The terms lining, underlining or backing, and interfacing need not be con fusing. They are self-explanatory if you think about them.

Lining gives a finished look to the inside of a garment. It is often used

in addition to an underlining. Most coats and jackets are lined, also custom-

made dresses.

A lining is constructed separately, then attached to the garment.

Underlining is a layer of light weight fabric cut from the same pattern pieces

as the garment. Each piece is basted to the corresponding garment piece and the sections are assembled as one fabric. Underlining gives sup port, adds

body, or gives strength to a fabric.

(Underlining is also referred to as hacking.)

Because it serves a definite purpose, choose the underlining fabric that your

garment fabric requires. Many types are available. Choose with care.

When a garment is underlined, interfacings may not be necessary, because the garment section is backed, also the facing section. So the two layers of underlining between the garment and the facing provide an adequate interfacing.

Many patterns say “underlining optional”. Many fabrics don't require underlining because the garment fabric has sufficient body and strength.

Interfacing is a piece of fabric that will lie between the facing and the outer section of the garment. It is used to serve a definite purpose.

1. To reinforce buttonhole and button areas.

2. To give support, shape and crispness to collars and cuffs. To give shape in tailored suits and coats.

3. To maintain the shape of necklines and armholes; also, to prevent them from wrinkling, sagging and stretching.

4. To add body and crispness to hemlines.

There are many types of interfacing fabrics. When choosing, fold the garment fabric over several types of interfacing. Is it suitable for the purpose? Choose with care.

Shrink all interfacings before cutting. Use washable interfacing for washable garments. Interfacings are cut on same grainline as facing, the exception being in man-tailored coats and suits.

Non-woven interfacings resemble light weight felt; don't have a grainline so can be cut in any direction. They are not suitable for all fabrics. Check by folding fabric over non-woven, then over woven, before buying; fold as for a collar; a smooth, soft roll is best. All-bias non-woven is also available.

“Iron-on” interfacing comes in non-woven or woven. It makes garment fabric stiffer so use with discretion.

INTERFACING FABRICS

* Flair canvas. Ranges in weight from very fine to very coarse. Used by tailors and dressmakers for coats, suits and dresses. It is pre-shrunk, crease- resistant and has permanent shape-retaining qualities.

* Linen canvas. Comes in various weights. Must be shrunk. Used in medium weight wool and wool-like fabrics.

* Organdy, organza, silk organdy. For silks, thin cottons. Use one or more thicknesses. (Organza and silk organdy are also used for underlining luxury dresses.)

* Lawn, muslin, handkerchief linen, percale, broadcloth, etc. For washable fabrics.

* Unbleached muslin comes in a variety of weights. For washable garments.

There are many trade name interfacings. New ones are appearing each year. Inquire about them in yard goods departments.

There are many fabrics around the home which can be used such as the good sections of shirts, pillow cases, sheets, etc., and they are definitely pre-shrunk.

APPLYING INTERFACING

Armhole and neckline. Cut interfacing the exact size and grainline of the facing. Baste sections together and treat as one. Stitch seams and press seams open. Machine stitch close to outer edge to fasten the two layers together. Trim close to stitching and zigzag to finish cut edges. Garment fronts. Interfacing is applied either to the garment section or to the facing section, depending on the type of buttonhole that will be used — bound buttonholes or worked buttonholes.

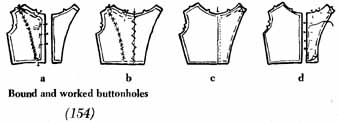

1. Bound buttonholes. Interfacing must be applied to the garment to rein force the buttonholes and buttons. Catch stitch interfacing to garment. (See diagram 154a and b.)

2. Worked buttonholes. Baste interfacing to facing of garment as shown. Interfacing may be machine stitched to garment along fold line as shown in C, stitching only part way if closing edge will be worn open. Finish outer edge of facing by stitching and zigzagging.

Bound and worked buttonholes