didn't end tragically) of a boss who had his workers frantically shovel a mountain of planer shavings into the street after he'd accidentally dropped the glowing end of his cigar into the pile. Similarly, tossing an oil finish-impregnated or solvent-soaked rag on a sawdust-strewn floor or chip-filled waste is asking for trouble. Even if your shop is usually clean and tidy, it can't hurt to keep a fire extinguisher on hand to prevent a small fire from becoming an all-consuming blaze.

Fig.: Grinding an edge on a tool, such as this bench chisel, generates a shower of sparks, which can quickly ignite any fine wood powder that has collected around the base of the grinder and cause a shop fire.

Although it might not seem obvious, fine wood dust can also pose as high a fire risk as chips and shavings (as well as an explosion hazard, as discussed later in the section). There are many documented cases of shop fires caused by a layer of fine dust atop overhead light fixtures, ignited by the heat of the lamps. With fluorescent lights, the heat of the ballast may be enough to cause a fire.

Believe it or not, chips and shavings from working unseasoned wood, such as from turning green wood, can also pose a fire hazard. Damp shavings left in a pile produce organic heat, like a compost pile, and can even generate enough heat to combust spontaneously. Just to be safe, remove damp shavings from the work area or keep them in a fire-safe container.

Cleanliness is the best way to prevent a fire in a workshop. Make sure to get out the shop vacuum every once in a while and clean off all light fixtures, electrical outlets, and piles of chips that have accumulated around benches and machine tools. (Even well-designed central collection systems aren't 100 percent efficient; some chips end up around the bases of the machines.) To ensure fire safety prior to disposal, store dust and chips in metal or fire-resistant containers. A regular galvanized-metal trash can with a tight-fitting lid works just fine.

AVOIDING THE "BIG BANG"

It's ironic, but the same dust-collection system that helps keep sawdust off the floor to reduce the possibility of fire can be responsible for a rare yet devastating kind of danger: an explosion caused by the ignition of fine wood dust by a static-electric charge. When certain concentrations of fine wood dust are mixed with air (the lower explosive limits are 109 to 300g of dust per cubic meter of air), an errant spark can cause an explosion with tremendous force (see the photo at right). In a woodshop, the most common place where dust concentration can reach explosion potential is in the collection system itself: inside the ductwork, the blower, or, most often, the dust-filter bag or canister. If a spark from a static-electric charge ignites a cloud of fine dust, it can cause an explosion strong enough to blow the dust collector apart. But what's worse is that the burning dust and gases that are expelled by the shock wave can produce an additional source of combustion (especially if the shop is dusty), creating a chain of explosions that can level a large shop. Although such woods hop explosions are rare, I've read a few grisly accounts about woodworkers who were thrown through walls and were badly burned-enough to make it clear that it's worth taking every reasonable precaution to prevent explosions.

The best way to prevent a fine-dust explosion is to keep your shop clean, eliminate any open flames (such as from a furnace, water heater, or cigarette), choose a central collector with a non-sparking fan wheel, and make sure your dust system is properly grounded. Grounding allows most static charges to dissipate harmlessly, rather than building up and releasing in a sudden burst, which can trigger combustion.

Although it's probably not a big issue in most shops, be aware that working with aluminum can present a very serious danger, even if your wood-dust system is perfectly safe. Any reactive metal dust, such as from grinding or sanding aluminum, is much more susceptible to fire and explosion than regular wood dust.

For more information on protecting your shop from a disastrous conflagration, get a copy of The National Fire Protection Association's book, Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities (NFPA 664), available from the NFPA website (www.nfpa.org) or by calling the organization at (800) 344-3555.

Fig. : A small pinch of fine wood dust sifted over a blowtorch flame combusts with surprising volatility, demonstrating how readily fine dust in a collection system can burst into flames. (Please don't try this at home!)

===

Keep Shop Lights Fire Safe: YOU can help to prevent fires in a shop that has overhead lights by getting up on a ladder once every few months and vacuuming off the top surfaces of hanging fluorescent fixtures or the reflectors on incandescent lights. The wand or brush attachments that comes with most shop vacuums are great tools for this job.

===

Disposing of Sawdust

A custom furniture maker in New York, used to say that he gauged the success of his woodworking business by the size of the pile of chips and shavings that accumulated behind his shop (he called it "Mt. Sawdust"). Before going into a lot of detail in subsequent sections about the various methods of collecting dust and chips, a word is in order about what to do with these generally unwanted woodshop by-products.

Large cabinet- and furniture-manufacturing plants deal with the mountains of sawdust they generate by installing special equipment to turn their wood waste into a source of energy. These include furnaces that burn sawdust and chips directly, producing energy for powering plant equipment or for space heating. Another device called a "bricketer" compresses collected dust and fuses chips and shavings into little round briquettes that will be burned in a furnace. Unfortunately, such machines are big and expensive, making them highly impractical for all but the largest woodshops.

If you have a small shop in an urban area and don't produce much more than a bag or two of sawdust a week, you can probably get away with disposing of sawdust with your regular household garbage. Many municipalities require you to put the sawdust in sealed bags before placing it in refuse cans. This practice keeps clouds of dust from rising when cans are emptied into collection trucks. Plastic trash bags (4 mil thick, lawn size) work well. If you're against using plastic bags, you can fill regular paper grocery bags, and then seal them with masking tape.

Some sanitation districts also specify that refuse left for curbside pickup should not include construction debris. This shouldn't be a problem unless you're running a commercial woodshop at home and your sawdust and cutoffs outweigh the regular household garbage. If the city or county refuses to collect your debris, you might have to contract with a private disposal company. Alternatively, you might consider burning your wood debris, though strict air-quality standards in and around many suburban areas prohibit outdoor burning and incineration.

If you live outside a sanitation district, you're probably already hauling your sawdust to the local landfill along with your other trash. To reduce the fire hazard, keep sawdust awaiting a trip to the dump in metal containers (stored away from buildings). If you must pile your sawdust, locate the piles well away from buildings and dry vegetation, and keep them covered.

Other creative ideas for getting rid of sawdust? If you have any friends who are into ceramics, it's possible they'll gladly haul away some of your sawdust to fire raku-style pottery. If there's a large pet store, horse farm, or animal-feed and farm-supply store in your area, the owners might be happy to pick up your sawdust and shavings, depending on the wood species, to use for animal bedding (they might even pay you for it!) .

USING SAWDUST FOR COMPOST and MULCH

If you have sufficient acreage or a big yard and want to turn your woodshop disposal problem into a garden soil-improvement program, then composting is the answer. When combined with plenty of wet, green, nitrogen-rich material, compos ted sawdust can improve soil structure, build up the humus content in soil, and even help fight plant diseases. The catch is that it takes some time and work to transform sawdust into useful compost; you can't just shovel it into the garden because carbon-rich wood materials rob the soil of plant-feeding nitrogen. But if you mix the sawdust with green organic matter-such as grass clippings, garden debris, food waste, or barnyard animal manure (no dog or cat waste !) and allow it to decompose, you'll create better fertilizer than you can buy. You can compost sawdust from just about any kind of wood species, although you might want to limit the quantity of dust from extractive-laden exotic species (rosewood, teak, etc. ). and , of course, never compost sawdust from pressure-treated wood.

A compost bin, such as the commercially made model shown in the photo above, keeps materials contained and speeds up the composting process greatly. Mix three parts of green waste to each part of sawdust, and let it sit for a month or so. If the ratio of greens-to-sawdust is right, your pile should steam and begin to shrink down in size. Then, tear the pile apart and rebuild it, moving the outside material to the center and vice versa to speed the process along. The compost is ready to use when all components have broken down into a black/deep brown soil-like mixture.

Composting larger wood chips is possible, but it's tricky and takes forever. It's better to use them as mulch for pathways. Don't ever use wood chips or sawdust as a mulch right around living plants-the plants can starve to death as the wood absorbs the soil's nitrogen while decomposing.

Fig.: To transform sawdust into soil-enriching humus, the author uses a commercially made plastic compost bin, located behind his home workshop. Here, he mixes fresh sawdust with grass clippings, green food waste, and other nitrogen-rich organic matter, which help the sawdust decompose into a rich garden fertilizer.

===

Spreading Composted Sawdust: When you're ready to mix compost into your garden, cover the soil with a 1-in.-deep layer; that's all the food a garden plant needs. To feed your lawn with compost, apply X in. on top of your turf and water it well. Apply compost twice a year: once in the fall and again in the spring.

===

Prev.: (none)

Next: Strategies for Controlling Dust