AMAZON multi-meters discounts AMAZON oscilloscope discounts

Air laden with contaminants isn’t a foregone conclusion. The first line of defense is to make the envelope mold proof (for more, see the sections on building science, roofing, and siding). We can’t control mold spores but we can control moisture. By following green-building practices, the house should be protected for its lifetime. Skimping on the details is to invite trouble—nothing else matters if mold makes the occupants sick.

When it comes to other potential contaminants, the strategy is pretty simple: minimize exposure to toxic materials, either by keeping them out of the house altogether or by choosing safer alternatives to building products that contain hazardous compounds.

Isolate the garage

A garage can be a cauldron of unhealthy materials: fuels, solvents, adhesives, and especially carbon monoxide. One of the consequences of negative pressure inside the house is the likelihood that car exhaust will be drawn in from an attached garage. In cold climates, a homeowner might start the car in the garage and leave it there to warm up. With an attached garage, and a leaky door or wall between it and the house, exhaust gases can easily get inside. In the mid-’90s the EPA conducted a test of in door air quality on a variety of homes in Denver and concluded that car exhaust from attached garages was by far the greatest toxin in interior air. Garage workshops in general are a great source of harmful chemicals. Pesticides, cleaners, polishes and waxes, workshop chemicals, paint and paint strippers—the list of possible contaminants is long indeed.

Two approaches should be used together. First, the wall between the house and the garage must be airtight. The best way to ensure that contaminants do not reach the house is to insulate the wall with spray-in foam insulation. Don’t forget the wall/ceiling intersection if there is an attic above, If there is another bedroom above the garage, seal the floor joists in a similar fashion. The intent is to isolate the air in the garage from the house. Second, install an attic fan on the opposite side of the garage from the door. The fan should be on a timer to run for 10 or 15 minutes after opening the garage door or the light goes on. That way the exhaust gasses are evacuated away from the house.

Volatile organic compounds in conventional solvent-based

wood stains and finishes lower indoor air quality. Using water-based

finishes or allowing finishes to cure completely before wood products

are installed, are healthier choices.

Radon mitigation

Radon is the second most frequent cause of lung cancer behind smoking in the U.S. It is a radioactive gas that percolates through rock and soil to find its way into the house. Radon is measured in picocuries/liter (abbreviated as pCi/L), with 4 pCi/L the current maximum level suggested by the EPA before mitigation is recommended. A radon collection system consists of perforated PVC pipe installed beneath the concrete slab of the basement and connected to a pipe that runs up and out of the house.

A fan draws the gas through the pipe and exhausts it. It is much easier to design for radon mitigation before the fact than to go back and install pipes under the slab or basement floor if a problem is detected. It doesn’t cost very much to rough in the system as the house is being framed. It can be left inactive and a fan added later if tests show the recommended levels of radon have been exceeded.

Kitchen cabinets made with conventional particleboard

off-gas formaldehyde long after installation. Specify greener materials,

such as wheat-board.

Use safer products

Using green products is one of the best ways to improve indoor air quality. Specify building products that contain fewer hazardous materials, and suggest to homeowners that carpet, furnishings, and other household goods be chosen with the same care. For example, builders can use formaldehyde-free products when they are available (medium-density fiber-board, certain door cores, and fiberglass batt insulation are three such products). Specifying low-VOC paints and water-based rather than solvent-based clear finishes will help. Using less carpeting is yet another avenue, as is installing direct-vent, sealed-combustion furnaces and water heaters.

Filter the air

Furnace filters were designed to protect the fan motor in your furnace, not your health. The original fiberglass filter was designed to filter coal dust out of the air to help the fan last longer. We still use those filters today even though a wide range of better filters are available. Pleated media, electronic, and electrostatic filters are all more effective. Some of them are capable of filtering out dust measured in millionths of a meter.

Ventilation

As described more thoroughly earlier, ventilation is vital for human health. Fresh air should be part of our daily lives, yet we spend 90% of our time inside buildings where stale air is cycled and recycled through heating and cooling equipment. We wonder why we feel groggy at work in the afternoons. Bringing fresh air into the home is a requirement for health and safety. and ventilation is the only way to dilute unwanted toxic gasses.

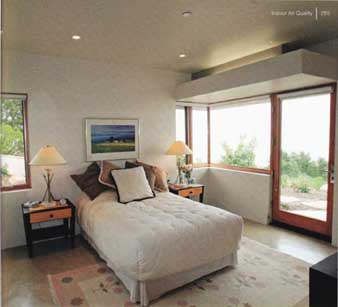

Beauty is more than skin deep. Stained concrete floors and low-VOC paints contribute to high indoor air quality as well as

an aesthetically pleasing interior.

When you suspect a problem

If there’s a suspicion of a problem when a house is finished, or occupied, the first step is to test the air. There are experts in mold mitigation, industrial hygienists who specialize in air contaminants, and indoor air-quality experts who have been trained to deal with a range of potential problems. Usually the best way to find one is to start with a list of specialists from a local green-building program. To find one, start by calling your local building office or contacting your state section of the U.S. Green Building Council. Local experts are always better because they know what types of mold are prevalent in the area and have learned to recognize typical building failures in that particular climate, If no one can be found, a new national program is being developed by National Jewish Hospital in Denver, Colorado., and should be in place by 2008. A test kit will be able to identify various types of IAQ contaminants.

Prev.: Building Products

that Off-Gas

Next: Green

Building Basics