There’s no denying that a fireplace adds character and ambience to a home’s interior, but when the traditional coal- or wood-burning fireplace lost its central- heating role to the automatic furnace, many homes went hearthless. Retrofitting a traditional masonry fire place in most of those homes is an expensive and complicated project, but a modular metal fireplace that burns gas can provide a convincing substitute, without the need for a heavy, expensive masonry chimney. Most units operate with the flick of a wall switch or remote control, and optional blower units expand their heating ranges by actively distributing heated air into the room.

Aside from their simpler, more affordable installation, direct-vent gas fireplaces eliminate the need to haul firewood through the house or clean out ashes, and more flexibility in locating the unit. The insulated metal duct that exhausts hot gases and brings in combustion air can usually be installed through either an exterior wall or the roof.

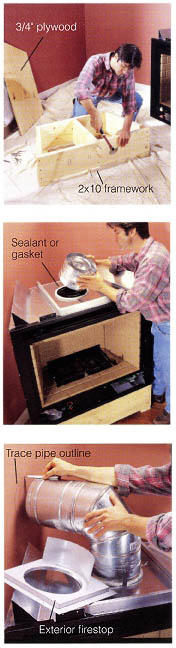

1. After mocking up the fireplace in several locations or test-fitting the unit itself, use framing lumber to construct a base platform the same size as the fireplace module. Fit a 3/4-in. ply wood top onto the base and fasten it with screws. Slide it temporarily into position to check the fit against the wall or corner. |

|

2. With the necessary sealant, which is typically a stove cement, rope gasket or high- temperature silicone caulk, fit the first vent- pipe section in place. Fasten it securely according to the instructions and add the next fitting. In this installation, it’s a 9Q0 elbow with a straight pipe extension on the back end. |

|

3. Mark an outline of the vent pipe on the wall surface and temporarily move the fire place out of the way. Cut a 12-in. (30-cm) square opening around the vent-pipe location; add blocking and a header around the opening. If a wall stud obstructs the path, cut a larger opening to alter the framing, as shown in Step 4. |

|

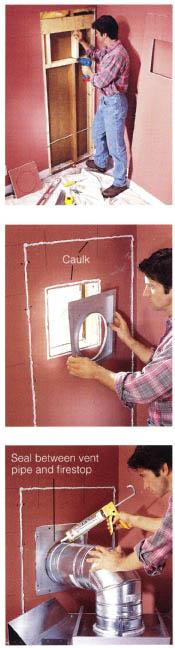

| 4. Drill holes at the corners of the square vent opening, penetrating the exterior wall sheathing and siding. This transfers the opening to the outer face of the wall so you can cut through the siding and sheathing. Next, fit the outer fire-stop and cap against the siding and trace the outline; cut through only the siding. |  |

5. Replace the wall insulation and patch the interior wall surface—a rough patch is fine if you’ll add a fireplace surround and mantle to cover the area. Apply a bead of caulk around the patch and around the perimeter of the vent opening; press the interior fire-stop into the caulk and fasten it to the wall with screws. |

|

| 6. Move the fireplace unit into position and insert the interior vent pipe through to connect with the exterior fire-stop. The procedure for making the vent-pipe connection can vary with the manufacturer and model, so follow the instructions provided. Seal around the vent pipe with a bead of high-temperature silicone caulk. |

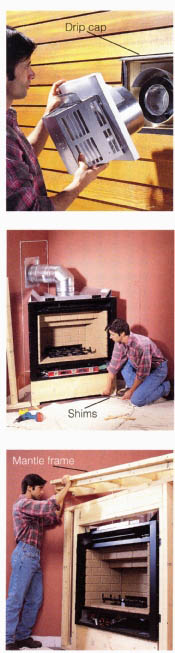

7. Slide the exterior vent fitting (a combination fire-stop and cap) onto the pipe coming through the wall. If necessary, install a metal drip cap under the siding, as shown here, and use screws to fasten the fire-stop flange to the wall. Use caulk to seal the joints between the siding and the metal flange. |

|

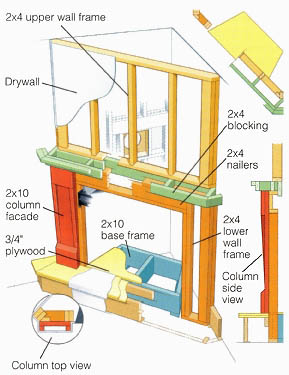

8. After installing the required gas and electrical lines (we suggest you hire pros for this), level and fasten the wood platform. Using the illustration at far right as a guide, frame the remaining structure for the fireplace surround. The detailing can vary from the example shown, as long as you provide a nailing base for the drywall. |

|

9. The mantle frame is the next assembly required to complete the structural framework for the fire place surround. Slide it into position atop the main façade frame and fasten it with screws. Follow this step by installing the angled frame pieces at each end; then build and install the hearth extension and upper wall frame. |

|

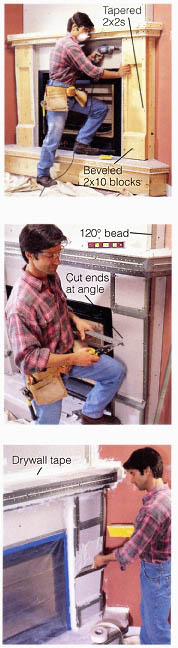

10. Cut the column parts from

2x10 and 2x2 stock and screw them to the lower wall frame of

the surround. Note that the vertical 2x2 cleats taper to a point

at their lower end and that the lower 2x10 block is beveled

45° on its upper edge. When complete, fasten drywall over the entire

assembly. |

|

11. Cover all the outside corners with metal drywall corner bead. Where two or more corner beads meet, cut angles at the ends to form a point so the flanges don’t interfere with each other. Nail the bead tight with drywall nails. For corners greater than 90°, install a special 120° metal bead. |

|

| 12. At inside corners, embed paper drywall tape in joint compound and apply the compound to all surfaces to cover the joints and corner bead. Let dry; then sand and repeat one or two applications until joints and surfaces are smooth and flat. If desired, apply a troweled or sponged texture, prime and paint. |

Fireplace surround details (image, right). This illustration reveals the basic framing components of the fireplace surround, mantle and hearth. Make certain to follow the manufacturer’s guidelines, which specify safe clearances from combustible materials.

No-vent Gas Fireplaces

No-vent, or vent-free, gas fireplaces represent the simplest route to getting a fireplace, but they aren’t legal everywhere because of air-quality concerns. Like a gas kitchen range, they burn natural gas or propane and do it so cleanly that the tiny amounts of combustion by-products generated don’t require a vent. These units have an oxygen-depletion sensor that automatically shuts the gas off if the oxygen level in the room falls below 18 percent; many also integrate carbon-monoxide detectors. Air circulates around the firebox by natural convection, but the heat output is modest