|

The thread of textile weaves through history, touching each civilization since the dawn of man and creating a tapestry of variety and excitement. Each culture has made its own unique contribution, and the panorama of fabric designs and types provides deep insight into the development of artistic achievement. Despite these subtle cultural distinctions and mechanical developments that have vastly increased the speed at which textiles can be produced, the basic principles involved in textile construction have remained essentially the same for centuries. The basics still remain weaving, knitting, knotting and felting. |

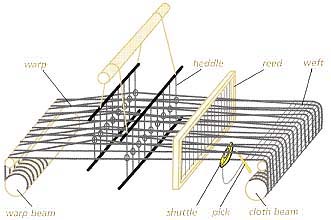

Weaving A woven fabric is easy to recognize by the fact that there

are two sets of yarns at right angles to each other. The loom

that produces it, while it may be an extremely complex device,

works on a fairly simple principle. A frame holds a series of

yarns called the warp taut between two rollers, one each at

the front and back of the loom. Arranged in a specific order

and extending the width of the projected fabric, these yarns

are each drawn first through a heddle, which has an eye like

that of a needle and may be raised to alter the position of

its yarn, then through a space in the reed, which is a comb

like device at right angles to the warp yarns, serving to keep

each thread straight and in its proper place. The heddles are

raised in a specific sequence as the design dictates, and a

single crosswise or filling yarn or pick is drawn between the

warp yarns with a shuttle and beaten into place against the

previous filling threads by the reed. Then the warp yarns are

lowered, a different series is raised, and another filling yarn

is drawn through and packed in place. This series of crosswise

threads forms the weft or woof. As the fabric is completed,

more yarn is released from the back warp beam and the fabric

is rolled toward the front of the loom and wound on the cloth

beam. |

See which of our web site's "Fabric" products the popular search engines have chosen to list...

- Google listing

of all "Fabric" items on our site

- Yahoo! listing

of all "Fabric" items on our site

- Alta Vista listing of all "Fabric" items on our site

Recommended Reading

Recommended Products

Want to learn more about sewing, knitting and related arts and crafts? Browse our reading list.

If you need specific fabric supplies, have a look at these pages:

Weaving (continued)

The warp must withstand considerable

strain in weaving. It undergoes tension as it is held between the front

and back beams and considerable abrasion as the reed slides back and

forth through it. Its threads must be strong, tightly twisted, and uniform

in structure. Consequently, the lengthwise grain (warp direction) will

stretch less, may wear better, and because of its stronger yarn, will

drape differently than the crosswise grain (filling direction). The selvage is

formed along the edges of the warp where the filling thread changes direction.

It is likely to be a tighter weave, since the warp edges must support

the greatest strain. Fabric durability is found in the proportion of

warp to filling yarns. Fabric with a nearly equal thread count in both

directions often gives longer wear.

The warp must withstand considerable

strain in weaving. It undergoes tension as it is held between the front

and back beams and considerable abrasion as the reed slides back and

forth through it. Its threads must be strong, tightly twisted, and uniform

in structure. Consequently, the lengthwise grain (warp direction) will

stretch less, may wear better, and because of its stronger yarn, will

drape differently than the crosswise grain (filling direction). The selvage is

formed along the edges of the warp where the filling thread changes direction.

It is likely to be a tighter weave, since the warp edges must support

the greatest strain. Fabric durability is found in the proportion of

warp to filling yarns. Fabric with a nearly equal thread count in both

directions often gives longer wear.