For the first 75 years of their existence nearly all skyscrapers had windows—traditional windows that opened and closed to allow natural ventilation. But with the rise of the international style in the mid-1900s, traditional windows all but disappeared from commercial office towers (though not from residential ones). Concrete or brick walls punctuated regularly with window frames gave way to sleek, uniform walls of metal or glass—most of which didn’t open at all.

These “curtain walls,” as the façades of these new buildings came to be known, were defined by a system of metal frames into which panels of metal, stone, or glass could be inserted. This new type of building skin carried no load except its own weight, which it transferred—along with any wind loads pressing on the building—to the building’s floor structure through a system of anchors.

The earliest curtain wall was composed of steel frames (known as ‘ into which glass or metal panels (called “infill”) were placed. The seven-story Hallidie Building, located on Sutter Street in San Francisco, is generally acclaimed as the country’s first curtain wall structure. Opened in 1918, it featured a regular grid of mullions that held glass panels in place—three vertical panels per floor. The building was renovated in 1979 but has retained its signature blue and gold coloring for almost 100 years.

But curtain wall technology was not really popularized until three decades later, by which time glass technology had matured significantly. Lever House, which was designed by Gordon Bunshaft at Skidmore, Owings & Merrill and opened in New York in 1952, featured a skin composed of stainless steel and heat-resistant glass. The windows did not open; to clean them, a window-washing gondola was lowered from tracks along a parapet at the roof of the building. The idea of the building was revolutionary, and its stylish execution gained worldwide recognition.

___Hallidie Building, San Francisco (1918) The Hallidie Building is considered one of the first glass curtain wall buildings.

___Lever House, New York (1952) Lever House is among the earliest “modern” glass curtain wall buildings.

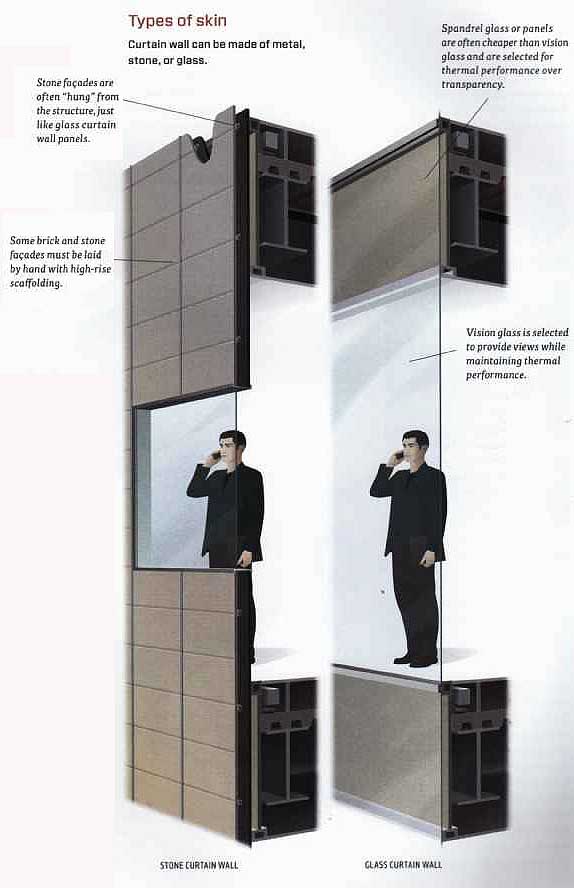

Types of skin-- Curtain wall can be made of metal, stone, or glass.

STONE CURTAIN WALL; GLASS CURTAIN WALL

Stone façades are often “hung” from the structure, just like glass curtain wall panels.

Some brick and stone façades must be laid by hand with high-rise scaffolding.

Spandrel glass or panels are often cheaper than vision glass and are selected for thermal performance over transparency.

Vision glass is selected to provide views while maintaining thermal performance.

Some brick and stone façades must be laid by hand with high-rise scaffolding.

The opening of Lever House coincided with the development of the “float glass” process patented by the Pilkington Company. The process involved floating molten glass on a bed of molten tin to produce glass sheets of uniform thickness. The process was continuous, allowing a high volume of production of consistently high-quality glass. Most important, the panes it produced were large—with perfectly flat and parallel surfaces.

Commercial manufacturing of float glass began in 1959. Glass soon became the material of choice for skyscrapers around the world—and it remains so today. Of the 53 million tons (48 million metric tons) of float glass produced in 2008, 70 percent was used for buildings; the rest was used for automotive, furniture, and other interior applications. Advances in float forming now allow the production of glass as thin as one one-hundredth of an inch (three tenths of a millimeter) and as thick as an inch (25 millimeters).

Mullions have also changed since the debut of the glass curtain wall building. Today the mullions that glass panels slide into are no longer steel; they are instead made of extruded aluminum, which is made by pouring molten aluminum through a mold or die and then cutting it down to size.

Vision glass is selected to provide views while maintaining thermal performance.

Making Glass:

The Pilkington process of making float glass proved the culmination of years of experimentation in glassmaking. Traditionally window glass had been made by blowing large cylinders from molten glass, cutting them into pieces, and then flattening the pieces. Because the cylinders were generally no more than a foot in diameter, the width of the panes that could be cut out of it was limited. To match the size of the glass, windows needed to be divided into relatively small panels by transoms.

In the late nineteenth and early twentieth centuries, a variety of attempts were undertaken to produce a continuous ribbon of flat glass from a molten material—either by putting it through rollers or pulling it upward from a tank—including one by Bessemer, who had successfully pioneered the mass production of steel. None proved easy to commercialize, however, as they required polishing and grinding, which added considerable cost to production.

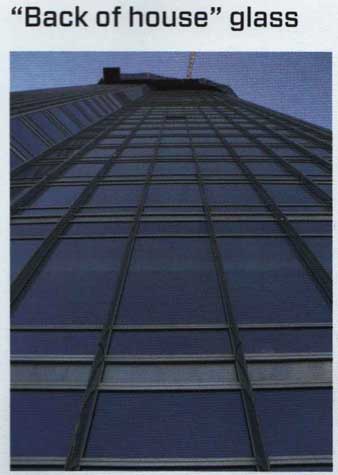

“Back of house” glass -- Not all float glass is created equal. On most skyscrapers, glass that will serve as windows for offices or residences needs to be highly transparent and is generally known as “vision glass.” It’s usually double-glazed.

In contrast, the glass that covers the “back of house” sections, For example, where the curtain wall meets the floors (often referred to as the “spandrel”) or where mechanical floors are located, need not be as transparent. Generally known as “spandrel glass,” it may contain a fritting on the external glass or be used in the creation of a “shadow box.” Also referred to as “monolithic glass,” it’s usually one quarter of an inch (6.4 millimeters) thick—half the thickness of vision glass.

Where is float glass made?

Around 70 percent of the 53 million-ton (46 million- metric-ton) worldwide float glass market is consumed by windows for buildings. Most of it’s manufactured in Europe and Asia, although some is made in the eastern United States and a few plants can be found in South America.

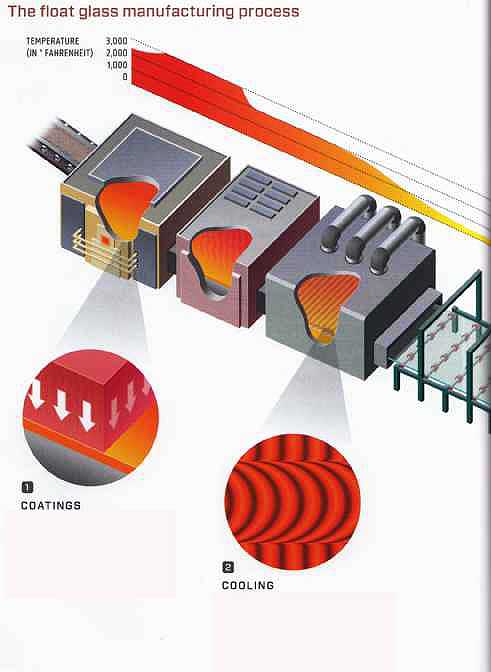

The float glass manufacturing process:

1. COATINGS: As the glass ribbon flows beneath coaters, multiple coatings can be deposited to change its visible and thermal properties.

2. COOLING: If the glass is not cooled properly, it will break beneath the cutter. The lehr is a long furnace used to relieve the stresses from cooling.

PROTECTION: The temperatures needed for the float process are so high that some workers must wear heat-protective clothing.

3. DEFECTS: Lasers are used to detect defects invisible to the naked eye—such as bubbles, unmelted sand grains, or tin debris from the float.

4. CUTTING: Diamond wheels trim off the stressed edges of the glass and cut the ribbon too size dictated by computer.

Curtain Wall Systems:

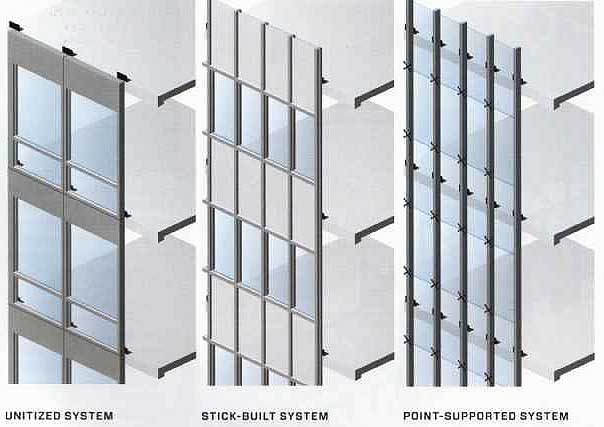

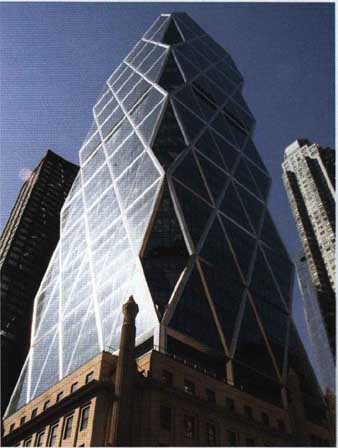

There are two main types of curtain wall, which differ primarily in where they are assembled. A “stick system,” popularized by a company called Pittsburgh Plate Glass (PPG) in the mid-twentieth century, involves the assembly of curtain wall panels at the building site. The mullions, or curtain wall frames, are installed first, and then panels of glass (or in some cases metal or stone) are inserted into the mullions.

In contrast, a “unit system” (also called a “unitized” system) is composed of wall units that have been previously assembled and glazed in the factory, then shipped to the construction site for erection. The units are generally one-story tall and between five and six feet wide (1.5 to 1.8 meters), with vertical and horizontal connections that allow the individual panels to “snap in” to one another. Because most of the assembly work has been done at the factory, rather than in the field with more expensive construction labor, labor costs associated with unitized systems tend to be lower—offset, not surprisingly, by a higher price for the preassembled curtain wall itself.

Both stick and unitized systems can be assembled from either inside the building’s steel frame or from outside it. “Interior glazed” panels are inserted into the frame opening from the inside of a building under construction. While they are somewhat complicated to erect, due to the requirement for obstruction-free interior space for insertion, they are relatively easy to replace subsequently. In contrast, “external glazed” panels are installed from the outside, and therefore require no internal staging area, but do require scaffolding, a crane, or a swing stage to be erected when or if they need to be repaired.

A third system, called “point-supported glass,” is now used to create walls that demand maximum transparency—such as lobby façades, large retail windows, or atria roofs. In these cases, glass is attached to the structure by bolted fittings that are connected through holes in the glass. These seemingly “pure glass” walls are designed in varying thicknesses to take account of projected wind loads and, in cases where they serve as ceilings for atria or lobbies, gravity loads as well.

UNITIZED SYSTEM: Unitized panels are fabricated and assembled at the factory. The panels are then taken to the construction site, where they are attached to a building structure. This is the quickest system for installation.

STICK-BUILT SYSTEM: In a stick system mullions (sticks) are fabricated in the factory and installed and glazed in the field. Sticks are placed between floors vertically to support individual components, such as horizontal mullions, glazing, and spandrels.

POINT-SUPPORTED SYSTEM: In this system the vertical framing member is a stick, cable, or another custom structure. The glass is supported by a system of four-point brackets and the joints are sealed with silicone.

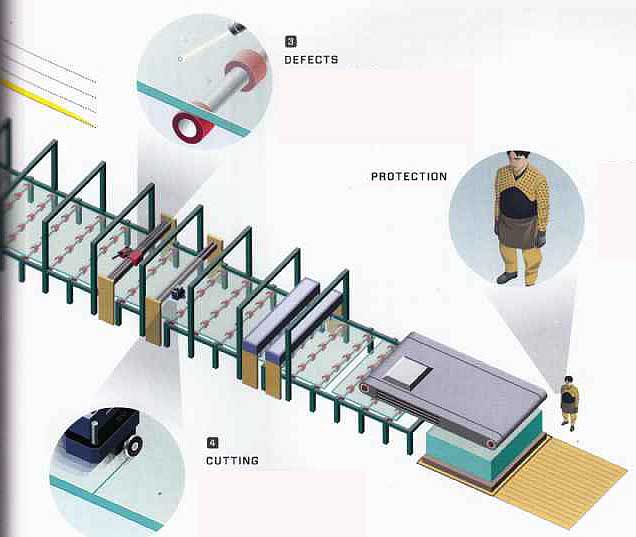

Installing the glass curtain wall

1. Unitized panels, generally one- story high, arrive on the site fully assembled. Each unitized panel is attached to a crane or davit located on a higher floor.

2. The crane lifts the panel into place while workers, generally two below and one or two on top, guide the panel into its assigned place.

3. Once in place, the panel is hung from brackets installed on the building and adjusted to be flush with the adjacent panel.

4. To complete panel installation, workers snap and then bolt the panel into place and seal its joints with silicone, caulking, or gaskets.

Diagrid dreaming:

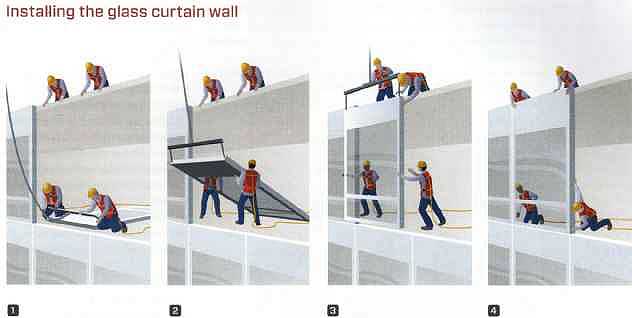

When William Randolph Hearst designed his six-story headquarters at New York’s Columbus Circle in 1926, he envisioned the area as a magnet for media companies and assumed he would one day build a tower atop his building. The Great Depression put an end to his skyscraper plans, and it would not be until the next century—2003 to be precise—that a tower would begin to rise on his cast-stone façade, now preserved as a city landmark on the corner of West 57 St. and 8 Ave.

The 46-story Hearst Tower, designed by Norman Foster, is notable on many counts—including being one of the first “sustainable” buildings in New York. But it’s recognizable above all for the unconventional triangular framing pattern that supports the structure, known as a “diagrid” (short for diagonal grid). Rather than rising vertically, the building’s steel columns are inclined and therefore function as both bracing and column for the building—reducing the amount of steel used in its construction by about 20 percent.

The tower’s unitized skin is composed of what appears to be triangular, but is in fact diamond-shaped facets of glass. Each of the four-story facets is 54 feet tall (16.5 meters), with floor-to-floor glazing made up of high-performance, low-emission glass. The curtain wall is accompanied by integral roll-down blinds. Light sensors constantly measure the amount of light penetrating the glass and automatically adjust the amount of electric lighting provided within the building.

Water:

Above all else, curtain walls are designed to keep out the elements--—primarily water and air. Of the two, the former is more dangerous, as water penetration can rapidly lead to the deterioration of the structure and mold. And yet, even today, all buildings leak: the trick is to “weep out the water in a controlled and predictable route.

Thanks to advances in technology, less water infiltration occurs today than it did in the early days of skyscrapers. Yet the water that penetrates the curtain walls of modern towers is more problematic than that which penetrated stone or masonry walls, as neither of these materials deteriorated when in contact with moisture. But with the introduction of metal into building frames, and subsequently into building studs and other components, water became a more potent enemy —prompting the development of innovations to ensure its drainage. Today most modern curtain wall systems feature innovations like “weep holes” or “condensation gutters” to allow water to drain from the curtain wall to the exterior of the building.

To prevent water from penetrating the wall in the first place, a variety of sealant systems are used. The simplest rely on “face- sealed” barrier walls, with no provision for removal of water that successfully penetrates the barrier. More sophisticated “water-managed” systems contain drains to provide an exit channel for water that enters the glazing pocket between the panes of the panel.

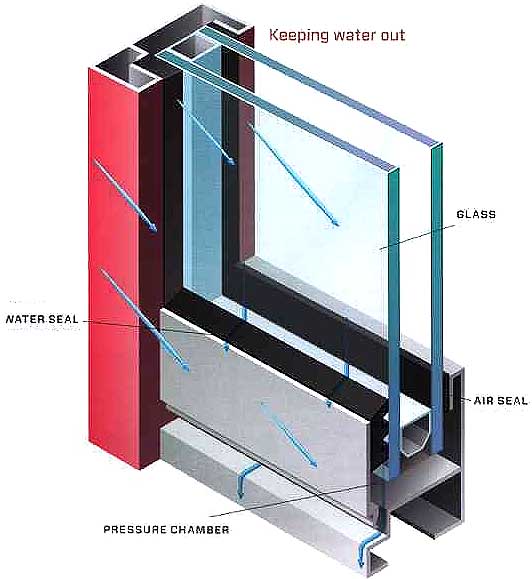

Even more protection is offered by a third system known as a “pressure-equalized rain screen.” The rain screen principle involves creating a pressure-equalized chamber that functions as an air barrier between the outside-exposed face of the wall and the interior one. By eliminating pressure differences between the two, water is prevented from entering the glazing pocket. Because it’s highly resistant to air and water infiltration, most unitized systems rely on the rain screen system.

Keeping water out:

WATER SEAL -- Any water that leaks past outside seals is designed to —i drain back to the outside.

GLASS -- Most wind-driven rain is blocked by the glass and pressure chamber baffle.

AIR SEAL -- An inner air seal moderates pressure in the chamber and protects the interior environment.

PRESSURE CHAMBER -- A pressure chamber with a baffle collects and drains any wind-driven rain.

Noise:

The building’s skin also acts as a barrier between outside noise and the interior of a commercial or residential tower. Historically, unusually thick or multiple panes of glass ( For example, “double glazing”) have been used to minimize the penetration of noise into a tall building. The most effective double glazing for purposes of blocking sound is thought to be two panes of glass of differing thicknesses—which for some reason insulate more effectively than two panes of equal thickness.

Where noise presents a serious problem, three panes of glass maybe used. “Triple glazing” involves placing an additional pane of glass roughly three inches away from a one-inch insulated unit comprising two panes. The airspace between the double- and single-pane units can absorb a significant amount of additional noise.

Several other technologies may be employed to minimize outside noise infiltration. Sound-attenuating infill, often composed of a composite plastic material, can be placed between panes of glass to further minimize air and noise leakage. A variety of special seals and sealants may also be employed. Gaskets, typically placed between pressure bars (fastened to the outside of mullions to retain the glass panel) and the mullions to minimize heat conductivity, often help to reduce noise as well.

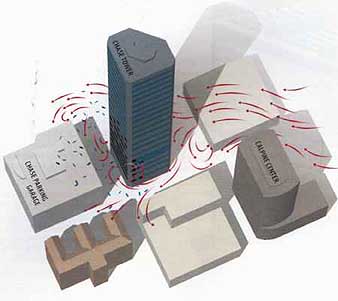

Somewhat ironically, the level of noise penetration in a city rarely decreases with height—in fact it can be noisier at the top of certain skyscrapers than it’s at the bottom. At times this can be a function of the proximity of mechanical systems, such as fans, generators, and cooling towers on upper mechanical floors and roofs. But it’s more often due to street noise bouncing, or “canyoning,” off nearby buildings. Just how loud those street sounds are as they rise is a function of both the proximity of nearby buildings and the materials those buildings are made of: stone and masonry walls absorb considerably more noise than glass.

Canyons of glass -- In dense cities, street noise often seems to travel upward with little diminution of volume. Just how pervasive street noise is to a skyscraper dweller dozens of stories above the earth depends not only on the sound absorption properties of the building’s skin, but also on the nature of the skin of nearby buildings and the width of adjacent streets. Holding aside changes in traffic volumes, cities have become noisier places than they once were due to the fact that the glass skin of today’s buildings absorbs sound far less well than the masonry walls of older buildings.

Light and Heat:

Both the metal and glass components of modern curtain walls conduct heat in quantities far greater than earlier stone or masonry building skins did. Aluminum mullions can get particularly hot, so thermal breaks—generally made of polyvinylchloride, or PVC—are regularly placed between the exterior and interior metal layers of the building’s skin to lower heat conductivity.

Significant heat can also be carried into a building through glass. Glass is often characterized in terms of “solar gain” and assigned a “solar heat gain coefficient,” or SHGC (in Europe, it’s referred to as a “G-value”). In addition, glass is also categorized by how much heat is transferred through it from the outside and is assigned either a U-value or an R-value (its inverse) to represent heat transfer qualities.

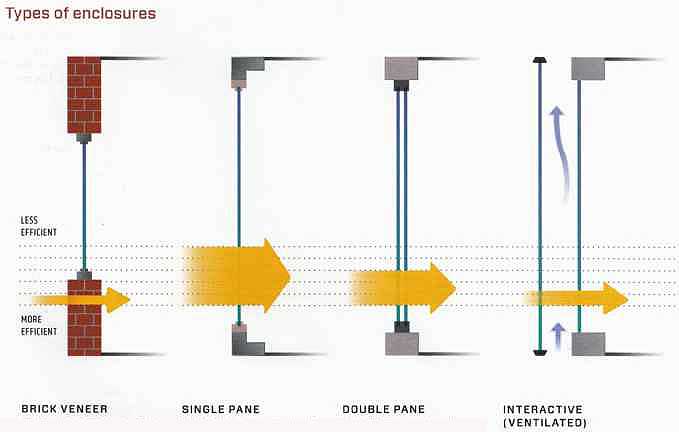

Several technologies have been developed to minimize heat transfer and loss. “Insulated glazing” involves reliance on a gas contained in the space between the two sides of double- or even triple-glazed windows and is commonly used in the United States. Less common in the United States, but increasingly found on skyscrapers in Europe and Asia, are “double-skin” curtain walls, which feature an external layer of safety glass complemented by an interior skin of single-or double-pane glass. Between the two is a vented cavity through which outdoor air either flows naturally or is forced by mechanical means.

Glass is also measured by how much light is able to move through it. Historically, the amount of light transmitted through glass (often referred to as “visible light transmittance,” or the “daylight factor”) closely tracked the amount of heat transmitted through it—e.g., glass that blocked 70 percent of the solar heat would also block roughly 70 percent of the light. Advances in technology have facilitated the production of glass that today allows more light to pass through than heat.

Types of enclosures:

BRICK VENEER--While not seen in many modern “glass box” skyscrapers, a ratio of approximately 25 to 40 percent window-to-wall area may yield the best compromise between maximizing daylight and controlling thermal performance.

SINGLE PANE--Early gloss skyscrapers built in the 1960s and 1970s used only single-pane systems and therefore perform poorly from a thermal perspective.

DOUBLE PANE--Probably most common in high-rise applications today, a double-pane system affords a high degree of transparency as well as some improvement in thermal performance.

INTERACTIVE (VENTILATED) -- An interactive or double-skin ventilated system, in which air moves through the space between the glass “skins,” is highly transparent and performs similarly too masonry façade from a thermal perspective.

LESS EFFICIENT; MORE EFFICIENT

Improving thermal performance: A variety of techniques are available for improving the thermal performance of vision glass in ways that don’t obstruct views from the building.

LOW-E COATINGS--Low-emittance coatings, microscopically thin metal or metallic oxide layers deposited on the glazing surface to suppress radiative heat flow, are used widely.

GAS--Filling the void between two panes of glass with inert gases like krypton or argon can further increase overall heat transfer of the glass system.

OVERHANG: Recessed windows or overhangs can reduce solar he at gain by taking the glass out of direct sun exposure.

SHUTTERS: Exterior shutters will also reduce solar heat gain by blocking the sun on exposed faces of the building.

FRITTING: Ceramic fritting, when applied properly to the glass, can reduce solar transmittance without blocking vision, as the eye will read around the frits.

SHADES: Automatic shading systems, integrated with the curtain wall and controlled by a building management system can be highly effective.

Killer glass:

Both tinted and clear plate glass are invisible to birds. When glass is clear, birds see only what’s behind it. When it’s reflective, they see only the reflection of sky and trees.

While glass at all heights can pose a hazard to birds, skyscrapers pose a special threat—during the day, because of their height, and at night, because artificial lights attract birds (especially during bad weather). One skyscraper alone was found to have killed over 100 birds in a single day.

To minimize the danger to birds, cities have increasingly adopted light-dimming strategies at night during bird migration seasons in spring and fall. Chicago was the first to implement a voluntary “Lights Out” program in its skyscrapers in 1999; proponents claim it has reduced bird deaths by an estimated 80 percent annually. New York and Toronto, among other cities, have since followed suit and introduced their own light-dimming programs.

Extreme Loads:

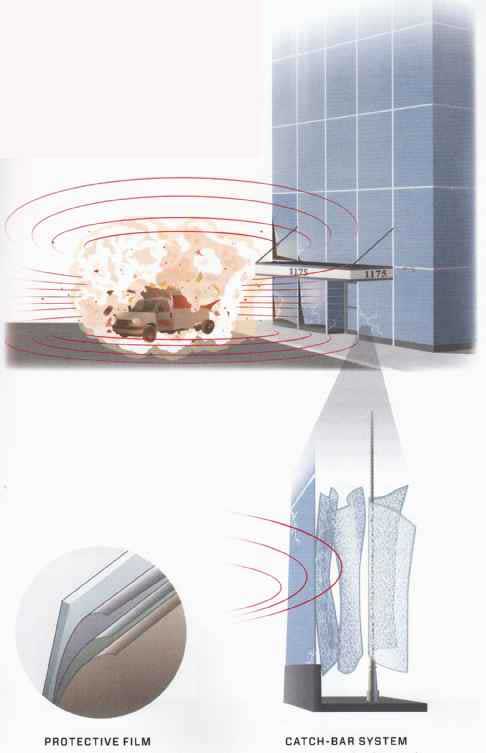

Standard curtain wall systems contain joints between panels and are built to withstand a certain amount of floor movement (generally less than an inch) without experiencing panel breakage or water leaking in from the outside. To protect against movement larger than that, from wind or an explosion, a range of technologies are available.

One involves the application of a special film upon curtain wall glass and is known as “fragment retention film.” It’s composed of a polyester laminate, easily colored, and similar to conventional window film, but it’s generally thicker and attached with a stronger adhesive. While this film doesn’t improve the blast resistance of the glazing system as a whole, it typically prevents glass from shattering inward or becoming airborne—the primary causes of injuries in extreme load conditions.

Other energy-absorbing “catch systems” rely on the capacity of window materials to absorb and dissipate large amount of energy from a blast. In cable-protected window systems, the damaged glass pushes against a cable catch system that in turn acts to deform the window frame itself—capturing energy that would otherwise be transmitted to the inside of the building.

HURRICANE IKE--During Hurricane Ike in September 2008, the 75-staryJP Morgan Chase Tower in downtown Houston experienced significant curtain wall damage an the downwind side of the lowest third of the building. The shorter Calpine Center, located upwind of the tower, likely magnified the damage by causing destructive downwind vortices.

The plywood palace:

The 60-story John Hancock Building has been Boston’s tallest building for 30 years. Designed by Pei & Cobb, its curtain wall was noteworthy: it used the largest panes of glass possible, with minimal mullions and no spandrels, and featured a bluish- tinted glass that superbly reflected the sky and buildings around it.

But the Hancock proved a difficult building to construct. Its opening was delayed five years, from 1971 to 1976, due to concerns about both its lateral stability and the unexpected settlement of its foundations. To make matters worse, its glass “windows” kept falling out.

On January 20,1973, in 75-mph (120 km/hr) winds, a total of 65 panels, each weighing 500 pounds (227 kilograms), crashed to the ground. Over the next several months, dozens of others would fall—forcing the city to close the streets around the tower when winds exceeded 45 mph (72 km/hr). The tower was dubbed “the Plywood Palace,” a reference to the plywood that replaced glass in over an acre of the building’s skin.

Various theories were examined to explain the failure of the curtain wall. The problem was ultimately attributed to movement and heat stresses caused by contraction and expansion of the air between the inner and outer panels of glass. As a result, the building’s designers decided to replace all 10,344 double-pane glass panels with single-pane glass— a process that took nearly three years and cost over $5 million.

Blast protection:

Of all the components of a building, windows are among the most vulnerable

to terrorism. While it may be impractical to design all windows to resist a

large-scale  explosive attack, it’s desirable to limit the potential for injuries

due to glass breakage. Some of the most common solutions used to minimize glass-related

injuries are laminated annealed glazing, anti-shatter films, and energy-absorbing

catch systems.

explosive attack, it’s desirable to limit the potential for injuries

due to glass breakage. Some of the most common solutions used to minimize glass-related

injuries are laminated annealed glazing, anti-shatter films, and energy-absorbing

catch systems.

PROTECTIVE FILM: Laminated and anti-shatter films may be placed on glass to hold it together after impact to minimize the amount of glass debris that is launched into the air.

CATCH-BAR SYSTEM: In an energy-absorbing catch system, a cable system is used to absorb significant amounts of energy—keeping the glass debris intact and impeding its flight into occupied spaces.

A shattering event:

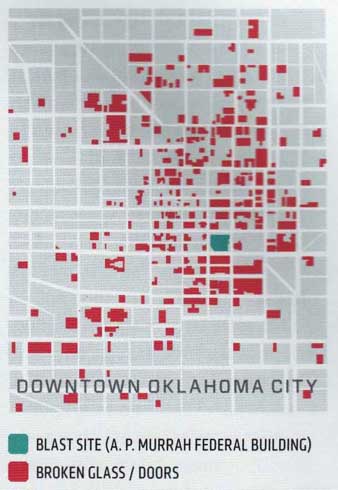

BLAST SITE ( A. P. MURRAH FEDERAL BUILDING); BROKEN GLASS/ DOORS

No matter how thick or reinforced it may be, glass is the weakest part of a building’s envelope—and the part most responsible for injuries in an explosion or weather-related event. Just how sensitive it’s to impact was shown during the bombing of the Oklahoma City Federal Building in 1995. The blast damaged 312 buildings within a 20-block radius. Thirty sustained serious damage (12 have since been torn down), but nearly all were left with broken glass.

To provide additional security and safety, many public buildings rely on “tempered glass” in areas where human impact could occur. Tempering involves heating a sheet of glass and then slowly cooling it with air; the compression that results from the differential in temperature between the inside of the glass and the outside makes it denser than it would be otherwise. This density causes it to break into many small pieces, rather than large shards—one reason why it’s also used on retail storefronts as well as on side and back wind in automobiles.

Previous: Structure

Next: Construction