Troubleshooting and Repairing--Refrigerators and freezers (part 1)

| HOME | Troubleshooting | DIY Tips |

|

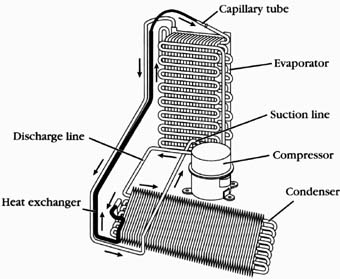

One of the most important applications of refrigeration (which was invented in the early 1900s) was for the preservation of food. When different types of food are kept at room temperature, some of them will spoil rapidly. When foods are kept cold, they will last longer. Refrigerator/freezers prevent food spoilage by keeping the food cold. The refrigerator/freezer consists of three parts. They are: 1. The cabinet. 2. The sealed system, which consists of the evaporator coil, the condenser coil, the compressor, and the connecting tubing. 3. The electrical circuitry. THE REFRIGERATION CYCLE The sealed system ( Figr. --1) in a refrigerator or freezer consists of a compressor, a condenser coil, an evaporator coil, a capillary tube, and a heat exchanger and its connecting tubing. This is the heart of the refrigerator or freezer that keeps the food cold inside of the cabinet. Starting at the compressor, refrigerant gas is pumped out of the compressor, through the discharge tubing, and into the condenser coil. When the gas is in the condenser coil, the temperature and pressure of the refrigerant gas greatly increases because of the capillary tube at the discharge end of the condenser coil. From the surface of the condenser coil, the heat spreads out into the room via air moving over the condenser coil. The condenser coil cools the hot refrigerant gas. As the refrigerant gas gives up the heat it obtained from inside the refrigerator or freezer cabinet, the refrigerant gas changes into a liquid. This liquid then leaves the condenser coil and enters the capillary tube. This capillary tube is carefully made, as to its length and inside diameter, to meter the exact amount of liquid flow through the sealed system (as designed by the 1 Dairy products, meats, seafood, fruits, and vegetables will all spoil rapidly, if not kept cold or frozen. The colder temperatures of the refrigeration compartment, between 35 and 40 degrees Fahrenheit, in a refrigerator will slow the spoiling of foods. Most foods will last from 3 to 7 days at that temperature. If the foods were frozen, and packaged properly, they could last for several weeks in a domestic refrigerator with a temperature of 0 degrees Fahrenheit to -10 degrees Fahrenheit. Evaporator; Heat exchanger:

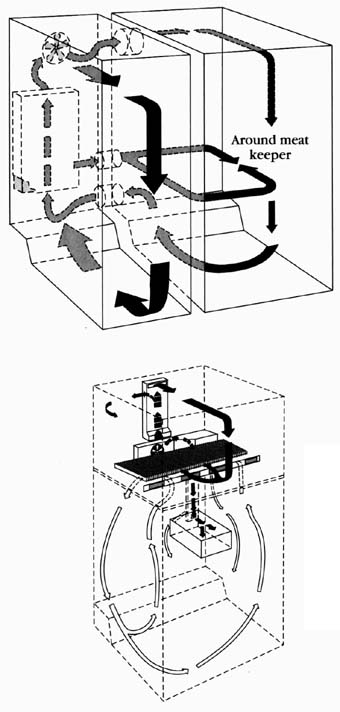

As this mixture of liquid and gas passes through the evaporator coil, the refrigerant absorbs heat from the warmer items (food) within the refrigerator or freezer cabinet, slowly changing any liquid back to all gas. As the refrigerant gas leaves the evaporator coil, it returns to the compressor through the suction line. This entire procedure is called a cycle. Depending on where the cold control is set, the thermostat can show how cold it’s inside the cabinet, and then control the actuation of the cooling cycle. It will determine whether to turn the system on or off, to maintain the temperature within the cabinet. Inside the cabinet, the cold air is circulated by convection and/or by means of an electrical fan. In Figr. --2, the arrows are showing the air flow patterns in this type of side-by-side refrigerator. Figr. --3 shows the air patterns in this type of two-door refrigerator with a top freezer. Storage requirements for perishable products: Table 1 represent the recommended storage temperatures, relative humidity, and the approximate storage life for perishable products. These values are used in designing commercial refrigeration systems, which house large quantities of perishable products. Large warehouses are usually equipped to store foods at those temperatures best adapted to prolong the safe storage period for each type of food. In the domestic refrigerator, most foods are kept at 35 to 45 degrees Fahrenheit, and the humidity is kept around 50%. The freezer temperature is between zero and 10 degrees Fahrenheit. It Discharge line; Suction line; Condenser --- Refrigerators and freezers

Table 1. Storage requirements for perishable products.

SAFETY FIRST Any person who cannot use basic tools, or follow written instructions, should not attempt to install, maintain, or repair any refrigerators or freezers. Any improper installation, preventive maintenance, or repairs could create a risk of personal injury or property damage. --- Refrigerators and freezers: If you don’t fully understand the installation, preventive maintenance, or repair procedures in this section, or if you doubt your ability to complete the task on your refrigerator or freezer, then please call your service manager. Before continuing, take a moment to refresh your memory of the safety procedures in section 2. This section covers the electrical components and how to diagnose the sealed system. The actual repair or replacement of any sealed system component is not included in this section. It’s recommended that you acquire refrigerant certification (or call an authorized service company) to repair or replace any sealed system component. The refrigerant in the sealed system must be recovered properly. REFRIGERATOR/FREEZERS IN GENERAL Much of the troubleshooting information in this section covers refrigerators and freezers in general, rather than specific models, in order to present a broad overview of service techniques. The pictures and illustrations that are used in this section are for demonstration purposes to clarify the description of how to service these appliances. They in no way reflect on a particular brand’s reliability. Location and installation of refrigerator/freezer: Thoroughly read the installation instructions that are provided with every new refrigerator/freezer. These instructions will provide you with the information needed to properly install the refrigerator or freezer. Listed are some general principles that should be followed when performing the installation. 1. The refrigerator/freezer must be installed on a solid floor capable of supporting the product up to 1000 pounds. 2. For proper air circulation around the refrigerator/freezer, some models require a one-inch clearance at the rear and top of the cabinet, and adequate clearance near the front grille at the bottom of the refrigerator/freezer. 3. Don’t leave the refrigerator/freezer on its side longer than necessary to remove the shipping base. 4. When removing or reversing the doors on a refrigerator, always reinstall them according to the installation instructions, and remember to realign the doors properly. 5. Level the refrigerator/freezer cabinet so that the doors will close properly. What’s that “different” sound in your kitchen? If you have bought or serviced a new refrigerator within the past few years, you’ve probably noticed that it sounds “different.” Here’s why. New refrigerators use only half as much electricity as the older models. In fact, a new 20.6-cubic foot refrigerator with top freezer uses no more electricity than a 75-watt light bulb. Most new refrigerators are also larger, and they have such added conveniences as automatic defrost systems, icemakers, and perhaps even a “built-in” look. These new features result in different sounds, such as: • High-pitched whine; from the more energy efficient compressors that have smaller, higher speed motors. • Soft hum; from the evaporator fan in the freezer and/or from the condenser fan under the refrigerator. • Clicks; from the automatic defrost timer, switching on and off; the thermostat, turning the refrigerator on and off; or the water valve, refilling the icemaker. • Boiling and/or gurgling or trickling water; when the refrigerator stops running, the refrigerant continues to circulate within the system; or, the defrost water runs into the drain pan. • Running water and “thuds;” as the ice cube tray fills, and as the ice cubes drop into the storage bin. To help deafen these new sounds: • Be sure that the refrigerator is level, and that the defrost water collection pan is in position (usually reachable behind the bottom front “toe plate”). • Put a piece of carpet or a sound-absorbing ceiling tile on the wall behind the refrigerator. • Allow enough space between the back of the refrigerator and the wall, unless it’s designed as a “built-in.” Check your use and care guide for the needed space. To reduce the compressor “run time”: • Vacuum the condenser coils at least twice a year, more often if you have pets. • Keep your freezer at least three-fourths full. Use partially filled water jugs to fill any large empty space. Many of the consumers filing “refrigerator sound” complaints with MACAP rep resent one or two-family households; or they have recently moved to smaller retirement homes; or they have remodeled, with the kitchen open to a family living area. Sounds are most noticeable in quieter surroundings. Consumers with hearing aids are especially sensitive. Some consumers report to MACAP that their refrigerators are “louder” than an identical model in a friend’s or a relative’s house. This might be because of the number of people in the house, as well as different furnishings and room arrangements. Carpeting, drapery, upholstered furniture, and wall coverings can help to muffle refrigerator sounds . Are refrigerator/freezers snowbirds? Putting that extra refrigerator or freezer in any area in which the temperature falls below 60 degrees Fahrenheit might be a problem in colder areas when the winter months are approaching. Combination refrigerator/freezers, and freezers with automatic defrost systems, are sensitive to the ambient air temperature surrounding them. As this ambient temperature rises, the compressor runs more to maintain the storage temperature in the fresh food and frozen food compartments, thus wasting energy. As the ambient temperature falls, compressor operation decreases. When temperatures fall below 60 degrees Fahrenheit, the compressor won’t operate long enough to maintain low storage temperatures in the freezer compartment. This is because the fresh food compartment contains the primary sensor, and it’s satisfied quickly at a low ambient temperature. The lower the temperature goes, the worse that this condition becomes. At about 38 to 42 degrees Fahrenheit, the compressor won’t run at all. The freezer compartment temperature will increase to the ambient room temperature, and the frozen food in the compartment will defrost and spoil. --- Refrigerators and freezers Combination refrigerator/freezers and automatic defrost freezers should not be operated in unheated places like garages or porches, where room temperatures are likely to drop below 60 degrees Fahrenheit, unless they are specifically designed for operation in low temperatures. Check the manufacturer’s use and care booklet for the lowest safe operating temperature. At any time that the temperature will be less than 60 degrees Fahrenheit, it’s best to empty the freezer compartment of the refrigerator/freezer, in order to pre vent defrosting and the possible spoilage of the frozen foods. You might want to consider removing all of the food from the unit; turning it off; and propping the door open, if you will be absent for an extended period of time. The door must stay open to prevent mold and odor. Don’t do this if your refrigerator has a latch-type handle (pre-1958 model) because of the potential for child entrapment. Manual defrost freezers can usually be operated in an unheated garage or porch, without affecting the unit or the frozen food. However, check the use and care manual to determine if your unit needs special care. “Freezer” in single-door refrigerator has limited function: “I just bought a single-door refrigerator and my ice cream won’t harden. It’s like cold soup,” a consumer recently complained to MACAR “If I turn the temperature control to a colder setting, the food in the refrigerator section freezes, but the ice cream remains soup. Something’s wrong with the freezer.” Approximately 6% of all refrigerators sold each year are “single-door” models. That is, the model has only one outside door. Inside (usually across the top or to one side) is a small freezer compartment with its own door. Most combination “refrigerator/freezers” have two or more doors on the outside, providing independent access to separate freezer or refrigerated sections. In the course of investigating this consumer’s complaint, MACAP found that consumers have reason to be confused about the capabilities of “single-door” refrigerators. Many manufacturers refer to the separate frozen food compartment as a “freezer section,” as a “freezer compartment,” or as a “freezer” in their specification literature. MACAP has found that a majority of consumers expect to be able to keep such hard-to-freeze items as ice cream and orange juice in this “freezer” compartment. These items have a high sugar content, and they freeze at lower temperatures than water. The Association of Home Appliance Manufacturers (AHAM), in its nationally accepted standard, calls such a unit a “basic refrigerator,” and specifies that it’s “in tended for short-term storage of foods at temperatures below 32 degrees Fahrenheit and normally above 8 degrees Fahrenheit.” However, most newer models have temperatures at (or near) freezing level, which is not adequate to freeze foods. Distilled water freezes at 32 degrees Fahrenheit, but all frozen foods must be stored at a temperature lower than that to freeze. Vegetables begin to freeze at 29 to 31 degrees Fahrenheit, meats at 25 to 29 degrees Fahrenheit, and orange juice concentrate at about 8 degrees Fahrenheit. Ice cream begins to stiffen at 27 degrees Fahrenheit, but is considered at an ideal hardness for scooping at 8 degrees Fahrenheit. If reference is made to the compartment as being a “food freezer” or as a “frozen food storage compartment” (as in double-door units), the consumer can expect that it will Store already frozen foods for several days, or even months, without deterioration. However, a “freezer section” or “freezer compartment,” as found in single- door refrigerators, might only freeze ice cubes. MACAP recommends that consumers determine their food freezing needs and carefully read available literature before making a purchasing decision. REFRIGERATOR/FREEZER MAINTENANCE The inside of the cabinet should be cleaned at least once a month, to help prevent odors from building up. Of course, any spills that might happen should be wiped up immediately. Wash all removable parts by hand with warm water and a mild detergent; then rinse and dry the parts. The inside walls of the cabinet, the door liners, and the gaskets should also be washed, using warm water and a mild detergent, rinsed and dried. Never use cleaning waxes, concentrated detergents, bleaches, or cleansers containing petroleum products on plastic parts. On the outside of the cabinet, use a sponge with warm water and a mild detergent to clean dust and dirt. Then, rinse off and dry thoroughly. At least two times a year, the outside cabinet should be waxed with an appliance wax, or with a good auto paste wax. Waxing painted metal surfaces provides rust protection. The defrost pan, which is located behind the toe plate or behind the cabinet, should be cleaned out once a month. The condenser coil should also be cleaned of dust and lint at least once a month also. The floor should be free of dirt and debris when the cabinet is rolled out away from the wall. After the cabinet is rolled back into place, you must check to be sure that the cabinet is level. STEP-BY-STEP TROUBLESHOOTING BY SYMPTOM DIAGNOSIS When servicing an appliance, don’t overlook the simple things that might be causing the problem. Step-by-step troubleshooting, by symptom diagnosis, is based on diagnosing malfunctions, with possible causes arranged into categories relating to the operation of the refrigerator/freezer. This section is intended only to serve as a checklist to aid you in diagnosing a problem. Look at the symptom that best describes the problem you are experiencing with the refrigerator/freezer, then correct the problem. ---Compressor won’t run: 1. Is there voltage at the wall receptacle? Check this with voltmeter. 2. Check for loose electrical connections. 3. Is the condenser coil dirty? A dirty condenser coil will overheat the compressor. --- Refrigerators and freezers: 4. Check the condenser fan motor. 5. Test the cold control for continuity. 6. Test the compressor, the relay, and the overload switch. Compressor kicks out on overload: 1. Check for high or low voltage when the compressor tries to start. High voltage will overheat the compressor. Low voltage will try to run the compressor with the start winding. A compressor is designed to start and run within a 10% tolerance of the rated voltage. 2. Test the capacitor. A shorted or open capacitor will overheat the compressor. 3. Test the compressor relay. 4. Test the overload for continuity. 5. Test the compressor windings for a short. Refrigerator too cold: 1. Check the damper control setting. Check to see if the damper is stuck open (thermostatically controlled dampers only). 2. Test the cold control switch contacts for continuity. Test for stuck contacts. 3. Check the location of the refrigerator. If outside in the winter, the ambient temperature may be too cold. Refrigerator too warm: 1. Check for restricted air circulation around the condenser coil. 2. Check the location of the refrigerator. 3. Check the door gaskets for proper sealing. 4. Check to see if the cabinet light is staying on when the door is closed. 5. Check the defrost heaters. Use a clamp-on ammeter (or wattmeter) to test the heaters, if they are coming on when the refrigeration cycle is running. 6. Check the cold control setting. 7. Check the compressor. Is it operating properly? 8. Is the evaporator fan running? 9. Check the air duct for restriction. 10. Check for a leaking air duct. 11. Check the evaporator coil for excessive frost build-up. 12. Check the defrost cycle. Is it working properly? 13. Check the damper control setting. Check to see if the damper is stuck closed (thermostatically controlled dampers only). Refrigerator/freezer too noisy: 1. Check for loose parts. 2. Check for rattling pipes. 3. Check the fan assembly, the evaporator, and the condenser. 4. Check the compressor. 5. If normal operational noises, so instruct the consumer. 6. Refrigerator/freezer not properly leveled. 7. Check the floor, it may not be structurally sound. Sweating on the outside of the cabinet: 1. Check the location of refrigerator/freezer. If located in an area of high humidity, it will begin to sweat. 2. Check for a void in the insulation between the cabinet and the inner liner. 3. Test the mullion and/or stile heaters for continuity. 4. Is the energy saver switch in the on position? 5. On older models, check for wet insulation. 6. Check for suction line, or any low side tubing, touching the cabinet. 7. Check for water leaks from icemaker. 8. Check chilled water supply lines and connections. 9. Check for a kinked, misaligned, or blocked drain system. 10. Check the defrost drain pan for misalignment, or for leaking cracks. 11. Are the doors aligned properly? Sweating on the inside of the cabinet: 1. Check for any abnormal usage. Instruct the consumer. 2. Check the door gaskets for proper sealing. 3. Check for defrost drain water leaking into the cabinet. 4. Is the condensate drain blocked? 5. Are the doors aligned properly? 6. Inspect all access holes where tubing or wires enter the refrigerator/freezer. Seal with perma-gum if necessary. 7. Inspect cabinet outer walls and seams for any openings. Seal with perma gum if necessary. 8. Are there excessive door openings on hot, humid days? 9. Check for improper food storage. Incomplete defrosting of the evaporator coil or high temperature during the defrost cycle: 1. Test the defrost thermostat. 2. Check for loose wiring in the defrost electrical circuit. 3. Test the defrost timer for continuity. 4. Test for defective defrost heaters. Odor in cabinet: 1. Check for spoiling food in the cabinet. 2. Check the defrost water drain system. 3. Check the defrost heaters. --- Refrigerators and freezers: Excessive frost build-up on evaporator coil in freezer: 1. Check the defrost cycle. 2. Check for loose wiring. 3. Is the heater making contact with the evaporator coil? 4. Check for proper door alignment. 5. Check the door gaskets. Freezer run time too long: 1. Check the thermostat setting. 2. Check for excessive loading of unfrozen food. 3. Check for incorrect wiring. Temperature in freezer higher than normal: 1. Check the thermostat for proper temperature calibration. 2. Test evaporator fan motor and blade. 3. Check the defrost timer. 4. Check for excessive loading of unfrozen food. 5. Check door gasket for proper sealing. Refrigerator/freezer runs excessively or continuously: 1. Check the interior lights for staying on continuously. 2. Check condenser coil for air restriction. 3. Check door gaskets. 4. On older models with automatic icemakers, check to be sure that the icemaker is operating properly. SAVING THE OZONE LAYER High above the earth is a layer of ozone gas that encircles the planet. The purpose of the gas is to block out most of the damaging ultraviolet rays from the sun. Such compounds as CFCs, HCFC5, and Halons have depleted the ozone layer, allowing more UV (ultraviolet) radiation to penetrate to the earth’s surface. In 1987, the United States, the European Economic Community, and 23 other nations signed the Montreal Protocol on Substances that Deplete the Ozone Layer. The purpose of this agreement was to reduce the use of CFCs throughout the world. To strengthen the original provisions of this protocol, 55 nations signed an agreement in London on June 29, 1990. At this second meeting, they passed amendments that called for a full phase out of CFCs and Halons by the year 2000. Also passed at that meeting was the phase out of HCFCs by the year 2020, if feasible, and no later than the year 2040, in any case. On November 15, 1990, President Bush signed the 1990 Amendment to the Clean Air Act, which established a National Recycling and Emissions Reduction Pro gram. This program minimizes the use of CFCs, and other substances harmful to the environment, while calling for the capture and recycling of these substances. The provisions of the Clean Air Act, signed by the president, are more stringent than those contained in the Montreal Protocol as revised in 1990. Beginning July 1, 1992, the Environmental Protection Agency (EPA) developed regulations under Section 608 of the Clean Air Act (the Act), that limit emissions of ozone-depleting compounds. Some of these compounds are known as chlorofluorocarbons (CFCs) and hydrochlorocarbons (HCFCs). The Act also prohibits releasing refrigerant into the atmosphere while maintaining, servicing, repairing, or disposing of refrigeration and air conditioning equipment. These regulations also require technician certification programs. A sales restriction on refrigerant is also included, whereby only certified technicians will legally be authorized to purchase such refrigerant. In addition, the penalties and fines for violating these regulations can be rather severe. TROUBLESHOOTING SEALED-SYSTEM PROBLEMS If you suspect a sealed-system malfunction, be sure to check out all external factors first. These include: 1. Thermostats. 2. Compressor. 3. Relay and overload on the compressor. 4. Interior lights. 5. Evaporator and condenser fans. 6. Timers. 7. Refrigerator/freezer getting good air circulation. 8. Food loaded in the refrigerator/freezer properly. 9. Check if heat exchanger has separated. Alter eliminating all of these externals, you will then systematically check the sealed system. This is accomplished by comparing the conditions found in a normal operating refrigerator/freezer. These conditions are: 1. Refrigerator/freezer storage temperature. 2. Wattage. 3. Condenser temperature. 4. Evaporator inlet sound (gurgle, hiss, etc.) 5. Evaporator frost pattern. 6. High side pressure 7. Low side pressure 8. Pressure equalization time. One thing to keep in mind: no single indicator is conclusive proof that a particular sealed system problem exists. Rather, it’s a combination of findings that must be used to definitely pinpoint the exact problem. If you open up the sealed system, you will void your warranty. The sealed system must be repaired by an authorized service company. --- Refrigerators and freezers: Refrigerant leak: To determine a refrigerant leak in the sealed system, the symptoms are: 1. Temperatures in the storage area are below normal. 2. The wattage and amperage are below normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be cool to the touch; at the last pass, or even as far as midway through the coil. 4. At the evaporator coil you will hear a gurgling noise, a hissing noise, or possibly an intermittent hissing or gurgling noise. 5. When the evaporator coil cover is removed, the evaporator coil will show a receded frost pattern. 6. The high and low side pressure will be below normal. 7. The pressure equalization time might be normal, or shorter than normal. Overcharged refrigerator/freezer: If the sealed system is overcharged, the symptoms are: 1. The storage temperature will be higher than normal. 2. The wattage and amperage are above normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be above normal. 4. At the evaporator coil, you will hear a constant gurgling noise. Generally, a higher sound level than normal. 5. When the evaporator coil cover is removed, the evaporator coil will show a full frost pattern. If you remove the back cover, located behind the refrigerator/freezer, you will possibly see the suction line frosted back to the compressor. 6. The high and low side pressure will be above normal. 7. The pressure equalization time will be normal. Slight restriction: If you suspect a slight restriction in the sealed system, the symptoms are: 1. The storage temperature will be below normal. 2. The wattage and amperage are below normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be slightly below normal. 4. At the evaporator coil, you will hear a constant gurgling noise and a low sound level. 5. When the evaporator coil cover is removed, the evaporator coil pattern will be receded. 6. The high and low side pressure will be below normal. 7. The pressure equalization time will be longer than normal. Partial restriction: If you suspect a partial restriction in the sealed system, the symptoms are: 1. The storage temperature will be higher than normal. 2. The wattage and amperage are below normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be below normal, more than half way on the coil. 4. At the evaporator coil you will hear a constant gurgling noise, and a considerably low sound level. 5. When the evaporator coil cover is removed, the evaporator coil will be considerably receded. 6. The high and low side pressure will be below normal. 7. The pressure equalization time will be longer than normal. Complete restriction: If you suspect a complete restriction in the sealed system, the symptoms are: 1. The storage temperature will be warm. 2. The wattage and amperage are considerably below normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be cool, or at room temperature. 4. At the evaporator coil, you will hear no sounds. 5. When the evaporator coil cover is removed, the evaporator coil won’t have any frost on it, or the frost will be melting. 6. The high side pressure will be equal to the pressure of refrigerant at room temperature. 7. The low side pressure will be in a deep vacuum. 8. There will be no pressure equalization time. Moisture restriction: If you suspect a moisture restriction in the sealed system, the symptoms are: 1. The storage temperature will be above normal. 2. The wattage and amperage are considerably below normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be below normal. 4. At the evaporator coil you will hear a constant gurgle, low sound level, or no sound at all. 5. When the evaporator coil cover is removed, the evaporator coil might have some frost on the evaporator inlet. 6. The high side pressure will be below normal. 7. The low side pressure will be below normal or in a deep vacuum. 8. The pressure equalization time will be longer than normal or there will be no equalization at all. Low capacity compressor: To determine a low capacity compressor in the sealed system, the symptoms are: 1. Temperatures in the storage area are above normal. 2. The wattage and amperage are below normal, as indicated on the model/serial plate. 3. The temperature of the condenser coil will be below normal. 4. At the evaporator coil, you will hear a slightly reduced gurgling noise. --- Refrigerators and freezers: 5. When the evaporator coil cover is removed, the evaporator coil will show a normal frost pattern. 6. The high side pressure will be below normal, and the low side pressure will be above normal. 7. The pressure equalization time might be normal, or shorter than normal. Prev: Refrigerator/freezer electrical schematics Next: Part 2 Home top of page All related articles |