If breaking ground for a new skyscraper represents the beginning of construction, it also represents the culmination of a multiyear process of design and documentation. Architects, engineers, and a host of other consultants will have spent months and months conceptualizing the building, refining and developing their designs, doing the detailed construction drawings that need to be completed before bidding, and awarding bids for the individual phases of construction.

While these architects and engineers stay involved in the process, the balance of responsibility during construction shifts to an entirely new cast of characters.

Foremost among these is the construction manager, who is hired by the developer to oversee and coordinate the entire construction process. And coordination is the operative word: up to 75 or so different subcontractors will work on specific aspects of the construction before the project is complete. These “subs,” as they are commonly known, represent a wide variety of trades—from plumbers and electricians to steelworkers and carpenters. Each plays a critical role at a particular stage of the building process.

To complicate matters for the construction manager, the process isn’t linear. At any one point in time, different trades will be active on different floors of the site. As soon as steel has risen on a particular floor, concrete flooring will be poured and the curtain wall or enclosures will be raised. Once the floor is protected from the elements, mechanical and electrical work can be undertaken—followed by interior finishes. As a result, the lower floors of any skyscraper job will be well along toward completion while higher floors may still be unenclosed or even un-built.

Just keeping track of who’s doing what, let alone making sure they are doing it correctly and safely, is a herculean task. It’s also a long one. Timing varies greatly from case to case, but a 50-story skyscraper will generally take between three and five years to construct. Add to that 12 to i8 months spent on developing the design and preparing the drawings for construction, and you’re talking anywhere from four to six years from start to finish.

In part because of this elongated time- frame, there is an expectation that the building will be constructed as quickly as possible. Time is money to a developer; in the case of a skyscraper, it’s a lot of money— typically hundreds of millions of dollars. In most cases the developer has relied on short-term borrowing (often referred to as “construction financing”) to cover the costs of construction and is eager to replace this loan with longer-term, cheaper debt when the building is complete. Equally, the developer is likely to have a lease with a tenant or tenants that starts on a particular date—making delays doubly costly.

Construction timeline

The time required to design and build a skyscraper will depend upon the size and complexity of the design, as well as the site location and complexity of site logistics and access. The following timeline, for a one- million square foot skyscraper on a typical site in Manhattan, is representative only.

YEARS […]

The design of a skyscraper will require six months to a year to complete.

Construction drawings must be completed and the job will be bid out.

Site work then begins and foundations are laid, generally over a period of six to eight months.

Following foundation completion, structural steel is raised. This can take a year or more.

While erection of the building’s skin is under way, mechanical plant installation begins on the completed enclosed floors.

Roofing installation follows “topping off,” the completion of steel erection and concrete and fireproofing work.

Elevator installation closely follows core wall construction and can take up to two years to complete.

The pouring of concrete slobs and fireproofing work follow closely behind steel erection.

Curtain wall installation follows structural completion and con take up to two years.

Tenant fit-out of interior space could begin as soon as 18 months after steel erection gets underway.

===

Men of steel:

No ethnic group is more associated with skyscraper construction than the Mohawk Indians, an Iroquois nation located along the St. Lawrence River in upstate New York and Canada. For the Mohawks, the demise of the fur trade in the early nineteenth century cost them their livelihoods. Some turned to farming or timber rafting; others joined traveling circuses or became medicine peddlers. Many remained unemployed and drank heavily.

The arrival of the Dominion Bridge Company to construct a cantilever railroad bridge across the St. Lawrence offered one Mohawk tribe—the Caughnawagas—a way to get its men back to work. In 1886, the right to use reservation land south of the river for a bridge abutment was exchanged for a guarantee to employ the tribe’s men during the bridge’s construction.

Hired as unskilled laborers to unload wagons, the Indians were repeatedly found walking out on the narrow steel spans projecting high above the river, alongside the highly paid riveters who worked there. Besieged by requests from the Indians to work steel, the company eventually acquiesced and began training them.

The collapse of the unfinished Quebec Bridge in 1907 killed 35 Mohawks but did not dampen the Indians’ hunger for steel work. As bridge jobs became less frequent, the gangs shifted to other high- steel work, mainly construction, in Canada. Ultimately they drifted toward New York City—where they would build some of the most famous skyscrapers in the world.

Today there are an estimated 80 Mohawk steelworkers registered to work in Manhattan. Originally from two reservations (the Kahnawake in Quebec and the Akwesasne in Ontario), a small number of them still reside in Brooklyn—just as their fathers and grandfathers did a century ago. Most choose instead to make the 360-mile trip down the New York State Thruway each Monday morning and return home Friday night—an ancestral ritual known as “booming out.”

Raising Steel:

The first things that rise from a construction site are typically vertical columns of steel. For each of these columns, being lifted and bolted into place marks the end of a long and complicated journey that has generally begun overseas and involved at least three separate journeys—by boat or barge and by rail or road—to arrive at its ultimate destination.

Much of the steel used in the United States is imported from abroad by American fabricators—the middlemen who take sheet steel and turn it into the columns, beams, bolts, and connectors specified by engineers and architects for a particular construction job. Each component is carefully crafted by the fabricator to match the desired specification, including the number and location of holes, the width and length of the beams, the size of the flanges on its edges, etc. It will then be labeled, numbered, and possibly color coded to ensure that it can be correctly and easily matched to the construction drawings on-site.

Once manufactured, the steel components will be shipped from the fabricator’s factory by barge, rail, or truck to a marshaling yard relatively close to the building site. It’s the fabricators job to ensure that the components arrive at the yard in time to be unloaded and catalogued so that they are easily accessible on the day they need to be trucked to the job site.

Steel delivery between the marshaling yard and the job site generally works on a just-in-time principle. Due to space constraints at urban sites, deliveries to the site are typically staggered so that only those pieces to be lifted that day will be delivered early in the morning. Any foul-up at the marshaling yard—e.g., the placement of the wrong set of beams on the delivery truck—can result in expensive and time-consuming delays.

Journey of a steel beam:

SHIPPING AND FABRICATION: In Antwerp, the steel is loaded on a ship for a four-week journey to Houston, Texas, where it’s cut into finished components and connections are added based an measurements from construction documents.

AT THE MARSHALING YARD: The barge contents are offloaded in Pittsburgh onto trucks. One barge will carry the load of approximately 50 tractor- trailer trucks.

ANTWERP PRODUCTION: Raw steel is produced at a steel mill in Luxembourg and trucked to Antwerp, Belgium.

BARGING UP THE RIVER: Finished columns and beams are loaded onto barges far a three- to four-week journey from Houston to Pittsburgh, via the Mississippi River.

TRUCKING TO SITE: The steel is trucked to a marshaling yard in New Jersey, where it will be held until needed at the job site in Manhattan.

SHAKING OUT: The steel needed for the day is trucked to the job site and “shaken out,” or laid out in the order and expected position of the day’s erection.

GUIDING: The beam is lifted by crane and guided into its final position by the steel-raising gang.

CONNECTING: Final connections are made and the journey of the steel beam is completed.

Topping off:

The completion of the steel skeleton of a skyscraper is often cause for celebration—known as “topping off.” Once a quiet Nordic ritual that involved the hoisting of a fir tree or branch to the top of small timber homes to placate tree-dwelling spirits, topping off in its American incarnation has evolved into more of a media event.

As far back as 1912, with the completion of the Woolworth Building, the unfurling of an American flag along a building’s highest beam has also been part of the ceremony. Today both fir trees and flags are commonly found in topping off ceremonies; in addition, the last beam up will frequently be painted white and signed by the steelworkers, designers, and project management team before being hoisted into place.

Cranes and Hoists

Once foundations are poured, cranes and hoists become the primary workhorses of a construction site. Cranes are responsible for moving large structural components from the ground to their designated positions hundreds of feet up in the air. Hoists are responsible for lifting the people, equipment, and materials necessary to lock these components into place and to undertake the work that follows frame completion.

While other types of cranes play an important role in foundation work, tower cranes are the ones most associated with skyscraper construction—no doubt because they seem to hang so precariously hundreds of feet above city streets. They are also the most self-sufficient: they take up little or no space on-site, can assemble themselves, and—when their work is done— can take themselves apart almost fully with no outside assistance.

Tower cranes swing in a gentle arc and are erected gradually as the building grows in height. They arrive in pieces— triangulated, lattice components, 10-feet (3.3 meters) square and anywhere from 14 to 20 feet (4.2 to 6 meters) high, ready to be placed one above the other to form the crane’s mast as the building grows.

In addition to the mast, tower cranes feature what’s known as a “slewing unit” containing the gears and engine, which is located just below the unit’s boom. The boom itself reaches out horizontally from the mast, complete with a mobile trolley that runs along its length. The back of the boom contains one or more steel or concrete blocks.

Computerized indicators help prevent the crane operator from lifting more than the crane can handle. Switches monitor both the load on the cable and its distance from the mast to ensure that the crane does not exceed its rated capacity.

Guiding a crane: Communication between the crane operator and the ground is often done with radios, but hand signals can also be used.

RETRACT BOOM; TRAVEL; MOVE SLOWLY; STOP; EXTEND BOOM; RAISE BOOM; HOIST EMERGENCY

STOP; LOWER BOOM

TRUCK-MOUNTED AND CRAWLER CRANES: The workhorses of a job site are the tower crones, but smaller ones, like truck-mounted and crawler crones, will often be used for lighter lifts on the site.

The high life:

Perhaps not surprisingly, crane operators are among the most highly paid construction workers. But their pay is not based on the height to which they must climb each morning—it’s based instead on the length of the boom they operate from their cab high above city streets.

The crane operator is not alone in the sky. He or she shares the rarefied air with an “oiler,” an operating engineer responsible for maintaining the moving parts of the crane. The cab is their base in the sky: with amenities ranging from the necessary, such as a heater and portable john, to the nice to have, such as a fridge and a television, both operator and oiler will often stay aloft all day.

The cab is in many ways the nerve center of steel erection. From it the crane operator stays in communication with the “signaler on the ground via a speaker box. The cab’s instrument panel shows the weight of the load and the boom’s radius at any given point in time—with warning lights ready to flash if the load approaches the crane’s limit. Most cranes also feature an automatic shut off mechanism that is tripped if the lift exceeds those limits.

HOISTS--Made up of one or two cars, or “cages,” hoists rely on cable or rack and pinion elevator technology to travel vertically at varying speeds. The two types of hoists found on a construction site bring construction workers and materials, respectively, to whatever floor requires them.

Erected next to the tower, hoists are braced roughly every three floors for

stability. Like tower cranes, they are generally leased from companies responsible

for erecting and dismantling them. They stay in place until permanent elevators

are completed, and are refurbished and re-let at the job’s completion.

Tower Cranes:

Tower cranes are valued for their self-sufficiency and their ability to do many things besides lifting. For one thing, they can grow in place, thanks to something called a “jumping” or “climbing” frame, which encases the main tower of a crane like a sleeve and relies on a hydraulic lift to raise the top portion of the crane sufficiently to fit in a new section.

Tower cranes can also shut themselves off if they find themselves lifting something too heavy or too far out along the jib; automated devices alert the crane operator when the crane is reaching its capacity. And like certain other skyborne craft, they can refuel themselves in midair in a relatively simple process that relies on gravity.

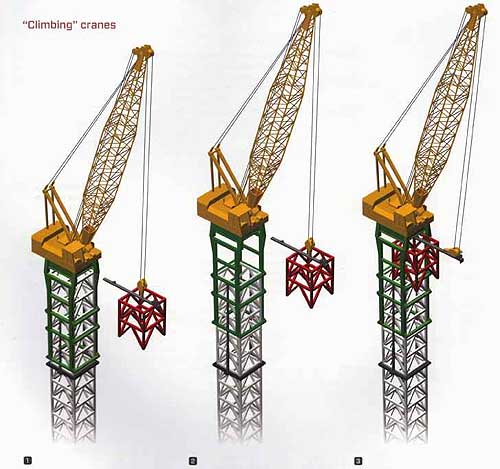

“Climbing” cranes:

1. The crane operator lifts the new mast section onto a plot farm on, or suspended from, the climbing frame. The upper portion of the climbing frame is attached below the crone’s slewing module.

2. The ram of the hydraulic cylinder is then extended, lifting the top of the crane roughly 14 feet (4.25 meters creating an opening large enough to admit the new most section.

3. After the new tower section is moved into line, it’s secured to the existing most by the erection team. The crone top is then lowered onto the new section of the most and secured in place by the erection team.

How much it can carry?

Tower cranes work on a simple counterweight principle: the heavy blocks at the back of the boom provide an offset to the weight being lifted at a point along its length. The lifting capacity of the crane varies with the position of the trolley: it can lift greater loads from points closer to, rather than farther from, the mast tower.

Refueling:

Tower cranes are powered by diesel fuel. Roughly once a week the crane operator lifts a tank to cab level and feeds it by gravity into the crane engine’s tank. Because they are expensive to rent, tower cranes are expected to work nonstop throughout the day, and generally do—with the exception of bad weather. Bylaw, tower cranes must stop work when winds reach a certain level—usually in the neighborhood of 40 to 45 mph (65 to 80 km/hr).

===

Crane accidents:

Though tower crane accidents happen rarely, they are often fatal. Most often these accidents occur during the jumping or disassembly of a crane. Rarely do they occur when it’s fully erected.

Despite the odds, New York experienced two crane accidents within three months of each other in 2008—one involving a fully erected crane and one involving a crane being raised. Both resulted in the deaths of workers on the site; one also killed a tourist passing by.

Like many other cities, New York has for many years required the filing of elaborate plans before a tower crane can be erected. Operators must state where and when it will be built, as well as its radius of movement and the load weight it will carry. Since the tower crane accidents, however, operating rules have become more stringent, and random audits of crane jumps are being conducted by the city’s Department of Buildings inspectors.

=

Concrete:

The pouring of concrete marks a critical milestone in the construction of any skyscraper, even those framed in steel. In nearly all cases concrete is used to construct the core of a building as well as its floor slabs. In many residential towers concrete will also be used for the structural frame or support columns.

Concrete is a mixture of cement, water, and a variety of additives. Its consistency is often measure by its “slump,” or how fluid it is: the higher the slump, the wetter the concrete. While greater fluidity makes it easier to pump, adding water to concrete can make it less durable and more prone to cracking. High-strength concrete, in contrast, has a lower water-to-cement ratio than average.

While concrete takes on average between 14 and 28 days to gain its full strength, it sets almost immediately. The time that it takes to set varies greatly, depending on climate: in hot weather, it sets more rapidly than in cold. To adjust for climate, a range of admixtures known as “retarders” can be used to slow setting time from a few minutes to several hours; these include simple carbohydrates such as molasses or corn sugar. Other admixtures, called “accelerators,” are used to speed up the setting process in cold weather.

The strength of concrete can vary as well. Because concrete is strong in compression and weak in tension, a variety of methods of pre-stressing it have been developed to mitigate its natural weakness. This generally involves pairing it with steel tendons that are embedded in the concrete at pouring. After three or four days, these tendons are stretched—putting permanent compression force on the concrete and giving it greater strength to offset future tension loads.

Pre-stressed concrete is commonly used in the construction of high-rises. “Pre-tensioned concrete is prefabricated and brought to the construction site; “post-tensioned” concrete is poured on-site. Due to their ability to resist deflection, both forms allow floor slabs to be thinner and lighter than they would otherwise be—reducing the building’s gravity load and the number of required columns.

CONCRETE TRUCKS: Contrary to what most people think, the turning drums of concrete trucks ore not full of concrete. They leave the factory with a variety of dry materials, which get commingled as the drum turns en route to the construction site. Water is carried in a separate compartment, generally on top of the truck’s cab, and is added gradually to ensure the right consistency at the time the concrete needs to be poured on-site.

SELF-CLIMBING FORMS: Forms used to shape the concrete core of a building are known as “jump forms” or “climbing forms.” They comprise wooden formwork, or molds, of a desired shape that encase the poured concrete until it hardens to a minimum strength, at which point they can be removed and relocated to another floor or place—generally by a crane. Typically the concrete deck and cores, comprising elevator and stair shafts, will be poured individually, and then the formwork will be lifted—with the process repeated over a two- or three-day cycle.

For skyscrapers, however, it’s more economical to use “self-climbing” forms that lift themselves by a hydraulic jack to the next level with no need for support from a crane. In “slip-forming,” these self-climbing forms are attached to a steel frame that is hydraulically lifted along a vertical rail. As the concrete begins to solidify at one level, the climbing form is lifted along the rail and the steel grid is extended— resulting in a single and continuous sheet of vertical concrete.

ANATOMY OF A FLOOR SLAB: A typical floor section involves panels of corrugated, galvanized metal deck, which have been laid on top of steel beams and welded into place. Somewhere between five to six inches (125 to 150 millimeters) of concrete will then be poured on the decking to complete the floor slab. Alternatively, the floor slab can be composed of precast concrete or can incorporate the decking into a “composite” slab. In constructing floors, deflection caused by the weight of the concrete— particularly in the center of the slab—must be taken into account. To counteract the long-term effects of this deflection, floors can be “precambered,” or bent upward, during construction—usually to no more than half the projected deflection.

===

Pumping high:

Concrete trucks are the workhorses of construction sites. Typically they rely on “trailer pumps,” steel or rubber hoses attached to outlets on their drums. While these are fine for smaller jobs, for taller skyscrapers a different sort of pump—called a “boom pump”—is required for construction. Its advantage lies in its ability to pump high volumes of concrete, at high pressures, via a remote-controlled robotic arm.

But even traditional boom pumps are not sophisticated enough to meet the altitude needs of today’s supertall buildings. For the Burj Khalifa, the world’s tallest structure, a new, super-high- pressure pump was developed. Sturdy enough to withstand the enormous forces emanating from the high-strength concrete that was moving through it, the pump required the development of “emergency emptying procedures so that any batch not placed on a floor within 90 minutes of leaving the mixing chamber could quickly be removed from its length through a combination of compressed air and—in a particularly low-tech touch—a sponge ball.

Stud shear connector; In situ concrete; I-section; Reinforcement

===

Inspection:

Erecting a skyscraper according to plan is an incredibly complex undertaking—and one impossible to do well without making sure that each step along the way is being done correctly. To ensure that this happens, subcontractors from each trade working on the building are generally required to hire independent inspectors to check their work and report directly to the project manager or superintendent.

Inspection begins at the bottom, with the foundation. Geotechnical engineers ensure that the piles, caissons, or mats are functioning as expected and that no undue settlement has occurred during construction. Footings, where the column loads are transferred to the foundation, are checked carefully to ensure that connections are robust and have followed the design precisely.

Erection of steel requires particular precision. Surveyors are hired to ensure that all angles are consistent with the drawings and to highlight any deviations from the vertical so that they can be corrected quickly. The surveyor will also make markings on the floor (e.g., to show the center point), so that workers drilling holes or installing partitions are able to follow measurements on the detailed construction drawings more easily.

Both bolts and welding are tested on- site. The integrity of a bolted connection is largely a factor of the tightness of the bolts. This is tested by a calibrated torque wrench, which measures the amount of tightness applied to a bolt. For welds there are a multitude of nondestructive tests to verify the integrity of a connection. They can range from simple visual inspections or the application of a liquid dye that makes minor surface cracks visible to more complicated tests, such as ultrasonic testing and industrial radiography.

Concrete is also inspected, both on-site and off. Independent laboratories are hired to test the strength of the concrete, roughly 28 days after pouring, to ensure it will perform as expected. In addition, surveyors examine the finished floor slab to ensure that it’s smooth and flat.

TESTING CONCRETE: Because concrete behaves so differently based on its ingredients and the weather, testing it’s an important part of construction. Concrete is tested both as it’s poured, in what is known as a “slump test,” and over an extended period of time. On-site, the rate at which concrete “slumps,” or shifts its shape, is tested to ensure the appropriate consistency. Simultaneously, a cylindrical batch of this concrete will be put aside for 28 to 56 days to allow it to reach its final strength. That strength is then measured by putting the specimen in a compression-testing machine. SLUMP TEST; COMPRESSION TEST

In the United States, the onus has often been on the developer to show that test results, typically produced by private concrete testing labs, meet building code specifications. This system of self- policing has came under fire in a number of American cities, including New York. In 2009, the city found that one concrete testing company had falsified results an over la projects, including same of the mast prominent civic projects. As a result, the city is setting up its awn testing lab and will compare random samples from construction sites to the results submitted by private labs.

The elusive “C of O” -- In many countries new buildings cannot be occupied without what is known as a “certificate of occupancy,” a document that certifies that the building complies with local building codes. Occasionally, however, skyscrapers have been occupied while still under construction. In Chicago, the Trump Tower (above) began renting out hotel rooms in 2008 while construction continued on its upper floors. That same year, Morgan Stanley moved into the International Commerce Center in Hong Kong while the top third of the building was being constructed. Both were granted “TCO5” or temporary certificates of occupancy—short-term, renewable permits certifying certain floors as habitable.

Coming up short

From time to time inspection of a particular aspect of construction will cause a slight delay to the project timetable. But rarely if ever does inspection put a halt to a project, or fundamentally change its scope and program.

Yet in 2008 that is precisely what happened at the Harmon—a 49-story mixed-use hotel and residential tower designed by Foster + Partners as part of the MOM Mirage City Center project in Las Vegas. As the tower reached 20 floors, the project’s engineer-of-record noticed problems with the rebar (reinforced concrete) on many of the completed floors. On some floors the rebar was simply spaced wrong; on others the ties that held it together had been cut.

A stop-work order was issued immediately. Despite three months of daily rebar inspection reports that had been submitted by the contractor’s consultant, inspectors found major problems on 15 of the 20 completed floors. The building owners were given two options: either move the rebar to the correct location, which would involve complete demolition and rebuilding, or shorten the building to 28 floors—finishing the hotel, but doing away with the 200 condos that were designed to stand above it.

They chose the latter, refunding tens of millions of dollars in deposits to buyers. But in shortening the building they also saved roughly $200 million in construction costs and, perhaps more important, avoided the risk that many of the planned condos would not have sold quickly in a collapsing real estate market. The hotel’s opening has been delayed following removal of the contractor.

Checking all the angles:

“Plumbing up,” or ensuring that the columns are vertical, is accomplished through the use of guy lines and turnbuckles before bolting or welding is completed.

Surveys are used to ensure that columns ore properly aligned and straight. Laser levels may be used to ensure the proper flarness of decks.

Manual or vibrating straight edges are used to ‘strike off’ or ‘screed’ the freshly poured concrete, twinging it to proper grade and ensuring e smooth finish.

Who Builds It?

EQUIPMENT OPERATORS--Construction equipment operators run and maintain mechanized equipment at the site, ranging from bulldozers and backhoes to construction hoists.

CONSTRUCTION MANAGERS--Managers oversee the complex orchestration of many trades and are responsible for ensuring the project is completed on time and on budget.

SIGNALER--The signaler of the raising gang communicates with the crone operator and hooker-on. The position is usually reserved for older steelworkers.

DOCK-BUILDERS--Dock-builders work in the foundation pit, underpinning adjacent buildings and installing shoring or dewatering equipment.

The raising gang:

Raising steel is akin to Completing a complex jigsaw puzzle—one in which each piece is labeled clearly with its ultimate destination. The center of gravity is also marked on individual steel components, indicating to the signaler and hoisting team on the ground the best place along its length to place the sling.

Roughly half of all erection time is spent hoisting steel; the remainder is spent connecting and leveling the structural members. Once a beam or column is hoisted into its rightful place, bolts are inserted loosely to make a temporary connection. The beam is then “plumbed” to ensure that it’s level, before the bolts are tightened permanently by a compressed-air gun. Subsequently, the connection is inspected to ensure that the proper washer is in place and that the bolt has been adjusted to the correct tightness.

HOOKER-ON-- The hooker-on prepares beams and columns for crane lifting by finding the exact center of each piece of steel. He or she sets the pace of the gong.

TAGLINE PERSON -- The tagline person keeps the steel steady during its ascent and safely guides it around obstacles to the connectors at the top.

CONNECTORS -- Connectors, working in pairs, shimmy up steel columns and connect beams and columns high above the ground.

CARPENTERS -- Carpenters build scaffolding and concrete forms during steel and core construction. Later, during construction of finishes, carpenters will complete sheet rock walls in common areas.

STEAMFITTERS / PLUMBERS -- Steamfitters ore responsible for installing and welding piping systems that provide heating, ventilation, and cooling. Plumbers install piping systems that connect to washroom fixtures such as toilets and sinks.

TAPERS -- Sheet rockers install gypsum wallboard and are followed by tapers and plasterers, who give the spaces a finished look.

BOLTING-UP GANG - The bolting-up gang follows the connectors and temporarily bolts beams and columns in preparation for plumbing and detailing.

CONCRETE WORKERS -- Working against time, the concrete workers must keep the concrete pouring from the hoses in a choreographed but continuous process.

ELECTRICIANS -- Electricians run electricity cables and high-voltage feeds to connect individual building occupants and fixtures to the grid.

DETAILING GANG -- The detailing gang follows the bolting-up and plumbing-up gangs to ensure that the steel is welded or bolted as required.

TIN-KNOCKERS -- Tin-knockers, named for their work on large ventilation ducts, install the building’s heating, ventilation, and air conditioning systems.

GLAZIERS -- Glaziers install glass curtain wall and form part of a mixed crew that also includes ornamental-iron workers.

Safety:

Construction remains a relatively dangerous profession, with somewhere around 50 deaths per 100,000 workers each year in the United States. That makes it less risky than logging or aircraft piloting but more dangerous than many other professions. For that reason safety is paramount on construction sites and is regulated heavily both by the federal Occupational Safety and Health Administration (OSHA) and by localities.

Typically, all workers on a construction site in the United States are required to wear goggles or “safety glasses,” as well as a helmet or a “hard hat” to protect them from loose or falling debris. In some cases they are also expected to wear face shields. Due to their exposure to great heat and light, welders must wear greater protection—including heavy leather gloves, protective jackets, and special welding helmets that protect against ultraviolet penetration, which can burn the retina (sometimes referred to as “arc eye”).

Depending on the level of protection provided by safety nets, workers must be prepared to “tie off”—or use what are known as “personal fall arrest systems”— to prevent themselves from plummeting downward if they lose their balance on a beam. These systems generally involve wearing a safety harness, which can easily be hooked to a cable running along a beam.

Strict regulations govern “safe” falling distances. In the United States, safety nets or a fully planked floor deck must be located no farther than two floors, or 30 feet (9 meters), from “leading edge” workers. In addition, workers must be able to rely on safety harnesses to prevent falls between 15 and 30 feet (4.s to 9 meters).

Fall prevention is as important as fall protection. To minimize the number of falls, specific regulations govern the height, location, and appearance of guardrails. They also dictate their strength, as well as the strength of the midrails, screens, or mesh that must form part of the guardrail.

Steel-toed boots protect the feet and toes from damage resulting from falling materials.

Safety body harnesses must be warn by workers who have the potential to fall six feet (1.8 meters) or more.

Goggles help to protect against eye injuries resulting from the use of dangerous equipment such as grinders and chipping hammers.

Hard hats protect workers from head injuries resulting from falling debris or tools.

High-visibility vests ensure that workers can be seen.

Gloves protect workers’ hands from injury.

Safety body harnesses must be warn by workers who have the potential to fall six feet (1.8 meters) or more.

Steel-toed boots protect the feet and toes from damage resulting from falling materials.

Safety on American construction sites

GUARDRAILS -- Guard rails along the edges of floors must be between 39 and 45 inches high (i meter) and be able to withstand 200 pounds of pressure within two inches (to millimeters) of the top rail. Midrails, screens, or a mesh must be provided below the guardrail so that no openings larger than 19 inches (0.5 meter) exist; they must be able to withstand i pounds of pressure.

SAFETY NETS AND SCREENS -- Safety nets must be located within 30 feet (12 meters) of workers and project out between 8 and 13 feet ( to s meters) from the building’s edge and have a mesh size no larger than six inches by six inches. To ensure that safety nets are strong enough to take the impact of a falling body, a “drop test” is conducted using a 400-pound (182-kilo) bag of sand roughly two and a half feet in diameter.

Sidewalk sheds must be installed at street level to protect pedestrians walking below from injury due to falling objects at an adjacent construction site.

Unguarded steel reinforcing bars present an impalement hazard. Workers must cover all protruding ends of steel rebar with rebar caps or wooden troughs, or bend the rebar so that the exposed ends are no longer upright.

Safety down under:

Some contractors opt to use a self-climbing perimeter-screen system to help ensure worker safety while speeding construction progress. The screen is often designed to protect three to four levels of a construction site at any given point in time.

Depending on the suitability of the shape of the building’s perimeter, integrated formwork equipment can be attached to the self-climbing screen. Most popular in Australia, these perimeter screens are now being marketed worldwide.

Previous: The Skin

Next: Inhabiting It--Elevators