AMAZON multi-meters discounts AMAZON oscilloscope discounts

There are three basic types of ventilators. Gravity ventilators have no moving parts and ventilate through the natural gravitation of air movement. Wind-driven ventilators rely upon the wind velocity to aid in exhausting the air from an attic structure. Power ventilators exhaust air through the addition of electrical power.

GRAVITY VENTILATORS

The efficiency or value of a gravity ventilator—assuming it offers adequate weather and insect protection—is expressed in terms of net free area. The net-free area of a ventilator is that free area that is not hampered or blocked by the insect protection—the screen—and the weather protection portion—the vanes—of the ventilator. This means it is the clear or free opening of the ventilator through which air can move.

The net-free area necessary for a properly ventilated home is generally based on a ratio of the attic floor space. The space to be ventilated should have a net-free area of 1/150 (for every 150-square feet of attic floor space, 1 square foot of net-free area is required). Under certain conditions, this ratio can be reduced to 1/300 (1 square foot of net-free area for every 300 square feet of attic floor space). If this 1/300 ratio is applied, the following conditions must exist:

+ A vapor barrier must be applied to the warm side of the ceiling of the structure.

+ At least 50 percent of the required ventilation must be located in the upper half of the roof structure and at least three feet above the eaves line. The other 50 percent of the required ventilation must be installed under the eaves or in the soffit area of the roof structure. If under-eaves vents or soffit vents can't be applied, the 1/150 ratio must be used.

For example, if an attic area measures 30 feet by 40 feet (1200-square-feet), the net-free area required is 1200/150 (or 8 square feet, 8 x 144 giving 1152 square inches of net-free area. If the 1/300 ratio is to apply, you would require 1200/300 (or 4 square feet, 4 x 144 for 576 square inches of net- free area). Half of this figure would be 288. So, 288 square inches would have to be applied under the eaves, and the same amount would have to be installed in the upper half of the roof structure.

A simpler formula to use if the 1/300 ratio is applied is to specify one- half inch of net-free area for every square foot of ceiling area. This ratio of one-half inch to 1 square foot is 1/288 (or ½ / 144, which is very close to 1/300).

Fig. 4-1. Cornice vents are among the most common intake ventilators.

Fig. 4-2. Continuous soffit vents come in various lengths.

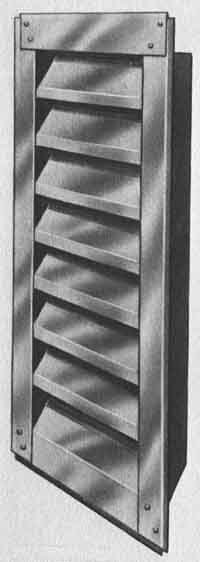

Fig. 4-3. This is the basic rectangular louver.

TYPES OF GRAVITY VENTILATORS

Before old, stale air can be pulled Out of an attic, you have to allow fresh, new air to pour inside. Ventco manufactures the largest variety of intake ventilators. Although they come in many shapes and sizes, the most common are the under-eaves vents that are very easy to install. Care must be taken to ensure that the vents are located strategically around the attic in order to avoid any hot spots and to assure complete removal of the attic air. They must also be installed in sufficient quantity to accommodate the exhaust ventilators you have chosen. Figure 4-1 shows the popular cornice vent and Fig. 4-2 shows an equally favorite continuous soffit vent.

Rectangular louvers come in several sizes to meet all spacing requirements. Figure 4-3 shows one of the larger vents, Fig. 4-4 shows a recessed mounting, and Fig. 4-5 shows a flush mounting in a smaller size. Table 4-1 shows the size of the vent and the area it will ventilate.

Gable louvers are the essence of basic ventilation and the foundation that built Ventco into the world’s foremost ventilation corporation. Clark David Jones invented the variable-pitch, adjustable louver to fit different roof pitches in the 1940s, and Ventco was established. They are ideal for remodeling and for new home construction. Figure 4-6 shows the adjustable attic vent. The ingenious design actually forces the louver blades to pivot, changing angle as the unit is adjusted to fit roof pitches. This permits maximum air flow capacity while assuring optimum protection from the weather.

Fig. 4-4. Rectangular flush mounts fit flush against the wall.

Fig. 4-5. This is a recessed–mounted louver.

Fig. 4-6. The adjustable gable louver was a major innovation in ventilators.

Fig. 4-7. A very wide flange ensures a secure fit.

All Ventco Van-Pitch Adjustable Louvers are constructed entirely of heavy-gauge aluminum, and an 8-x-8-inch mesh aluminum screen is included. Units are completely assembled, ready to install. To determine the size needed, you measure down along the roof line from the peak of the roof to the frame. The appropriate-size louver will adjust to the opening in seconds, and can be installed in minutes. Table 4-2 gives the statistics on selecting the right size louver.

Ventco also makes a twin section stationary louver. It can be used in matched pairs for roof peak installation or one by one for sheds, kneewalls, and similar structures. The rugged, all-aluminum sections are joined securely with quick and easy slip-joint center fasteners with 8-x-8-inch mesh screen installed. An extra-wide mounting flange permits easy installation. See Fig. 4-7. Table 4-3 gives the specifics on their use.

Roof-line louvers exhaust bad air out of attics, and there are two basic designs. Figure 4-8 shows a low silhouette type while Fig. 4-9 shows a larger model that exhausts more air. A roof-jack (Fig. 4-10) is perfect for use with powered kitchen and bathroom exhaust fans.

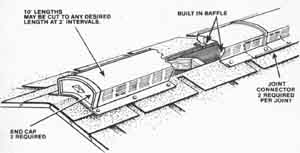

Ridge-line vents are becoming more and more popular. As their name dictates, they run along the peak ridge of the roof. They usually come in 10-foot lengths and may be cut to any desired size with end caps sealing them off. Figure 4-11 details their application.

Gravity ventilation works on exchanging the air in attics, as Fig. 4-12 depicts.

WIND-DRIVEN VENTILATORS

The turbine is the primary wind-driven ventilator. It is an excellent exhaust ventilator to remove excess moisture, arid it has the added advantage of removing excess summer heat from attics. The number of turbines needed on a house or building can be determined by the volumetric method or by the cubic method. With the volumetric method, you compute the cubic feet in the attic. For example, an attic that measures 30 feet by 50 feet with a 4/12 pitch will have a volume of 3,750 square feet. Mu the length times the width times five feet (the height of the attic) to get 7500, which is then divided by 2 to get the 3,750.

Attic height is determined by the roof pitch. With a 4/12 roof pitch, the rise of the rake is 4 inches for every 12 inches of horizontal measurement, i.e., 15 feet to center of the 30-foot span, 15 feet times 4 inches equals 60 inches or 5 feet. An attic structure represents one-half of a solid rectangle. This proves out when the dimensions of 30 by 50 by 5 are multiplied and then divided by 2, giving us the 3,750 cubic feet. To reduce the attic temperature to very nearly the outside temperature, the attic air must be changed 10 times per hour (or every 6 minutes). Therefore, take the 3750 and divide it by 6 to get 625 cubic feet per minute (cfm).

Ventco’s legendary Whirlybird turbine will remove 350 cfm at 5 miles per hour, 528 cfm at 8 714 cfm at 11, and 947 cfm at 15 miles per hour. If an area has a constant wind velocity of 11 miles per hour, only one turbine would be necessary. Because there is a variance in the strength of the daily breezes, two turbines are recommended.

Most hardware, home centers, and building supply firms have the Ventco Whirlybirds that sell for around $25 each. Millions of homes could save hundreds of millions of dollars for a small investment.

Fig. 4-8 Low profile exhaust ventilators are popular on the roof line.

Fig. 4-9. Larger roof-line ventilators exhaust more attic air.

The cubic-feet-per-minute-per-square-foot determination of the number of turbines requires 1 to 1.5 cfm for every square foot of attic space. The average wind velocity for most of the nation is almost 10 miles per hour. That means one turbine should provide for 600 square feet of attic space. Turbines can’t exhale the bad air if there is not enough inhalation. Adequate intake ventilators are essential. A turbine should have 80 inches of net-free intake for every 100 cubic feet per minute of exhaust capacity.

Fig. 4-10. Roof Jacks are made to work with kitchen and bath exhaust

fans.

Fig. 4-11. Ridge-line vents can be cut to the lengths needed.

The average exhaust capacity of a 12-inch turbine is approximately 635 cubic feet per minute. It would require, 6.35 times 80 (508 inches of net-free area intake ventilation) if a cornice vent with 65 inches of net-free area would fill the need. Take the 508 and divide it by 65, and you get 7.8. So, 8 vents per 12-inch turbine would give adequate intake ventilation.

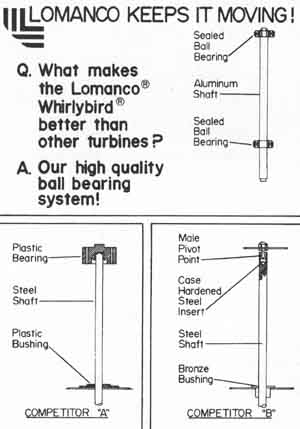

Not all turbines are created equal in quality. Indeed, there are some turbines that will not turn freely or do so much too reluctantly to be effective. Some are not the highest grade aluminum. Some do not fit together with great precision, and some have very poor design. The bearings are very important. Some firms use jewel-type bearings that tend to wear out rather quickly. Others use even less effective bearing systems.

Ventco has made the Whirlybird the most popular turbine by building the highest quality possible and by using aircraft-type ball bearings. They are subjected to the most demanding quality control in the Ventco factories. The special, sealed ball bearings let the turbines move with the slightest whisper of a breeze, and they have been certified to withstand wind speeds of 120 miles per hour. See Fig. 4-13. Ventco details its bearing system as shown in Fig. 4-14. Table 4-4 shows the capacity of different size turbines.

Fig. 4-12. Air rises due to natural gravity to exit out of the roof and gable ventilators.

Fig. 4-13. Turbines are the most popular wind-driven ventilator.

Fig. 4-14. Bearings are among the differences between Ventco, Inc. turbines and other types.

Fig. 4-15. Turbines are mounted quickly after the base is installed.

Ventco employed an independent research firm to conduct a study on turbines in Houston, Texas. In visits to Houston, Ventco executives had noted that a high proportion of turbines made by other manufacturers were not working. Its engineers suspected that the turbines were worn out due to the failure of the bearings.

The research group sent people to drive through middle and upper class neighborhoods to observe the turbines. When an inoperative turbine was spotted, the surveyor noted the house address. Later, with the use of a crisscross telephone directory, the name of the homeowner and the telephone number were determined. More than 1000 homes were identified where one or more turbines were not moving freely. Of this number, 303 heads of the household were interviewed.

The major findings of the study revealed some strong insights into how little most people know about ventilation. Three Out of four in the survey said their turbines were installed by someone else. Brand awareness is at a very low level; that is true even among people who did their own installation. Few people are aware that turbines serve more than one purpose. In particular, the anti-dampness benefit is not well known. Very few of the people were aware that their turbines were not operating properly.

The summary points also found that most people tend to overestimate the cost of a replacement turbine, which is less than $25. Only half the homeowners surveyed realized that the turbine alone can be replaced. Most people have no idea how long it takes to replace a turbine. Most people can install a replacement turbine in less than 30 minutes. A majority said they would handle the replacement themselves if they ever felt it necessary. Others declined on the basis of age, physical disability, or a dislike of the task of having to climb on the roof. The better educated, higher-income households tended to have someone install it for them. See Figs. 4-15 and 4-16.

Fig. 4-16. Two turbines are sufficient for most average-size homes .

Three out of four of those interviewed could not name the brand of turbine on their roofs. Because people have very little brand awareness about turbines—and about other types of ventilators—it seems quite logical to say they are also very unaware of the quality and structural differences among the various brands on the market. Three out of four of the people did recognize the values of their turbines. They know that they are mandatory to release heat from the attic. Only about 6 percent of the people were informed enough to know that they save a lot of energy. Some 4 percent knew that they prevented dampness, eliminating mold and mildew.

The most shocking information gathered was that an overwhelming majority of consumers in Houston indicated complete satisfaction with the operation of their turbines—even though they were not working at all or hardly moving!

“This is an amazing finding,” the report states. “We have not interviewed the general Houston population, but rather have singled out owners of homes where the turbine was observed to be inoperative! Yet, homeowners seem blissfully unaware of the malfunction or else—a more likely situation—feel that the turbine is designed to run only in relatively brisk wind.” Not true; see Fig. 4-17.

Fig. 4-17. Assembly line workers making turbines hold them up to

a small fan to ensure they turn freely.

POWER-DRIVEN VENTILATORS

Electrically powered ventilators perform the same function as turbines, and their efficiency is expressed in cfm also. The greater the cfm, the more efficient the unit or the greater the exhaust capacity. Power ventilators have the tremendous asset of being positively controlled by a thermostat. Most units are thermostatically set to activate or come on at 100 degrees and shut off at 85 degrees.

In addition to the thermostat, a humidistat may also be used to control the operation of the power vent. When excess humidity levels are reached in the attic, the power vent will activate—exhausting the water vapor.

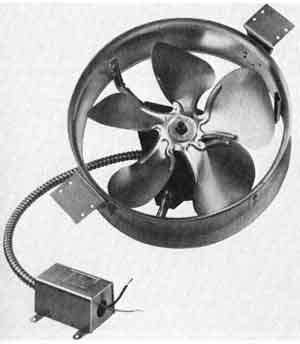

Fig. 4-18. Powered gable vents are highly efficient.

POWER GABLE VENTS

An excellent gable-vent fan should be easily installed between 16-inch or 24-inch on-center framing members with brackets included for the latter. Balanced, deep-pitch blades are needed for smooth operation and the highest volume air removal. A factory-set thermostat that switches on at 100 degrees and off at 85 degrees should be among the features. It should have the flexibility to be mounted in a horizontal, pitched, or vertical position. All aluminum construction assures that it will be permanent. Ventco’s Add-a-Vent 1800 meets all these requirements. It also has an automatic shutoff in the event of a fire. See Fig. 4-18. It can remove 1200 cfm.

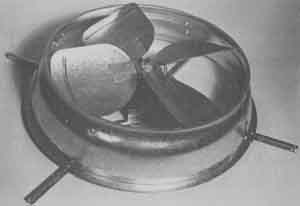

POWER ROOF VENT

These flying-saucer-shaped ventilators set low on a roof. They should have a deep drawn flange to ensure no water gets around them. Precisely balanced blades inside the hood make for the quietest operation. They are economical, easy to install, and are very effective. Ventco engineers note that they are ideal ventilators when they are coupled with an optional humidistat. See Figs. 4-19 and 4-20.

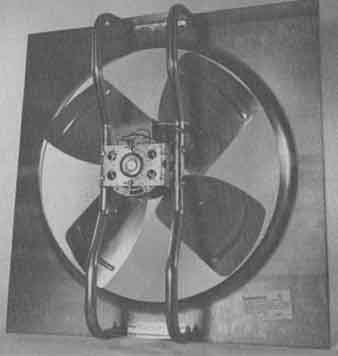

WHOLE-HOUSE FANS

A whole-house fan doesn’t do a whole lot without effective ventilation! Turbines, gable-end vents, ridge vents, or some type of power vent must be included in the total ventilation system. There must be enough exhaust vents to exhale the bad air.

A whole-house fan is proving to be one of the most effective ways of cutting cooling bills and proving adequate ventilation for the entire structure. When properly installed and used, these ventilators remove inside air from throughout the structure and replace it with cooler air from the outside. This reduces indoor temperatures and gives a breezelike cooling effect that comes from moving air.

The Home Ventilating Institute has researched the use of the whole- house fan thoroughly, and has established some specific guidelines and advice for owners.

Fig. 4-19. Inverted dish-shaped power roof vents can also extract

a massive volume of stale air.

Fig. 4-20. Tying a humidistat to a powered roof vent is an excellent

combination to extract air and control humidity.

+ As the name implies, the whole-house ventilator has been designed to provide cooling comfort for the entire house.

+ The whole-house fan provides indoor comfort by exhausting hot, stale air while drawing in cooler, fresh air. The mild breeze provided by the fan makes temperatures feel cooler than they actually are. This breeze-like effect can cause temperatures to feel from 2 to 8 degrees cooler.

+ The real advantage of the whole-house fan is that it offers dramatic savings in cooling bills. At temperatures up to 82 degrees, the whole-house fan has a cooling capacity equal to that of air conditioning, but the ventilator requires only a fraction of the energy an air conditioner needs to operate. Depending upon energy costs, the whole-house fan can be operated for as little as one-tenth the cost of an air conditioner.

+ The whole-house fan is normally installed in a centrally located hallway ceiling. It draws outside air through open screened windows and doors, pulling it throughout the house and exhausting it through existing or additional attic vent openings.

+ During early evening hours or when outdoor temperatures are below 82 degrees, screened windows should be opened and the fan should be turned on to draw in fresh air and to provide a steady breeze that will keep occupants comfortable. Later in the evening, rooms and doors of unoccupied areas should be closed and bedroom windows should be opened to provide cooling air-flow ventilation throughout sleeping areas.

+ During early morning hours, while it is still cool outside, the whole- house fan can be operated to flush Out heat and to draw in cool air. After brief operation, the fan should be shut off, windows should be closed with drapes drawn, and all entrances to the house should be closed. In a properly insulated home, the cool air will remain closed inside the house well into the day, delaying or eliminating the need for air-conditioning.

+ The whole-house fan can also be used to flush hot air out of a closed up house prior to turning on the air-conditioning. The ventilator quickly and efficiently removes the excess heat, greatly reducing the burden on the air conditioner.

INSTALLATION and ACCESSORIES

Whole-house fans are designed for easy installation and come with detailed installation instructions. Most fans are mounted horizontally over a ceiling opening, but they can also be installed vertically in the gable end of the house, or they can be located in places where air can be drawn from living areas and expelled outside the house without going through the attic. An example of such an installation is a fan placed in the window of a stairwell in a two-story home.

Ceiling-mounted fans are accompanied by louvers that open automatically when the fan is in operation. Louver models are available in enamel finishes and fit standard rafter-and-truss construction.

Switches are available for the whole-house fans that provide either high- and low-speed settings or continuously variable speed control. Timers can also be purchased that allow automatic shut off or start up of the fan.

The Home Ventilating Institute issued guidelines for whole-house fan selection in its quarterly publication Flow. The revised guidelines are aimed at better enabling consumers to properly select whole-house fans that have been developed by the Home Ventilating Institute.

HVI has long strived to make proper fan selection as easy as possible for the consumer. The organization has developed certified air delivery ratings for the products of its members and formulas for computing the necessary capacity of various fans to meet the ventilation needs for any size room. These two factors combine to allow the homeowner to quickly and accurately gauge ventilation needs.

The whole-house fan is designed to create cooling breezes within the home and to lower indoor temperature by drawing in cooler air from the outside. It can supplement air-conditioning and , because the whole-house fan uses as little as one-tenth of the energy required to operate an air conditioner, this can result in substantial savings in energy costs.

The new guideline adopted by HVI for whole-house fans reads as follows.

“The minimum recommended whole-house fan capacity for proper ventilation of a particular home can be determined by multiplying the gross square footage of the living area by 3. The resulting number equals the minimum actual air delivery needed as measured in cubic feet per minute (cfm). In warmer, more humid areas, a somewhat greater capacity may be desirable to provide more frequency air changes. In those cases, multiply the gross square footage by 4.”

“The gross square footage of the living area can be calculated by multiplying the overall exterior dimensions (length times width) of each floor, not including the basement, garage or attic. This formula compensates for the nonliving areas included in the overall square footage, such as closets, stairwells and wall spaces. As an example, for a single-story home measuring 35 feet by 40 feet, the calculation would be: 35 x 40 = 1400 x 3 4200. Thus, at a minimum, actual air delivery of 4200 cfm would be needed.”

“In all cases, the fan’s CFM rating should be measured at 0.1 inch static pressure with the manufacturer’s recommended louver in place in order to accurately reflect actual air delivery in a typical home. An HVI Certification label, granted as the result of stringent independent laboratory testing, assures consumers of an accurate CFM capacity rating.”

For ceiling whole-house fans exhausting air through the attic, it is important to have adequate attic exhaust venting. To determine how much attic vent area is needed, divide the fan’s cfm rating by 750. The result will be the number of square feet of free area needed to handle the exhaust from a fan of that size. The calculation for a fan with a cfm rating of 4,200 would be as follows:

4,200/750 = 5.6

Such a fan would need 5.6 square feet of unobstructed, attic vent openings to do its job properly.

The National Bureau of Standards conducted tests in Houston to determine how effective the whole-house fan is in cutting cooling costs. They turned off the air-conditioner, turned on the whole-house fan, and opened the windows when the outside temperature reached below 82 degrees. On particularly hot days, the savings was significant. The results were even more significant when the daily outdoor temperature averaged 76 degrees. Overall cooling costs were cut by nearly two-thirds. The chief conclusions of the National Bureau of Standards was that the whole-house ventilation not only reduces air-conditioning hours in warm climates, but also can be used as a major method of cooling in locations where the monthly summer temperatures average 75 degrees or less.

Whole-house ventilation is most satisfactory where high humidity is not a problem. The Bureau’s report concluded that inactive people would probably be comfortable even when the outside temperature was 82 degrees and the relative humidity was as high as 75 percent. Moderately active people would probably feel some discomfort with such a temperature and humidity combination.

Fig. 4-21. Quiet whole-house fan.

Fig. 4-22. Whole-house fans should be designed to install without cutting

into the framing of the house.

Fig. 4-23. These louvers will open and close automatically when coupled

with the E-Z Breeze whole-house fan.

There are some major drawbacks to the whole-house fan that consumers should note. If the summer night temperatures do not drop below 80 degrees, the system is limited in its ability to cool. Dirt, pollution and humidity are also pulled inside by the fan. If the house is closed, these conditions can become trapped inside. In houses located in such environmental conditions, the whole-house fan shows no economic or energy saving advantages.

Whole-house fans usually come in diameters of 24, 30 and 36 inches. Depending on their construction and speeds, they sell for $125 to $350. Fans offering variable speeds give more precise control and are more desirable.

If you have some carpentry and electrical skills, you can install the fan yourself. If you don’t have such skills, make sure that you have a reputable contractor or fan dealer to do the installing so that the fan will operate properly.

The American Ventilation Association recommends selecting a fan that is one size larger than is required for your home. They run at a slower speed and are quieter. Also, their life span is longer than others.

A whole-house fan is an attractive alternative to traditional air conditioning. One of the most impressive units we have encountered is the E-Z Breeze Whole House Central Fan. Made by Ventco, it is one of the easiest to install and has three speeds for precise control. One of its best features is its touch, very soft-start motor (Fig. 4-2 1). A larger model is available (Fig. 4-22), and an attractive louver (Fig. 4-23) can be used with either size.

Because the whole-house fan is one of the most expensive of all ventilators, care naturally should be emphasized in shopping for one. One major manufacturer encountered some unfavorable consumer publicity during the last year for allowing several faulty fans to reach the buying public.

There are numerous ways to effectively ventilate. Figure 4-24 illustrates the most popular ones.

Fig. 4-24. Ventilation equipment is compact and sleek.

Prev.: Indoor Pollution

Next: Humidity and Human

Conditions