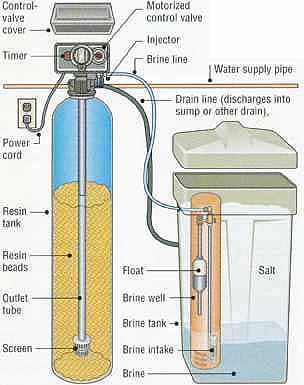

above: Typical water softener anatomy. Drain line (discharges into sump or other drain).

Water softeners remove minerals from water by means of an ion-exchange process. As water flows through a bed of sodium-impregnated resin beads in the resin tank, mineral ions are drawn from the water to the beads, while sodium ions leach out of the beads into the water. The unit periodically cleans and recharges the beads by rinsing them with brine, a salt (or for people on sodium-restricted diets, potassium chloride) solution. The recharging frequency affects the unit’s salt consumption and is controlled by a timer or sensor that operates a motorized control valve.

Some softeners have a separate resin tank and brine tank (as below). In single-compartment models, the resin tank is inside the brine tank. Modern water softeners generally require little maintenance aside from periodic salt refill (see Use and care).

Troubleshooting:

SYMPTOM: |

POSSIBLE CAUSE: |

SOLUTION: |

Motor not operating Water not softened Brine not flowing |

Power off at outlet Motor breakdown Brine depleted Regeneration not frequent enough Iron content of water too high Unit in bypass mode Water loss due to leaking pipes or running toilet Brine line clogged Injector or filter screen clogged Brine line kinked or cracked Brine line pressure too low |

See General Troubleshooting. Call dealer for service. Hush tank; add salt. Start regeneration cycle. Reset timer to increase regeneration frequency. Prefilter water or use salt with an iron control agent. Set the bypass valve to Service position. Make needed plumbing repairs. Flush out brine line. Clean or replace the injector and filter screen. Unkink line. Replace it if cracked. Set pressure according to owner’s manual. |

[Degree of difficulty: Simple ---Average --- Complex]

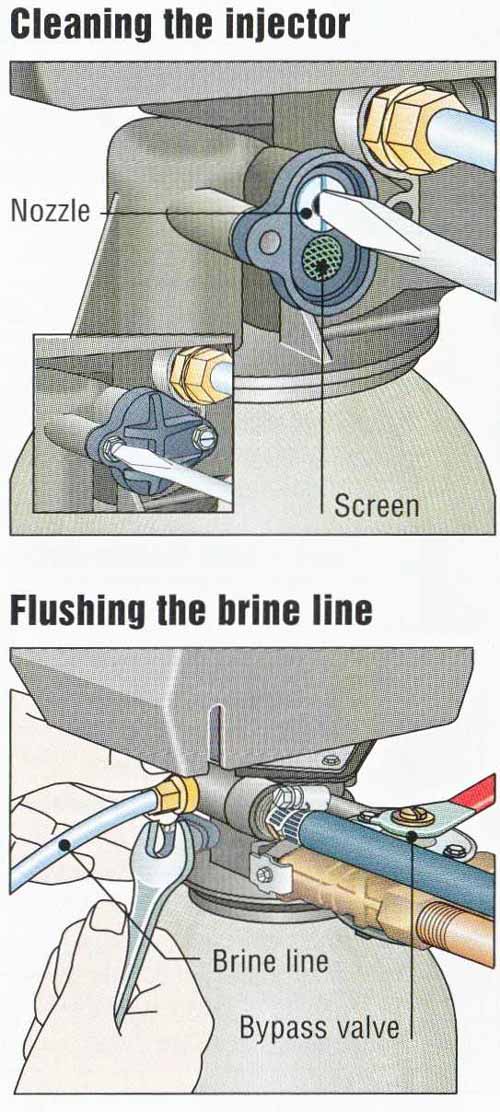

Cleaning the injector: The injector regulates the flow of brine into the resin tank. To remove blockage, put softener in bypass mode, unscrew injector cap, and remove screen and injector nozzle. Clean screen with warm soapy water. Clean nozzle by blowing air through it or gently clearing particles with a straightened paper clip.

Flushing the brine line: The brine line delivers brine to the resin tank. To check for clogs in the line, unplug the softener and put it in bypass mode. Then use a wrench to loosen the brine line fittings at the injector housing and salt tank, and remove the brine line. To clear a clog, use a turkey baster to inject warm water into the line.

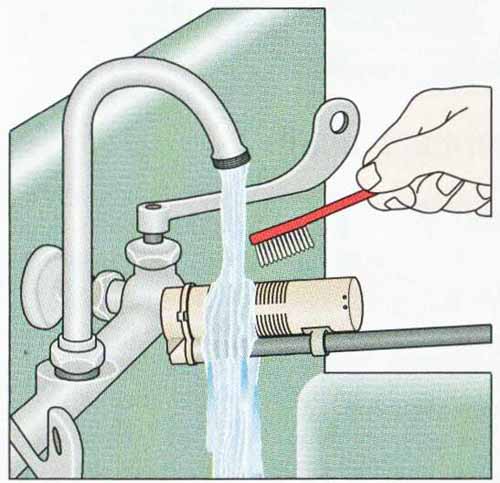

Brine compartment and intake maintenance:

Cleaning the brine compartment is important, especially in rural areas or areas with silty water. Wash brine intake with water and a small brush. Clean brine tank before each salt refill. Remove cover; dump out brine and any salt residue (or empty with a wet-dry vacuum). Flush tank clean with a hose; then refill with salt.

USE AND CARE:

Drain lines should be installed correctly, allowing an air gap for water discharge. Drain lines should be made of durable, high-quality piping and should be free of kinks or restrictions.

When replenishing salt, use the recommended type and amount. Prevent salt buildup by cleaning compartment before refilling.

During long vacations, disconnect the timer and put the unit into bypass mode. After an extended power outage, the time clock must be reset. If there is any danger of freezing, drain the tank. Don’t let the water softener operate empty.