Proper plastering is not easy. But DIY plasters are designed with ease of use in mind, and Artex is no more difficult to apply than thick paint.

It is best to wear gloves when mixing up dry plaster-based products - disposable plastic gloves are fine. Wear a face mask when mixing up fine powder.

Being able to use Artex and plaster can help keep the walls and ceilings in your home looking good.

A professional plasterer will normally use gypsum-based Carlite plaster applied in two layers, undercoat and finish.

The skill to do this properly takes years to acquire and the amateur should start with DIY plasters.

"Artex" is the best known make of textured coating, used on internal walls and ceilings to cover up cracks and uneven surfaces or fashioned into patterns. Some people may want to remove the patterned effect.

2 - Choosing the right product

Consider what you want the plaster and/or textured coating to do. If a wall or ceiling is basically in good condition, but has a few holes or hairline cracks, there are many different wall fillers that you can use to make the surface smooth for decorating.

Where an area of plaster is seriously damaged or has come away from the wall ('blown'), you can use a 'repair' plaster (a DIY plaster undercoat) once all the old loose plaster has been removed. This has a good enough finish for papering or tiling, but if you want to paint it, apply a DIY plaster finish (also known as plaster skim) first.

DIY plasters are ideal for repairing the damage to walls created by holes made for electric wiring and plumbing waste pipes.

If you have rough or uneven walls, and using a wall filler will not be good enough, the whole wall can be given a coat of DIY plaster finish (it can be applied up to 3mm or 1/8in thick). Alternatively, you could apply a textured coating, with or without a patterned finish.

A new masonry wall can either be covered with plasterboard (often the best choice for a DIYer) or can be plastered using DIY plaster undercoat followed by DIY plaster finish. Only when you have had success with the DIY products should you attempt to use the professional products, though the technique is basically the same.

Any wall can be covered with textured coating to provide a patterned decorative finish. It has the advantage that it covers up damaged and unsightly walls, but can equally well be used on a wall in good condition if you want the decorative effect. Textured coatings are available in smooth, fine-textured and coarse-textured finishes.

3 - Using DIY plaster undercoat

The most likely time you will use a DIY plaster undercoat (repair plaster) is to repair damage to existing plaster - either damage you have created (perhaps by installing pipes or electric cables) or damage that has happened through accident or old age. It is also ideal for finishing off where you have bricked up a fireplace or a door opening.

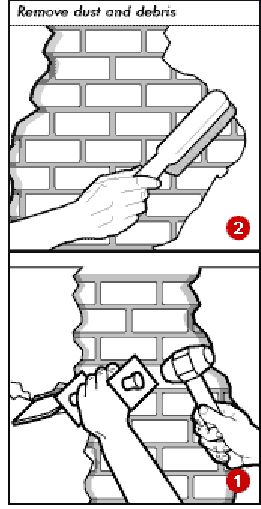

The first thing to do (especially with blown plaster) is to lay a dust sheet on the floor and cut back all existing loose plaster until you have a sound surface with solid edges. Use a club hammer and bolster chisel to do this (1) and remove all loose dust and debris with a stiff brush (2).

Unless the plaster undercoat comes ready mixed, use a large clean bucket to mix up the powder with water. Use a clean wooden stick to do the mixing. It is easier if you add the powder to the water rather than the other way round. The plaster should have a thick creamy consistency.

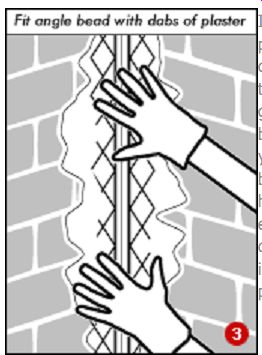

If the repair (or new plasterwork) includes a corner, fit metal angle bead to this first. Not only will it give a neat corner, but the bead will provide a guide for your leveling board. Cut the bead to length (with a hacksaw) and prime the cut ends. Fix it to the corner with dabs of plaster (3). Check it is vertical and leave the plaster to dry.

Before you apply the plaster, dampen the wall surface, using a large paint brush - this will help adhesion and make it easy to 'work' the plaster. On very absorbent surfaces (aerated concrete blocks, for example), add one part PVA adhesive to five parts water.

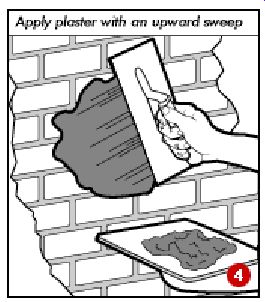

Transfer an amount of plaster to a hawk--a flat board about 30cm (1ft) square. You can buy a ready-made hawk or make your own from a piece of plywood nailed to a block of wood with a short handle (a bit of broom handle, for example) attached to it.

Carry the hawk to the wall and hold it in front of the area you want to plaster. In one movement, tip the hawk towards you, lift off an amount of plaster with the edge of a steel plasterer's trowel and press the plaster against the wall with an upwards sweep of the trowel (4).

The method of application is crucial--you start with the trowel at quite an angle to the wall and gradually reduce this angle as you move it up the wall. Do not allow the trowel to get flat against the wall or you will pull off the plaster you are trying to apply.

Carry on adding plaster until the whole area to be repaired is covered. Remember always to keep the trowel at an angle to the wall and leave the plaster slightly proud of the surrounding surface.

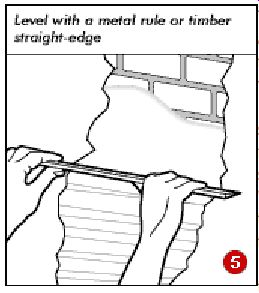

To get the surface level, use a piece of straight-edged timber held at an angle (or if you have one, a metal rule) moving it up the wall with a side-to-side action, holding it firmly against the existing sound plaster as a guide (5). When plastering a whole wall, timber screeds are attached to the wall (and leveled) before plastering to act as the guides for this straight edge.

Take care removing the straight-edge or rule from the surface together with the plaster you have scraped off. You should now be able to see any hollows which can be filled with more plaster before ruling off again.

Keep a bucket of cold water handy at all times, so that you can keep tools clean--especially the plasterer's trowel.

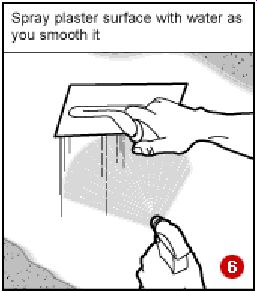

Allow the plaster surface to harden (but not completely dry) before dampening it and smoothing it flat with the trowel (still held at a slight angle) (6). If you are applying a finishing coat, scratch the surface of the undercoat with the edge of the trowel to provide a 'key'.

4 - Using DIY plaster finish

A DIY finishing plaster should be applied to the undercoat before the latter is completely dry. It can also be applied directly to plasterboard and to an existing plaster surface, provided this is roughened slightly (all paint and paper should be removed). Mix up the plaster finish if necessary with clean water as for undercoat.

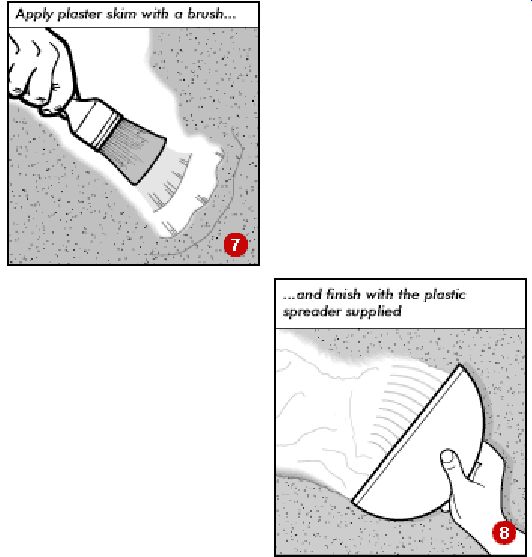

Application methods vary for DIY finishing plasters. Some are applied in the same way as DIY plaster undercoat (with a plasterer's trowel) in two layers (1mm followed by 2mm), whilst others are applied with a paint brush (7) and then smoothed with the plastic spreader supplied (8). Check the instructions for your plaster.

If you have used a plasterer's trowel to apply the plaster, give it a final smoothing with the trowel after it has started to harden. Dampen the surface with water as you do this - a simple spray bottle will help to apply this.

5 - Applying a textured coating

A textured coating will level up uneven surfaces and cover cracks up to around 3mm (1/8in) wide - the coating is flexible, unlike normal paint, and reduces the possibility of cracks reopening. Textured coatings can be used to provide a number of different finishes which, if required, can be painted in a color of your choice.

As with all decoration, proper surface preparation is vital.

Wallpaper (including painted wallpaper) must be removed and the surfaces thoroughly cleaned (in particular, getting rid of grease and nicotine stains). Sound paint can be left in place, but all loose and flaking paint (and all distemper) must be removed before you start. Remove any tiles from a ceiling along with their adhesive.

Porous surfaces should be treated with special sealer and cracks larger than 3mm (1/8in) should be filled with wall-filler: a special caulking tool is available to make this job easier. Filled cracks and joints between new plasterboard should be taped over with joint tape (tape should also be used on the edges of filled areas). If any parts of the wall are powdery or 'chalky' , use a stabilizing solution before coating.

Mix up powder, following the manufacturer's instructions. To speed up this process, whisk attachments are available for both hand and powered drills. Ready-mixed products can be applied straight from the tub. Use masking tape to protect electrical fittings, timber paintwork and exposed plumbing pipes. Lay a dustsheet on the floor.

A brush or roller will leave a relatively flat surface (its texture depending on the type of coating being used), but if you want to provide a decorative pattern, this is done once the coating is on the wall. There are several different texturing tools you can use to provide the pattern:

patterned rollers for producing diamond, diagonal, bark and stipple patterns.

brushes and stippers for creating a wide range of textured effects.

combs for creating artistic combed textures (including flower and rose designs as well as standard linear ones).

lacers (triangular plastic hand-held blades) for smoothing tips of heavier random textures (broken leather, bark and swirls, for example) to reduce the sharpness of the peaks; a standard set includes medium and small sizes. The tool is kept damp with water and is used before the texture has gone firm.

margin brush for creating borders around textured patterns and also for painting around fittings.

You could also use a damp sponge to create a stipple effect or your own swirl design.

If you have moved into a different house and want to remove at least some of the patterned textured coating from the walls and ceilings, there are two choices: cover or strip.

Covering is the easiest choice. You can get specific products designed for doing this and all you do is to apply them on top of the existing patterned coating (with a plasterer's float) so that the surface is restored to a smooth flat surface which you can then paper or paint. Remember, though, that you will now have quite a thick coating. Stripping is the alternative. There are specific products made for stripping textured coatings, though they may not work on all types. If the chemical stripper does not work, you can try a steam wallpaper stripper to soften the coating so that you can strip it off by hand. A large hired type will work better than a DIY wallpaper stripper, but the job is messy and jolly hard work! Some old textured finishes may contain a small proportion of asbestos. For further details , consult the appropriate supplier or manufacturer.

-------