Preparing a Wood Subfloor

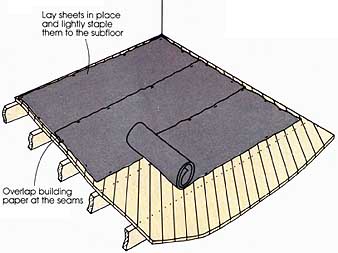

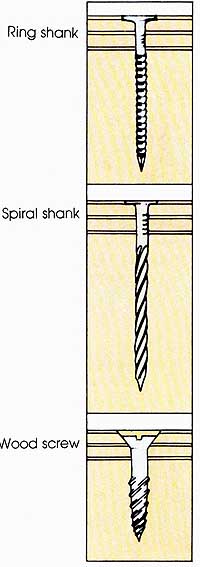

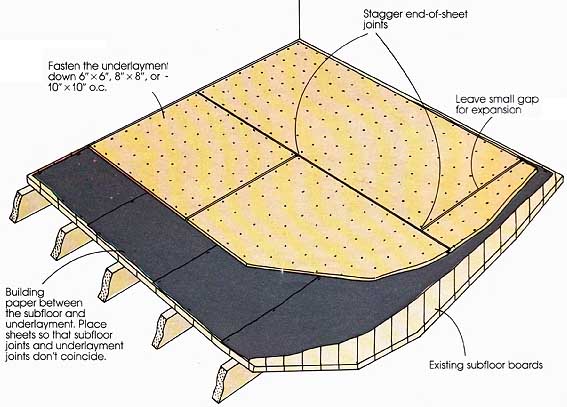

Most preparation tasks for wood subfloors involve surface repairs or require the installation of a new underlayment over existing floors. The charts outline the preparation guidelines needed for installing each of the four main types of flooring. To select specific underlayment materials for your particular job, see previous discussion. To remove flooring to accomplish proper preparation, see previous discussion. To make surface repairs, see the following suggestions for correcting some common problems. Squeaks are caused by movement between parts of the floor structure, such as the subfloor and the finish floor. The source of a squeak might be nails that have worked loose, or boards that have shrunk or cupped. Locate the squeak and re-anchor the loose flooring using 6- or 8-penny nails. Spiral or ring-shank nails driven at an angle work best, since both the threads and the angle give the nails extra bite, If the squeak persists, drill pilot holes and countersink wood screws through the floor into the joists below, Cracks, voids, and small depressions can be filled. Use a filler that is compatible with any sealers or adhesives you plan to use later. Most fillers are water-based or latex-based, and need to be mixed just before you use them because their setup time is very fast. Clean the area of dust and debris so the filler will adhere. Trowel the filler into the crack or depression and feather its edges into the rest of the floor as smoothly as you can with a wide putty knife. Since the material dries very hard, smooth and feather it as fully as possible while it is still pliable. Alter it dries, sand the filled areas so that they are smooth and flush with the surrounding floor. Warped boards and high spots can be sanded or chiseled down to produce a smooth level surface. To avoid damaging your chisel, nail the board securely first, and set the nailheads. If a board is badly warped, remove that section; drill a line of holes across each end of the defective section. Break the line with a chisel, and re move the section. Chisel the remaining rough ends smooth, and install a piece of wood to match, or build up the hole with filler. Slick surfaces need to be roughened if you plan to use adhesives to install your new floor, since the sheen makes a poor bonding surface. A light sanding using a long-handled floor or wall sanding block is the best method.

About Underlayments Underlayments can equilibrate uneven subfloor surfaces and provide an appropriately smooth surface for the finish floor. They inhibit dust, drafts, moisture, and other undesirable elements from entering the room through the floor. They can serve to join building materials that might otherwise be incompatible, and some underlayments also afford additional structural strength. Plywood is made of an odd number of thin sheets of wood (called veneers or plies) that are glued cross- grain, and laminated together under pressure. It has a great deal of dimensional stability, and is not inclined to warp, buckle, twist, cup, or split, Because of its inherent rigidity plywood underlayment adds structural strength, bridges gaps, and equilibrates irregularities or uneven conditions in the subfloor surface quite well. It is sold in a range of grades, thicknesses, and sheet sizes. Underlayment grade plywood is made to satisfy the general subsurface requirements of most types of finish floors, It will hold nails and fasteners well, has no inter- ply voids, has smooth outer faces since surface defects have been plugged and touch-sanded, and is considered water-proof. Particle board, also known as chip board and wafer board, is made of softwood chips that have been glued together, formed and compressed into sheets under heat and pressure. The material is, therefore, very dense and smooth surfaced, free of voids or knots. But since particle board has no continuous grain, it has less inherent rigidity and structural strength though it is able to bridge minor irregularities in the subfloor, Like plywood, it is sold in various grades, thicknesses, and sheet sizes, and some particle board materials are made with water-proof glues. Hardboard is a fine-fiber particle board made from wood pulp which has been formed into sheets. It is quite dense, somewhat brittle, difficult to nail, and adds little structural strength. It comes in a limited range of thick nesses, though it is available in several sheet sizes. Liquid underlayments are used to smooth, even out, level, fill, patch, and even moisture-proof floor surfaces needing these types of repair. Although a few products are suitable for non-professional installation, most entail several application steps and these require a professional’s skill and experience.

Prev.: Preparing a Concrete Slab |

Sunday, 2011-04-10 19:29