Siding

A BUILDING’S EXTERIOR WALL SURFACE is one of its most visible and defining features. Ideally, you want to choose an aesthetically appealing siding material for your home renovation — one that can stave off years of harsh weather, that will require minimal repainting and waterproofing, and that will optimize or avoid the use of wood. When you re-side your home, it is also a good time to consider wrapping the house with rigid foam to increase the wall insulation.

Wood is a popular siding that is readily available in most regions; unfortunately, it has become a problematic siding solution due to decades of overharvesting and the subsequent declining quality of materials. Vinyl siding (made primarily from polyvinyl chloride, or PVC) is wood siding’s chief competitor. PVC is currently under attack by many environmental groups, including Greenpeace, because of the persistent organic pollutants associated with PVC production. It is also incredibly difficult to recycle used vinyl siding into other products.

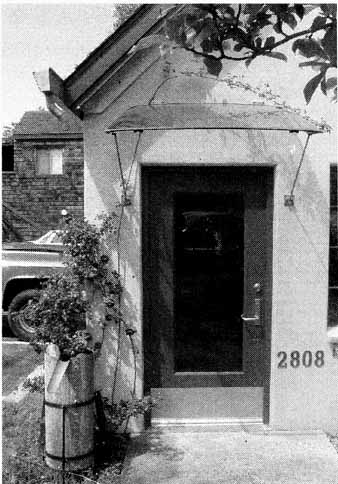

Innovative reuse of materials such as this car rear

window as a sun screen can make the exterior beautiful and unique.

Install Drainage Planes - RC

Without proper rain dispersion elements, water can easily be pushed by wind to where it is in contact with moisture-sensitive building materials.

This can cause mold and decay, and can potentially lead to structural failure. Drainage planes will ensure the longevity of your homes materials (see Section 4, Building Science Basics).

Recommendation: install a drainage plane such as #30 felt paper or a housewrap over the sheathing and under all siding. Make sure the drainage plane is shingled like a roof so all water drains down the wall and away from the house.

Use Alternatives to Wood - RC

• Consider using recycled plastic lumber trim, regionally produced brick, indigenous stone, natural stucco, cementitious siding, or molded cementitious “stone.” These attractive finishes use less wood, and in-the case of recycled content, make use of otherwise wasted materials. They are low maintenance, impact resistant, and fireproof.

• Recommendations: Use the above-mentioned materials in place of exterior wood finishes. Siding may require periodic refinishing if painted, but much less frequently than with wood.

Don’t get ripped off! Siding contractors generate more complaints to the Better Business Bureau than all other building contractors. • Ask for proof that the contractor is properly licensed in your state. • Get proof that the contractor is insured for workers’ compensation and liability. • Search your local Better Business Bureau website for complaints, or check with your local consumer affairs department. • Get at least three written estimates. Be wary of especially low ones; the contractor may be underestimating time or materials, or cutting corners. • Get a list of references and call those past clients with detailed questions about their experiences with the contractor. • Make sure the contract provides for a reasonable deposit (like 10%), with balance payable on satisfactory completion. Have an attorney review it. • Keep a copy of the product warranty; you’ll need it if there’s a defect or product recall down the road. • Keep siding wrappers, and keep extra siding handy for repairs. |

Use Fiber-cement Exterior Siding - $, RC

Fiber-cement siding is composed of cement, sand and cellulose fibers. It’s available in 4- to 12-inch lap planks or 4’ x 8’ sheets. It is textured to look like wood lap siding or stucco finish for sheets. Cement siding is more durable than wood (warranted to last o years). It looks like wood but won’t warp, twist, melt, or burn; it is resistant to moisture and termites; it inhibits fungal growth, holds paint very well, and is easy to install and finish. Using fiber-cement siding reduces the demand for old-growth redwood or cedar siding. It may also reduce homeowner’s insurance rates, especially in fire-prone areas.

Recommendation: Replace conventional wood siding with fiber-cement siding. This product can be cut with a diamond-tipped saw blade, snapper shears, or with a guillotine cutter. Dust protection and control are required when cutting with a circular saw. Available primed and painted.

Use FSC-Certified Solid Wood Siding - RC

Wood is renewable, locally available in many regions, relatively low in embodied energy, and ultimately biodegradable. Unfortunately, the most desirable and durable siding materials have traditionally come from old- growth trees, including mature cedar, redwood, and cypress. The ecosystems are often poorly managed and take hundreds of years to rejuvenate. When you buy certified FSC wood, you ensure the wood was sustainably harvested. (See Section 5 for more information about FSC.)

• Recommendation: Use FSC solid wood siding in place of traditional wood siding. It can be finished or left natural. FSC siding is available primed or painted. Be aware that wood siding can require frequent maintenance, generate significant waste during renovations, and can be short-lived.

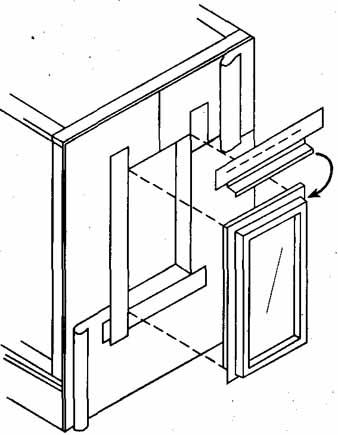

Flashing Detail.

Install Window and Door Flashing - $, HB

• Window and door penetrations through the exterior envelope are common places for water to leak into framing cavities and create mold. Specialized flashing materials and procedures, in addition to conventional house wrap, can prevent moisture from penetrating the building. Installing flashing, doors, and windows appropriately is an inexpensive way to prevent mold and decay and to ensure a healthy home environment.

• Recommendation: Install specialized flashing materials in addition to conventional house wrap. Check all flashing to ensure proper overlap of assembly.

As shown in the figure above, barrier strips are attached with nails and overlapped with successive barrier strips and weather-resistive barriers in shingle fashion. Do not depend on tapes or glues, as they may fail over time.

Siding helpful hints. • Check the old siding. If the siding is sound, new siding can go over it, especially if the original siding is plywood. Rotted wood siding should be replaced; check the wall behind it for damage and mold. • If old siding is removed, have a professional apply a code compliant drainage plane beneath the new siding, as well as beneath flashing around windows, doors, and other openings. • Check the windows. Replace all rotted windows and frames. • Save leftovers. Use spare panels for repairs. Keep labels and receipts in case there’s a product recall or you have to collect on the warranty. |

Decking

Building a deck is one of the easier ways to make your house more enjoyable. It is an inexpensive summer renovation project that is relatively easy to do yourself. However, as with any renovation project, there are ways to use resources more efficiently and to choose materials that do not negatively affect your health or the planet.

Build with Brick or Local Stone - RC

• Patios are generally more environmentally friendly than decks because they require fewer materials and resources to construct. When built out of bricks or local stone, patios are more durable, more weather resistant, and typically require less maintenance than decks. Many decks are made of old-growth trees like redwood and cedar, which take hundreds of years to regenerate. Pressure-treated wood is another common decking material, most of which is made with potentially carcinogenic chemicals (See “Wood Treatments” in Section 5). These chemicals leach into the soil, affect groundwater, and have led to an increased prevalence of arsenic poisoning, especially in young children.

• Recommendation: Build patios made of brick or local stone, instead of decks.

Use Recycled-content Decking - $, RC, HB

• There are two types of recycled-content decking: plastic lumber and composite lumber. Plastic lumber contains only recycled plastic resins, while composite lumber is made by combining recycled wood fiber and recycled plastic resins that are then formed into deck boards. The durability of these materials is greater than that of wood, providing cost savings to the homeowner over the life of the product. They will not rot, crack, or splinter, they do not require staining, and they are not treated with potentially toxic chemicals. Recycled-content decking eliminates the need to use old growth trees for your deck.

• Recommendation: Use recycled-content decking in all deck applications, excluding structural applications. Both composite and plastic lumber can be used in place of old-growth redwood, cedar, or pressure-treated pine.

These products accept screws and nails and cut like wood. Follow manufacturer recommendations closely regarding the amount of expansion that will occur when using plastic lumber. Beware of plastic decking that uses virgin materials. It’s best for the environment to use recycled materials, so look in the manufacturer’s literature for recycled content.

Use FSC-certified Wood Decking - RC

• It is important to buy FSC-certified wood for your decks, which proves that the wood came from well-managed forests, ensuring the long-term availability of precious woods without damaging old-growth forests. (See “Certified Wood”)

• Recommendation: Use FSC-certified lumber to ensure your decking comes from forests managed in an environmentally and socially responsible manner. FSC-certified lumber can be used for all exterior decking applications or as structural deck members.

Wood Treatments

Use Naturally Decay-resistant Wood – RC, HB

• Along with cedar and redwood, the following woods are considered resistant or very resistant to decay: bald cypress (old-growth), catalpa, black cherry, chestnut, Arizona cypress, junipers, black locust, mesquite, red mulberry, burr oak, chestnut oak, gambrel oak, Oregon white oak, post oak, white oak, osage orange, sassafras, black walnut, and Pacific yew. Naturally decay-resistant wood will reduce the need to apply toxic wood treatments that have known adverse health effects. FSC-certification ensures the wood has been harvested in a way that will minimize harm to forest ecosystems.

• Recommendation: Use naturally decay-resistant, FSC-certified wood in place of wood that requires toxic treatments.

Limit Use of Unsafe Treatments - HB

A healthier alternative to chromated copper arsenate (CCA) wood treatment is alkaline copper quaternary (ACQ). ACQ is applied just like CCA, but it is made of 100 percent recycled copper as its main component and contains no harmful chromium or arsenic ingredients. Other less toxic chemical treatments include borates, ACA (ammoniacal copper arsenate), ACZA (ammoniacal copper zinc arsenate), ACC (acid copper chromate), and CZC (chromated zinc chloride).

Recommendation: If you decide to use treated wood, use alternatives to CCA, such as ACQ To optimize durability, choose treated wood with a water repellent incorporated into the wood. Periodically apply a sealer to protect the wood against UV degradation and surface checking. Although not widely used, borate wood treatment is also an acceptable alternative for all types of wood — engineered, sheathing, or dimensional — in situations where the wood will not likely get wet. It is non-toxic for handling, cutting, and disposal. Additionally, borates are effective against fungus, preventive against insects, and suitable for brush application, spray application, or dipping. The lesser known water-borne preservatives (ACA, ACZA, ACC, CZC) can be used for hard-to-penetrate woods.

Beware of CCA Treated Lumber Since the 1940s, lumber producers and manufacturers have used a chemical compound mixture containing inorganic arsenic, copper, and chromium (hexavalent chromium, the kind we’re talking about, is toxic; trivalent chromium is a food supplement), called chromated copper arsenate (CCA), as a wood preservative. Manufacturers inject CCA into wood by a process that uses high pressure to saturate wood products with chemicals, creating what the public knows as ”pressure-treated lumber.” CCA protects the wood from dry rot, fungi, molds, termites, and other pests that can threaten the integrity of the wood. However, the EPA, the Centers for Disease Control (CDC), and the World Health Organization (WHO) classify a primary component of CCA — arsenic — as a known human carcinogen. Estimates suggest that between 75 and 90 percent of all the arsenic used in the United States is used for wood preservation; the rest is used for rat poison. Virtually all lumber used in outdoor construction is pressure-treated, with the majority of lumber treated with CCA. Once wood is treated, it is not recyclable. In some cases, the wood is considered toxic waste. Manufacturing of CCA lumber was phased out in the end of 2003. However, CCA lumber may still be sold after that date. |

Exterior Finish Checklist:

Siding

- Install drainage planes.

- Use alternatives to wood.

- Use fiber-cement exterior siding.

- Use FSC-certified solid wood siding.

- Use finger-jointed trim.

- Install window and door flashing.

Decking

- Build patios instead of decks.

- Use recycled-content decking.

- Use FSC-certified wood decking.

Wood Treatments

- Use naturally decay-resistant wood.

- Limit use of unsafe treatments.

Prev.: Structural Framing

Next: Roofing