The walls and ceilings of a house are some of its most important structural elements, but also offer considerable scope for creativity. This section will help you understand the structure of ceilings and walls, so that you can work out which options are most suitable when undertaking repair or renovation work.

TYPES OF CONSTRUCTION

A knowledge of how ceilings and walls are put together is important to fully understand the structure of your home. In the most general terms, ceilings usually have a wood-frame structure. Walls are either cavity or single-skin, and may be loadbearing or non-loadbearing. In addition, there is a variety of ways that ceilings and walls may be finished, and there are different combinations of materials that can be used to achieve these finishes.

CEILING COMPONENTS

The image below shows the basic structures of frame and concrete ceilings. Beneath these are shown the typical finishes used on their lower surfaces. Frame ceilings are traditional but still widely used. A framework of frame joists provides support for the floor above, and a surface for attachment of the ceiling finish below. Concrete ceilings can take a variety of forms. They are more often found in modern buildings, and their popularity has grown with the general use of concrete in the building industry.

Insulation and finishes

A wide range of materials can be used in finishing either a ceiling or wall—drywall can vary in thickness and density, and can also be purchased with useful retardant properties to make the surface more resilient, or to adhere to building and safety regulations. Different types of drywall will be explained in a future section of this web site . Insulation isn't shown in the illustrations here or overleaf, for reasons of clarity. However, in reality, many ceilings and walls will incorporate insulation. Choices and types of insulation are covered here.

UNDERSTANDING BEAMS AND JOISTS

Beams and joists aren't the same—beams support joists. Traditionally, they are made of wood, but modern types are often made of steel, and are known as “I-beams”. Rolled steel joists are also available. Wooden beams are often left uncovered to form part of a room’s decorative aspect, although they can be clad with plasterboard and then plastered. Old beams may even be found beneath lath and plaster.

I-beams are usually boxed in with drywall and then finished. To provide securing points for drywall, blocking (small vertical lengths of wood) is installed inside an I-beam. Lintels and headers look similar to beams, but perform a different function: they support the weight of a wall above an opening such as a window or door. They come in many materials and strengths, designed for a variety of uses.

Boxing in a beam: Beams are frequently enclosed and hidden behind a finish, but a little knowledge of basic house construction

should allow you to locate them. A traditional method of boxing in is

shown here, but it's also possible to use insulating panels and clips.

Ceilings are usually installed flush with the lower.

FRAME CEILING

Frame ceiling and finishes: The type of wood and dimensions of joists

will depend on the size of the ceiling and its function—ceilings with

a floor above must be more substantial. Blocking at right angles to

the joists can connect them to increase rigidity.

Drywall and plaster: Sheets of drywall are screwed directly to the joists,

the joints are taped, and the whole surface is covered with finishing

plaster.

Drywall: The most common system used in the US is drywall. The joints

between sheets are taped; fastener holes and joints are then tilled

with joint compound and sanded smooth.

Wooden cladding: Boards are attached directly to the joists, at right

angles to them, to give this wooden ceiling finish.

Lath and plaster: This is an old-fashioned construction. Thin, wooden

laths sit closely together beneath the joists, and at right angles

to them, and are covered with traditional lime plaster.

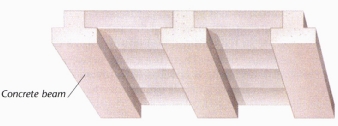

CONCRETE CEILING

Concrete ceiling and finishes: There are several ways of using concrete

to create a ceiling, but this beam-and-block structure is a common

system. Note: Concrete beam.

Furring strips, drywall, and plaster: Furring strips are attached to

the concrete; boards are attached to the furring strips. joints are

taped, and the whole surface plastered.

Furring

strips and drywall: Board is attached to a furring strip

framework, and then treated like drywall (see above).

Metal channels, drywall, and plaster: In this case, metal channels perform the same function as the furring strips in the previous example.

Metal channels and drywall: Again, the channels perform

the role of furring strips. The drywall is then finished for decoration.

WALLS

Most homes in the US are constructed from wood frames. Even if a house has masonry on the outside, its structure may be wood, as illustrated below.

Exterior walls

Exterior walls all have an internal layer made of wood, and an external cladding layer of siding material. There is a cavity between the two layers. The external face of the wood frame is covered with plywood sheathing for extra strength and rigidity. Building paper is usually needed to cover sheathing.

Wooden siding: The wooden shakes or shingles are nailed to

the external face. Some are made with interlocking edges. Types of siding

vary; 2 x 4 in or 2 x 6 in 50 x 100 mm (or 50 x 150 mm); Vinyl or

aluminum siding: Sheathing is first covered in strips

of building paper. Then vinyl or aluminum siding is nailed to the sheaths

starting from the bottom up.

Stone:

An exterior layer of natural stone is laid over the foundation and attached

to the wall using metal ties. Typically, studs are placed at 16-in (405-mm)

intervals. Brick: The inside wood frame is covered on one or

more external faces with a layer of brick and installed with a similar

method as stone veneer. Wall ties connect inner and outer leaf; Framework

is normally insulated.

Interior walls

These are the walls that create rooms. They may be filled with insulation to dampen sound, and may be loadbearing or non-loadbearing. Stud walls are a good choice in a renovation project because they are straightforward to construct. For more information, see this page.

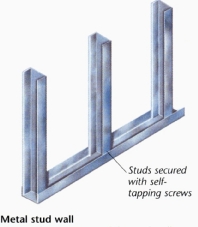

Stud wall: This is an easy-to-make partition consisting of

a wood framework that can take any of the finishes listed below.

Metal stud wall: This modern variation of the stud wall uses

metal channels instead of lumber studs to form the framework. Studs secured

with self-tapping screws.

WOODEN WALL FINISHES

All of these finishes can be used on the interior face of an exterior wall, or on either side of an internal wall. They all need a decorative layer such as paint or wallpaper, or in the case of wood siding, perhaps a natural wood finish.

Drywall: Taper-edged drywall is used to cover the frame. The joints are then taped and filled with joint compound to create a smooth surface for decoration.

Lath and plaster: In this traditional wall covering, wooden laths (narrow strips of wood) are attached to the wooden wall frame. They are then covered with several coats of lime plaster.

Plastered drywall: Straight-edged drywall is attached to the wooden frame. joints are taped and filled with joint compound, and the surface is plastered.

Wooden paneling: Panels, often in board form, are attached directly to the frame. Stone is tongue-and-groove. Depending on the material used, it may or may not need decoration after installing.

Dry partition drywall: Drywall panels are secured between studs. The finish depends on whether the panels have tapered or non-tapered edges. Dry partition walls are non-loadbearing.

MASONRY WALLS

Masonry houses have block, stone, or brick as the structure for the house. While living spaces with block walls have finished interiors, garages and outbuildings may have unfinished walls.

Exterior masonry walls

These are usually made up of two layers of masonry. The two layers of a cavity wall are held together by metal wall ties. The cavity may contain insulation and a vapor barrier.

Solid brick: The internal and external layers are made of brick,

with no cavity between the layers of masonry. Brick and block with

cavity: The external brick layer provides

the finished exterior look. The internal layer is of blocks, and requires

a finish (see below).

Solid block: A modern construction that uses thick, thermally

efficient blocks to create a solid wall. Block and block with cavity:

Both layers are made of modern blocks, so both the interior and exterior

faces need finishing (see below for finishes).

Solid stone: This may use one or two layers

of stone — the space between layers is often filled with broken stone and mortar. Sometimes the external face is stone and the internal brick. Stone and block with cavity: An external layer of natural stone

provides the finished look, while the internal layer is of blocks that

need finishing (see below).

Interior masonry walls

These are the walls inside a building, dividing it into rooms. They may be loadbearing or non-loadbearing.

Brick: (top) Modern ones are built of a single layer

of bricks, though older ones may have two layers.

Block: (bottom) A modern wall will be one layer,

but an older one may be made of several layers of stone blocks.

MASONRY FINISHES

Any of these finishes can go on any masonry wall, whether it's the internal layer of an exterior wall or either side of an interior wall.

Render and plaster: A coat of render or undercoat is covered with a layer of finishing plaster to give a smooth wall surface — getting this right requires considerable skill.

Drywall: Taper-edged drywall can be attached to a wall. The seam between the boards is taped, and filled with a filling compound (joint compound. The compound is applied in three layers before being sanded smooth with the surrounding drywall surface. The whole wall surface is then ready for further decoration. The drywall may be attached to the wall with screws.

Plastered drywall: Straight-edged drywall can be attached to a wall, with the joints between boards taped with joint compound, and then plastered over. The drywall may be attached to the masonry using dabs of adhesive, with a wood furring-strip frame, or using metal channels. This avoids the need for render or undercoat, but still demands great skill in plastering to achieve the top layer.

Wooden siding: A frame of wooden battens can be attached to the masonry, forming a base for the attachment of wooden panels.