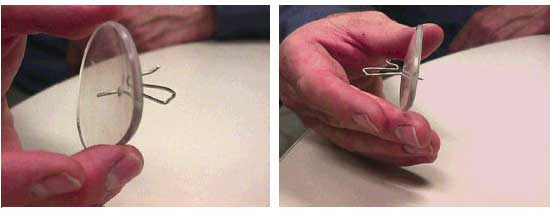

As the result of a private contractor safety glasses program, an employee began encouraging his eighteen year-old son -- who installs siding on houses -- to wear safety glasses while working. The son finally relented, when aluminum dust started getting in his eyes. About one week later, he was applying siding with an air-powered staple gun. When the son fired a staple, it hit a metal plate behind the siding, ricocheted back towards his face and one leg of the staple penetrated the safety glasses' lens (see picture below). The staple hit with such force that the frames were cracked and the son received bruising on the eyebrow and cheekbone.

(above) The safety glasses here prevented serious -- perhaps permanent -- injury to wearer's eye. Because the eye is soft tissue, it offers little protection ("shielding") for the organ immediately behind it: the brain. In the episode above, the use of eye protection may have even prevented the object above from entering the brain -- an event bound to cause much more severe injury or death. top of page

EYE PROTECTION IN THE WORKPLACE

Every day an estimated 1,000 eye injuries occur in American workplaces. The financial cost of these injuries is enormous--more than $300 million per year in lost production time, medical expenses, and workers compensation. No dollar figure can adequately reflect the personal toll these accidents take on the injured workers.

The Occupational Safety and Health Administration (OSHA) and the 25 states and territories operating their own job safety and health programs are determined to help reduce eye injuries. In concert with efforts by concerned voluntary groups, OSHA has begun a nationwide information campaign to improve workplace eye protection.

Take a moment to think about possible eye hazards at your workplace. A 1980 survey by the Labor Department's Bureau of Labor Statistics (BLS) of about 1,000 minor eye injuries reveals how and why many on-the-job accidents occur. top of page

WHAT CONTRIBUTES TO EYE INJURIES AT WORK?

• Not wearing eye protection. BLS reports that nearly three out of every five workers injured were not wearing eye protection at the time of the accident.

• Wearing the wrong kind of eye

protection for the job. About 40 of the injured workers were wearing

some form of eye protection when the accident occurred. These workers

were most likely to be wearing eyeglasses with no side shields, though

injuries among employees wearing full-cup or flat-fold side shields

occurred, as well. top of page

WHAT CAUSES EYE INJURIES?

• Flying particles. BLS found that almost 70% of the accidents studied resulted from flying or falling objects or sparks striking the eye. Injured workers estimated that nearly three-fifths of the objects were smaller than a pin head. Most of the particles were said to be traveling faster than a hand-thrown object when the accident occurred.

• Contact with chemicals caused

one-fifth of the injuries. Other accidents were caused by objects swinging

from a fixed or attached position, like tree limbs, ropes, chains, or

tools which were pulled into the eye while the worker was using them.

top of page

WHERE DO ACCIDENTS OCCUR MOST OFTEN?

Craft work and industrial equipment operation.

Potential eye hazards can be found in nearly every industry, but BLS

reported that more than 40% of injuries studied occurred among craft

workers, like mechanics, repairers, carpenters, and plumbers. Over a

third of the injured workers were operatives, such as assemblers, sanders,

and grinding machine operators. Laborers suffered about one-fifth of

the eye injuries. Almost half the injured workers were employed in manufacturing;

slightly more than 20% were in construction. top of page

HOW CAN EYE INJURIES BE PREVENTED?

Always wear effective eye protection.

OSHA standards require that employers provide workers with suitable

eye protection. To be effective, the eyewear must be of the appropriate

type for the hazard encountered and properly fitted. For example, the

BLS survey showed that 94% of the injuries to workers wearing eye protection

resulted from objects or chemicals going around or under the protector.

Eye protective devices should allow for air to circulate between the

eye and the lens. Only 13 workers injured while wearing eye protection

reported breakage.

Nearly one-fifth of the injured workers

with eye protection wore face shields or welding helmets. However, only

six percent of the workers injured while wearing eye protection wore

goggles, which generally offer better protection for the eyes. Best

protection is afforded when goggles are worn with face shields.

Better training and education. BLS reported

that most workers were hurt while doing their regular jobs. Workers

injured while not wearing protective eyewear most often said they believed

it was not required by the situation. Even though the vast majority

of employers furnished eye protection at no cost to employees, about

40% of the workers received no eye safety training on where and what

kind of eyewear should be used.

Maintenance: Eye protection devices must be properly maintained. Scratched

and dirty devices reduce vision, cause glare and may contribute to accidents.

top of page

WHERE CAN I GET MORE INFORMATION?

• The OSHA website or your nearest OSHA area office. Safety and health experts are available to explain mandatory requirements for effective eye protection and answer questions. They can also refer you to an on-site consultation service available in nearly every state through which you can get free, penalty-free advice for eliminating possible eye hazards, designing a training program, or other safety and health matters.

• The National Society to Prevent

Blindness. This voluntary health organization is dedicated to preserving

sight and has developed excellent information and training materials

for preventing eye injuries at work. Its 26 affiliates nationwide may

also provide consultation in developing effective eye safety programs.

For more information and a publications catalog, write the National

Society to Prevent Blindness, 79 Madison Ave., New York, NY 10016-7896.

top of page

EYE PROTECTION WORKS!

BLS reported that more than 50%

of workers injured while wearing eye protection thought the eyewear

had minimized their injuries. But nearly half the workers also felt

that another type of protection could have better prevented or reduced

the injuries they suffered.

It is estimated that 90% of eye injuries

can be prevented through the use of proper protective eyewear. That

is our goal and, by working together, OSHA, employers, workers, and

health organizations can make it happen.

This is one of a series of fact sheets

highlighting U.S. Department of Labor programs. It is intended as a

general description only and does not carry the force of legal opinion.

This information will be made available to sensory impaired individuals

upon request. Voice phone: (202) 523-8151. TDD message referral phone:

1-800-326-2577. top of page

| U.S. Department of Labor Program Highlights Fact Sheet No. OSHA 92-03 |

CHOOSING AND USING EYE PROTECTION

Safety Glasses And Goggles

No matter where we work, flying particles,

dusts, fumes, vapors or harmful rays are apt to expose us to potential

eye injury. Fortunately, we can protect against these hazards by using

the appropriate protective eyewear for our jobs and by following our

companies' established safety guidelines. The following is a guide to

the most common types of protective eyewear and the specific hazards

they can guard against.

Safety Glasses

Standard safety glasses look very much

like normal glasses, but are designed to protect you against flying

particles. Safety glasses have lenses that are impact resistant and

frames that are far stronger than regular eyeglasses. Safety glasses

must meet the standards of the American National Standards Institute

(ANSI). (Safety glasses are also available in prescription form for

those persons who need corrective lenses.) Standard safety glasses can

be equipped with side shields, cups, or tinted lenses to offer additional

protection.

Safety Goggles

Like standard safety glasses, goggles

are impact resistant and are available in tinted lenses. Goggles provide

a secure shield around the entire eye area to protect against hazards

coming from many directions. Safety goggles may have regular or indirect

ventilation. (Goggles with indirect ventilation may be required if you

are exposed to splash hazards.)

Shields and Helmets

Face shields and helmets are not in themselves

protective eyewear. But, they are frequently used in conjunction with

eye protectors. Full-face shields are often used when you are exposed

to chemicals or heat or glare hazards. Helmets are used when welding

or working with molten materials.

Using Protective Eyewear

You can guard against eye injury by making sure that you are wearing the appropriate protective eyewear for the particular eye hazards you face. It's important to remember that regular glasses alone do not offer protection from eye hazards. Follow your company's established safety procedures, and never hesitate to ask your supervisor if you have any questions about what you can do to protect your sight for life.

It's come a long way

Protective eyewear has evolved dramatically

over the years. In the 1960s, standard safety glasses were worn mainly

in industry and made of tempered glass with unattractive frame styles.

But since then, a merge between safety glasses and sunglasses has made

eyewear more protective and fashionable. There's a much wider selection

of colors and styles to choose from. In fact, many sports and industry

safety glasses are made with anything from sports team logos to zebra

stripes on the frames. And instead of tempered glass, the majority of

lenses today are made of impact-resistant polycarbonate.

In terms of research to improve protective

eyewear, Dr. Williams noted that the process is ongoing: "A lot of work

has been done over the years to perfect the features of protective eyewear.

What we have today is quite good. The task now is to educate people

on how important it is to wear eye protection. People don't realize

that an eye can be destroyed in a fraction of a second."

top of page

Where to find protection